Anti-deformation sieve plate used for pulper

An anti-deformation and pulper technology, applied in textile and papermaking, raw material separation, fiber raw material processing, etc., can solve problems such as screen plate deformation, and achieve the effect of preventing plate surface deformation, prolonging service life, and increasing connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

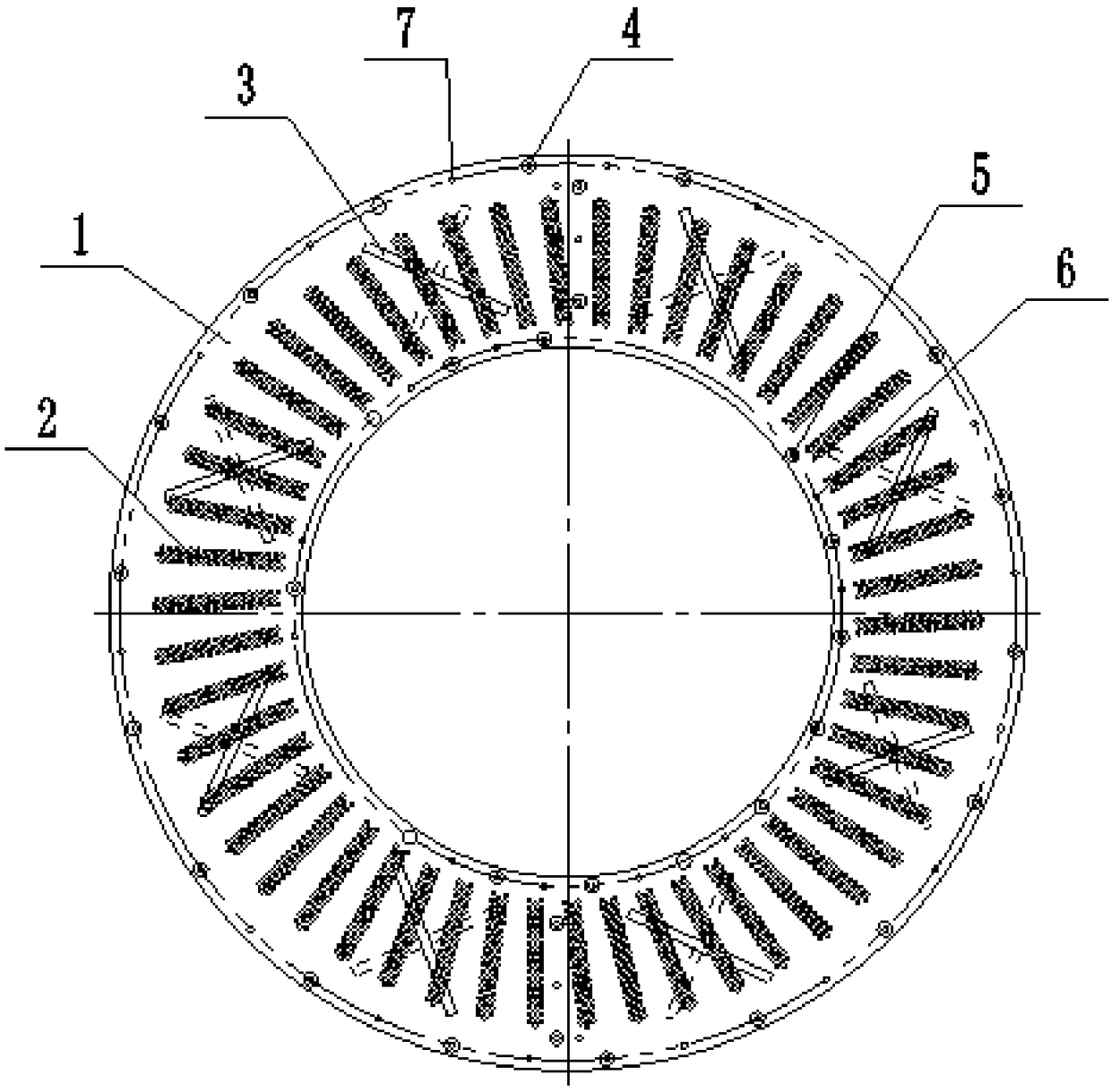

[0037] Such as figure 1 As shown, this embodiment provides an anti-deformation sieve plate for a pulper, which includes a circular sieve plate body 1 and support bars 3; wherein, the surface of the sieve plate body 1 is provided with sieve holes 2, and the support bars The strips 3 are arranged in pairs on the front and back sides of the sieve plate body 1 . In this embodiment, the support bar 3 is a rectangular plate-shaped structure, a plurality of support bars 3 are distributed in a spiral shape on the side of the sieve plate body 1, and the two opposite support bars 3 on the front and back sides of the sieve plate body 1 cross Staggered settings. In this structural form, the support bars 3 strengthen the sieve plate body 1, and the support bars 2 on the front and back sides are arranged in a cross shape, which has mutual pulling effect, and is squeezed by the slurry on one side of the sieve plate body 1. When pressing, the support bar 2 produces opposite tensile force, w...

Embodiment 2

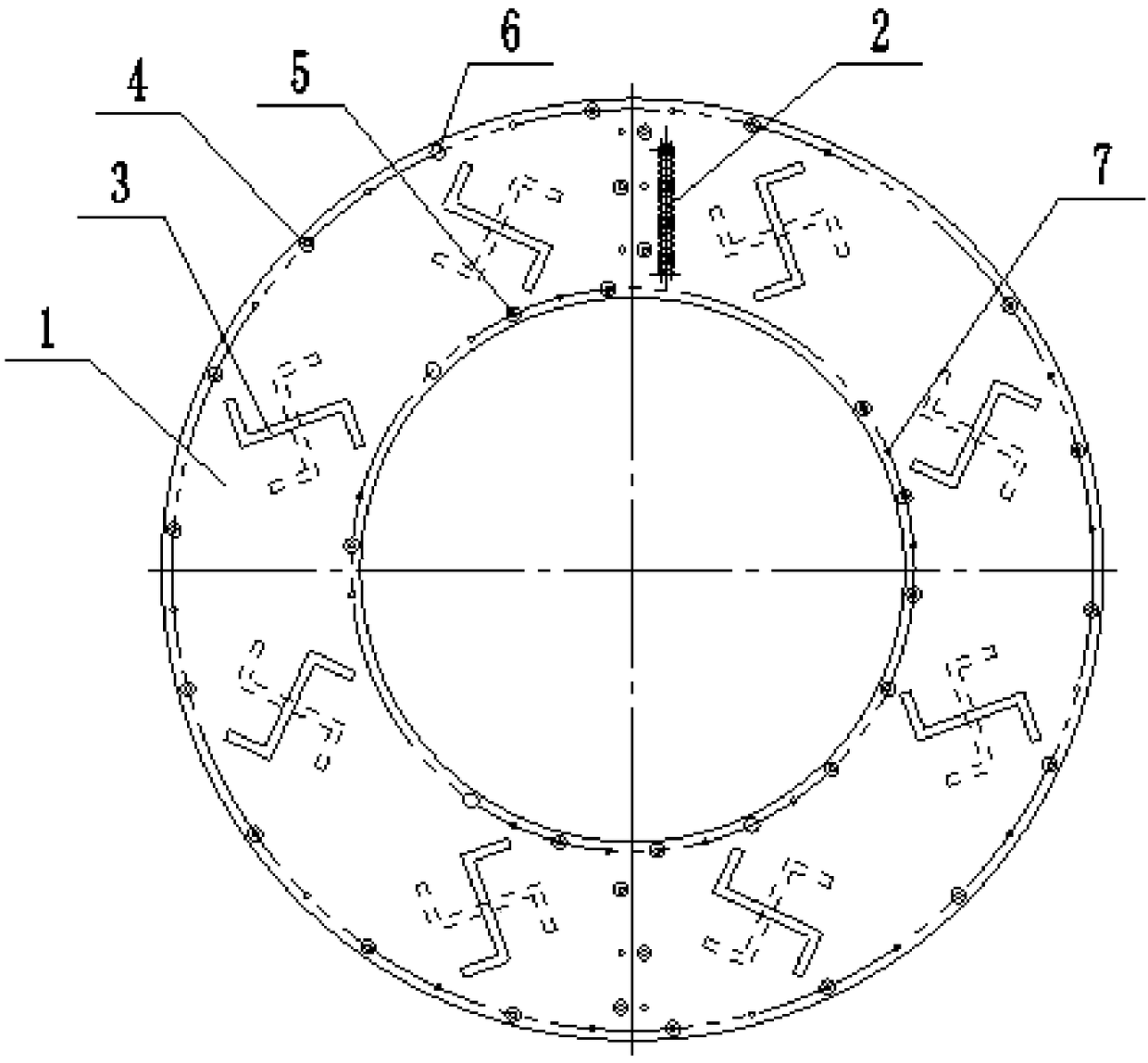

[0041] This embodiment provides an anti-deformation sieve plate for a pulper, which is basically the same as Embodiment 1, except that: figure 2 As shown, the support strips 3 on both sides of the sieve plate body 1 are in the shape of a "Z" plate, and a plurality of support strips 3 are evenly distributed in the circumferential direction on the side of the sieve plate body 1, and the front and back sides of the sieve plate body 1 The upper relative two supporting bars 3 are arranged crosswise. Such a structure further increases the connection strength between the support bar 3 and the sieve plate body 1, and its effect is better than that of Embodiment 1.

Embodiment 3

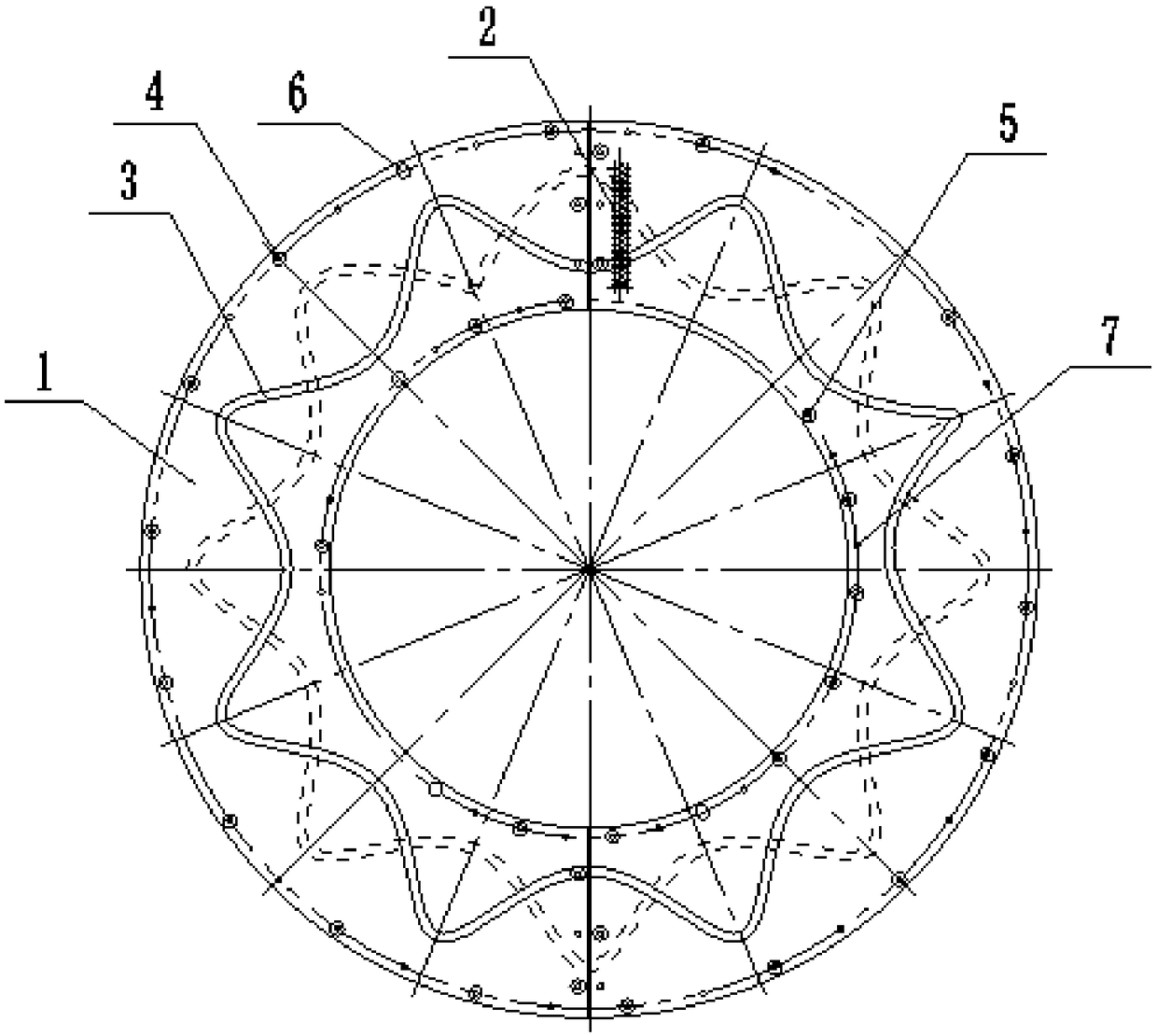

[0043] This embodiment provides an anti-deformation sieve plate for a pulper, which is basically the same as Embodiment 1, except that: image 3 As shown, the support bars 3 on both sides of the sieve plate body 1 are corrugated annular plates, one is provided on each side of the sieve plate body 1, and the crests of the two support bars 3 are opposite to the troughs, forming a staggered arrangement. This structure further increases the connection strength between the support bar 3 and the sieve plate body 1, and its effect is better than that of Embodiment 1 and Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com