Patents

Literature

107results about How to "Play a strengthening role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

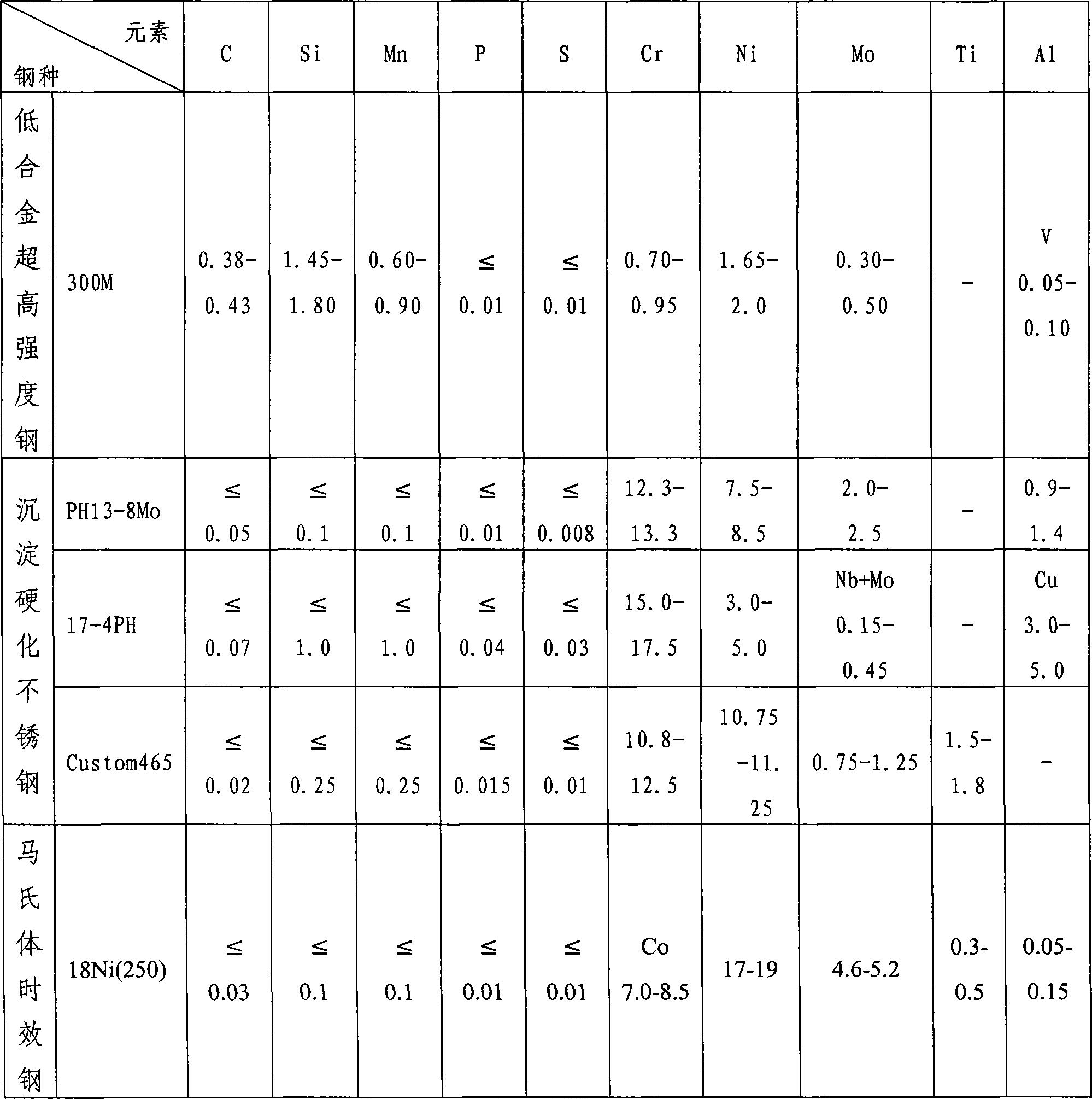

Martensite ageing stainless steel with high strength and high toughness

This invention relates to a high-strength and high-toughness maraging stainless steel, whose chemical composition is: C less than or equal to 0.02 wt.%, Si less than or equal to 0.1 wt.%, Mn less than or equal to 0.1 wt.%, S less than or equal to 0.01 wt.%, P less than or equal to 0.01 wt.%, Cr 10.0-11.5 wt.%, Ni 11.7-12.5 wt.%, Mo 0.5-2.0 wt.%, Ti 1.2-1.7 wt.%, Al 0.02-0.5 wt.%, and Fe as balance. The strength of the maraging stainless steel is 1700-1800 MPa. The maraging stainless steel has such advantages as low cost, high strength, high fracture toughness, and high corrosion resistance.

Owner:CENT IRON & STEEL RES INST

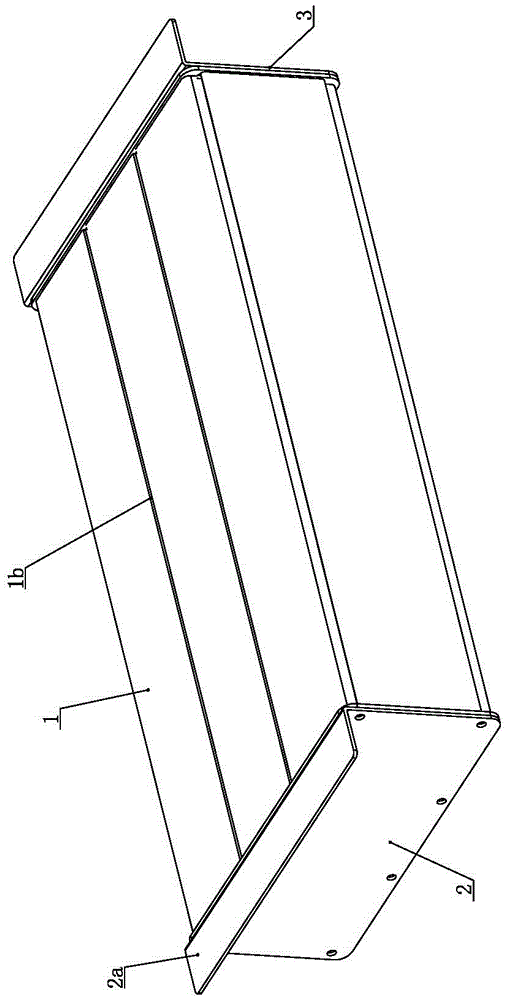

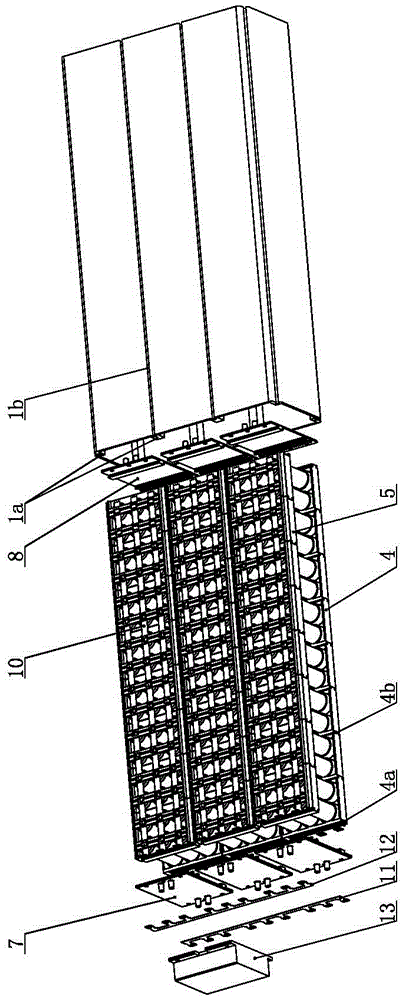

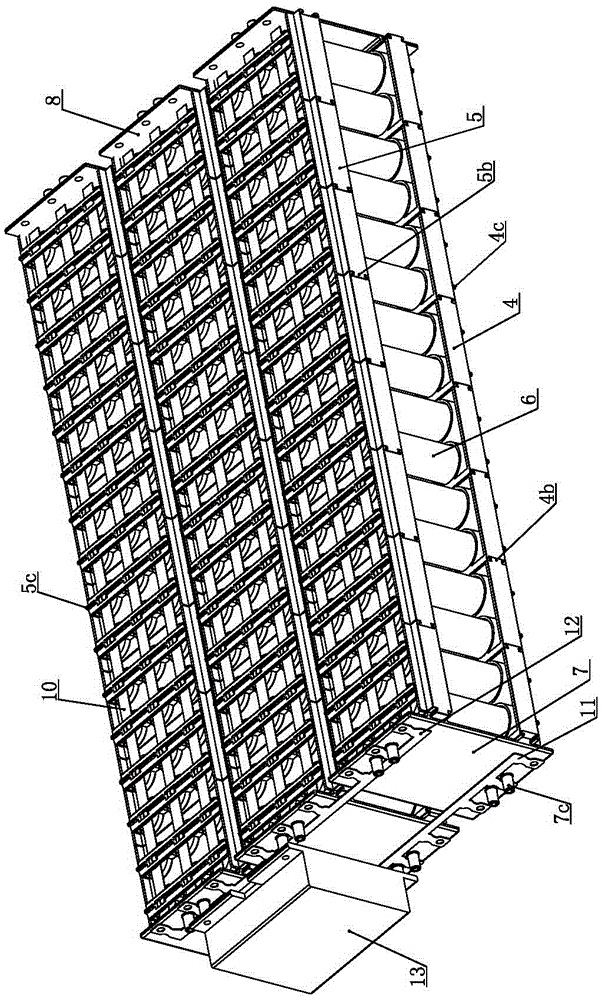

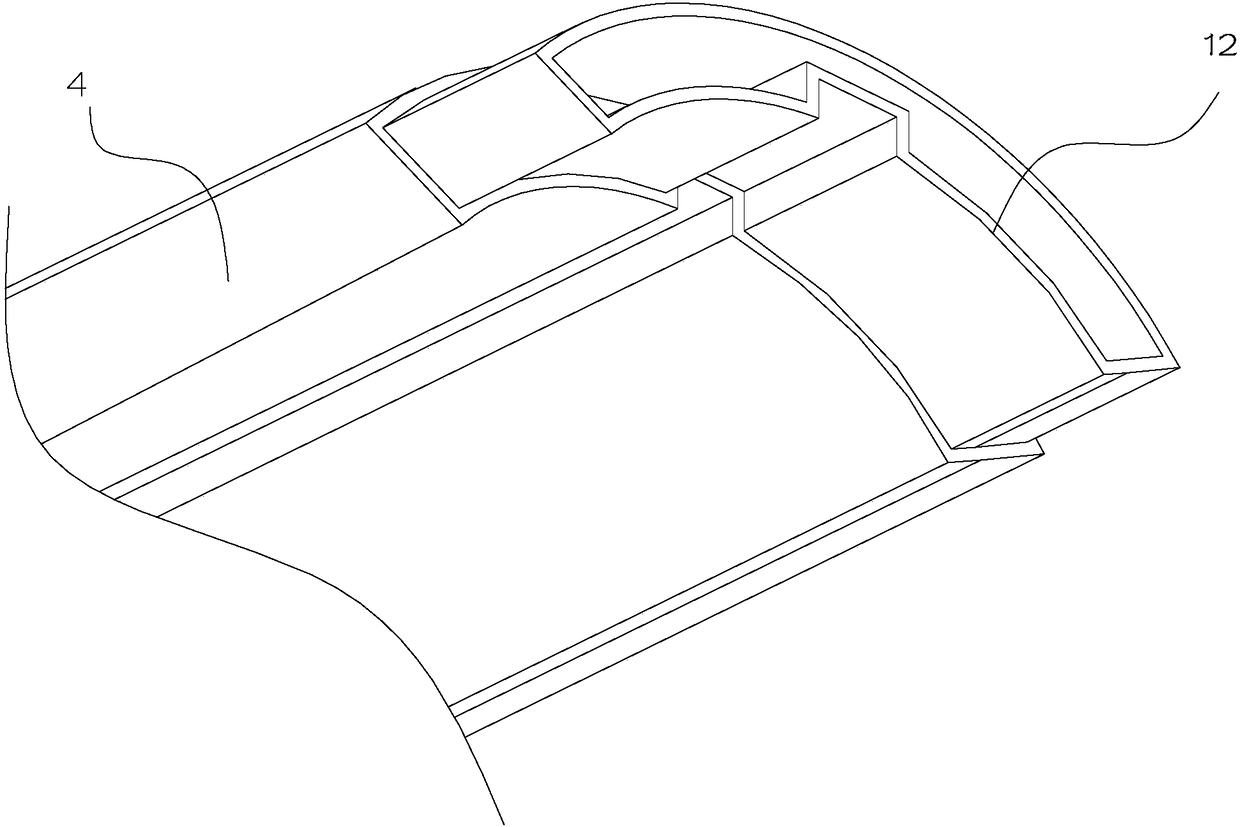

Combined type battery box

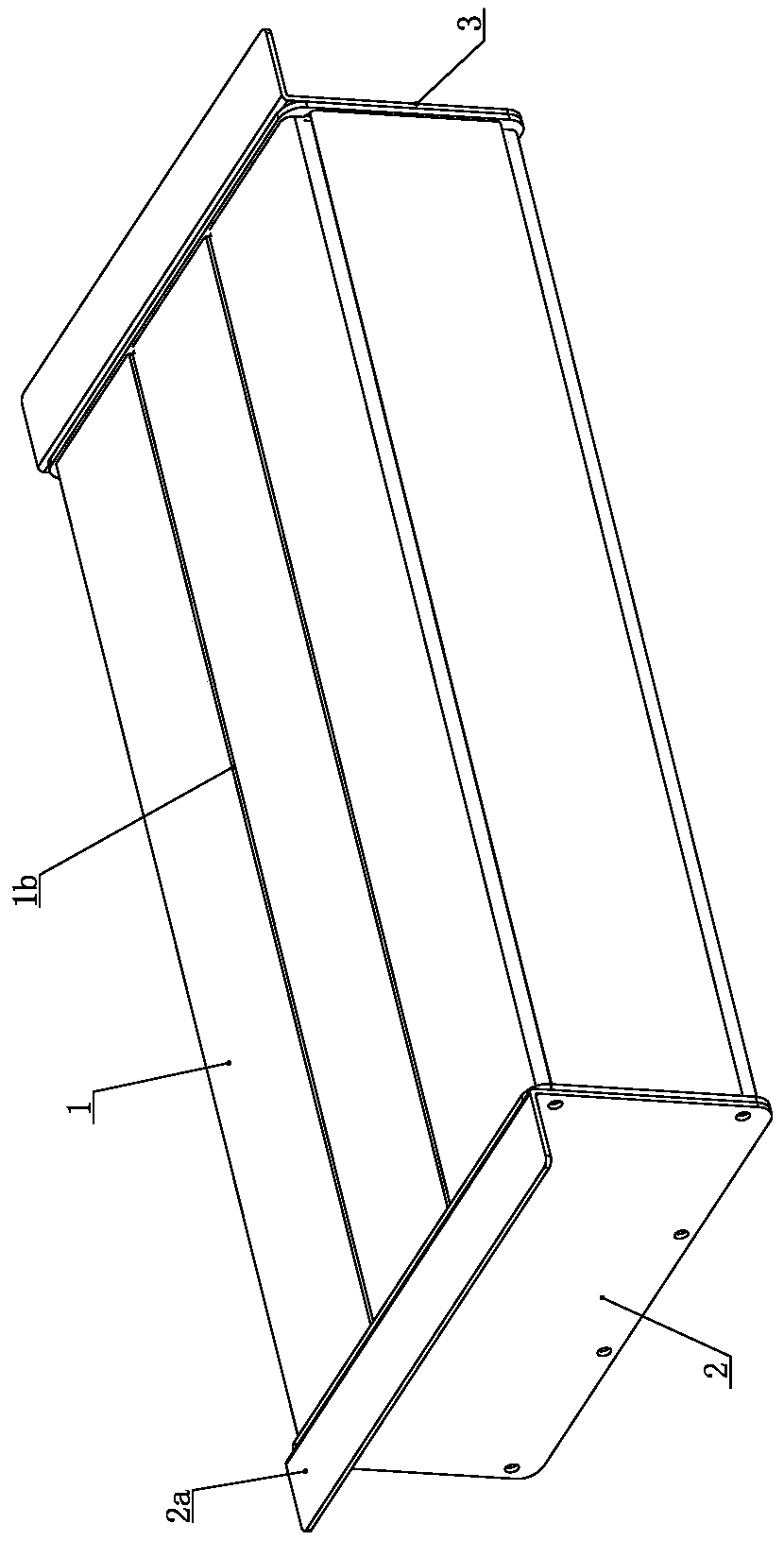

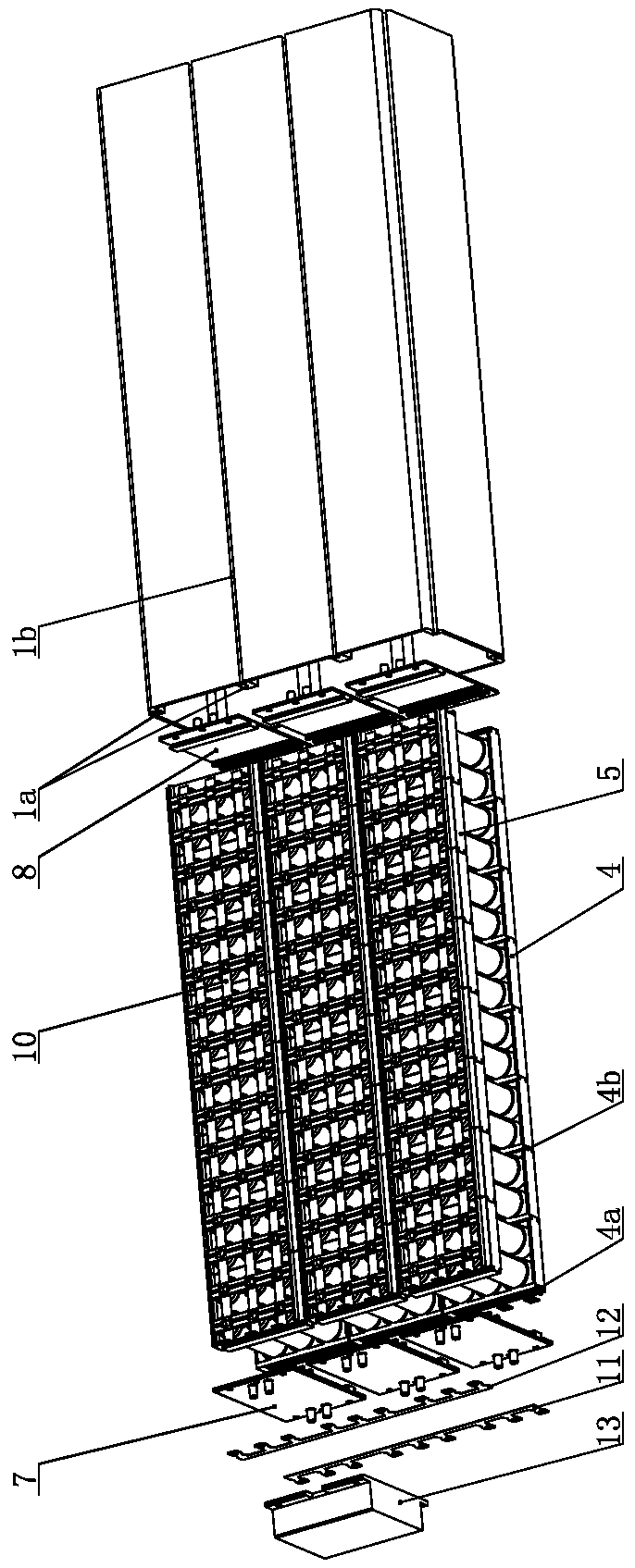

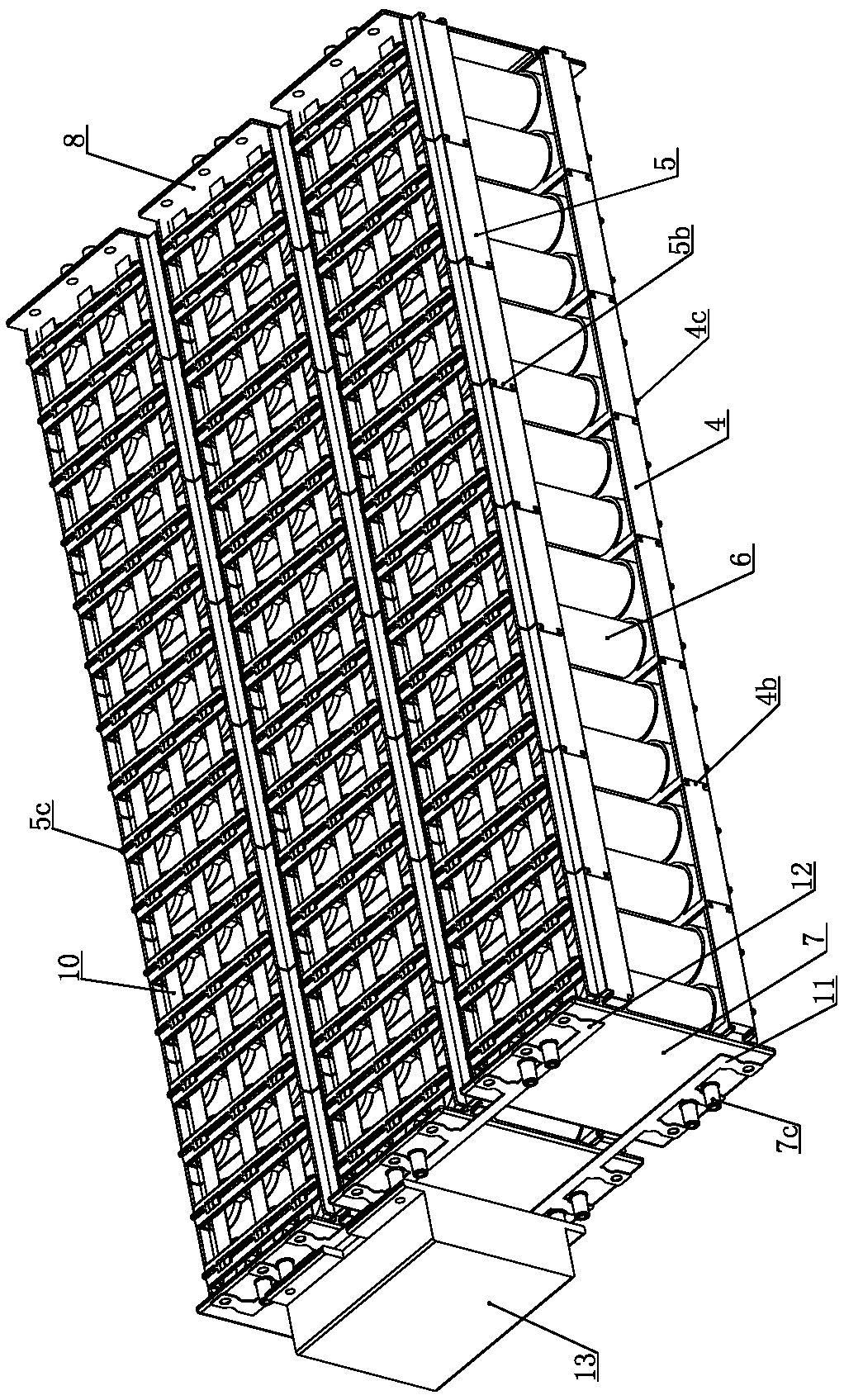

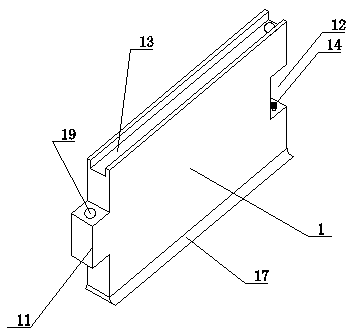

ActiveCN105742535AAchieve sealingReduce manufacturing costCell component detailsEngineeringFront and back ends

The invention discloses a combined type battery box. The box body is a cuboid with cut-through two ends, wherein multiple axial convex ribs are uniformly and symmetrically arranged on the top and the bottom of the box body; dovetail grooves extending along the full-length direction of the convex ribs are formed outside the convex ribs separately; a front end cover and a back end cover for sealing the box body are arranged at the front and back ends of the box body; sealing rings are arranged between the front end cover and the box body, and between the back end cover and the box body separately; the front and back end covers are fixed on the box body through end cover screws; the end cover screws are rotationally jointed in the dovetail grooves; multiple battery rows are mounted in the cavity of the box body; the four corners of each battery row are clamped among the convex ribs; each battery row is formed by multiple battery group units that are spliced from front to back in sequence; each battery group unit comprises a battery base and a battery top seat separately; multiple battery mounting holes are formed in the opposite end planes of the battery base and the battery top seat correspondingly; and a battery is mounted in each pair of the battery mounting holes separately. By adoption of the combined battery box, the batteries can be mounted and combined conveniently and rapidly, so that high space utilization ratio is realized.

Owner:陈杰

Preparation method of silver/silver alloy microwire

InactiveCN103614588AEasy to pullEasy annealingMetal/alloy conductorsCable/conductor manufactureSilver pasteIndium

The invention discloses a preparation method of silver / silver alloy microwire. The preparation method comprises the following steps: adding metallic elements with the concentration of 0-4wt% such as metal indium (In), copper (Cu), stannum (Sn) and zinc (Zn) to metal Ag with the high purity of 99.99% so as to form alloy, carrying out continuous casting, coarse drawing, intermediate drawing, mini-fine drawing and micro-drawing on a sliver / sliver alloy material and annealing, thus obtaining the microwire with the minimum diameter of 0.010-0.020mm. The silver / silver alloy microwire is superfine in wire diameter, has good mechanical property and electrical property and meets the requirement on the tensile strength of the microwire in a layout process and the requirement on the processing property of a material required in photovoltaic cell mass production. The silver / silver alloy microwire does not warp and fall off in sintering and annealing processes, has good interfacial adhesion with silver paste after being sintered, and can be applied to front electrode materials of Si solar photovoltaic cells.

Owner:苏州衡业新材料科技有限公司

Ceramic particle enhanced magnesium-based composite material and preparation method thereof

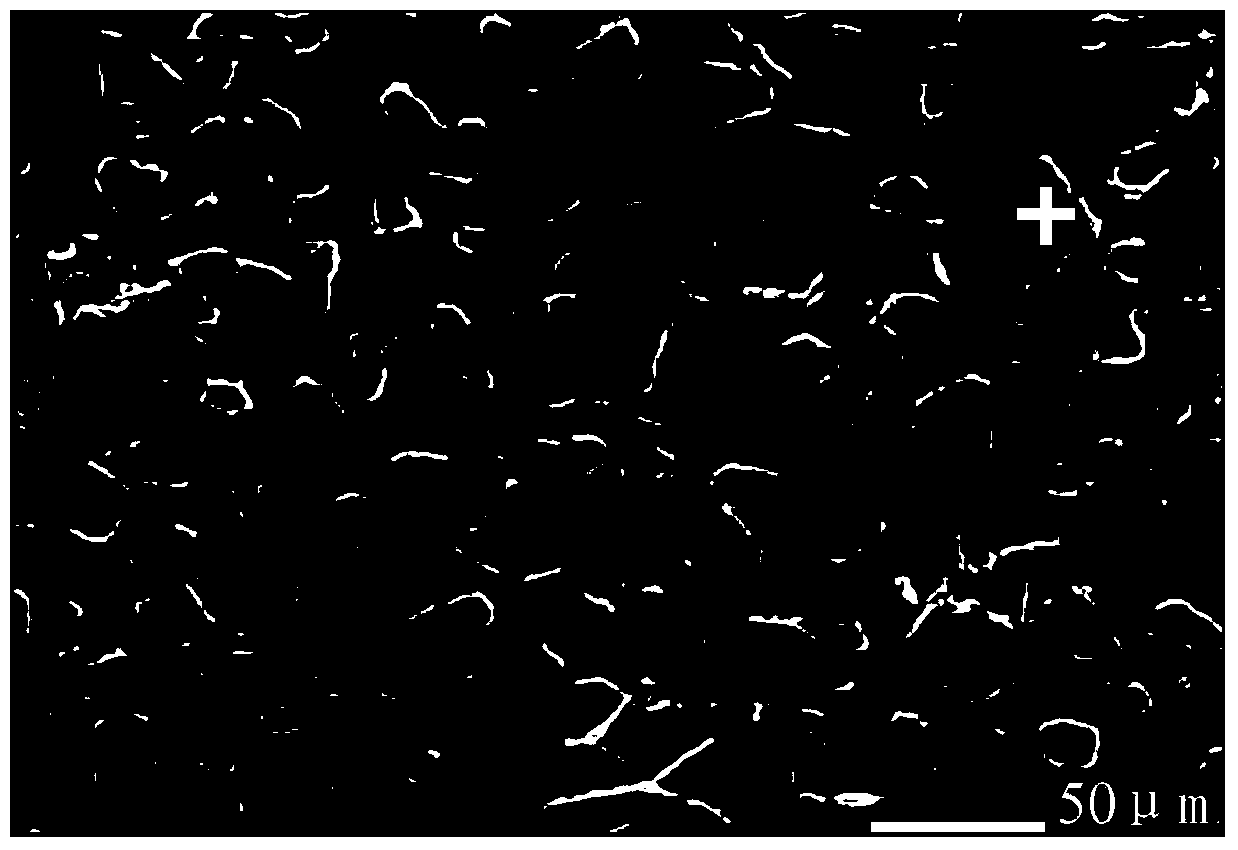

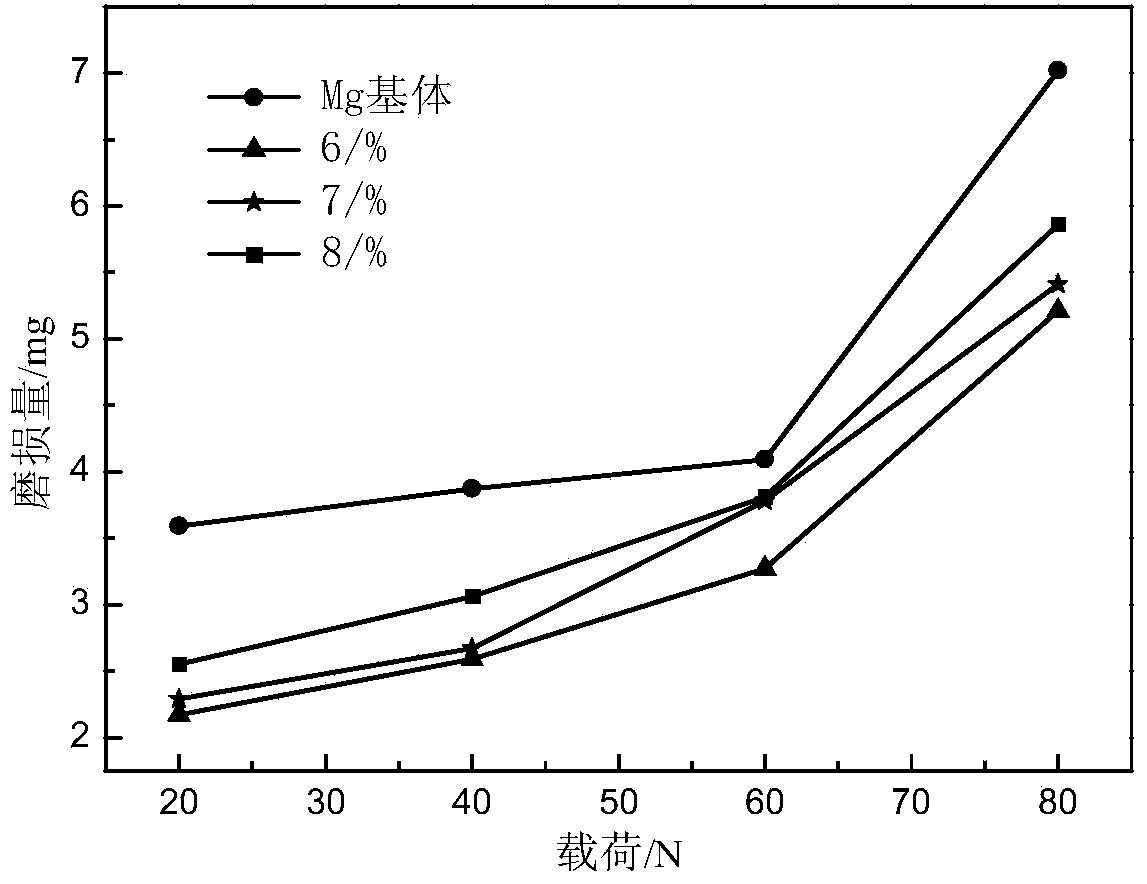

A method for preparing a magnesium-based composite material through a metal melt pressureless infiltration ceramic precast block is a preparation method which is low in cost, rapid and high-efficiency and realizes final forming. Because the wettability between ceramics and a metal system is low, the infiltration process is difficultly performed even cannot be performed. The invention provides a ceramic particle enhanced magnesium-based composite material and a preparation method thereof aiming at the problems. A small amount of the third-phase component metal Ti which has high melting point and is immiscible with a magnesium melt is added into the ceramic precast block to serve as a magnesium melt infiltration inducer, the wettability of a B4C / Mg composite material system is effectively improved, and a B4C / Mg series ultra-light wear-resistant ceramic particle enhanced magnesium-based composite material is prepared. The method comprises the following steps: mechanically and uniformly mixing B4C powder, Ti powder and an adhesive, performing cold pressing to prepare a ceramic precast block, putting the ceramic precast block and a pure magnesium ingot into an electric furnace for heating, melting the pure magnesium ingot, infiltrating the magnesium ingot into pores of the ceramic precast block, and preparing the ceramic particle enhanced magnesium-based composite material.

Owner:NORTHEASTERN UNIV

Method for manufacturing large-size heat-treatment aluminum alloy slab ingot capable of being strengthened

The invention provides a method for manufacturing a large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, and relates to a method for manufacturing the aluminum alloy slab ingot. The method for manufacturing the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened mainly solves the problems that as for an aluminum alloy slab ingot prepared in the prior art, the casting yield is low, and wide and thick slabs with excellent properties cannot be rolled out. The method comprises the first step of material weighing, the second step of smelting, the third step of casting melt preparation and the forth step of molding, and the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened is obtained. By means of the method, according to the prepared large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, the yield strength ranges from 98 N / mm<2> to 120 N / mm<2>, the tensile strength ranges from 182 N / mm<2> to 201 N / mm<2>, and the elongation percentage in a casting state ranges from 9.56% to 14.7%. By means of the method, the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

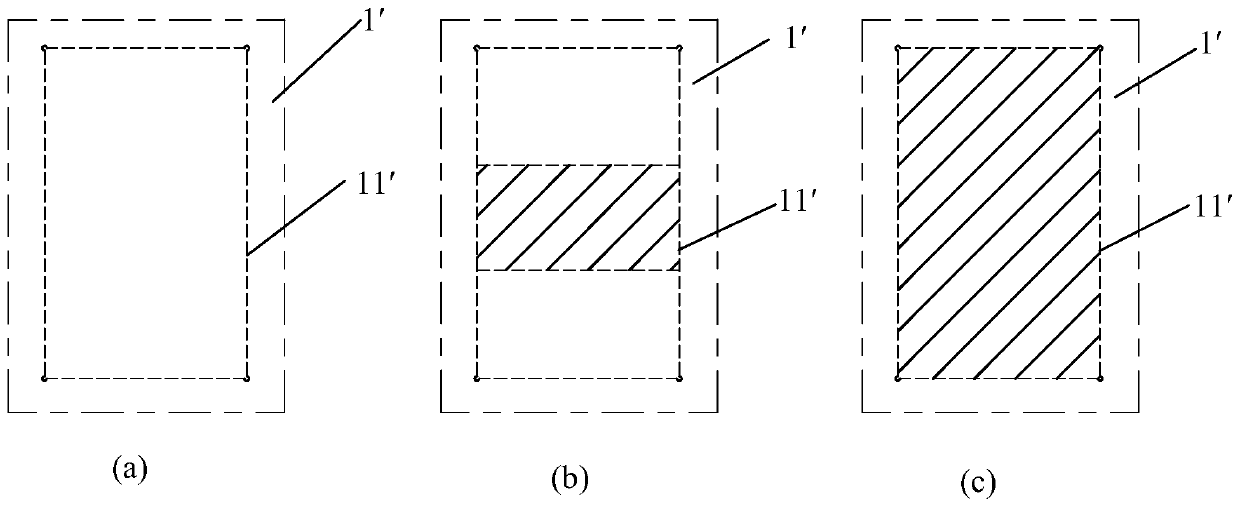

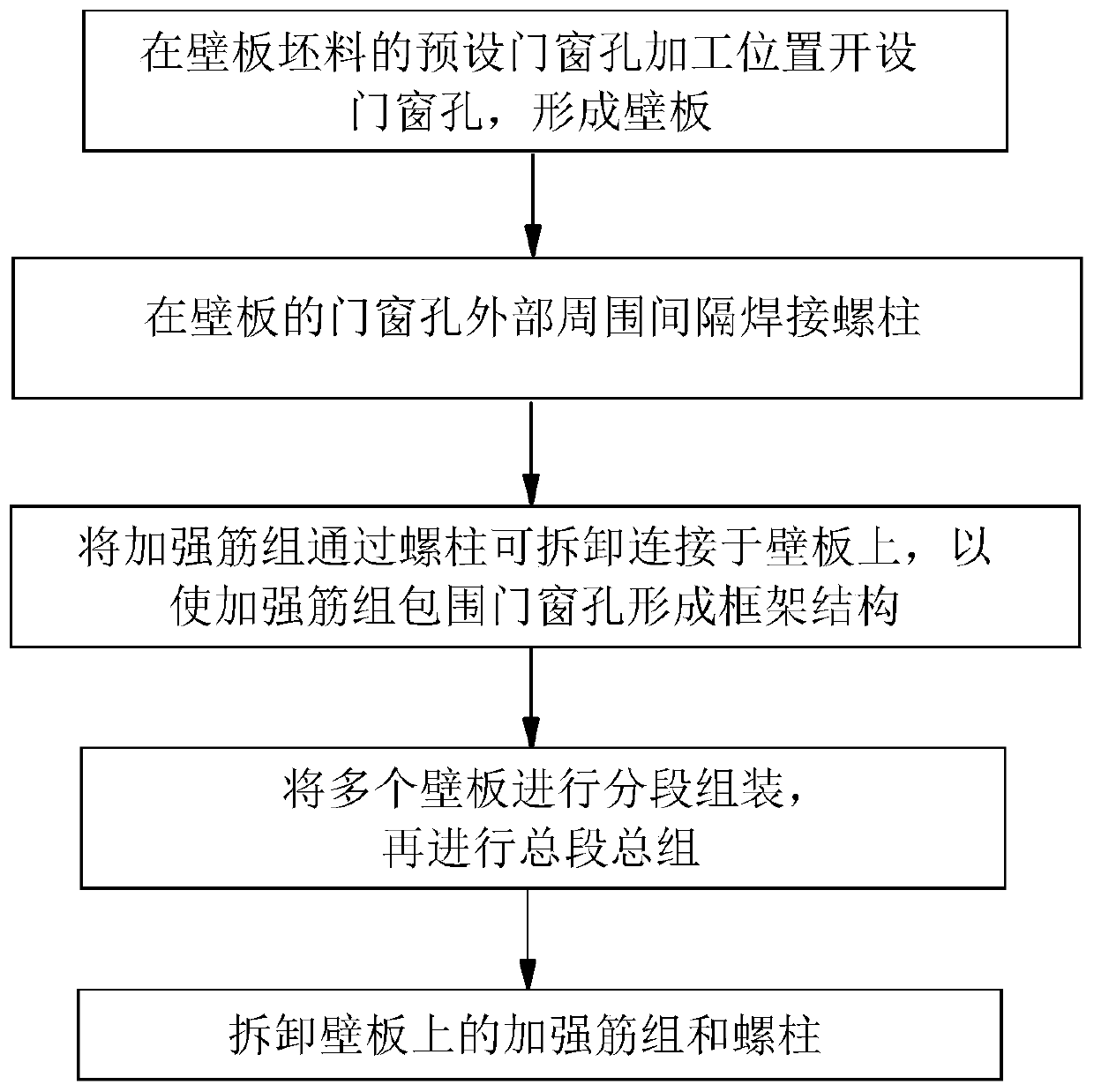

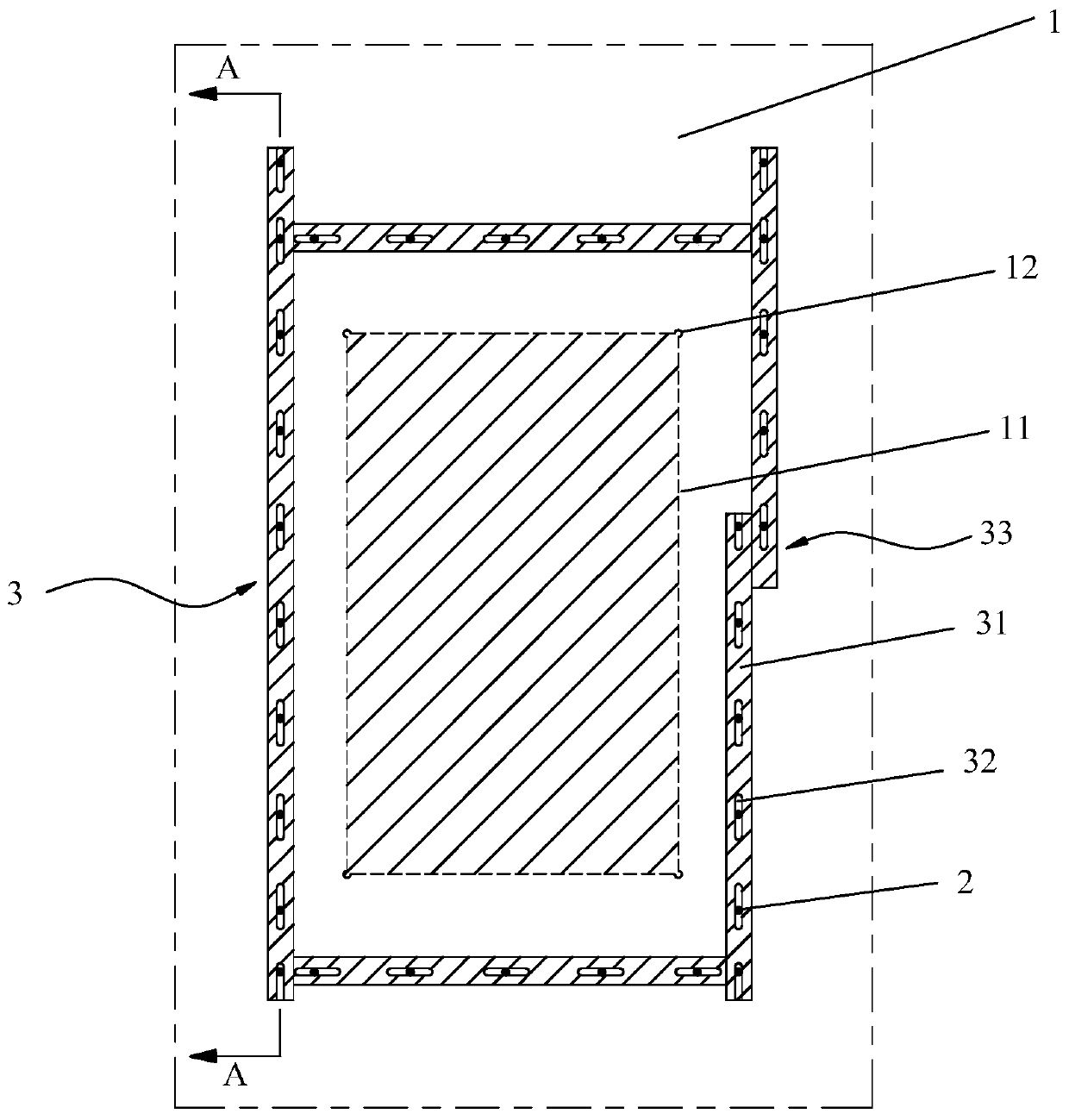

Ship wall door and window hole machining method and door and window hole shape maintaining tool

InactiveCN111470002AImprove construction efficiencyAvoid damageWaterborne vesselsAssembly disassemblyStructural engineering

The invention relates to the technical field of shipbuilding, and discloses a ship wall door and window hole machining method and a door and window hole machining hole shape maintaining tool. The shipwall door and window hole machining method comprises the steps of forming a door and window hole in the preset door hole machining position of a wallboard blank to form a wallboard; welding studs tothe periphery of the exterior of the door and window hole of the wallboard at intervals; detachably connecting a reinforcing rib set to the wallboard through the studs, and enabling the reinforcing rib to surround the door and window hole to form a frame structure; carrying out assembly segmentation on a plurality of wallboards, and then carrying out block assembling; and disassembling the reinforcing rib set and the studs on the wallboards. The door and window hole machined through the ship wall door and window hole machining method is small in deformation, and the damage to base metal is small. The door and window hole shape maintaining tool is easy and convenient to operate through the ship wall door and window hole machining method, and the deformation generated in the assembly segmentation process and the block assembling after door and window hole machining can be reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

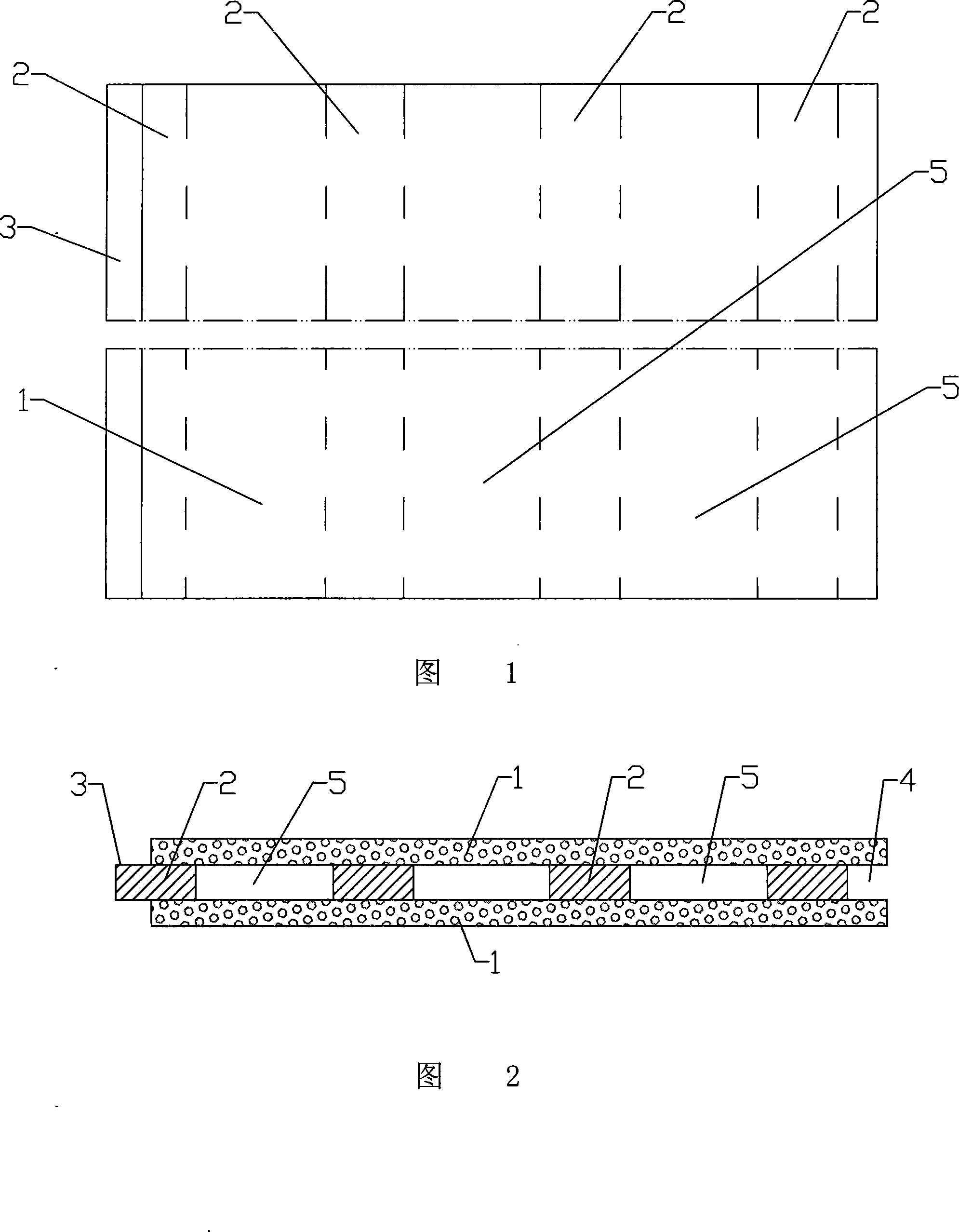

Light composite wall panel

The invention discloses a light composition wall board, which comprises two plates which are face to face arranged, at least two elongated stiffeners are horizontally arranged between the two plates which are face to face arranged, one portion of the stiffener on one lateral portion of the plate is arranged in the plates, and the other portion is extended out from the lateral surface of the plate to form a projection, and the stiffener on the other lateral portion of the plate is arranged in the plate, and a groove which can contain the projection is formed between the stiffener and the plates which are face to face arranged. The composition wall board has lighter weight, which is convenient for field construction, improves construction efficiency, lowers production cost, meanwhile lowers integral load of buildings, lowers foundation investment, reduces accommodation area when in use, and increases utilized time of buildings.

Owner:SHANDONG HONGTAI CONSTR GROUP

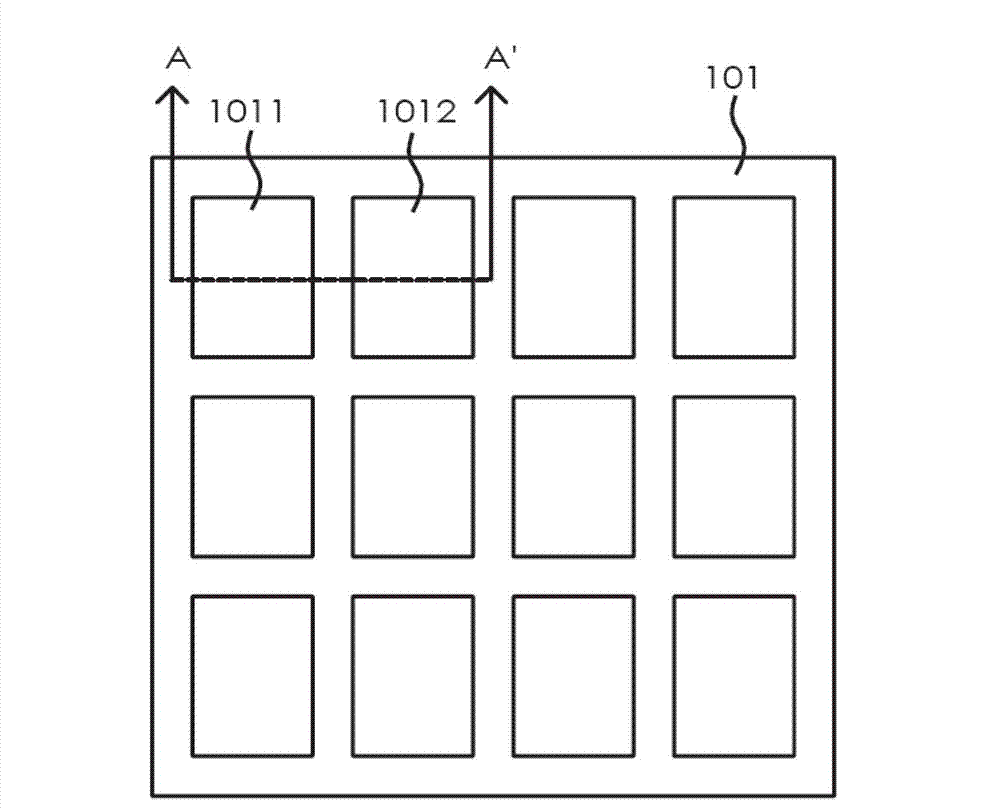

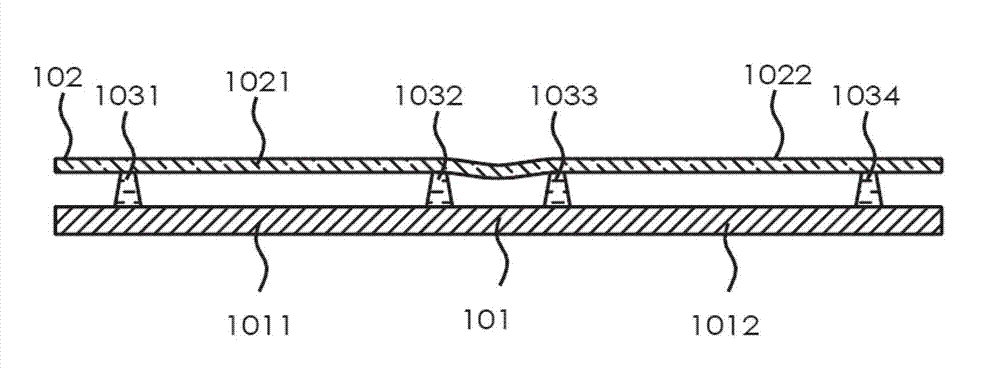

Organic light-emitting diode display panel and manufacturing method thereof

InactiveCN102856253AConnectivityPlay a supporting roleSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The invention discloses an organic light-emitting diode display panel, which comprises a first thin film transistor array substrate; a first cover plate is arranged on the first thin film transistor array substrate, wherein the first cover plate is provided with first sintering glue and second sintering glue, and an area between the first and the second glue corresponds to the first thin film transistor array substrate; and structural strengthening glue arranged outside the first and the second glue of the first cover plate and contacted with the first thin film transistor array substrate and the first cover plate. The invention further discloses a manufacturing method of the organic light-emitting diode display panel. The invention prevents the phenomenon that the thin film transistor array substrate or the cover plate warps caused by a negative pressure between the thin film transistor array substrate and the cover plate, so that the organic light-emitting diode display panel is more firm and stable in structure.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

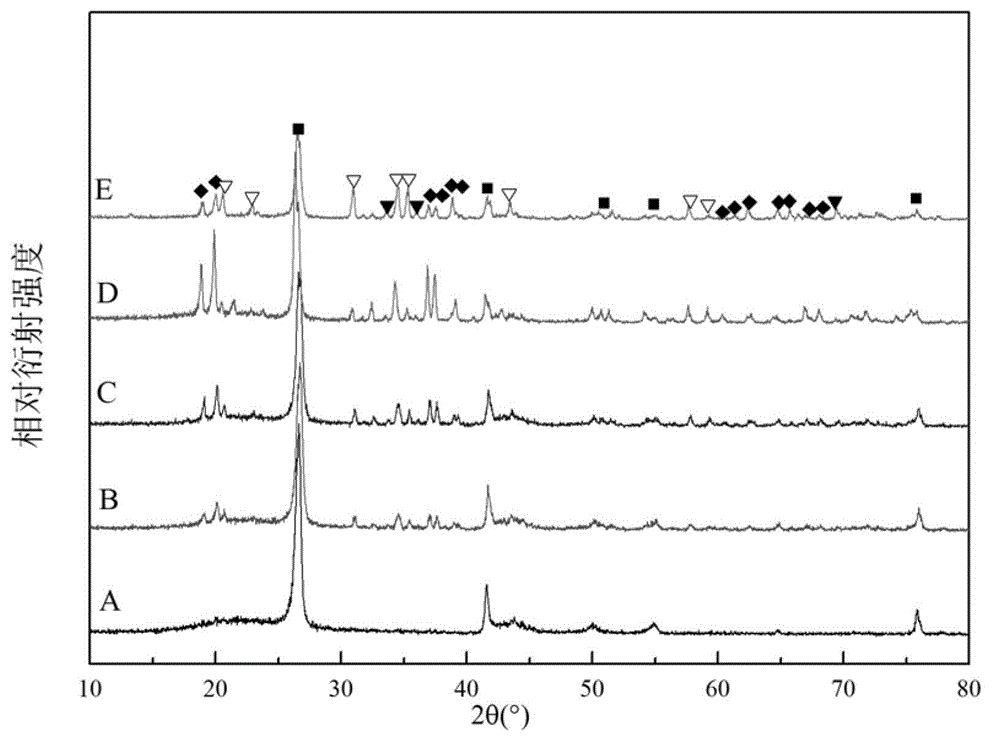

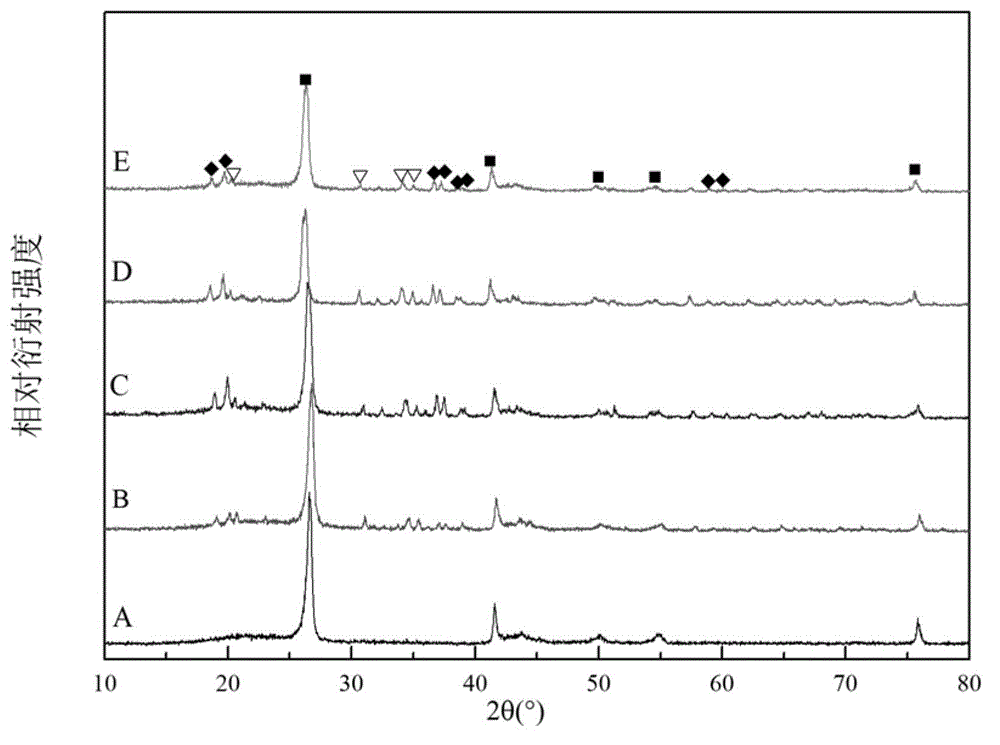

BN-Si2N2O composite ceramic and preparation method thereof

ActiveCN103145112AExcellent high temperature strength and oxidation stabilitySmall coefficient of thermal expansionCarbon compoundsSilicon nitrideBoron nitride

The invention discloses a BN-Si2N2O composite ceramic and a preparation method thereof, relates to a boron nitride based ceramic material and a preparation method thereof, and aims to solve the problems that an existing method for preparing the boron nitride based composite material is high in preparation cost, low in efficiency and difficult in preparation of large-size boron nitride based ceramic components. The BN-Si2N2O composite ceramic is prepared from amorphous nano silicon dioxide, silicon nitride powder and hexagonal boron nitride powder. The preparation method comprises the following steps of: one, weighing; two, preparing slurry through ball milling; three, drying to prepare powder; four, prepressing and forming; five, performing isostatic cool pressing treatment; and six, performing sintering treatment to obtain the BN-Si2N2O composite ceramic. The preparation method has the advantages that the preparation cost is reduced, the efficiency is improved, and the difficulty for preparing the large-size boron nitride based ceramic components is reduced. The preparation method is mainly used for preparing the BN-Si2N2O composite ceramic.

Owner:HARBIN INST OF TECH

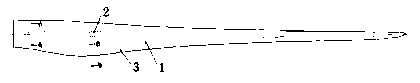

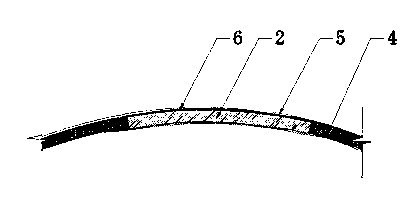

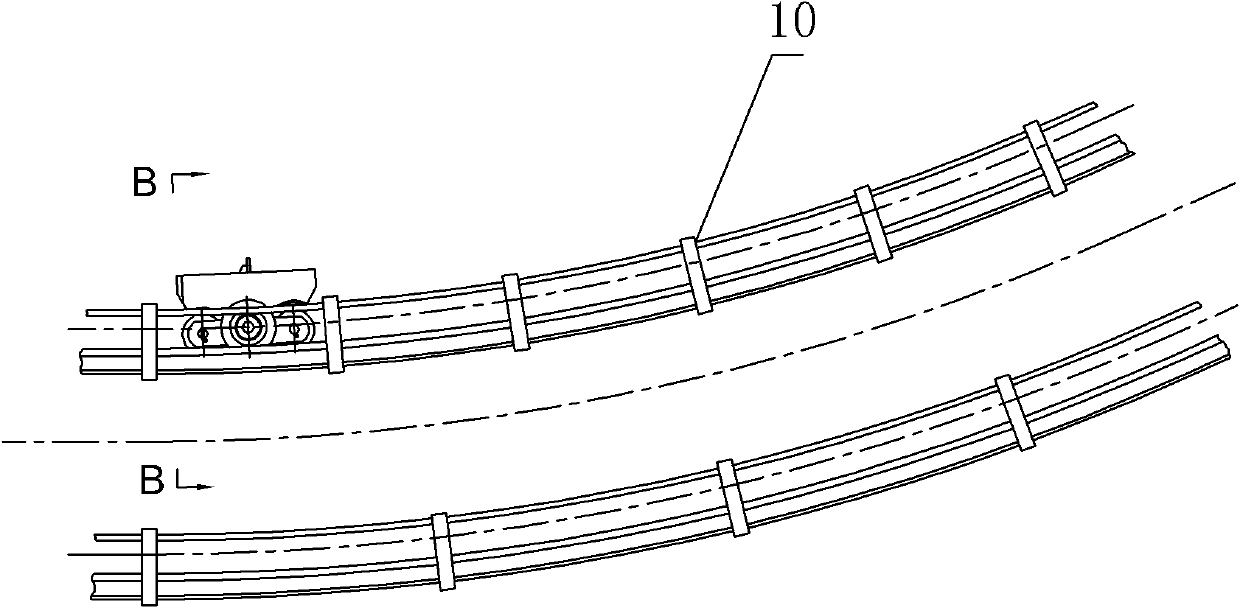

Method for remotely monitoring damage of interlayer structure of wind power blade

ActiveCN103994032AHigh sensitivityPlay a strengthening roleWind energy generationWind motor componentsElectricityFiber

A method for remotely monitoring damage of the interlayer structure of a wind power blade is used for monitoring the damage position and the damage degree of the interlayer structure of the wind power blade. According to the method, a carbon fiber intelligence layer (6) is laid on a beam cap (2) below one outer skin of the wind power blade (1) and a rear edge beam below another outer skin of the wind power blade (1) based on the functional characteristics of the carbon fiber intelligence layer (6) and the special shape following performance of composite materials, a sensitivity field is established between the carbon fiber intelligence layer (6) and the structure to be monitored, the carbon fiber intelligence layer (6) converts a force field of the structure to be monitored into an electric field easy to detect, the conditions of stress and strain of the structure to be monitored can be known through an ERT tomography system (10) according to resistivity distribution of the electric field, and then the damage position and the damage degree of the structure to be monitored can be judged. By means of the method, the use process of the wind power blade (1) can be remotely monitored in real time without disassembly of the blade or a halt which influences normal operation of a wind power generator, and the condition of crack growth in the structure of the wind power blade (1) can be known in real time so as to give an alarm in time.

Owner:大连双瑞风电叶片有限公司

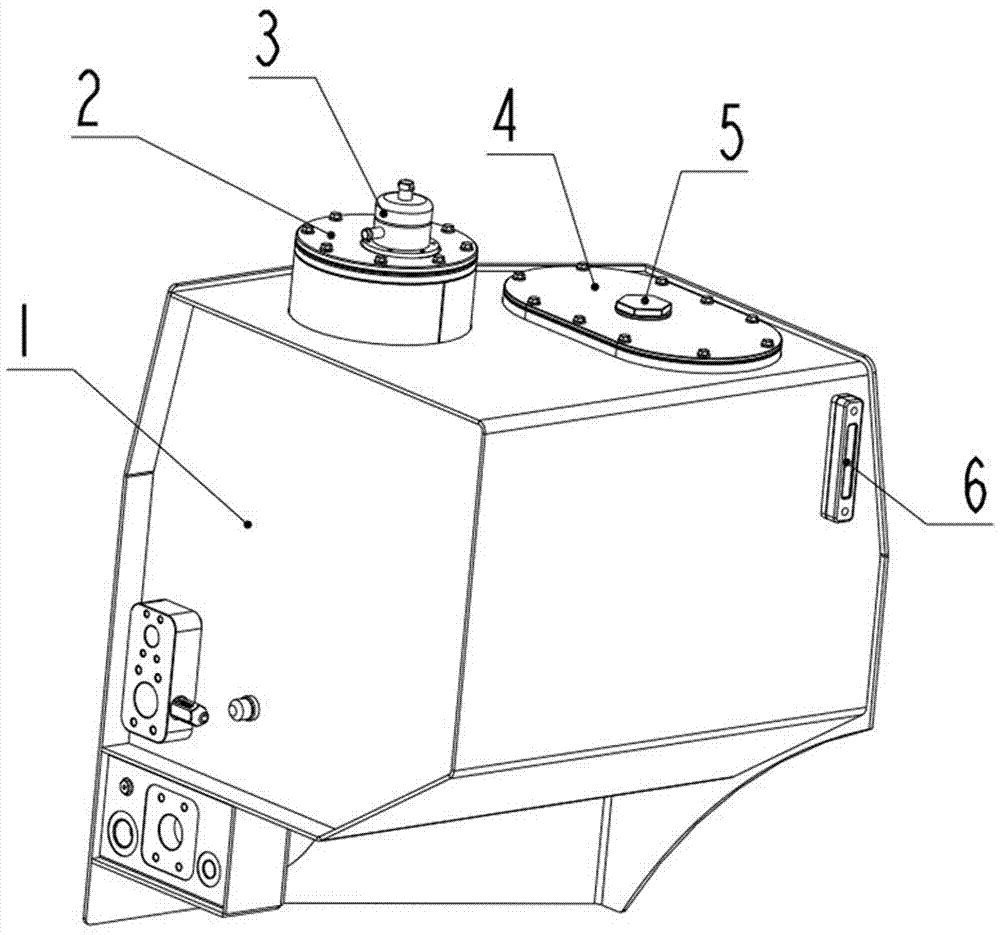

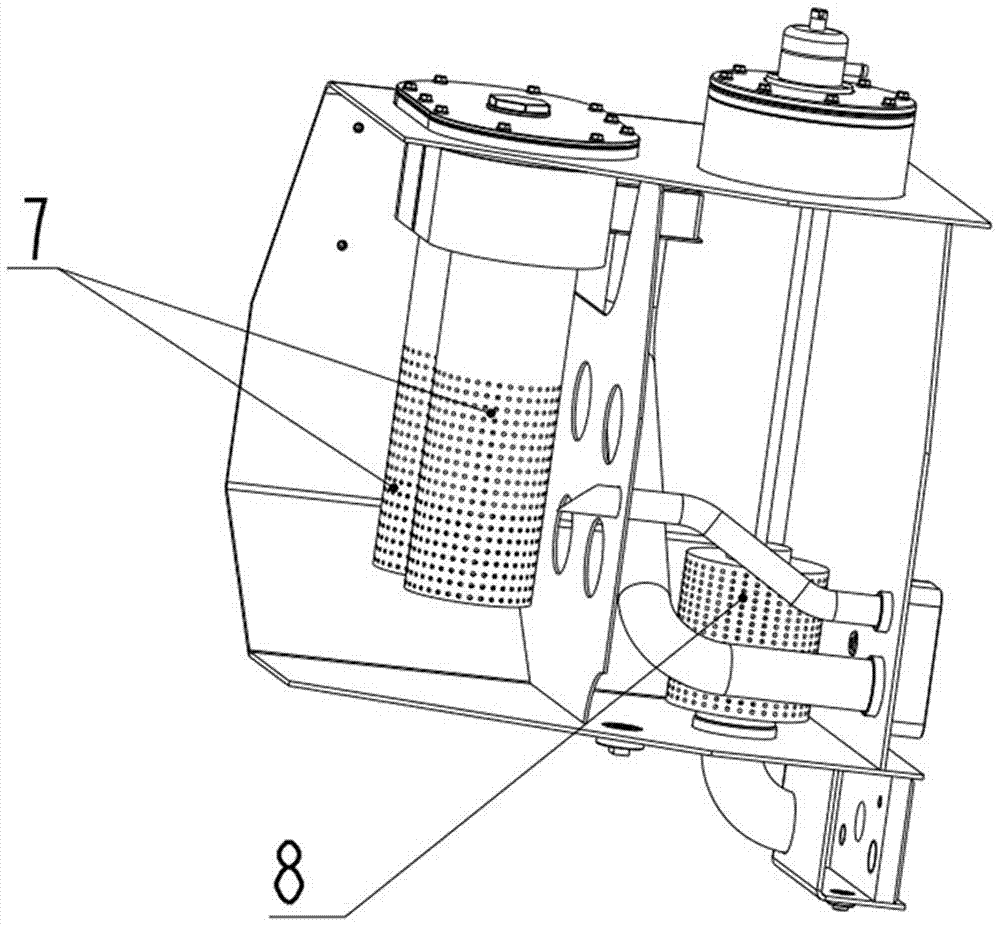

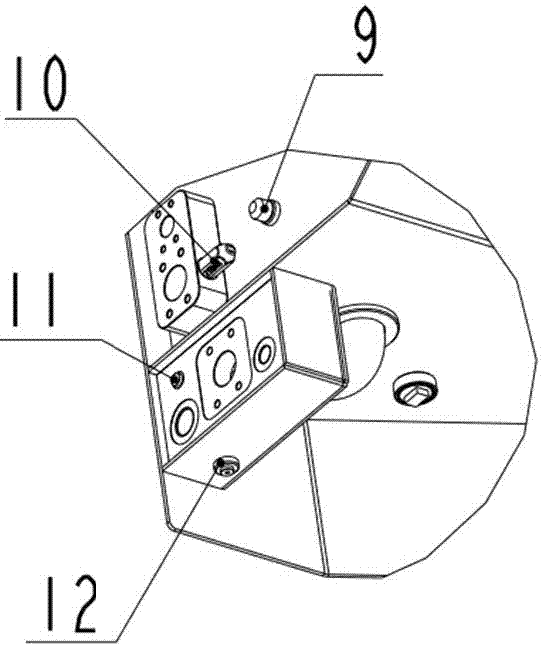

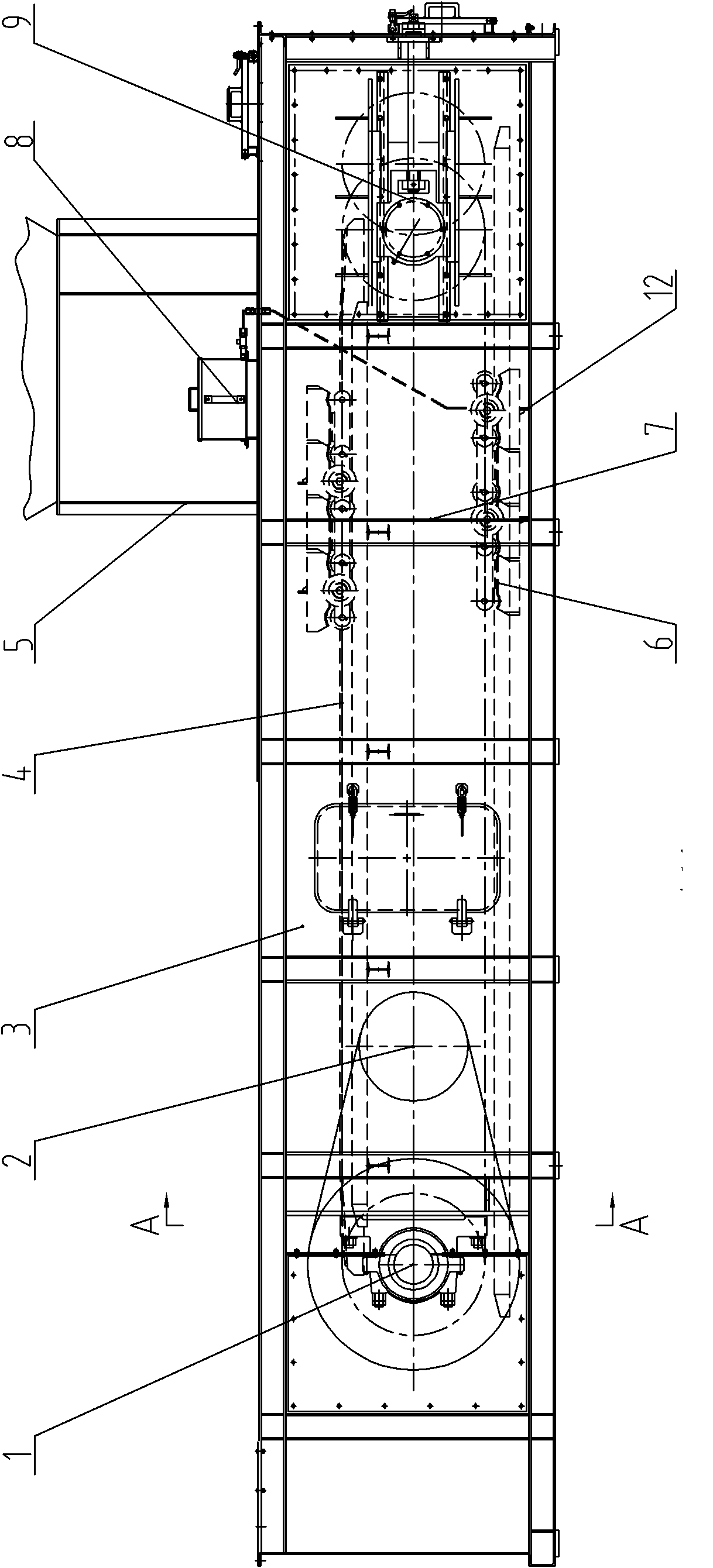

Hinge type dumper hydraulic oil tank

PendingCN107420358AGuaranteed uptimeMeet oil cleanlinessFluid-pressure actuator testingPump assembliesOil filterFilter element

A hinge type dumper hydraulic oil tank comprises a hydraulic oil tank body. An oil return cavity is formed in the top face in a cavity body of the hydraulic oil tank body. An oil return pipe communicating with the oil return cavity is arranged on the side face of the oil return cavity. The other end of the oil return pipe communicates with an oil return port, wherein the oil return port is fixed to the side face of the hydraulic oil tank body and is close to the position of the bottom face, and the oil return port communicates with an outer hydraulic system. The hinge type dumper hydraulic oil tank further comprises a plurality of oil return filters. Oil inlets of the oil return filters are arranged in a cavity body of the oil return cavity, and after penetrating out of the bottom face of the oil return cavity, oil outlets of the oil return filters extend towards the cavity body of the hydraulic oil tank body; and the part between the radial outer circumferential face of each oil return filter and the oil return cavity is sealed. The novel hinge type dumper hydraulic oil tank is provided, the hydraulic system oil liquid cleanliness can be achieved, oil suction and return oil filter element replacement is simple, and stable running of the hydraulic system is guaranteed.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

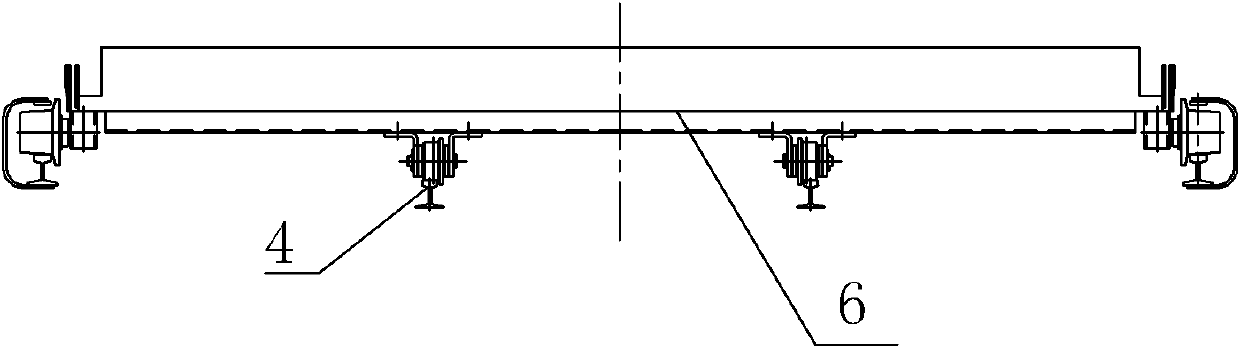

Ultra-wide apron conveyer

Owner:宜都中起重工机械有限公司

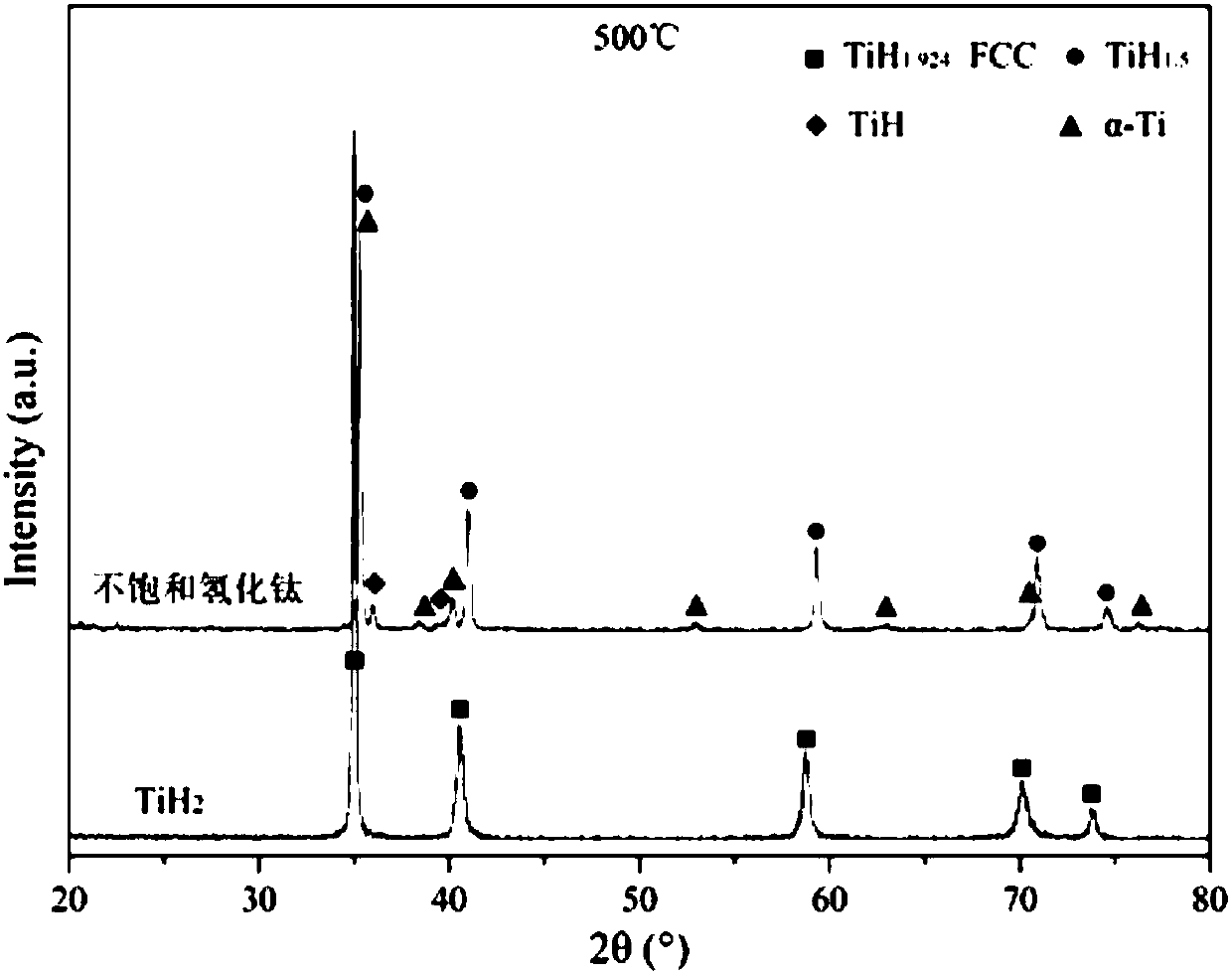

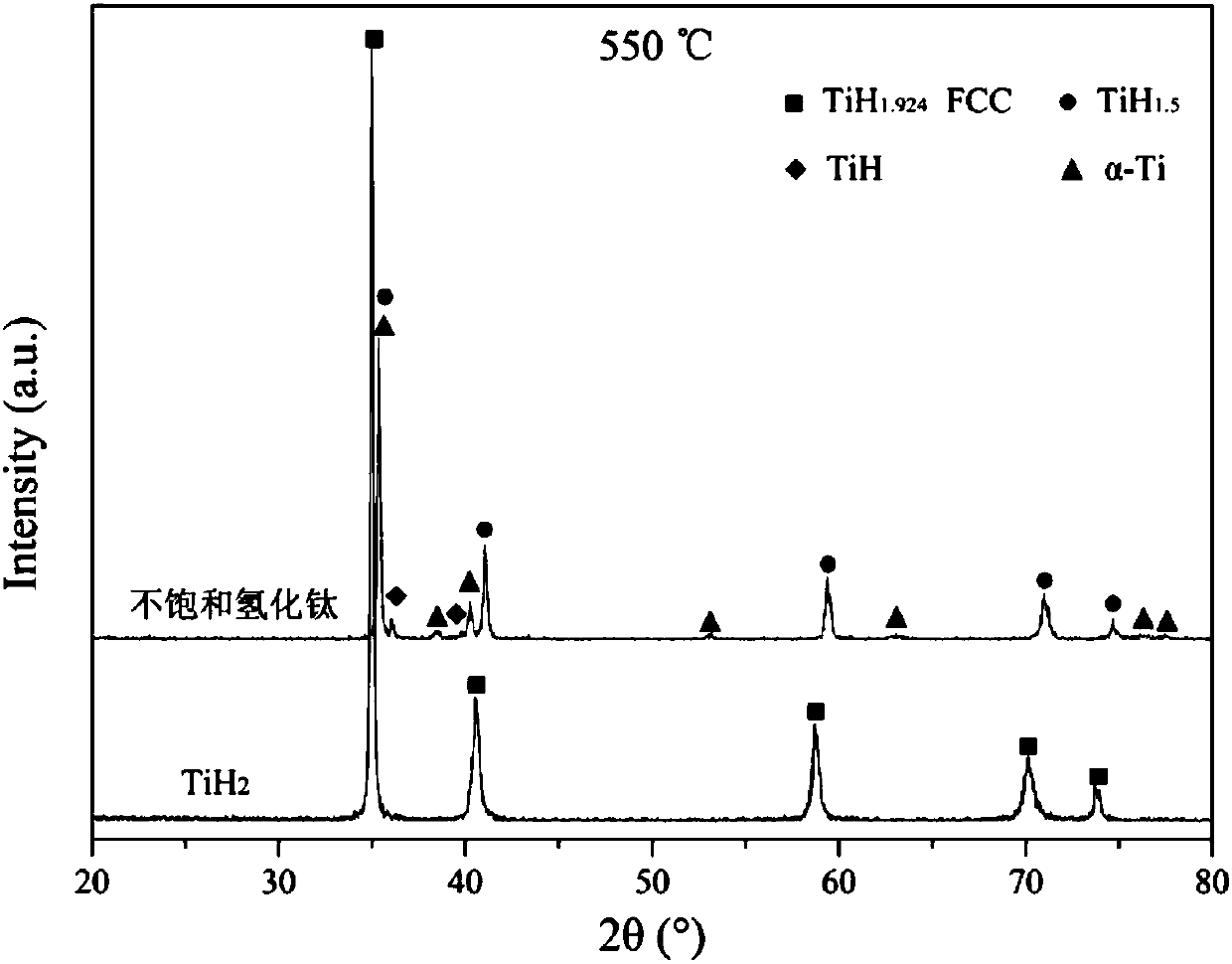

High-formability unsaturated titanium hydride powder and preparation method thereof

ActiveCN107640744AGood formabilityPlay a strengthening roleTransition element hydridesDehydrogenationTitanium alloy

The invention belongs to the field of titanium alloy powder metallurgy materials and provides high-formability unsaturated titanium hydride powder. The high-formability unsaturated titanium hydride powder comprises 70wt%-77wt% of a main phase TiH1.5, 13wt%-18wt% of an alpha-Ti phase and 10wt%-15wt% of a TiH phase and is prepared by unsaturated hydrogen absorption of titanium sponge or incomplete dehydrogenation of TiH2 powder. The unsaturated titanium hydride powder is excellent in formability, less prone to cracking and layering in blank forming, high in forming rate and especially suitable for manufacturing of complex large parts and has advantages of high sintering yield in subsequent sintering and excellent product mechanical properties.

Owner:SICHUAN UNIV

Stable manufacturing method of aluminium-alloy medium-thickness plate

The invention discloses a stable manufacturing method of an aluminium-alloy medium-thickness plate and belongs to the technical field of aluminium alloy. The stable manufacturing method comprises thefollowing steps: (S1) preparation of aluminium-alloy molten liquid; (S2) preparation of an aluminium-alloy cast ingot; (S3) destressing treatment; (S4) sawing of the aluminium-alloy ingot; (S5) solution treatment; (S6) multidirectional forging; (S7) prestretching; (S8) ageing treatment to obtain the finished product. The stable manufacturing method disclosed by the invention has the beneficial effects that by adoption of a reasonable machining process, the comprehensive properties of ductility, strength of extension, yield strength and the like of the aluminium-alloy medium-thickness plate areimproved.

Owner:湖南恒佳新材料科技有限公司

Wear-resistant corrosion-resistant impeller for centrifugal pump

InactiveCN109578322AIngenious structural designStable and reasonable structurePump componentsPumpsWear resistantAgricultural engineering

The invention relates to a wear-resistant corrosion-resistant impeller for a centrifugal pump. The impeller comprises blades, an impeller disc, a front cover plate and a rear cover plate, the blades are arranged on the periphery of the impeller disc in a sleeving mode, the roots of the front cover plate and the rear cover plate are fixedly arranged on the impeller disc, the plate surfaces of the front cover plate and the rear cover plate cover the middle parts of the two sides of the blades correspondingly, the front cover plate and the rear cover plate can play a role in reinforcing the blades; and the impeller disc, the front cover plate and the rear cover plate are all made of wear-resistant alloy materials, the blades are made of silicon carbide ceramic materials, and the outer surfaces of the blades, the impeller disc, the front cover plate and the rear cover plate each are coated with a layer of corrosion-resistant coating. The impeller for the centrifugal pump is simple and reasonable in structure, easy to manufacture and stable in work, has excellent wear resistance and corrosion resistance and is long in service life.

Owner:ANHUI YINLONG PUMP VALVE

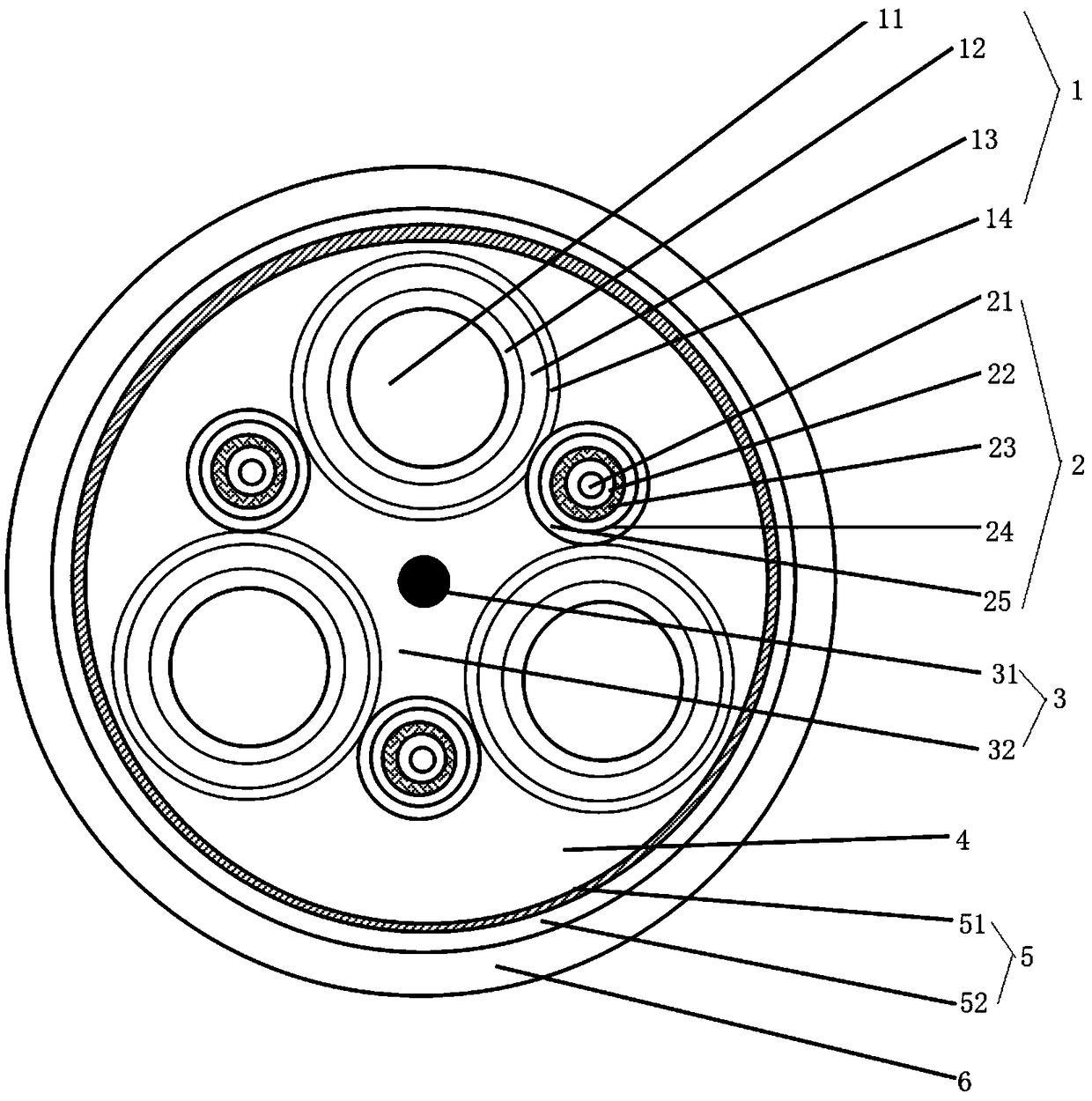

Production Technology of Frequency Conversion Cable Used in Coal Mine

InactiveCN109166677AReasonable structural designStable arrangementCable/conductor manufactureInterference resistanceFrequency conversion

The invention discloses a production process of a frequency conversion cable for a coal mine, comprising the following steps of: determining a cable structure; 2, respectively produce a power core, acontrol core and a filling core, and then forming that cable into a cable core; 3, squeeze that inner sheath out of the cable core; 4, manufacture a shielding layer by an inn sheath; 5, squeeze that outer sheath out of the shield layer. The cable structure of the invention is reasonable in design and stable in arrangement, and the produced cable has excellent anti-interference characteristics, voltage impulse resistance, wear resistance, tear resistance and flame retardancy, and the cable is flexible and easy to bend, and is particularly suitable for use in coal mine roadways with bad conditions.

Owner:FAR EAST CABLE +2

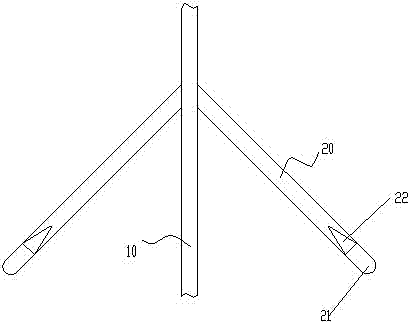

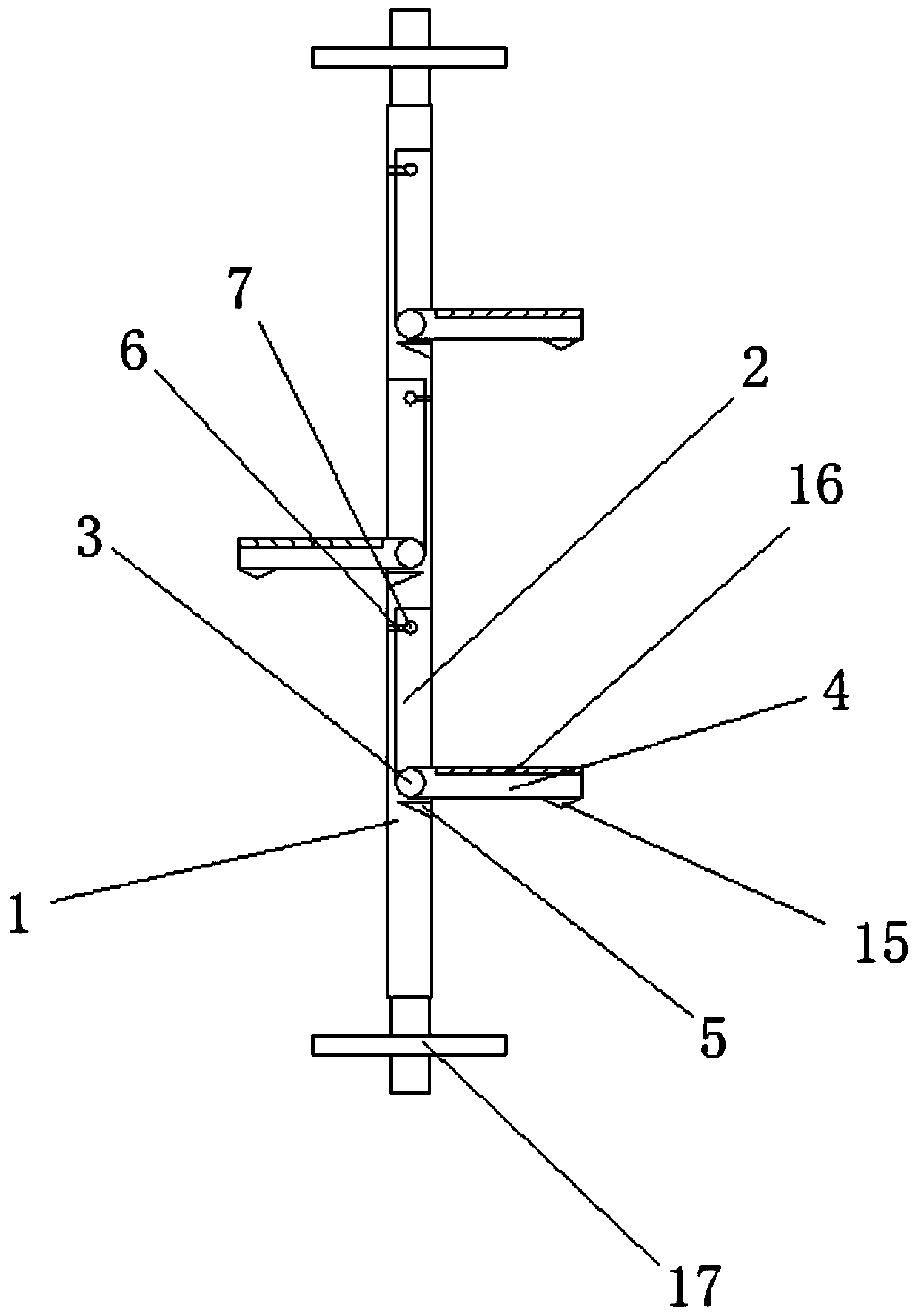

Wheel hub electrophoretic coating hanger

InactiveCN104775145AQuality improvementReduce workloadElectrophoretic coatingsElectrophoresesStructural engineering

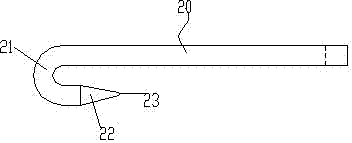

The invention belongs to the technical field of machinery equipment for electrophoretic coating, and especially relates to a wheel hub electrophoretic coating hanger. The hanger comprises a main rod and at least a pair of hanging rods; the main rod is a cylindrical steel vertical column, the hanging rods incline from the main rod downwards and are fixed on the main rod; each hanging rod is composed of a linear body and an end part, which is far from the body and is provided with a folded portion; the free end of the end part is a sharp part; the minimal distance between the base of the sharp part and the body of the handing rod is shorter or equal to the minimal distance between the base of the sharp part and the bottom in the folded part of the folded portion. By using the hanger, the wheel hub can be tightly fixed during electrophoresis, and the wheel hub needs little painting after electrophoresis.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

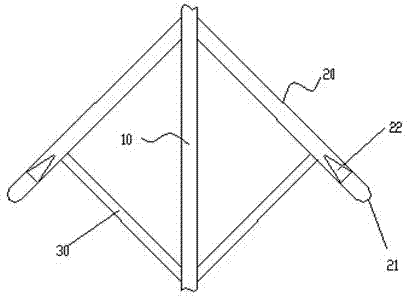

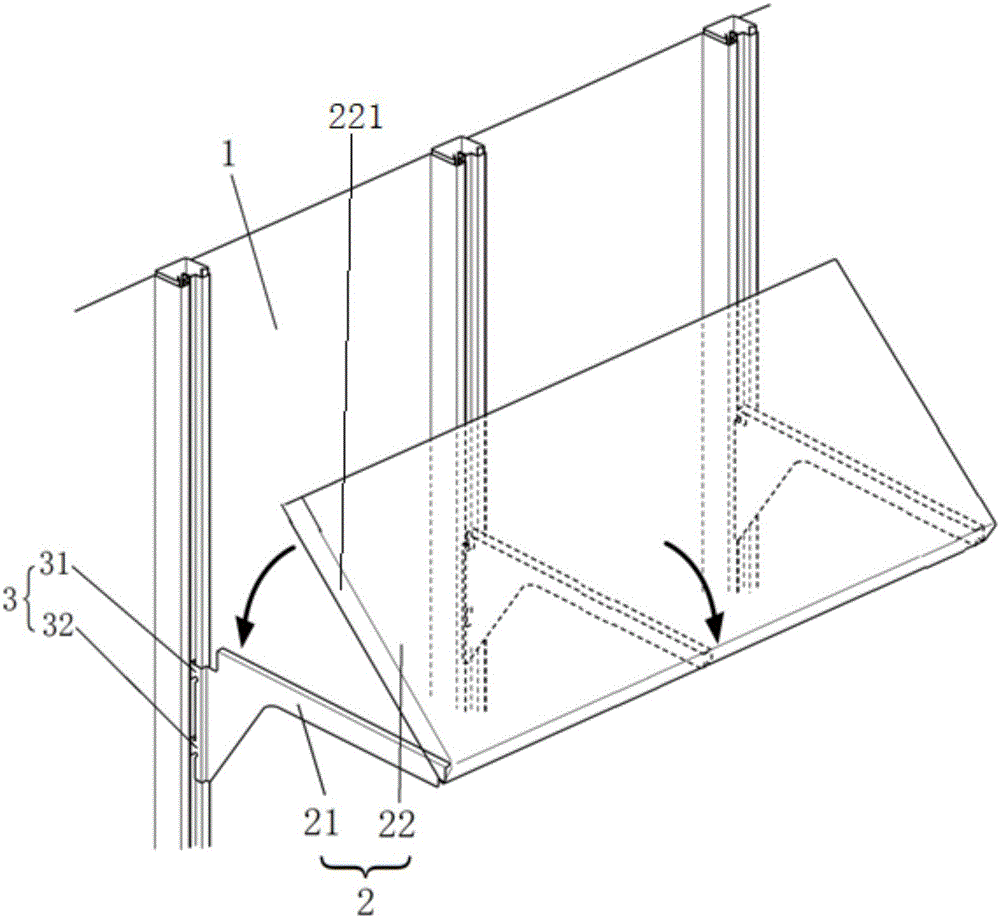

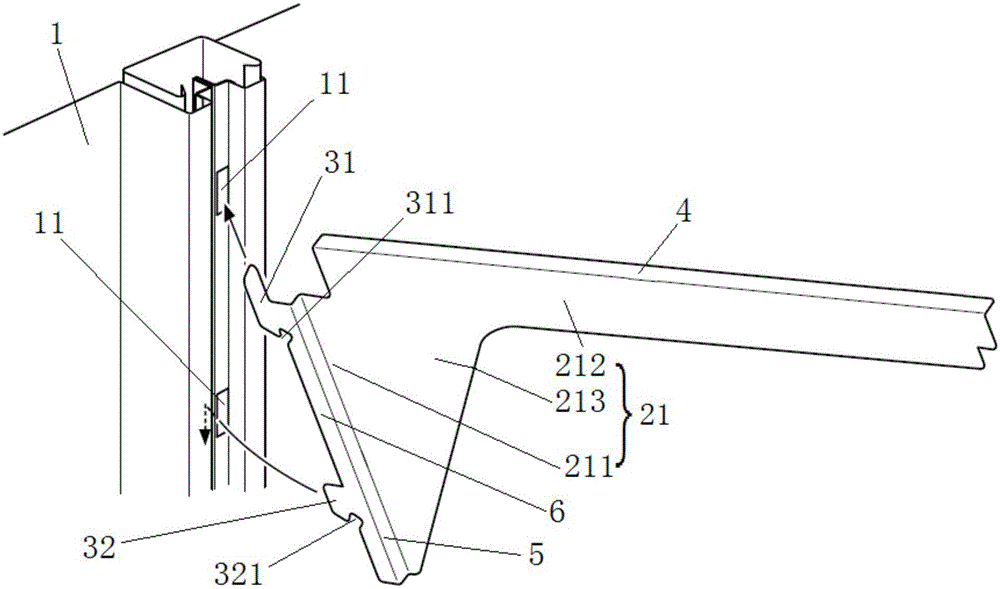

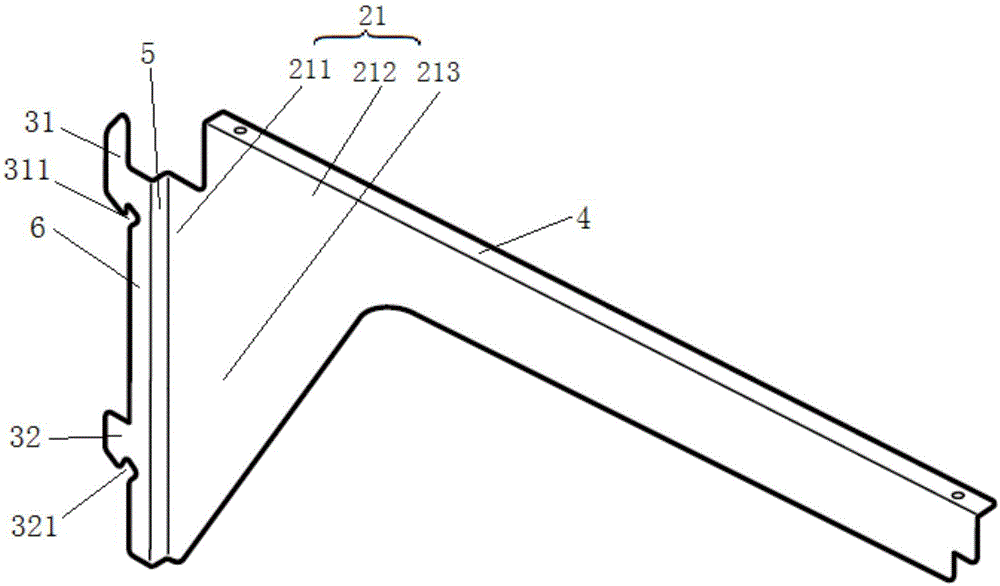

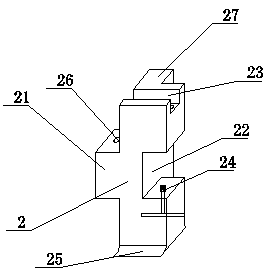

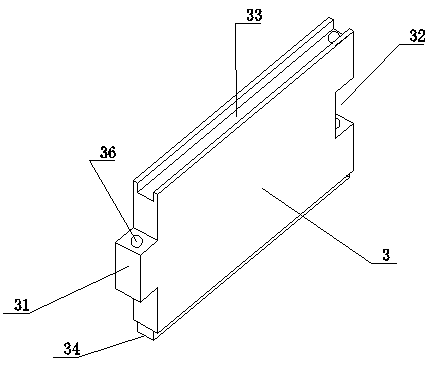

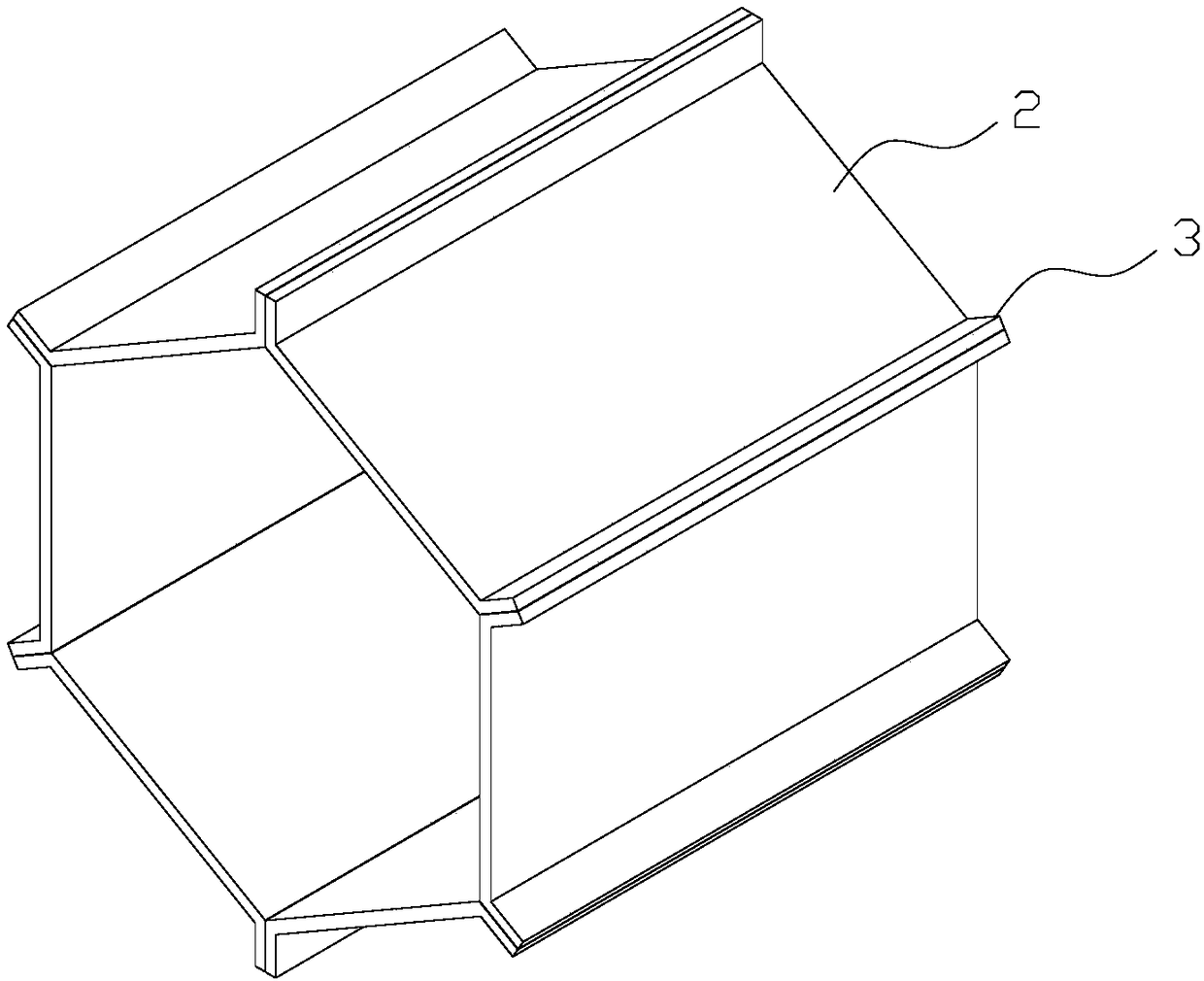

Suspended type multiple layers of clapboards for locker

PendingCN106473469AUnique shapeHigh strengthFurniture partsMovable shelf cabinetMultiple layerWall plate

The invention discloses suspended type multiple layers of clapboards for a locker. The clapboards are arranged into multiple layers from top to bottom along a wall plate (1) of a locker, and the clapboards (2) comprise multiple clapboard supports (21) and shelf boards (22) arranged on the multiple clapboard supports (21), wherein a buckling support part (3) is formed at one side edge of each clapboard support (21), and is fixed with a neck (11) on the wall plate (1) by buckling; a horizontal supporting plane is formed at the upper end of each clapboard support (21); and the shelf board (22) is buckled on the horizontal supporting plane (4) of the clapboard supports (21) in a mode of being vertical to the wall plate (1) of the locker. The clapboards provided by the invention can be distributed on the wall plate freely, and form buckling connection by virtue of the buckling support part and the neck on the wall plate, and a partition position can be changed very conveniently according to needs of a user, so that storage partitions formed by the clapboards in the locker have more special shapes.

Owner:CENT INT GROUP

Process for producing special steel mesh transmission belt

The invention discloses a process for producing a special steel mesh transmission belt, which is carried out by the following steps: (1) mixing: weighting and preparing all raw materials according toa process prescription to prepare rubber material; (2) rubber making: feeding all raw materials into a refining machine to mix for 8-10 minutes and then discharging; (3) canvas: carrying out double-surface bonding on the glue soaked canvas on a three-rolling calendar; (4) forming: placing a stainless steel mesh under the covering glue for forming; and (5) vulcanizing: carrying out pretreatment ona formed belt body according to different types of the transmission belt and vulcanizing according to operation process requirement. All positions of the transmission belt are uniformly stressed, andthe stress performance of the canvas is optimized so that the canvas is difficult to deflect and laniate; and V-shaped belts playing a role of positioning are respectively arranged at both side edgesof the belt body, thereby further preventing the deflecting phenomenon of the transmission belt, reducing the waste of materials, strengthening the transmission belt and further improving the mechanical performance of the transmission belt.

Owner:YANGZHOU DONGXING RUBBER

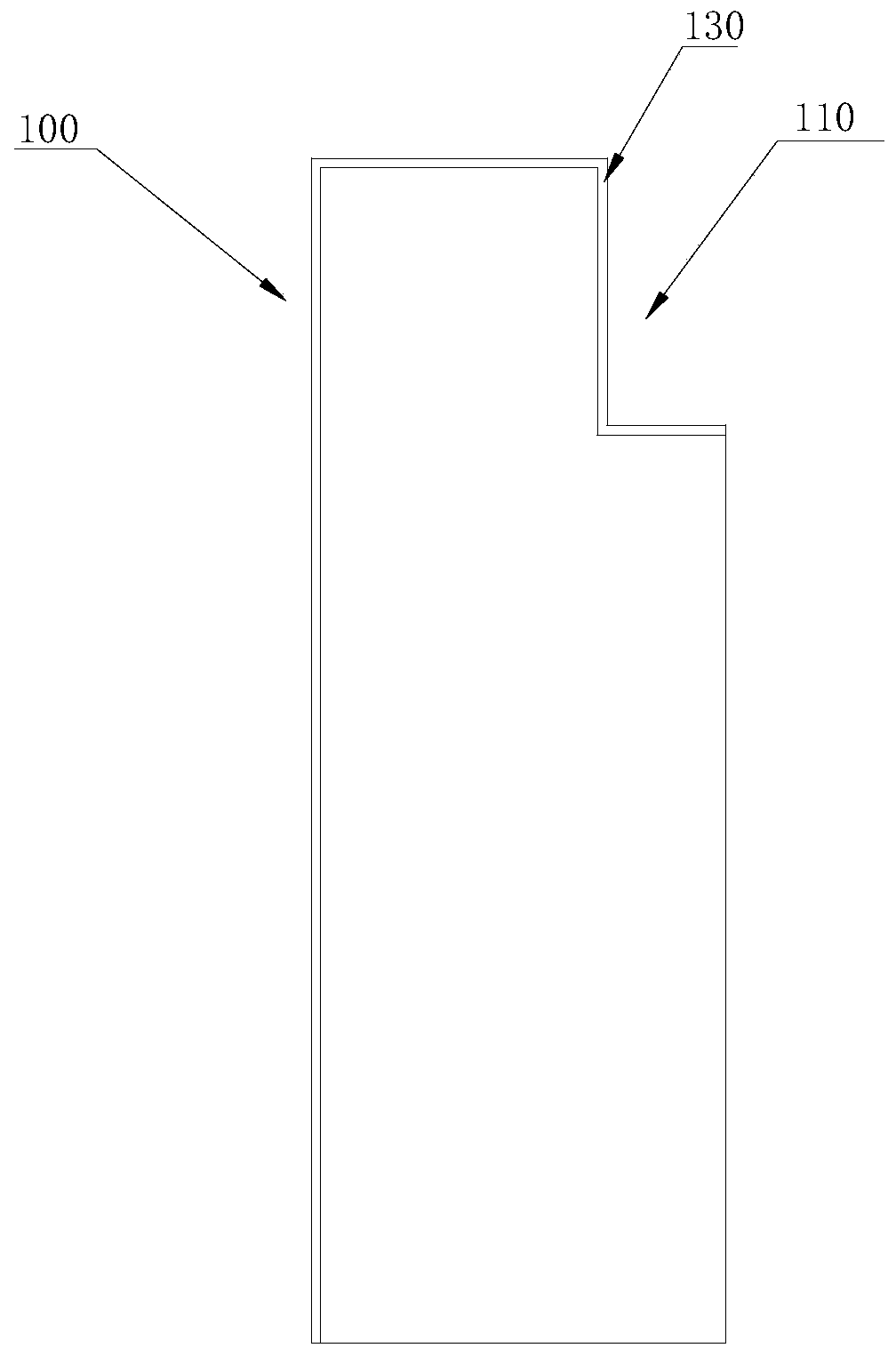

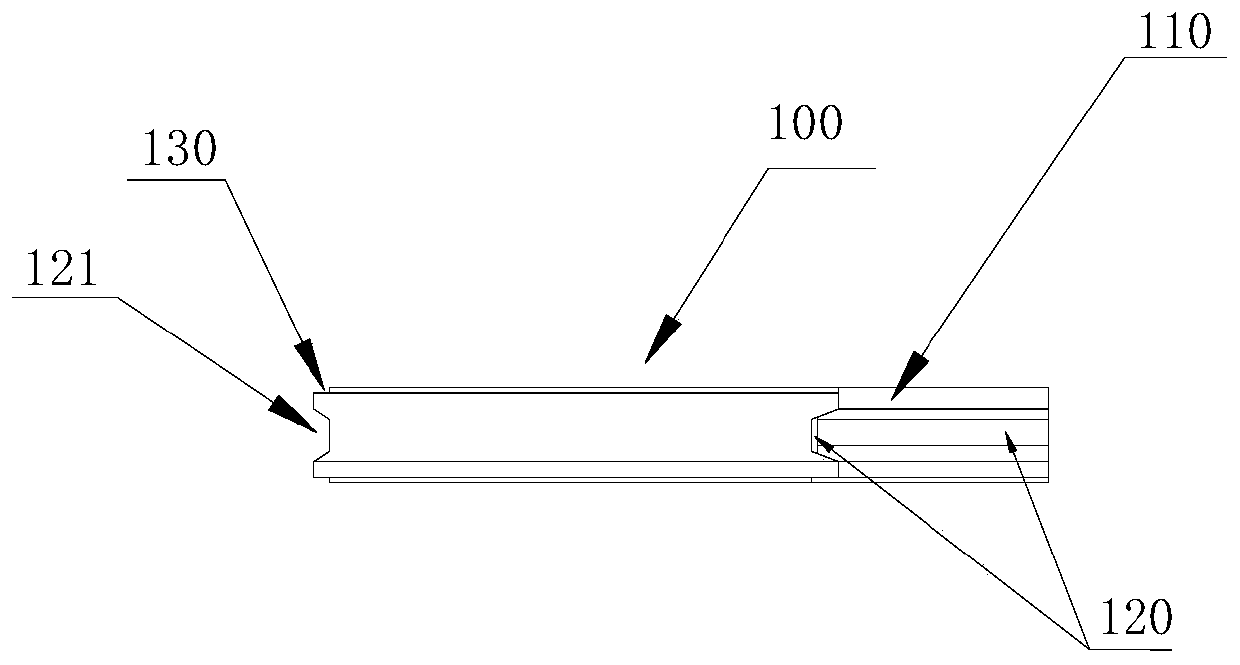

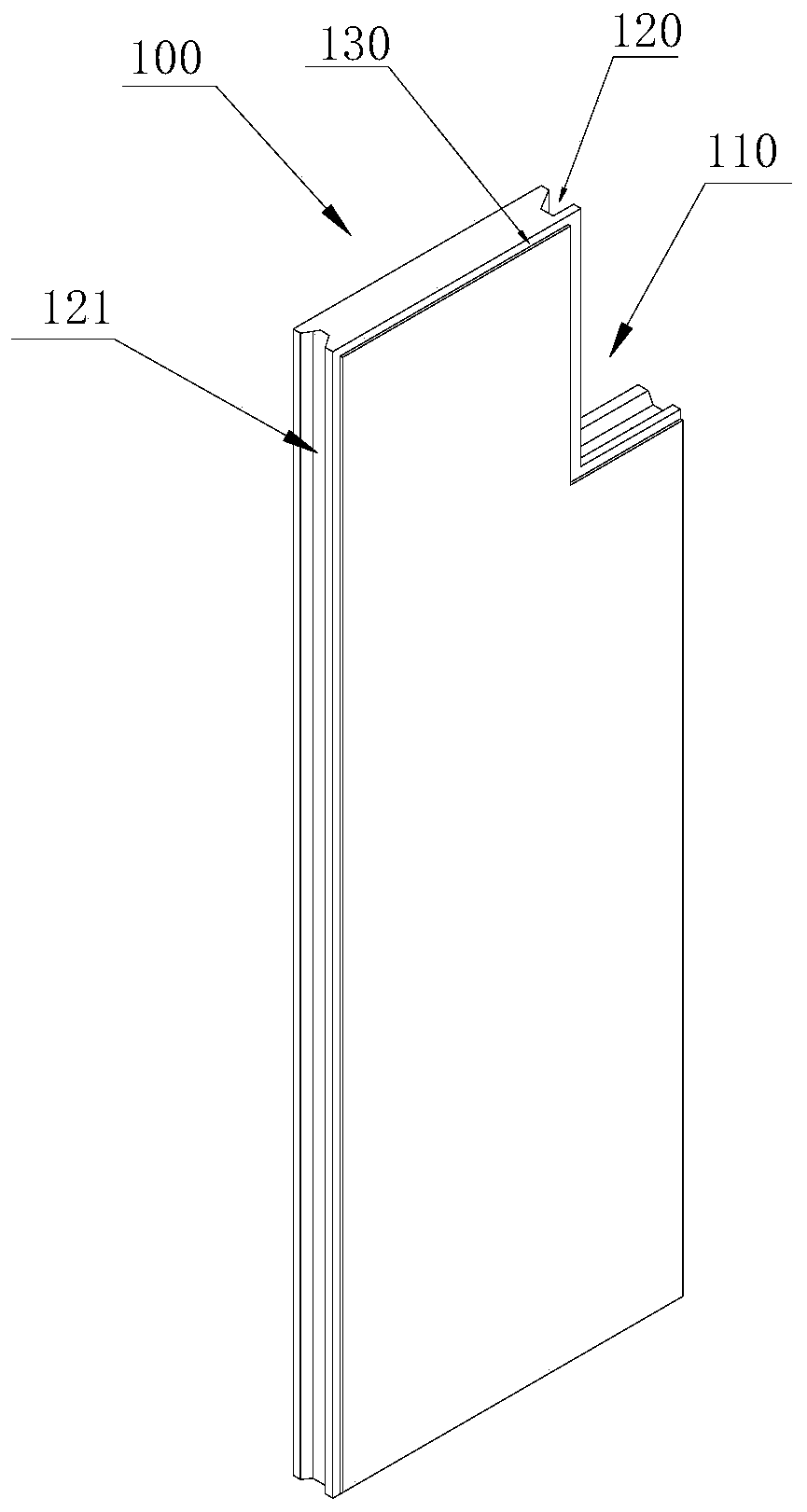

Prefabricated anti-cracking door frame vertical board for ribbon board internal parting wall door opening structure

PendingCN110029773AAvoid Live CutsImprove construction efficiencyConstruction materialUltimate tensile strengthElectrical and Electronics engineering

The invention discloses a prefabricated anti-cracking door frame vertical board for a ribbon board internal parting wall door opening structure. The prefabricated anti-cracking door frame vertical board comprises prefabricated door frame vertical board bodies; L-shaped notches are formed in the upper parts of the prefabricated door frame vertical board bodies, so that the prefabricated door framevertical board bodies are connected with prefabricated door head boards in a joint-staggering engaged mode to improve the connecting firmness of the prefabricated door frame vertical board bodies andthe prefabricated door head boards; prefabricated grouting grooves are formed in the outer side faces of the prefabricated door frame vertical board bodies, during door opening splicing, the prefabricated door head boards are inserted in the L-shaped notches of the two corresponding prefabricated door frame vertical board bodies to form a door opening, internal parting wall ribbon boards are spliced on the side face of the door opening, and prefabricated mortar storage grooves are compactly filled with mortar to form secondary connecting bodies with the internal bolting effect to be fixedly connected; and jointing grooves are formed in the edges of the outer sides of the L-shaped notches correspondingly and spliced with the adjacent prefabricated door head boards with jointing grooves andthe internal parting wall ribbon boards during door opening splicing to define anti-cracking edge sealing grooves, net laying and mortar smearing are conducted on the interiors of the anti-cracking edge sealing grooves to form anti-cracking connecting bodies, the connecting strength of joints is improved, and the phenomenon that as for an existing door opening structure, due to frequent opening and closing and vibration of a door, the spliced positions of the door opening are prone to being cracked is effectively avoided.

Owner:舒浪平 +1

A combined battery box

ActiveCN105742535BAchieve sealingReduce manufacturing costCell component detailsStructural engineeringMechanical engineering

The invention discloses a combined battery box. The box body is a cuboid whose two ends pass through. The inner walls of the top and bottom of the box body are evenly and symmetrically provided with a plurality of axial ribs. The dovetail groove extending in the whole length direction, the front and rear ends of the box body are provided with front and rear end covers to close the box body, and there are sealing rings between the front and rear end covers and the end surface of the box body, and the front and rear end covers are respectively passed through the end cover screws It is fixed on the box body, and the end cover screws are screwed into the dovetail grooves respectively. There are multiple rows of battery rows installed in the inner cavity of the box body, and the four corners of each battery row are respectively clamped between the convex ribs. Each battery row is formed by plugging a plurality of battery pack units sequentially from front to back, and each battery pack unit includes a battery base and a battery top seat respectively, and a plurality of battery installation holes are correspondingly provided on the opposite end surfaces of the battery base and the battery top seat , batteries are respectively installed in each pair of battery installation holes. The battery of the combined battery box is quick to install, convenient to assemble, and has high space utilization rate.

Owner:陈杰

Assembly type brick membrane

ActiveCN108560574AFirmly connectedRealize factory productionFoundation engineeringBrickAgricultural engineering

The invention belongs to the technical field of assembly buildings, and particularly relates to an assembly type brick membrane. The assembly type brick membrane comprises a prefabricated base, a prefabricated reinforcing column used for reinforcing and lengthening, and a prefabricated standard part located on the upper portion of the prefabricated base and used for heightening the prefabricated base. The prefabricated base and the prefabricated reinforcing column are located on the same horizontal plane. Due to the fact that the prefabricated base, the prefabricated reinforcing column and theprefabricated standard part can be spliced through convex blocks and grooves, the prefabricated base, the prefabricated reinforcing column and the prefabricated standard part which are spliced are connected through T-shaped rebars or lengthening rods in installing holes, concrete is poured into the installing holes, brick membranes used in production can be obtained through splicing of the parts,and the advantages that construction is convenient, assembly is rapid, and environmental friendliness is achieved are achieved.

Owner:THE CONSTR DECORATION OF CHINA CONSTR NO 7 ENG BUREAU

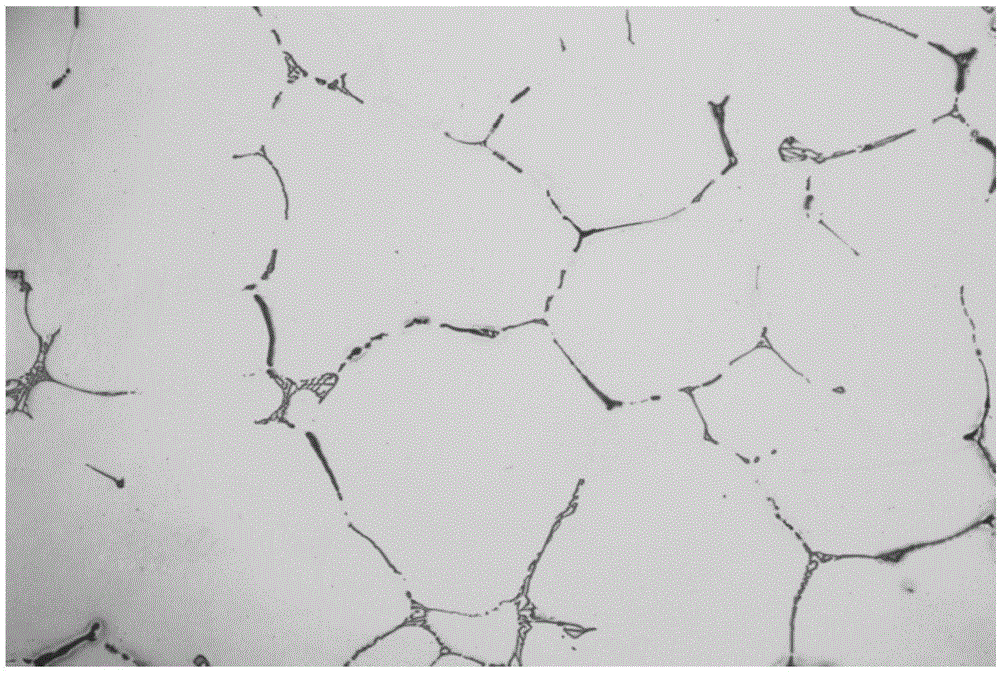

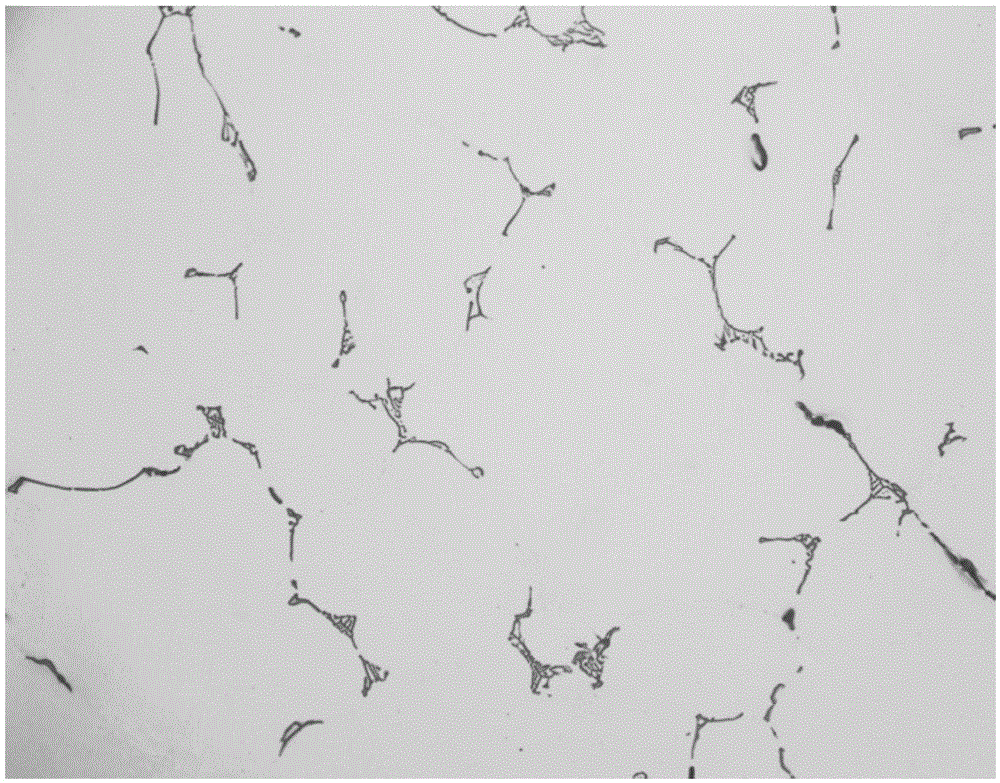

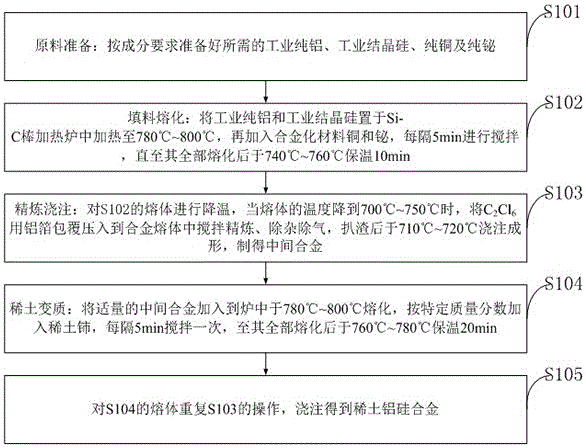

Novel damping wear-resisting hypereutectic aluminum-silicon alloy preparing method based on rare earth cerium modification

InactiveCN106381426AReduce wear massThe average coefficient of friction decreasesSilicon alloyCerium

The invention discloses a novel damping wear-resisting hypereutectic aluminum-silicon alloy preparing method based on rare earth cerium modification. The method comprises the steps of carrying out raw material preparing, padding melting and refining casting, obtaining an intermediate alloy, adding modification agent rare earth cerium according to the specific mass fraction, and carrying out stirring at a time every interval of 5 min until the intermediate alloy added with the medication agent rare earth cerium is completely molten at the temperature of 760 DEG C to 780 DEG C and is subject to heat preservation for 20 min; carrying out repeated refining casting operation on the a melt obtained after complete melting of the intermediate alloy added with the modification agent rare earth cerium, carrying out casting, and obtaining the rare earth aluminum-silicon alloy. According to the novel damping wear-resisting hypereutectic aluminum-silicon alloy preparing method based on rare earth cerium modification, alloying elements of Cu and Bi are adopted, and are dissolved in the aluminum-silicon alloy melt in a solid manner, in the casting and solidifying process of a metal mold, a second phase of a hard point is formed and distributed on an alloy base body, the effect of second phase reinforcing is achieved, and wear resistance of an alloy material is ensured.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

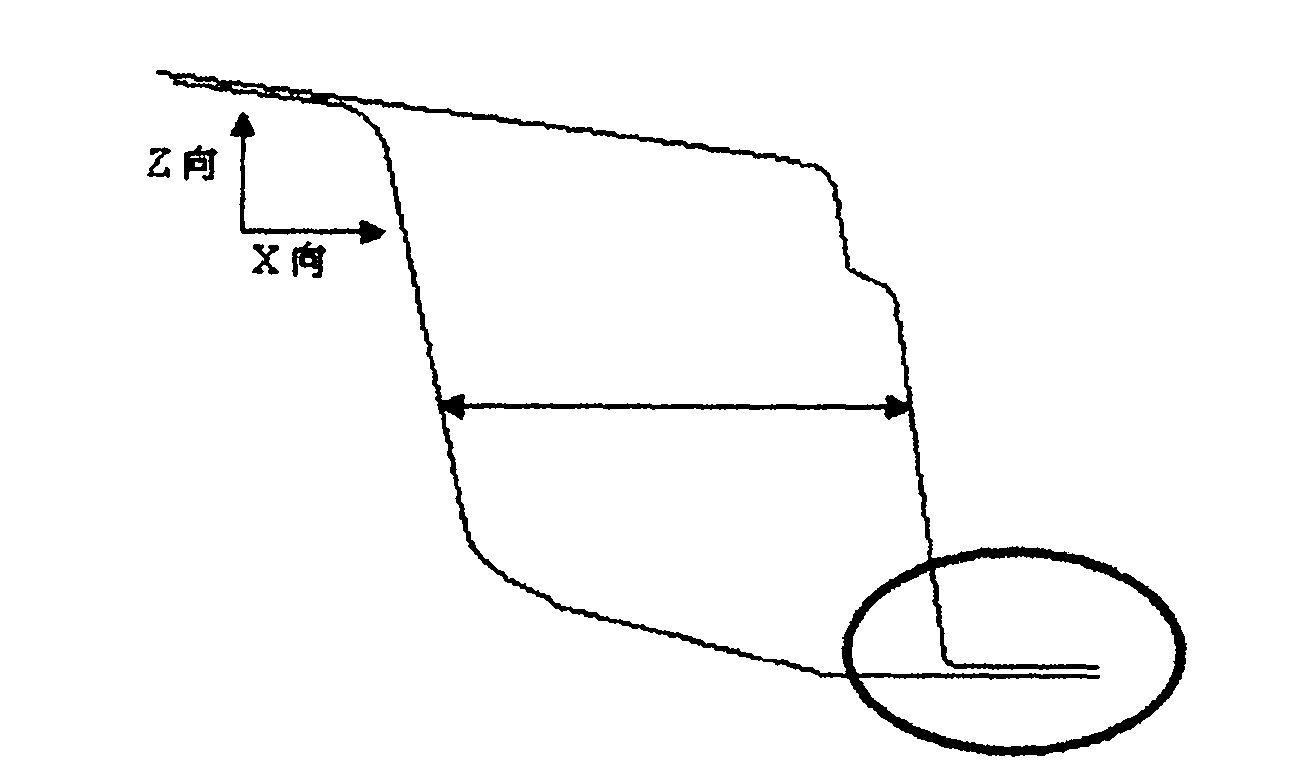

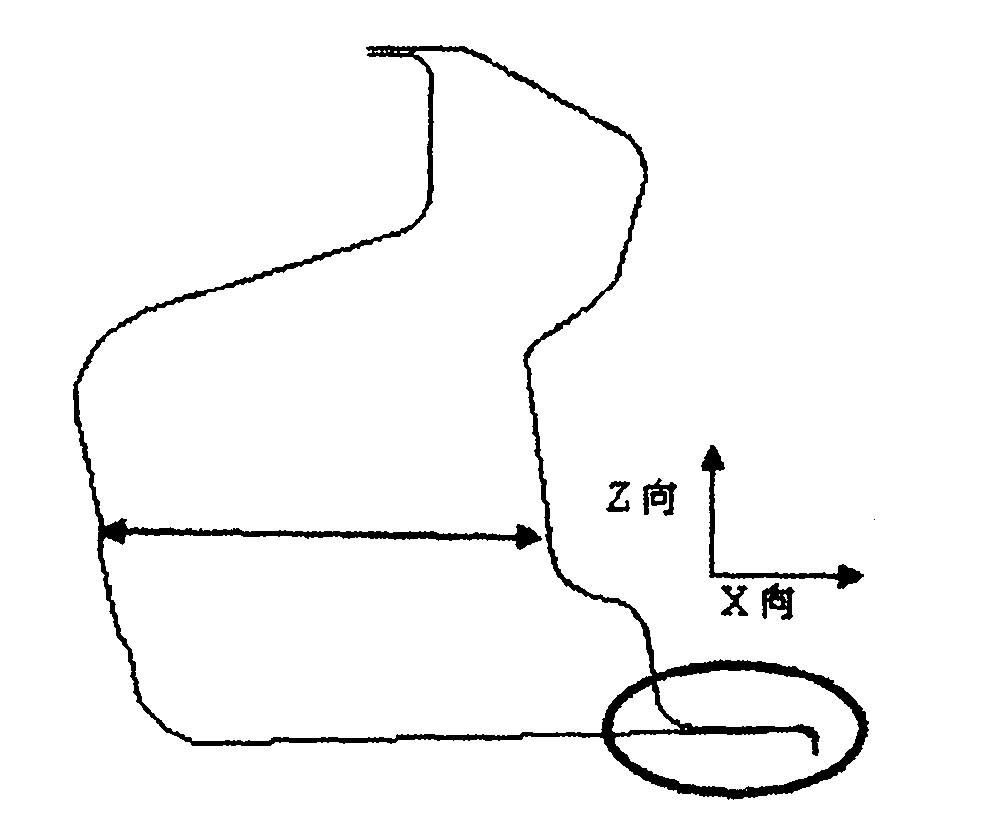

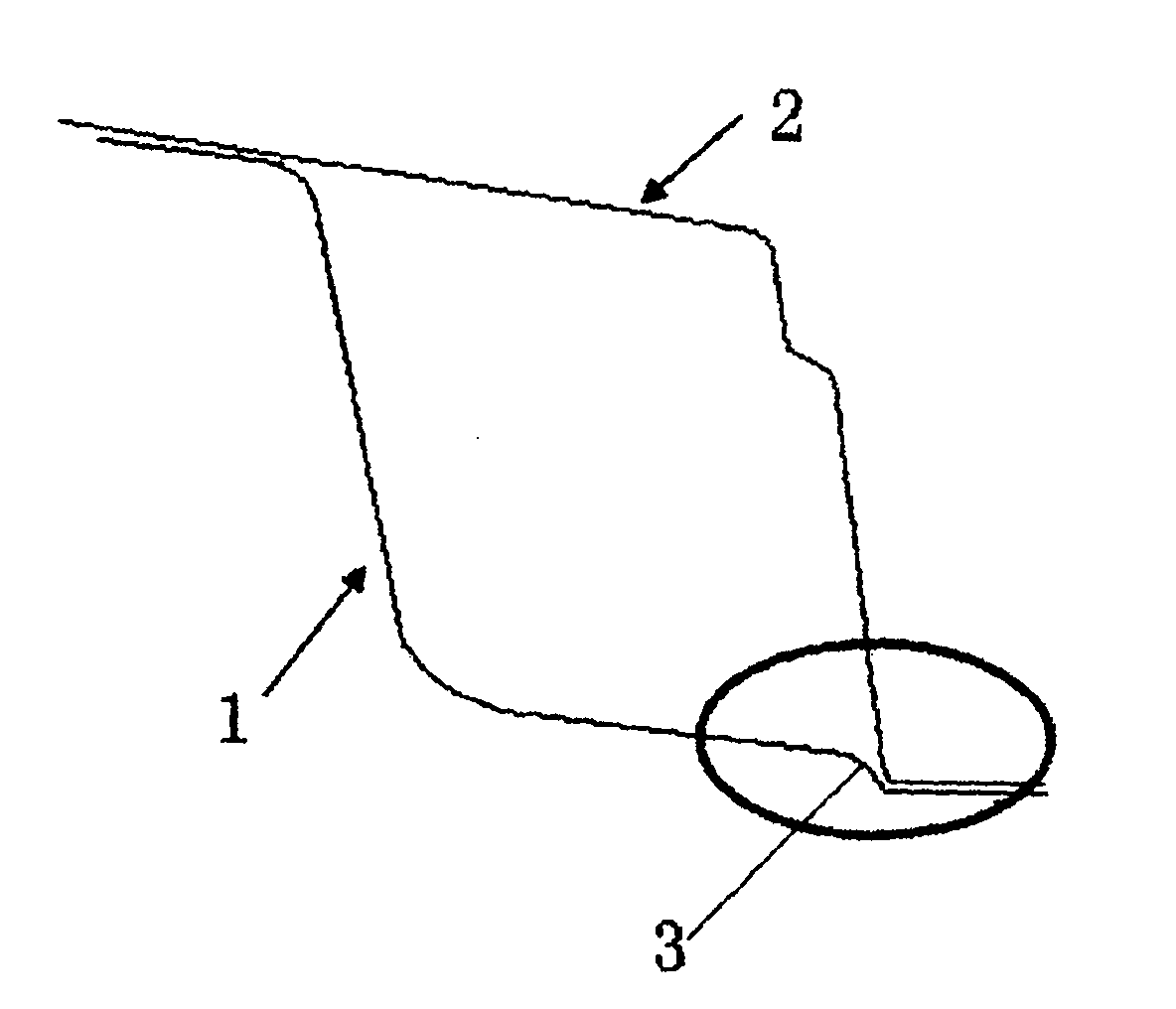

Method for installing and locating bodywork cavity

InactiveCN101837533ASolve the problem that one direction cannot be positionedEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLateral positioning

The invention relates to a method for installing and locating a bodywork cavity, aiming at effectively solving the problem of location when the bodywork cavity is installed. The method has the technical scheme that the tail end of a preposed welding part of the bodywork cavity is provided with a boss, and the boss is used for transverse location when a post-positioned welding part of the bodywork cavity is welded with the preposed welding part.

Owner:CHERY AUTOMOBILE CO LTD

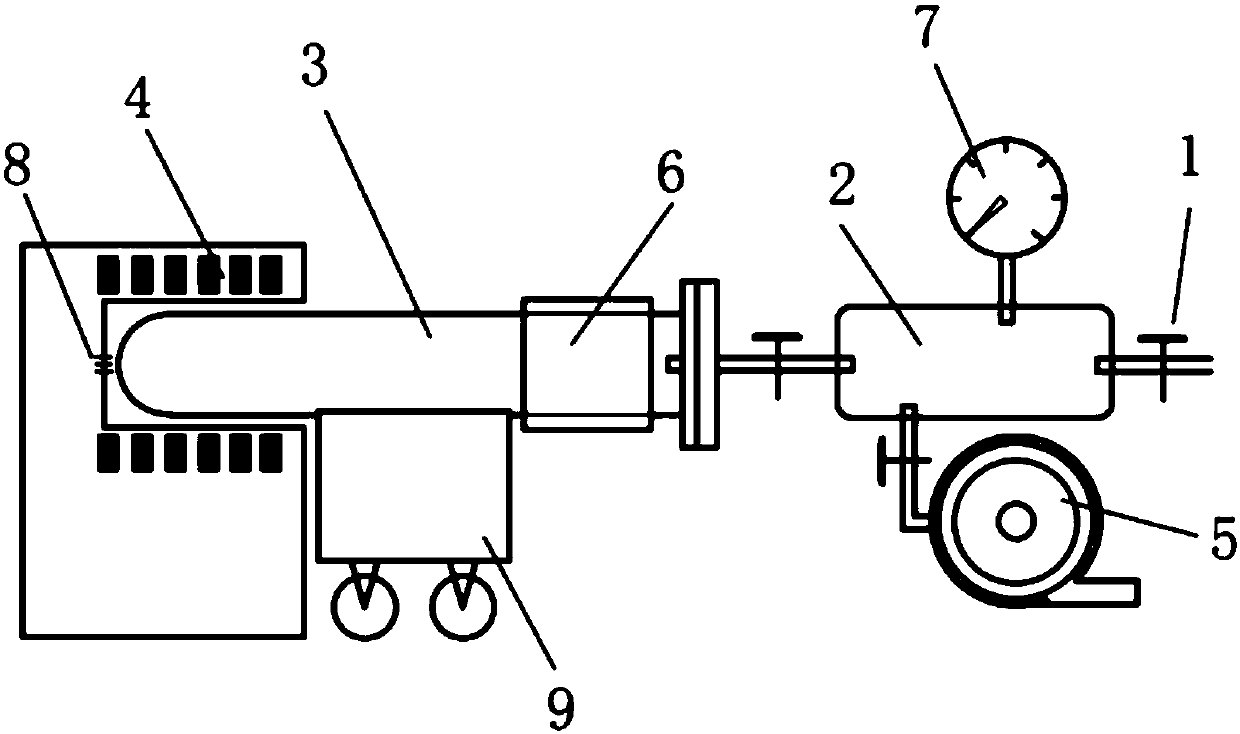

A luminescent method for microwave non-pole ultrasonic light source, device and application

InactiveCN101261925ASignificant progressOvercoming too fast decayElectric lighting sourcesElectric discharge lampsLuminous intensityMicrowave

The invention provides a method for the luminescence of a microwave electrodeless ultraviolet light source, comprising the steps as follows: microwaves from a microwave source are collected and transmitted through wave-collecting materials; the microwaves are gathered around a microwave electrodeless ultraviolet illuminant; the luminescence intensity of the microwave electrodeless ultraviolet illuminant is adjusted through regulating the degrees of the collected microwaves. The invention also provides a device for realizing the method, the structure of which is that the device consists of a microwave generator, a microwave-collecting device and an electrodeless ultraviolet illuminant. The electrodeless ultraviolet illuminant is arranged below the microwave generator; the microwave-collecting device is arranged around the electrodeless ultraviolet illuminant, and leads the microwave to be gathered around the illuminant. The method for the luminescence of the microwave electrodeless ultraviolet light source and the device for realizing the method can be applied for the photo-catalytic synthesis, the sterilization and disinfection and the water treatment, and can lead the electrodeless illuminants with lengths more than 80 cm to glow, control the luminescence intensity, improve the resource utilization, and reduce power consumption with wide application.

Owner:WUHAN TEXTILE UNIV

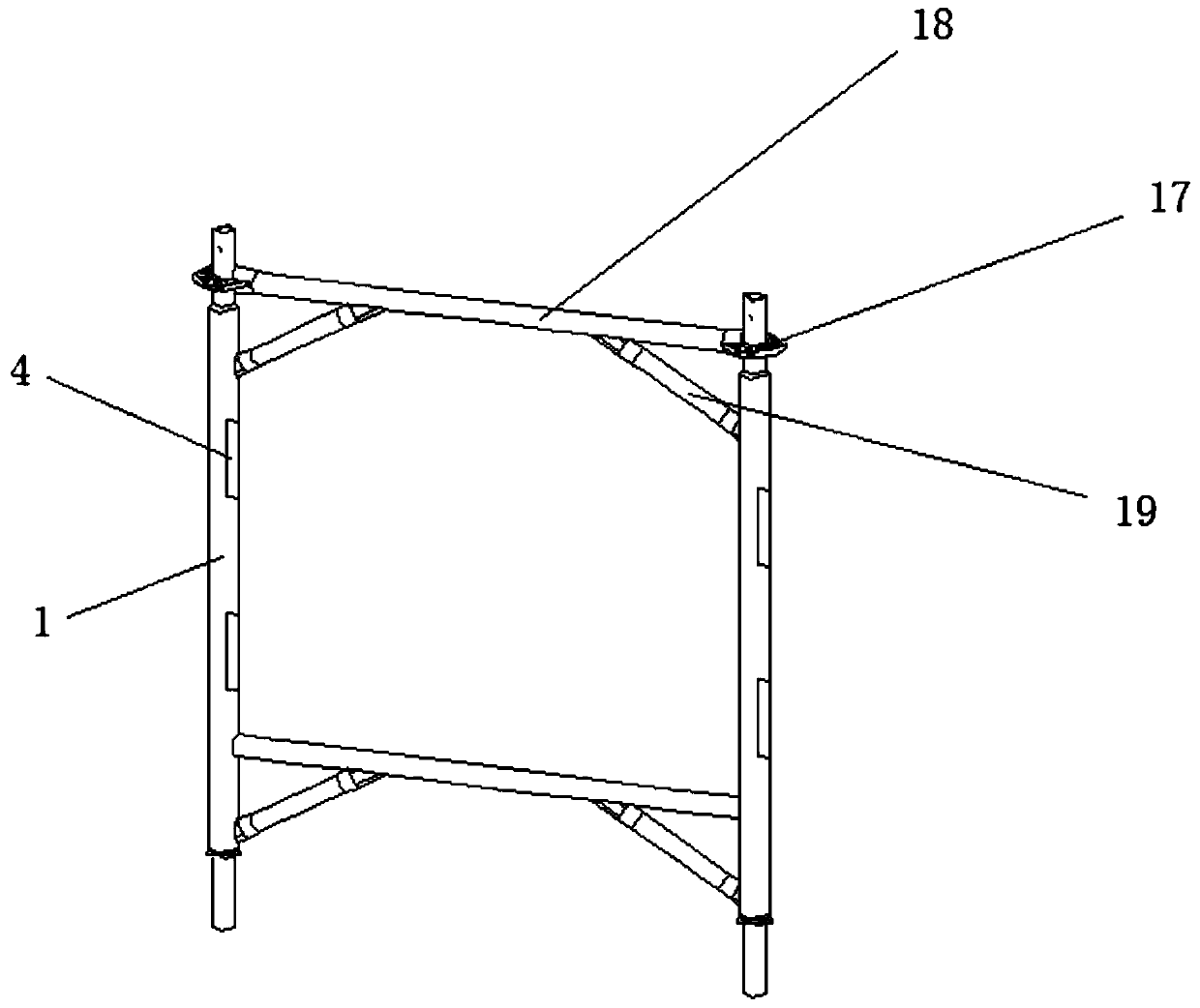

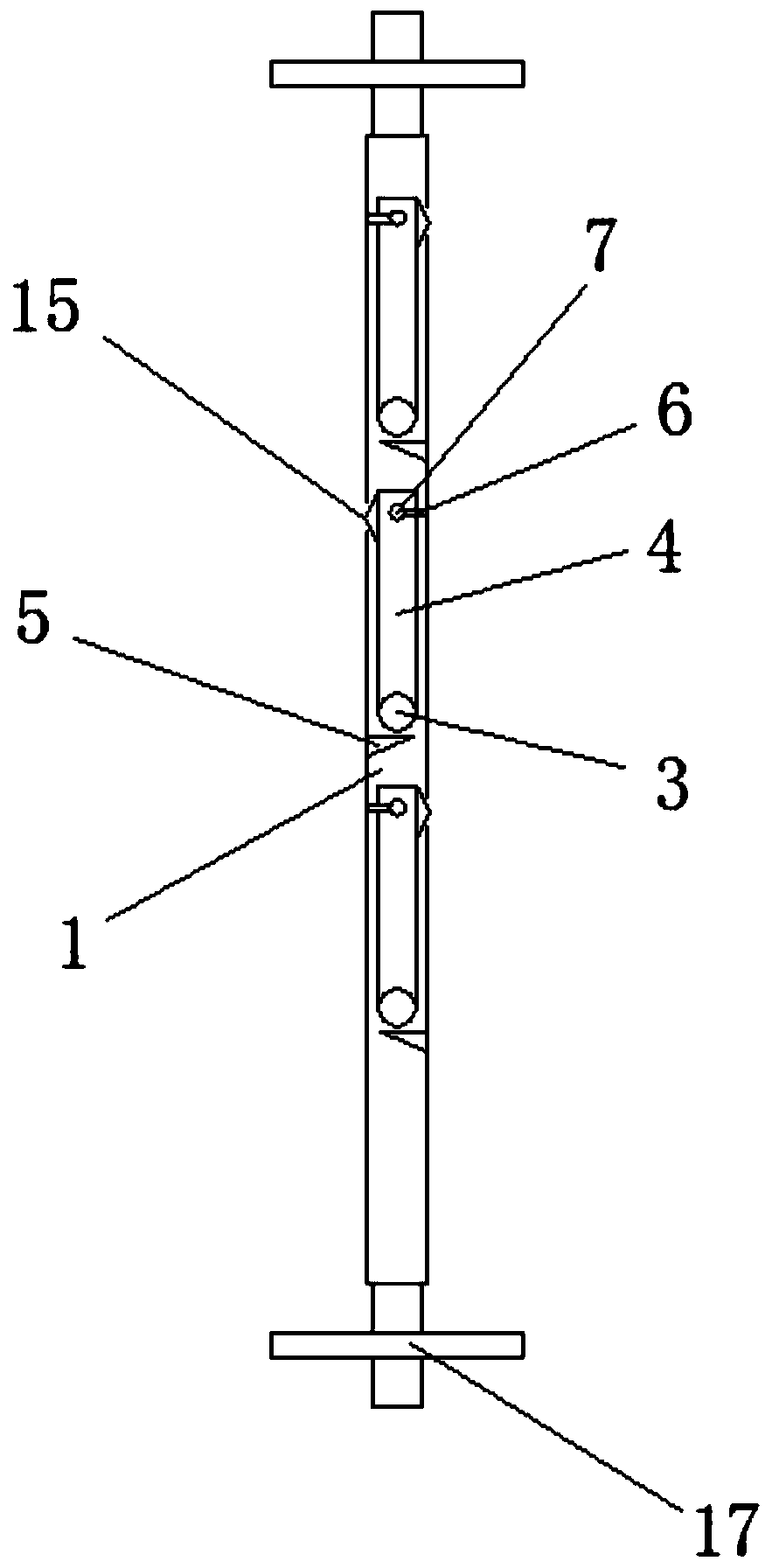

Climbing assisting scaffold

InactiveCN110644770AEasy to promote applicationsPlay a strengthening roleScaffold accessoriesSteel tubeEngineering

The invention discloses a climbing assisting scaffold which comprises two groups of steel pipes, wherein the upper ends and the lower ends of the two groups of steel pipes are fixedly provided with circular discs; transverse supporters are fixedly connected between the circular discs of the two groups of steel pipes; storage grooves are formed in the side walls of two sides of the steel pipes in astaggered way; a position limiting frame is fixedly arranged at the bottom of an inner cavity of each storage groove; a pin shaft is arranged on the top of each position limiting frame; a pedal frameis rotationally connected onto each pin shaft; and the pedal frame can be stored into the storage groove. The climbing assisting scaffold has the advantages that the structure is simple; convenienceand practicability are realized; when a user needs to use a climbing function, the pedal frames are pulled to a horizontal state from the storage grooves through handles, so that the user can upwardsclimb with the help of the pedal frames; and when the climbing function is not used, the pedal frames are collected into the storage grooves to realize the storage.

Owner:滁州金诚金属制品有限公司

A method for manufacturing a large-scale high-strength superhard hollow round ingot

The invention relates to a hollow billet and a manufacturing method thereof, and especially relates to a large-size and high-strength super hard hollow billet and a manufacturing method thereof. The purpose of the invention is to solve the problems of low yield, large production workload and difficult process control of casting of aluminum alloy hollow ingots prepared in the prior art. The large-size and high-strength super hard hollow billet comprises Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, B and Al. The manufacturing method comprises the following steps: 1, weighing; 2, smelting; 3, refining and casting of melt; and 4, molding. The method is mainly used for manufacturing the large-size and high-strength super hard hollow billet.

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

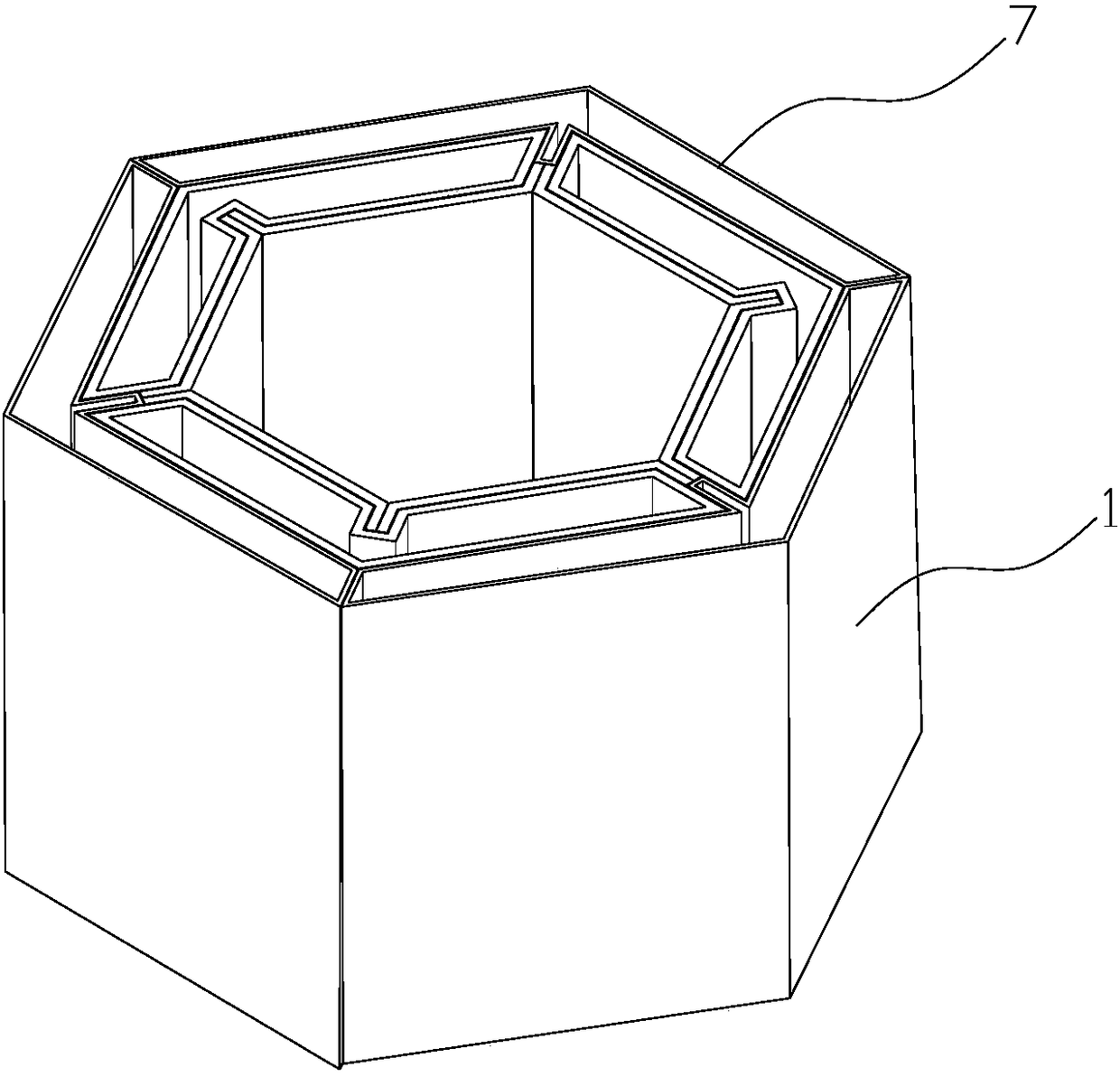

High-intensity and light-weight pole tower

The invention relates to the technical field of a transmission pole tower, in particular to a high-intensity and light-weight pole tower. The high-intensity and light-weight pole tower comprises a center shaft, the center shaft is spliced by several modules from top to bottom, each module comprises three layers of structures, and the structures are all combinations which are combined by several splicing blocks in the circumferential direction. The whole pole tower is modularized so that the pole tower can be transported in a decomposing mode, and the transport difficulty is lowered; meanwhile,through splicing of multiple layers of structures and each layer of structure, the intensity of the pole tower is effectively increased, and the design of different hierarchical structures and splicing seams in all layers of structures both support and reinforce the pole tower.

Owner:江苏佑能实业有限公司

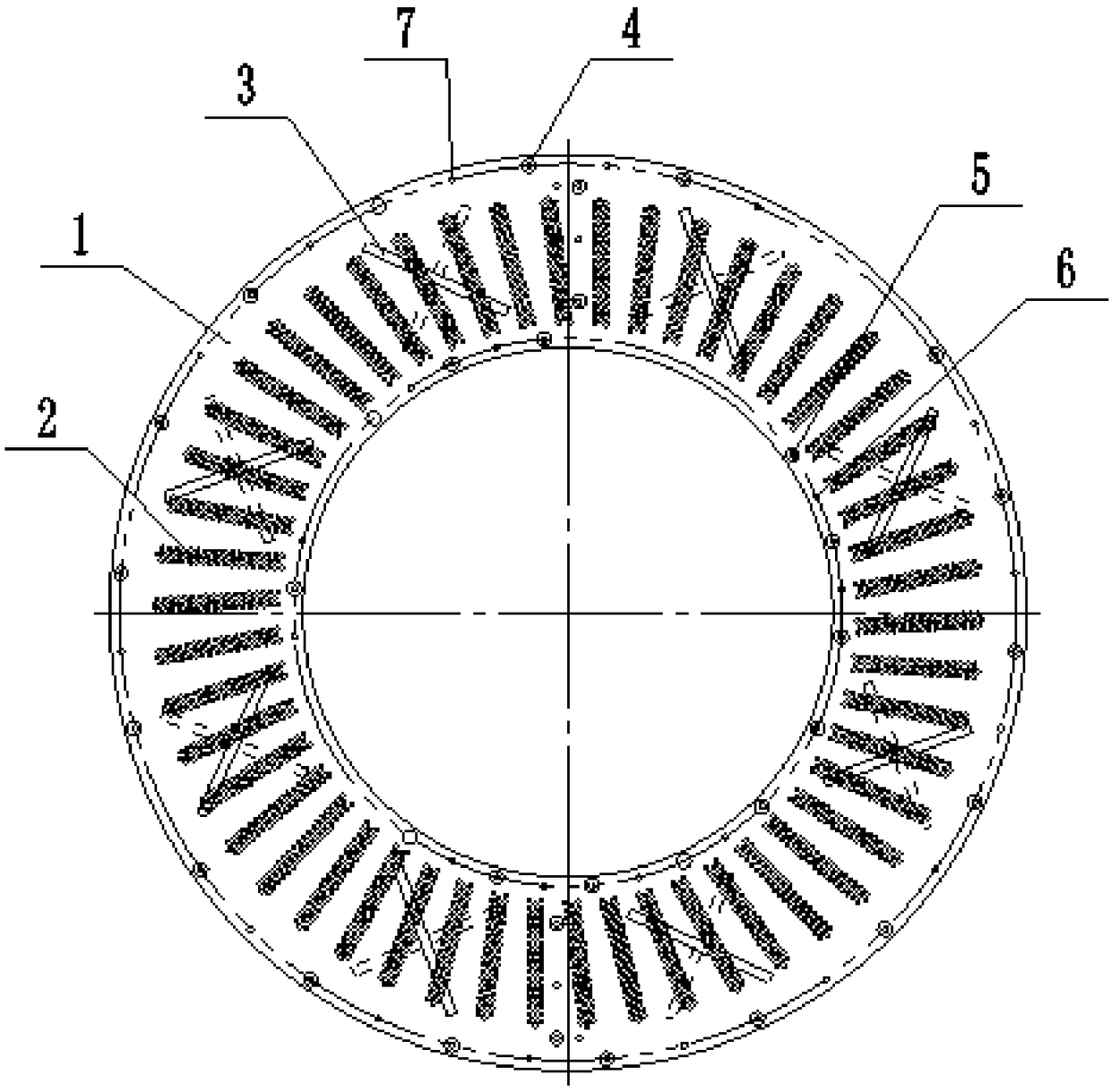

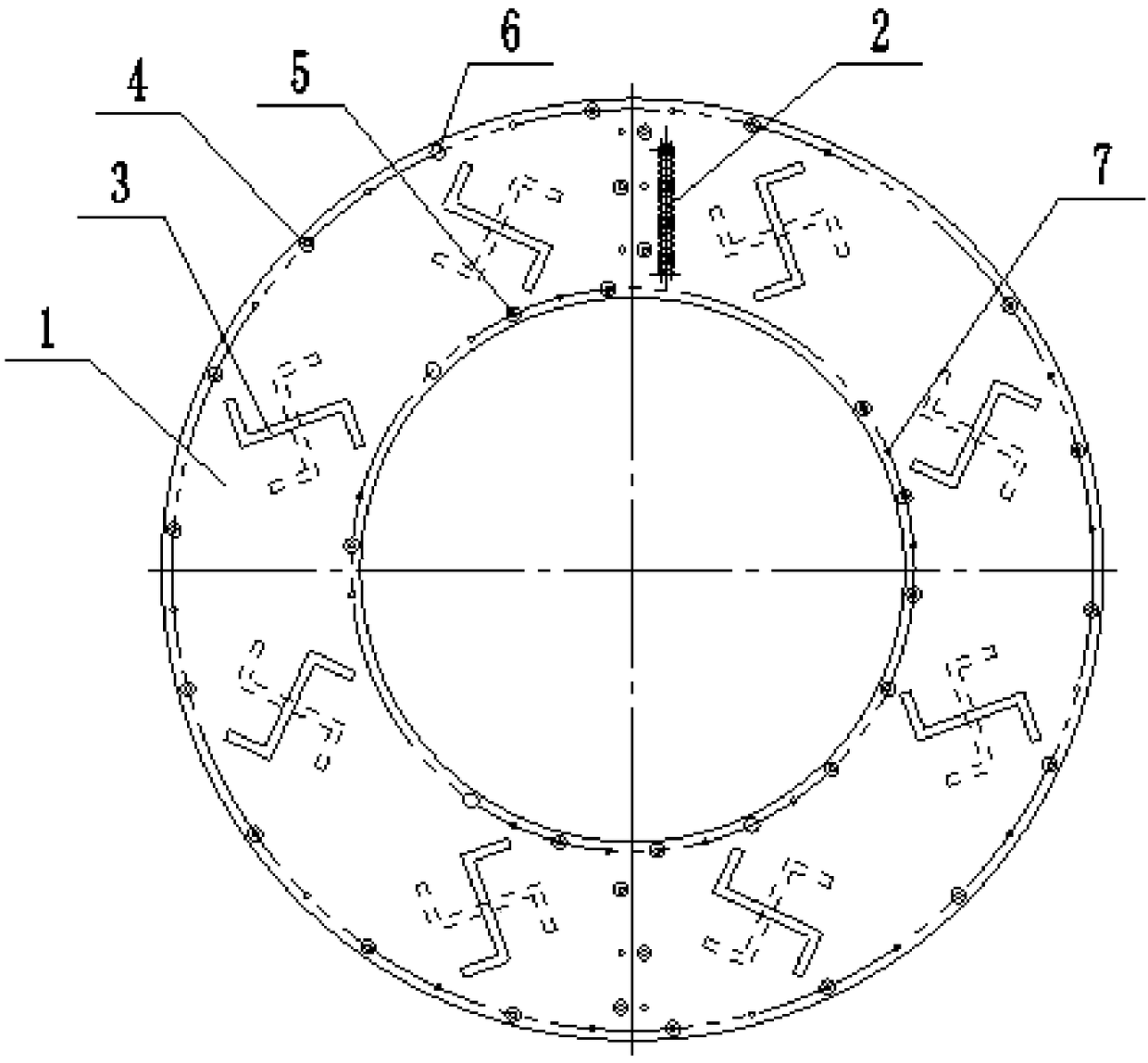

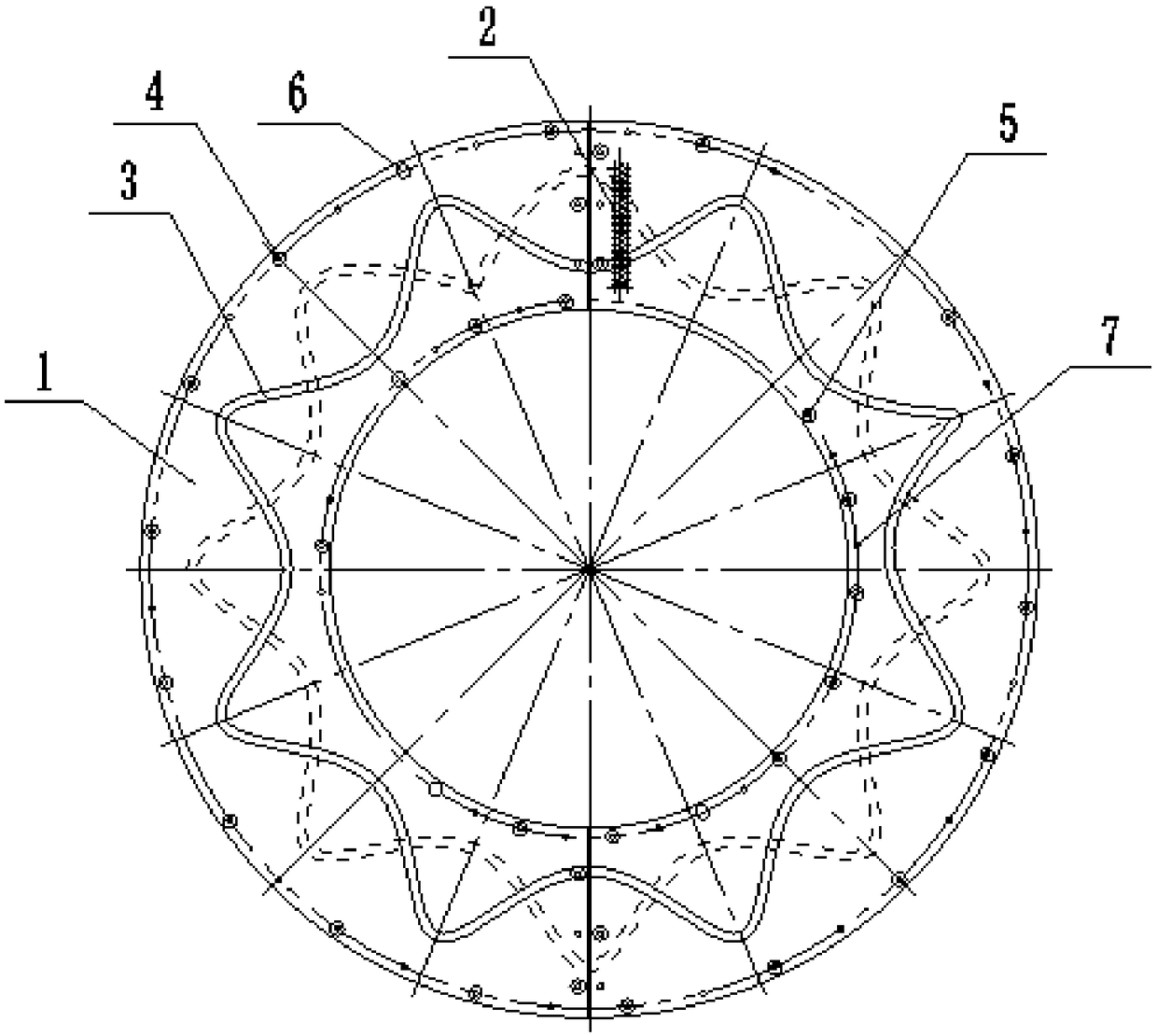

Anti-deformation sieve plate used for pulper

InactiveCN108660833APlay a strengthening roleGuaranteed smoothRaw material divisionWave shapePulp and paper industry

The invention discloses an anti-deformation sieve plate used for a pulper, and belongs to the field of pulper accessories. The sieve plate comprises a circular ring-shaped sieve plate body and supporting bars; the surface of the sieve plate body is provided with sieve holes; the supporting bars are arranged in pairs on the positive and negative side surfaces of the sieve plate body; each supporting bar has a rectangular plate-like structure, a ''Z''-shaped plate-like structure or a wave-shaped annular-plate structure; and the sieve plate body is formed by splicing of two semi-annular plates, and has a material of 0Cr17Ni4Cu4Nb and a thickness of 15.5 to 15.8 mm. According to the sieve plate disclosed by the invention, the supporting bars are arranged on the sieve plate body, so that the strength of the sieve plate is improved, the probability of deformation of the sieve plate caused by extrusion of slurry is effectively reduced, the thickness of the sieve plate is reduced, and the production costs are reduced.

Owner:SHANYING INT HLDG CO LTD

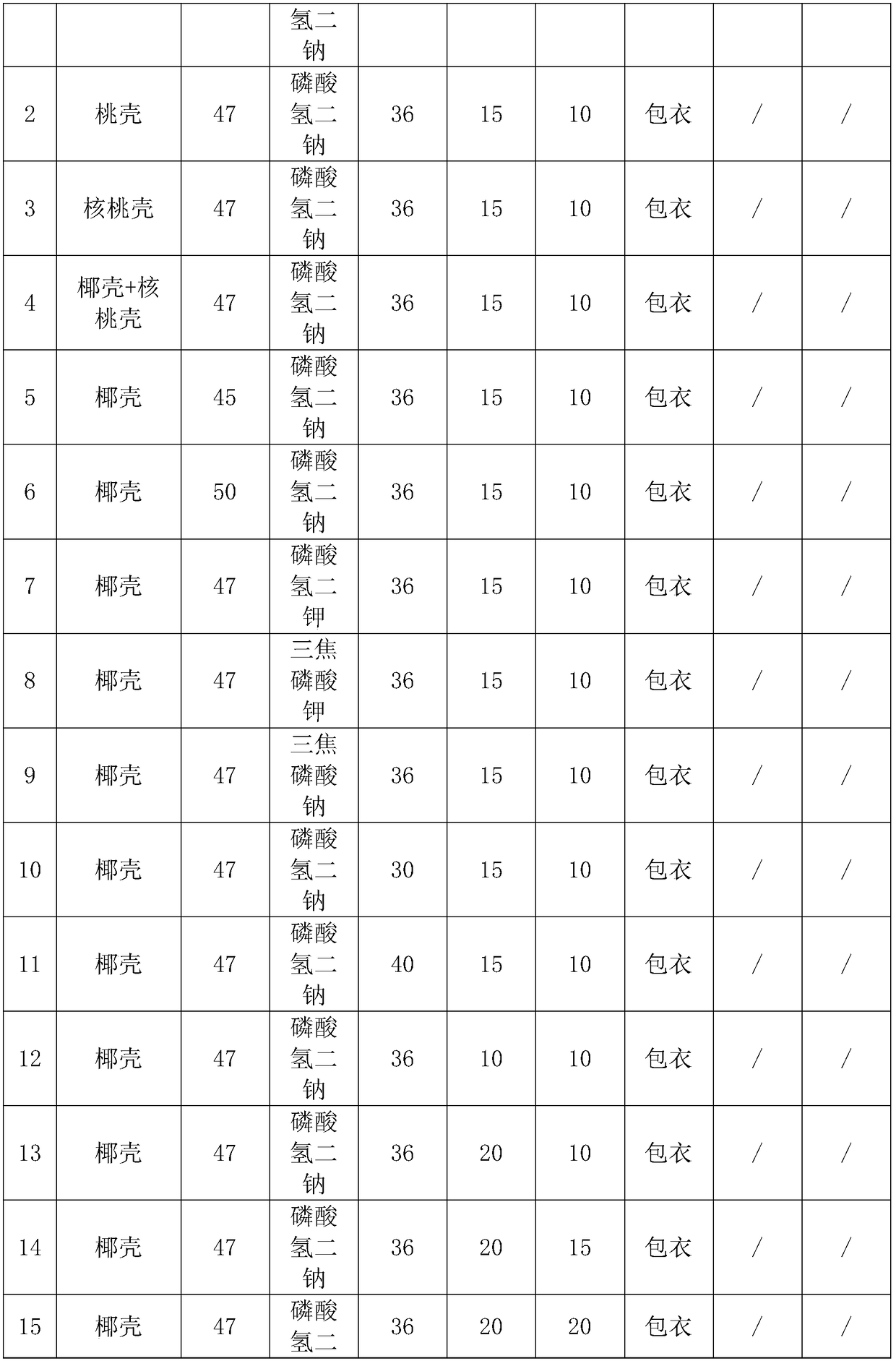

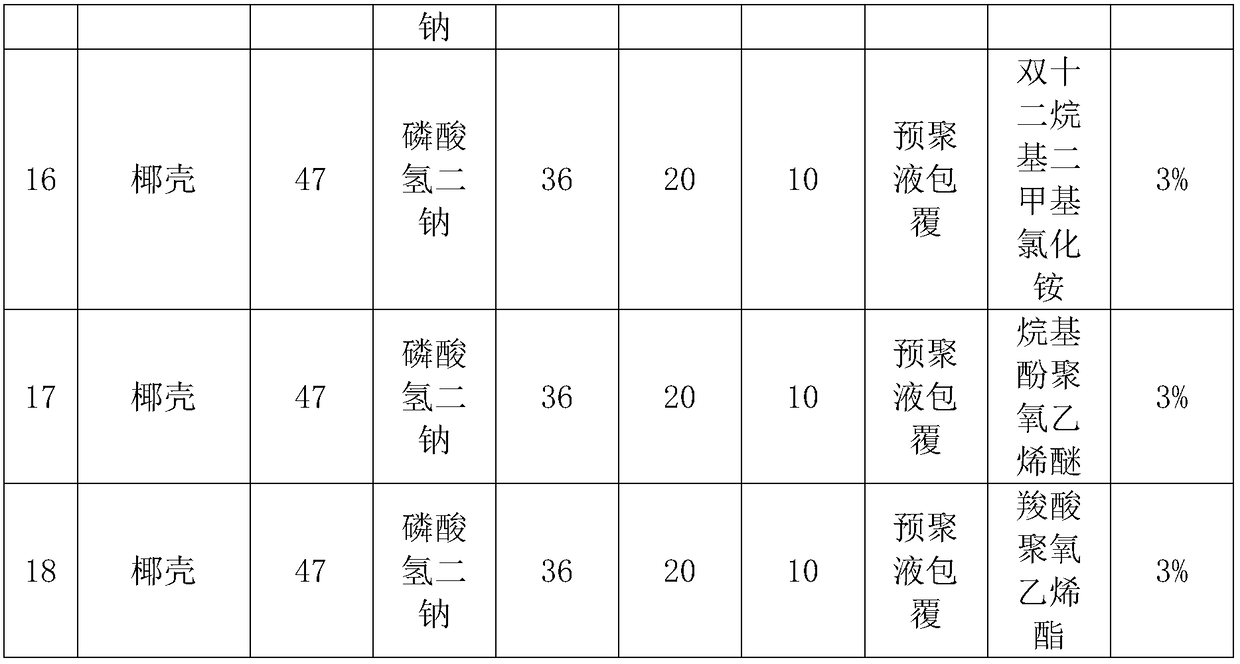

Preparation process of long-lasting composite preparation for treating soil cadmium pollution

InactiveCN109233845ACause secondary pollutionImprove adsorption capacityContaminated soil reclamationOrganic fertilisersPhosphateSoil cadmium

The invention belongs to the field of soil improvers and in particular relates to a preparation process of a long-lasting composite preparation for treating soil cadmium pollution. According to the specific technical scheme, a passivator comprises the following components in parts by weight: 45-50 parts of fruit shell activated carbon, 35-40 parts of an alkali phosphate chelating agent, 10-20 parts of water-soluble resin and 10-20 parts of water-soluble silicate. The passivator is natural in material and free of secondary pollution to soil, has super strong adsorption and precipitation capabilities for heavy metal cation pollutants such as Cd<2+> and the like in soil, is capable of effectively alleviating or relieving 'cadmium poisoning' of plants, is long lasting in effect and does not need to be repeatedly used within a short time.

Owner:四川省冶勘设计集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com