Telescopic suspension type fixed cylinder barrel

A fixed cylinder and suspension technology, applied in mining equipment, earth square drilling, mine roof support, etc., can solve the problems of smashing the bottom lifting jack and the wear-resistant sleeve of the bottom lifting jack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

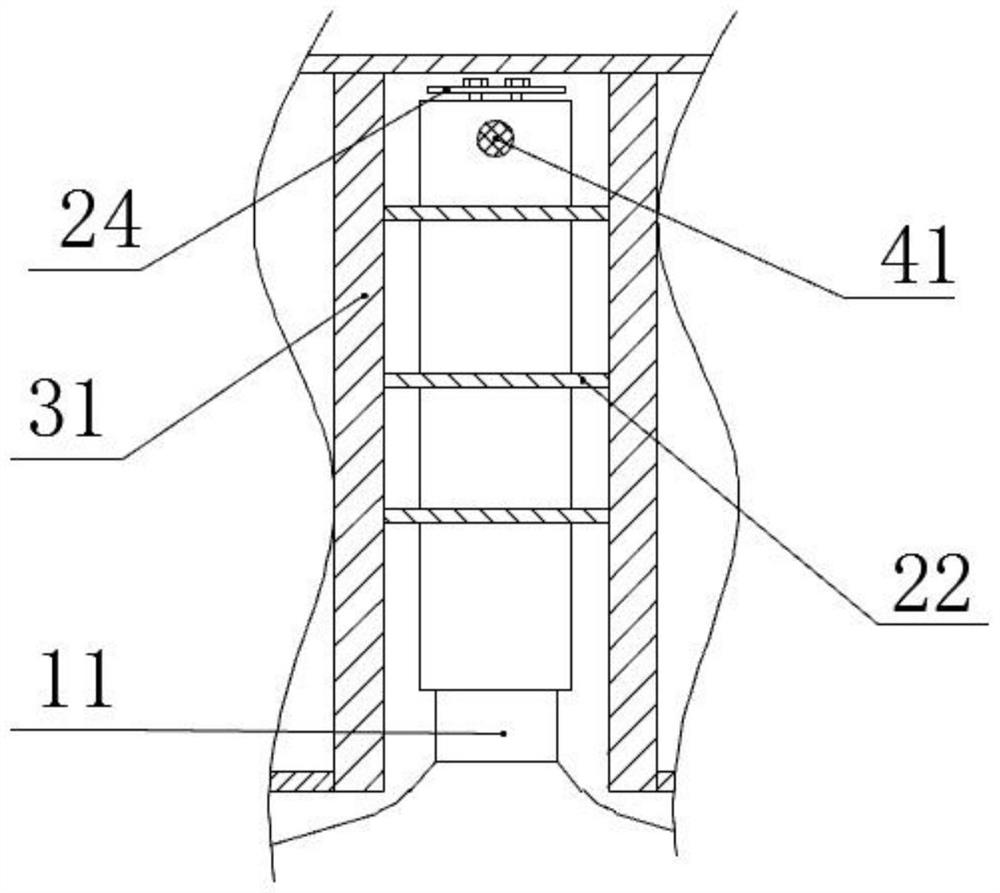

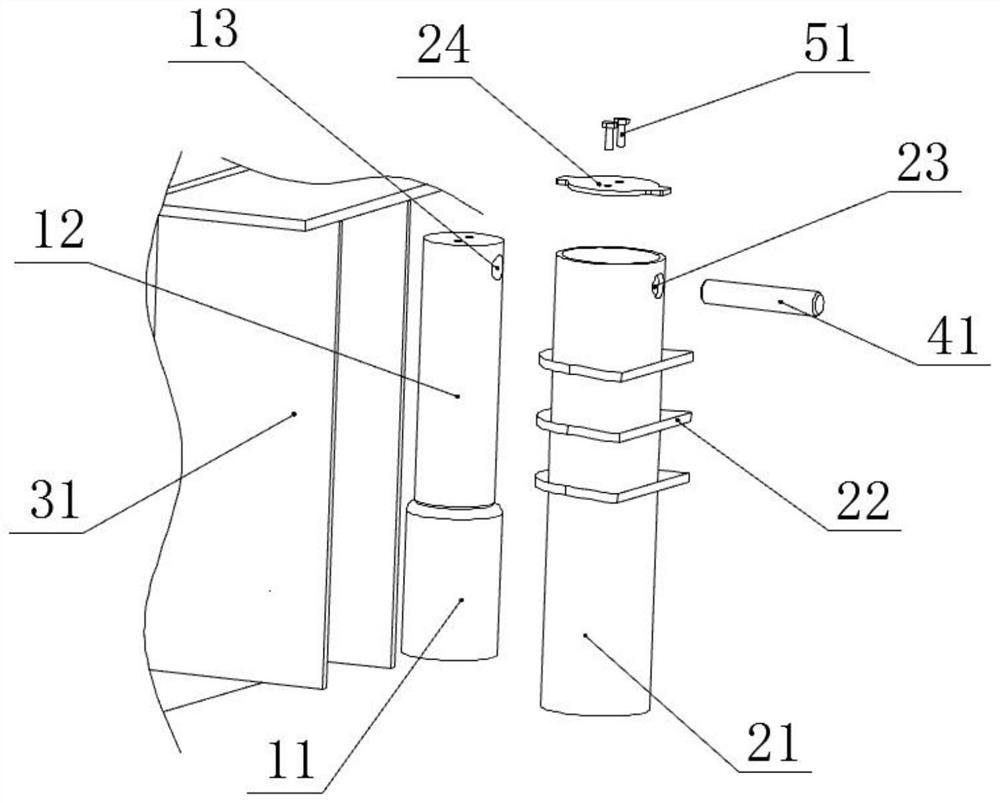

[0020] Such as Figure 1 to Figure 3 As shown, a retractable suspension fixed cylinder includes a bottom lifting jack 11, a fixed cylinder 21 and a hydraulic support 31, the bottom lifting jack 11 includes a piston rod 12, and the piston rod 12 is formed along the axial direction of the bottom lifting jack 11. Linear movement, the piston rod 12 is provided with a first pin hole 13, the fixed cylinder 21 is sleeved on the outside of the bottom lifting jack 11, the fixed cylinder 21 is provided with a second pin hole 23, and the second pin hole 23 is connected with the first pin hole 13 are concentric, the second pin hole 23 and the first pin hole 13 are simultaneously provided with a pin shaft 41, and the top of the piston rod 12 is also connected with a protective upper cover 24 through a connecting piece 51, and the connecting piece 51 is a screw to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com