Hinge type dumper hydraulic oil tank

A hydraulic oil tank and hydraulic oil technology, which is applied in the field of mining machinery, can solve the problems of increased oil suction pressure, labor-intensive and time-consuming operation, and easy clogging of oil suction filters, and achieve cleanliness, simple replacement and maintenance of cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

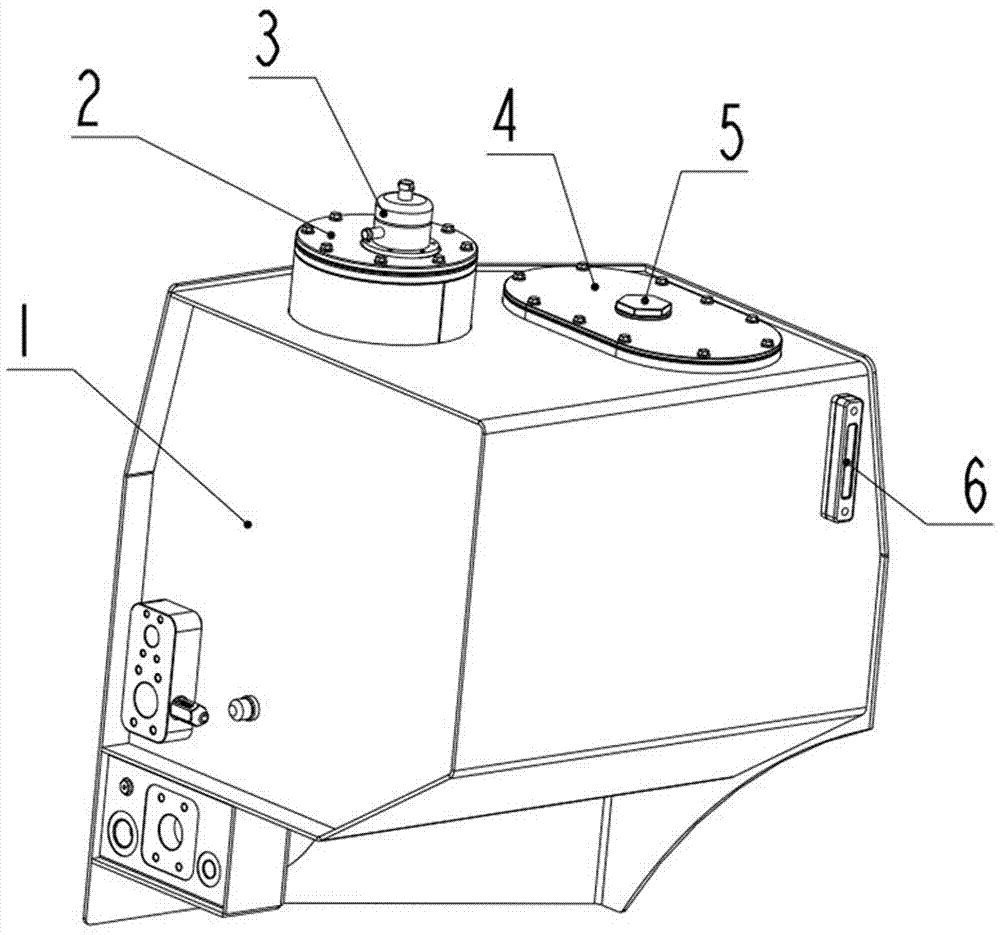

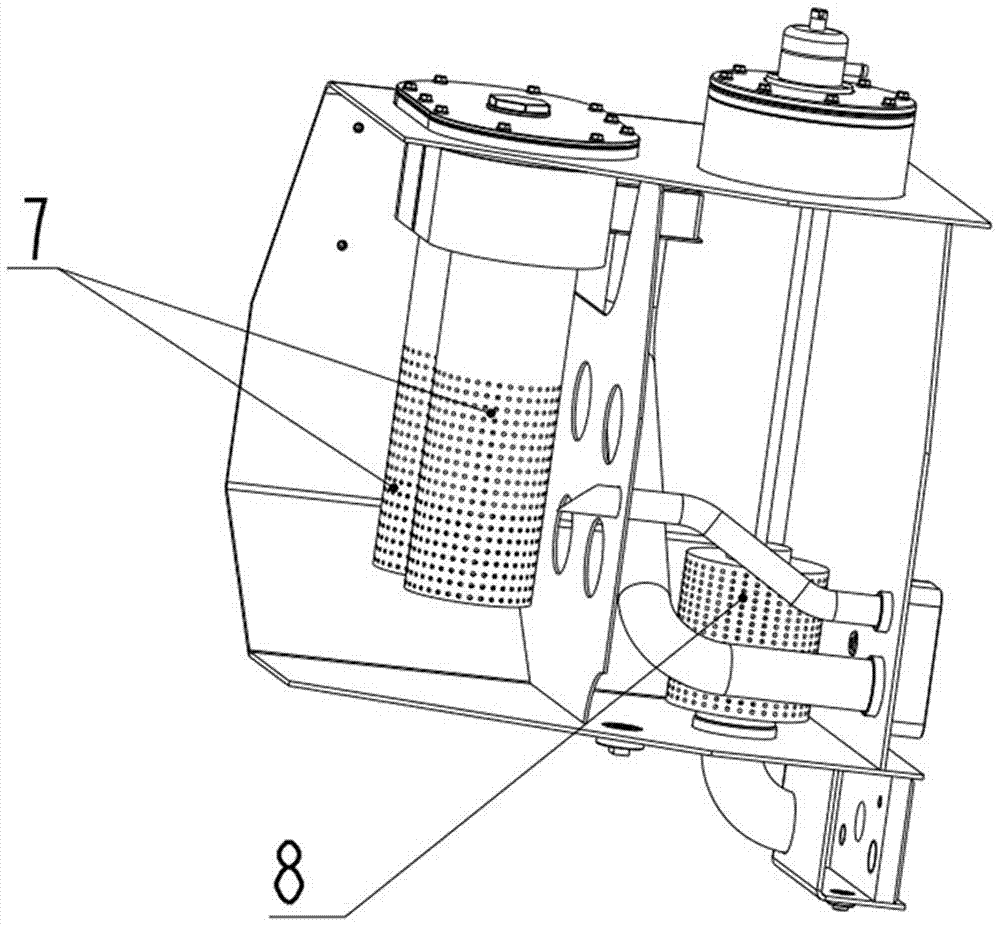

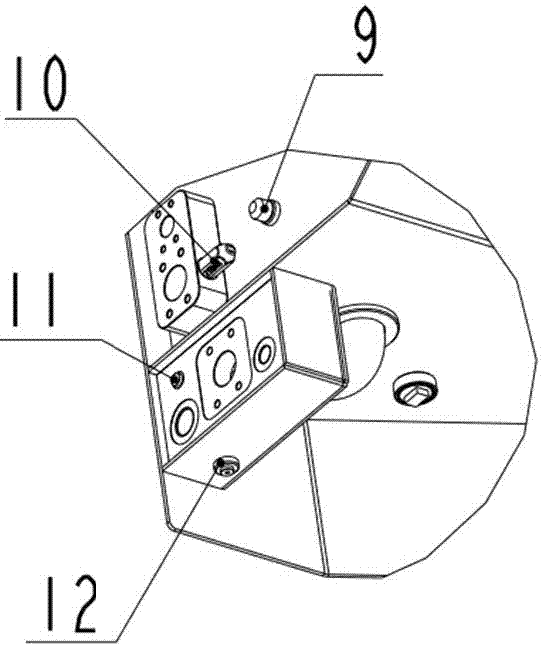

[0031] Such as Figure 1 to Figure 3 As shown, a hydraulic oil tank of an articulated dump truck includes a hydraulic oil tank body 1, an oil return chamber 1-1 is provided on the top surface of the cavity of the hydraulic oil tank body 1, and a side of the oil return chamber 1-1 is connected to it. The oil return pipe 1-4 is connected, and the other end of the oil return pipe 1-4 is connected with the oil return port fixed on the side of the hydraulic oil tank 1 and close to the bottom surface, and the oil return port is connected with the external hydraulic system; it also includes several return ports. Oil filter 7, the oil inlet of the oil return filter 7 is arranged in the cavity of the oil return chamber 1-1, and the oil outlet of the oil return filter 7 passes through the bottom surface of the oil return chamber 1-1 to the hydraulic oil tank The cavity of the body 1 extends, and the radial outer peripheral surface of the oil return filter 7 is sealed with the oil return...

Embodiment 2

[0039] Such as Figure 1 to Figure 4 As shown, a hydraulic oil tank of an articulated dump truck includes a hydraulic oil tank body 1, an oil return chamber 1-1 is provided on the top surface of the cavity of the hydraulic oil tank body 1, and a side of the oil return chamber 1-1 is connected to it. The oil return pipe 1-4 is connected, and the other end of the oil return pipe 1-4 is connected with the oil return port fixed on the side of the hydraulic oil tank 1 and close to the bottom surface, and the oil return port is connected with the external hydraulic system; it also includes several return ports. Oil filter 7, the oil inlet of the oil return filter 7 is arranged in the cavity of the oil return chamber 1-1, and the oil outlet of the oil return filter 7 passes through the bottom surface of the oil return chamber 1-1 to the hydraulic oil tank The cavity of the body 1 extends, and the radial outer peripheral surface of the oil return filter 7 is sealed with the oil return...

Embodiment 3

[0049] Such as Figure 1 to Figure 5 As shown, a hydraulic oil tank of an articulated dump truck includes a hydraulic oil tank body 1, the top surface of the hydraulic oil tank body 1 is provided with an oil filling port, and the gland I4 is fastened to the oil filling port by a plurality of bolts. Cover 5, an oil return chamber 1-1 is provided on the top surface of the cavity of the hydraulic oil tank body 1, and the top opening periphery of the oil return chamber 1-1 is sealed and connected with the periphery of the oil filler port, and a side of the oil return chamber 1-1 is installed The oil return pipe 1-4 communicated with it, the other end of the oil return pipe 1-4 communicates with the oil return port fixed on the side of the hydraulic oil tank 1 and near the bottom surface, and the oil return port communicates with the external hydraulic system; it also includes Several oil return filters 7, the oil inlet of the oil return filter 7 is set in the cavity of the oil ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com