Prefabricated anti-cracking door frame vertical board for ribbon board internal parting wall door opening structure

An internal partition wall and anti-cracking technology, applied in building components, building structures, building materials, etc., can solve problems such as cracking at splices, improve construction efficiency, avoid on-site cutting, and improve connection firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

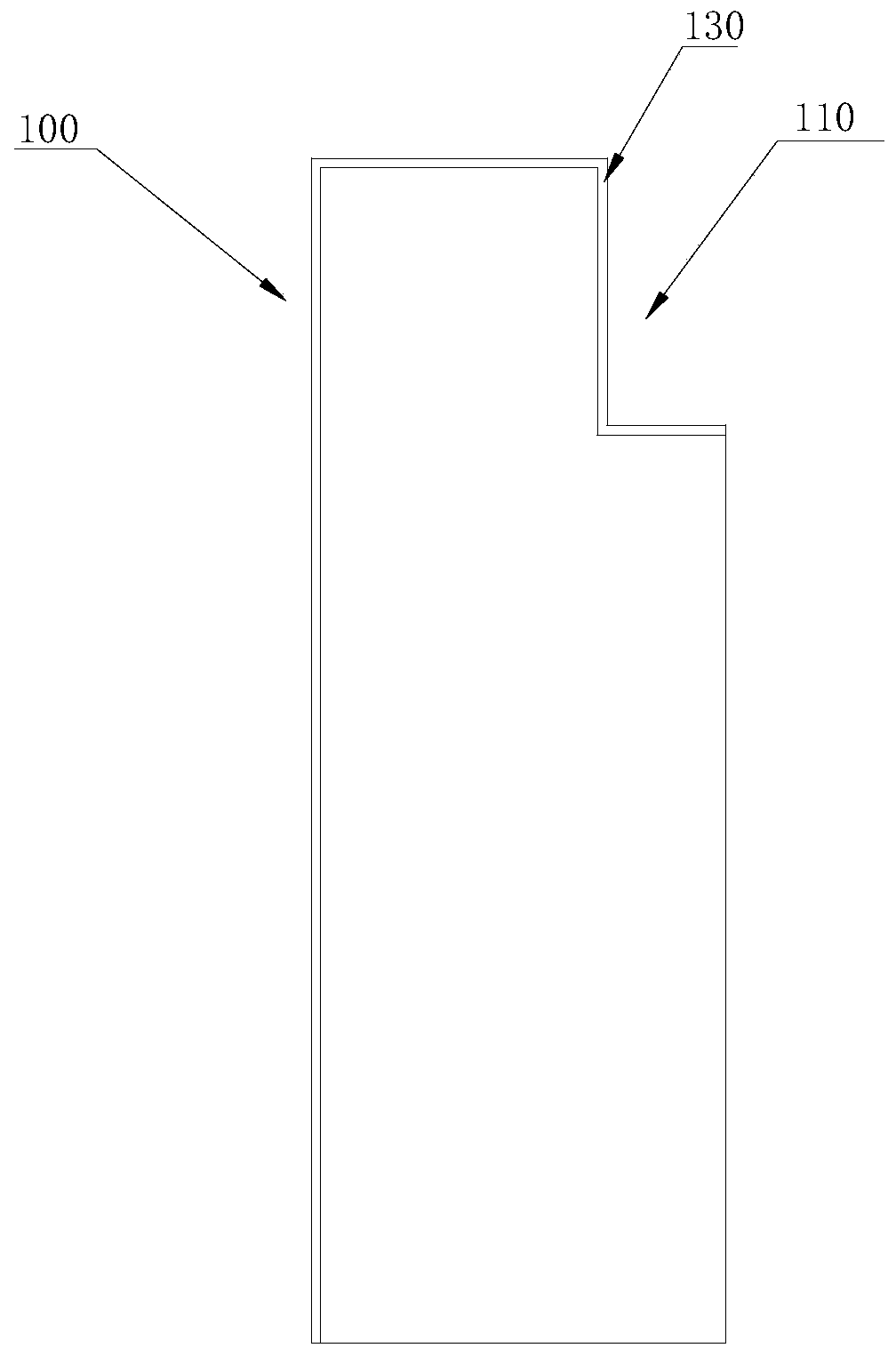

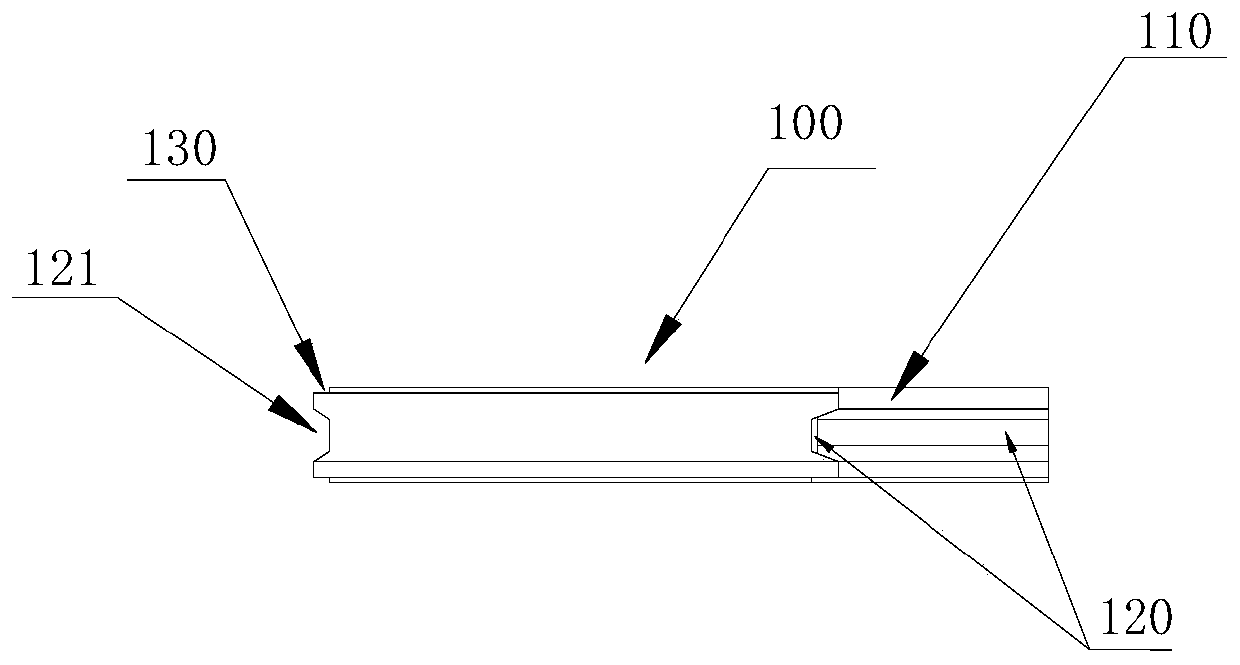

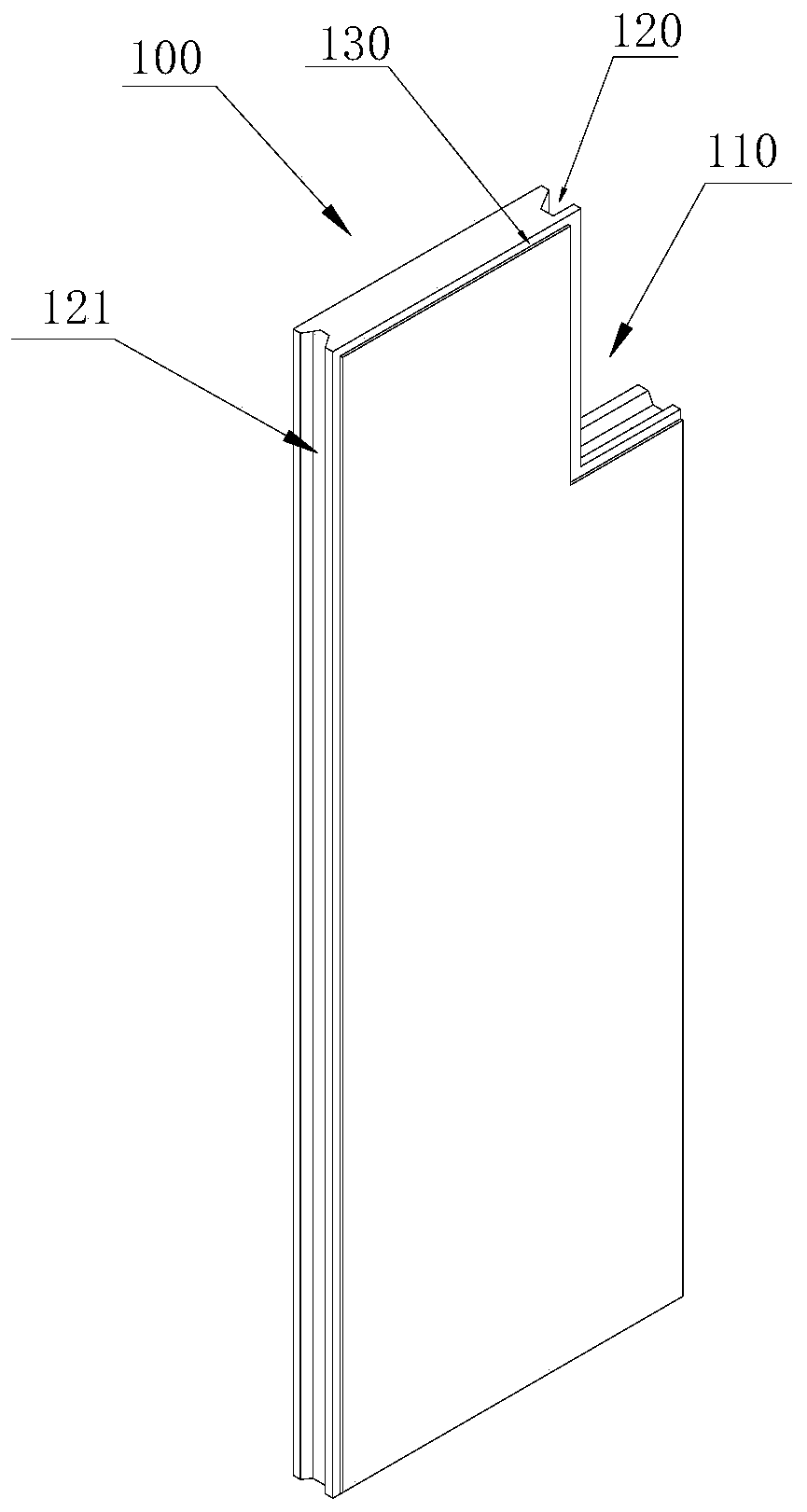

[0050] Example 1, see Figure 1 to Figure 3 , a prefabricated anti-cracking door frame riser for the door opening structure of the inner partition wall of the strip, including a prefabricated door frame riser body 100; the upper part of the prefabricated door frame riser body 100 is provided with an L-shaped gap for placing a prefabricated door head plate 110, a first prefabricated grouting groove 120 is provided on the inner surface of the L-shaped gap along the height direction and the horizontal direction, and the first prefabricated grouting groove 120 is provided on the inner surface of the L-shaped gap along the height direction and the horizontal direction, which may be impermeable The structure can also be a through structure. In this embodiment, the through structure is preferred; when assembling the door opening, the grouting channel is synthesized in the first prefabricated grouting groove and the corresponding spliced prefabricated door head plate prefabricated gr...

Embodiment 2

[0057] Example 2, see Figure 8 to Figure 10 , in the above structure, preferably, the upper end surface of the prefabricated door frame vertical plate body 100 is provided with a third prefabricated grouting groove 122, which is convenient for the prefabricated door frame vertical plate body and the top beam or floor slab or splicing above the prefabricated door frame vertical plate body The installation and connection of the inner partition wall slats is explained in this implementation by taking the inner partition wall slats above the prefabricated door frame vertical plate body as an example; the prefabricated door frame vertical plate body and the inner partition wall spliced above the prefabricated door frame vertical plate body A slurry storage channel is formed between the mating surfaces of the slats, and the mortar storage channel is densely filled with mortar. The secondary connector formed after the mortar solidifies also forms an inner bolt, which has strong coh...

Embodiment 3

[0058] Example 3, see Figure 11 to Figure 14 , in order to meet the requirements of some inner partition wall door openings with higher strength requirements; in the above structure, preferably, the prefabricated door frame vertical plate body is pre-embedded with steel bars 111 .

[0059] In order to further improve the connection strength between the present invention and the prefabricated door head panel, a steel bar insertion sleeve 112 is pre-embedded at the L-shaped notch 110 . When the door opening is actually built, the present invention is assembled together with the matching prefabricated door head plate. The prefabricated door head plate has steel bars protruding from the lower end surface and is inserted into the steel bar insertion sleeve of the L-shaped gap to realize connection, or the prefabricated door head plate is also connected. The pre-embedded steel bar inserting sleeve and the pre-embedded steel bar inserting sleeve at the L-shaped gap are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com