Light composite wall panel

A lightweight, wall panel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of high strength of organic composite sandwich panels, inconvenient construction, damage to decorative surfaces, etc. The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

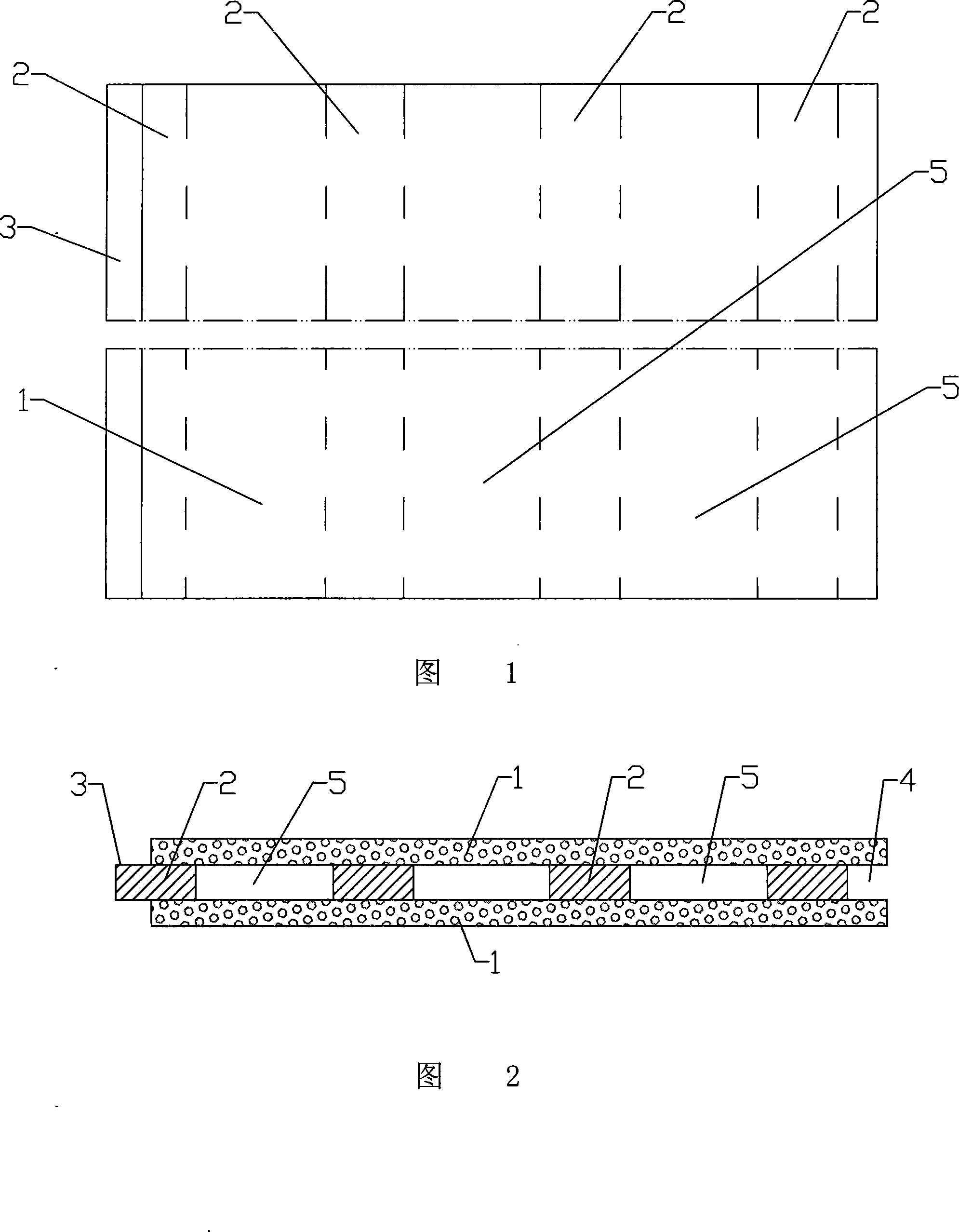

[0024] Embodiment 1, as shown in Figures 1 and 2, the lightweight composite wallboard includes two relatively arranged boards 1, the boards 1 are commercially available cement foam decorative boards, and longitudinally between the two oppositely arranged boards 1 There are 4 strip-shaped reinforcing plates, and the strip-shaped reinforcing plates 2 are equidistantly arranged in the plate 1, and form an equidistantly arranged cavity 5 with two oppositely arranged plates 1, and the reinforcing plates 2 are commercially available cement Foamed decorative slats, part of the reinforcing plate 2 located on the left side of the plate 1 is located in the plate 1, and the other part protrudes from the side of the plate to form a protrusion 3, and the reinforcing plate 2 located on the right side of the plate 1 is located in the plate 1 and between the two oppositely arranged plates 1 forms a groove 4 that can accommodate the protrusion 3, and the four strip-shaped reinforcing plates 2 f...

Embodiment 2

[0025] Embodiment 2, as shown in Figures 1 and 2, the lightweight composite wallboard includes two oppositely arranged boards 1, between which two oppositely arranged boards 1 are longitudinally provided with four strip-shaped reinforcement boards, the strips Shaped reinforcing plates 2 are equidistantly arranged in the plate 1, and form an equidistant arrangement of cavities 5 with two opposite plates 1, a part of the reinforcing plate 2 at the left side of the plate 1 is located in the plate 1, and the other part Protrusions 3 protrude from the side of the plate, and the reinforcing plate 2 located on the right side of the plate 1 is located in the plate 1 and forms a groove 4 that can accommodate the protrusion 3 between the two opposite plates 1. The strip-shaped reinforcing plate 2 forms three cavities 5 with two opposing plates 1, the thickness of the plate 1 is 30mm, the thickness of the strip-shaped reinforcing plate 2 is 30mm, and the total thickness of the wallboard i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com