Floor structure and its construction method between building pipes

A construction method and a technology between pipelines, which are applied in the direction of building structure, building components, and building materials, can solve the problems of complex floor structure, complicated construction procedures, and inconvenient construction, so as to facilitate construction, shorten construction period, and connect convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

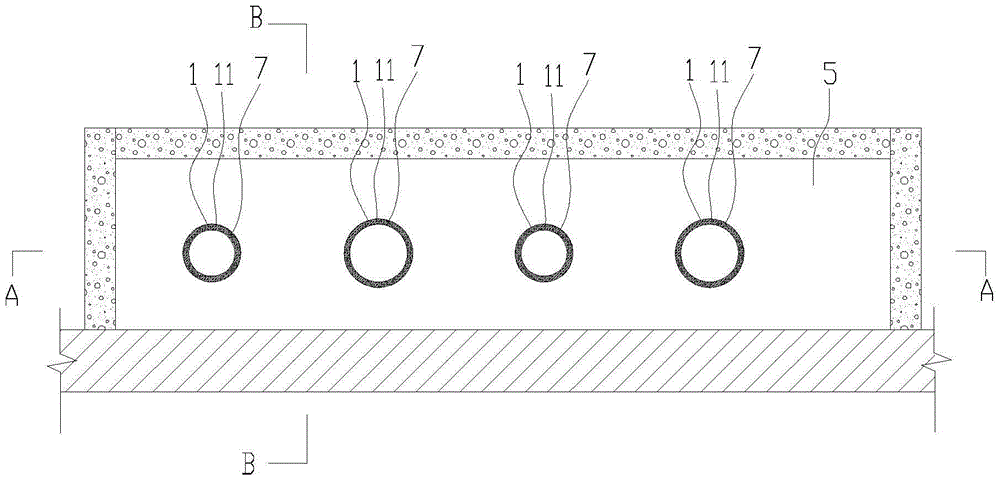

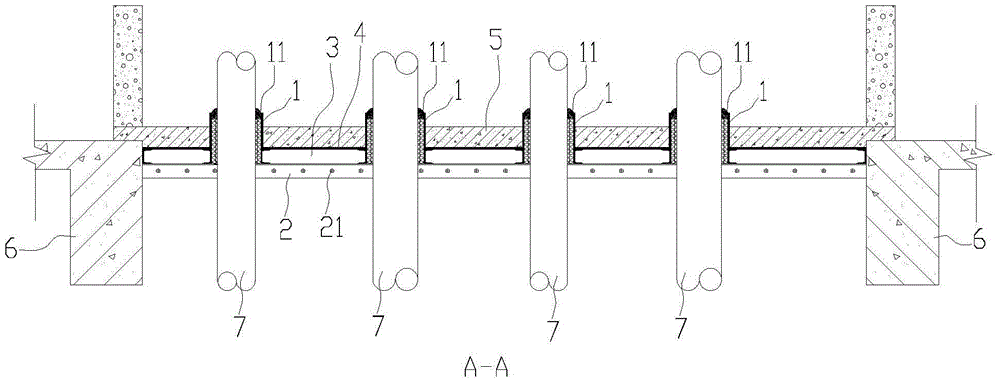

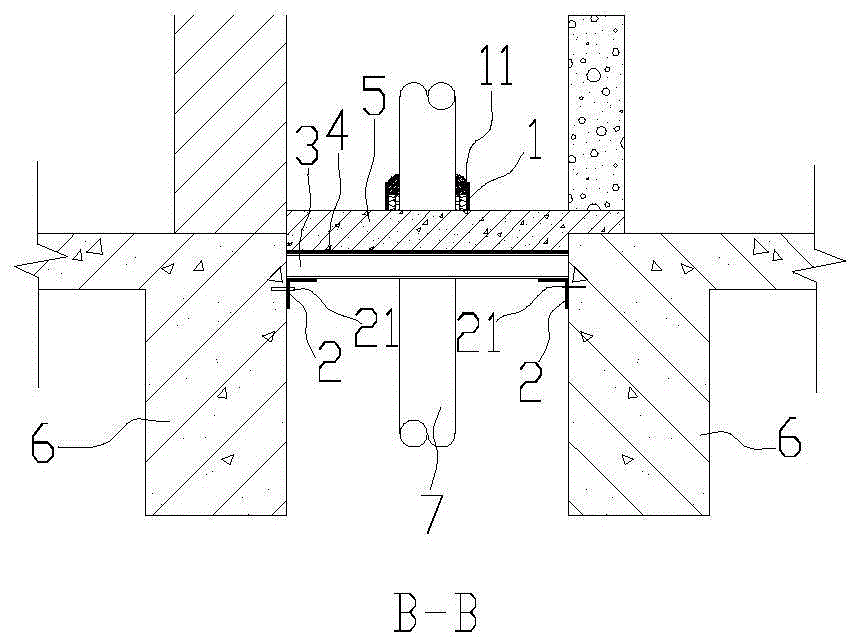

[0023] Such as figure 1 , figure 2 , image 3 The floor structure between the pipelines of the building shown includes two angle steels 2 horizontally installed on the pipeline shaft structural beam 6, and a channel steel load-bearing frame 3 welded by a plurality of channel steels, which can be penetrated by pipelines, welded on the angle steel 2, a steel plate 4 is laid on the upper surface of the channel steel bearing frame 3. The steel plate 4 is provided with a hole for the pipeline 7 to pass through. The steel plate 4 is welded with a plurality of sleeves 1 that are placed outside the pipeline 7, and the sleeve 1 is provided with a buffer layer 11 for wrapping outside the pipeline 7. The buffer layer 11 can be cement oil hemp silk or waterproof Putty, the sleeve 1 corresponds to the hole. A concrete decorative layer 5 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com