Unsupported deep foundation pit support system

A deep foundation pit support and unsupported technology, which is applied in infrastructure engineering, construction, excavation, etc., can solve the problems of high cost, achieve the effects of shortening the construction period, stabilizing the support, and avoiding on-site cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

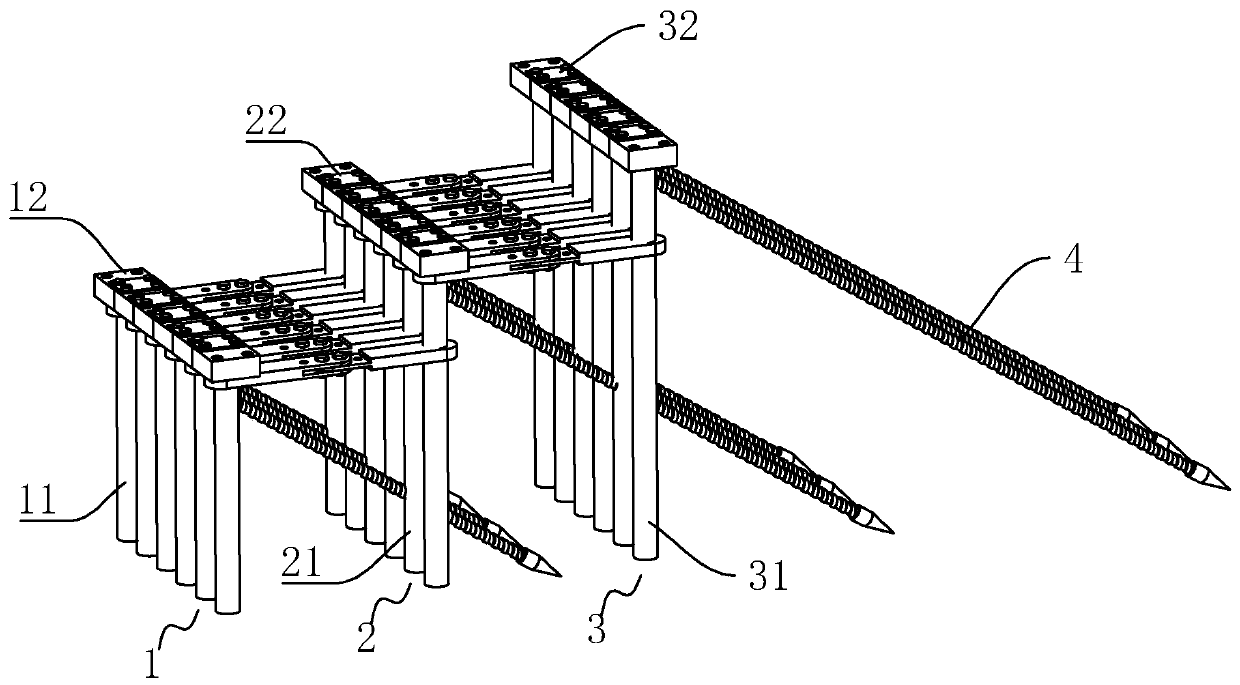

[0043] Embodiment 1: a kind of unsupported deep foundation pit supporting system, such as figure 1 As shown, it includes the inner row of piles 1, the middle row of piles 2 and the outer row of piles 3 arranged in sequence from the inside to the outside around the periphery of the foundation pit, and the top heights of the three are arranged in sequence from low to high. Due to the stepped arrangement of the inner row of piles 1, the middle row of piles 2, and the outer row of piles 3, the stress on the inner row of piles 1 and the middle row of piles 2 is reduced, so that the inner row of piles 1 and the middle row of piles can be reduced. The row of piles 2 is inserted into the depth of the soil, and the use of materials is reduced, which is energy-saving and environment-friendly.

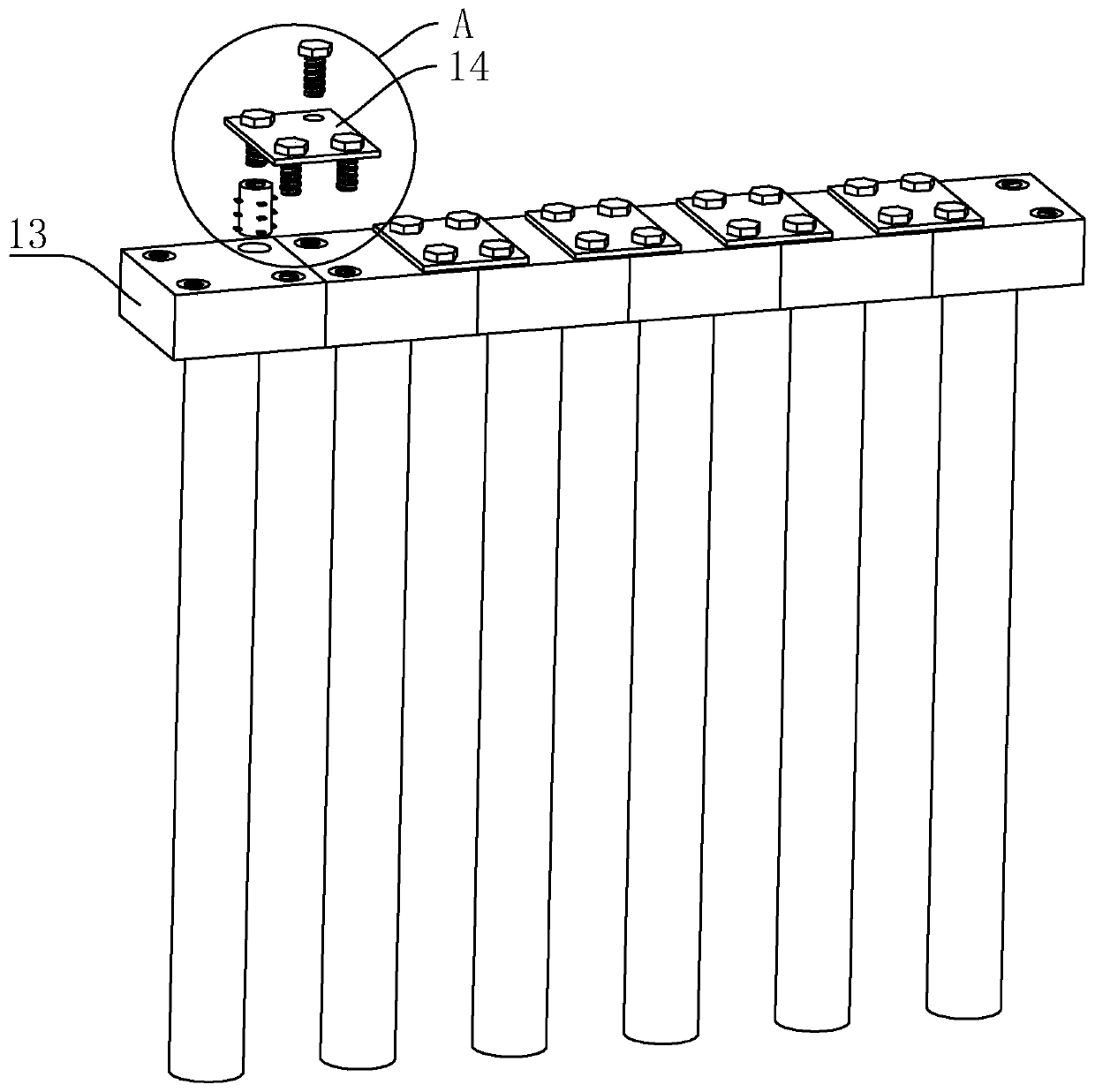

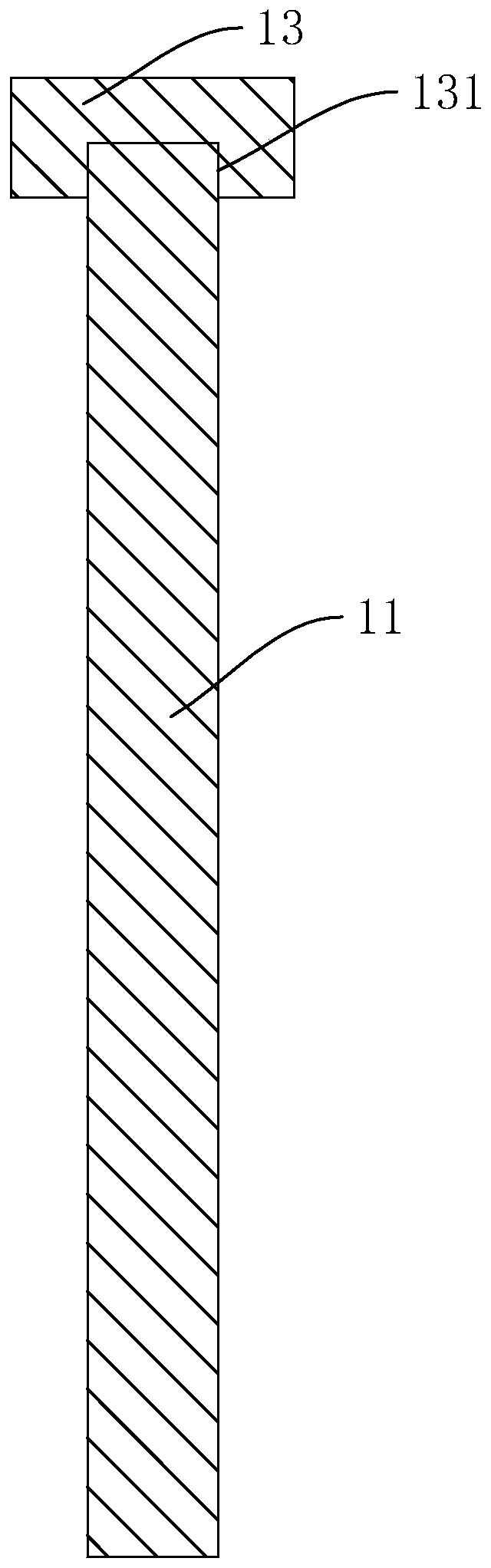

[0044] Such as figure 1 As shown, the inner row of piles 1 is surrounded by the edge of the foundation pit. The inner row of piles 1 includes a number of inner foundation piles 11 arranged side ...

Embodiment 2

[0054] Embodiment 2: a kind of unsupported deep foundation pit supporting system, such as Figure 7 As shown, the difference from Embodiment 1 is that the connection assembly 14 includes a number of nut seats 146 equidistantly arranged on the crown and beam modules 13 , and fixed holes are inserted between the nut seats 146 on two adjacent crown and beam modules 13 . The bolt 148 is covered with a fixing nut 147 , and the part of the fixing bolt 148 located between the two nut seats 146 is also covered with a limit nut 149 . The two crown beam modules 13 are installed together by screwing the fixing bolts 148 , and the connection of two adjacent crown beam modules 13 is made more compact according to the screwing depth of the fixing bolts 148 . In addition, since the two nut seats 146 are installed and screwed together by the fixing bolts 148 for a long time, the two nut seats 146 are deformed or even broken, and the limit nut 149 is located between the two nut seats 146, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com