High-formability unsaturated titanium hydride powder and preparation method thereof

A titanium hydride powder, unsaturated technology, applied in the direction of transition element hydride, etc., can solve the problems of reduced sintered yield, high brittleness, cracks in titanium or titanium alloy products, etc., to reduce cracks, improve formability, and excellent forming. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

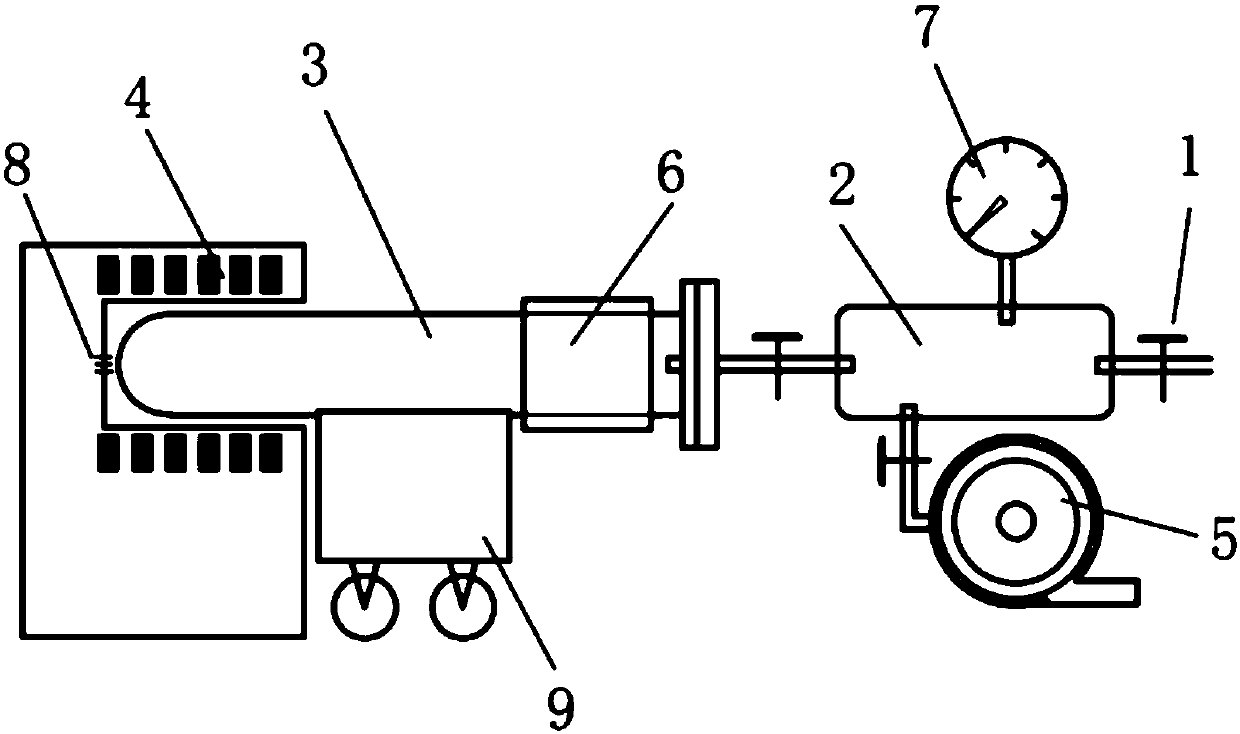

Embodiment 1

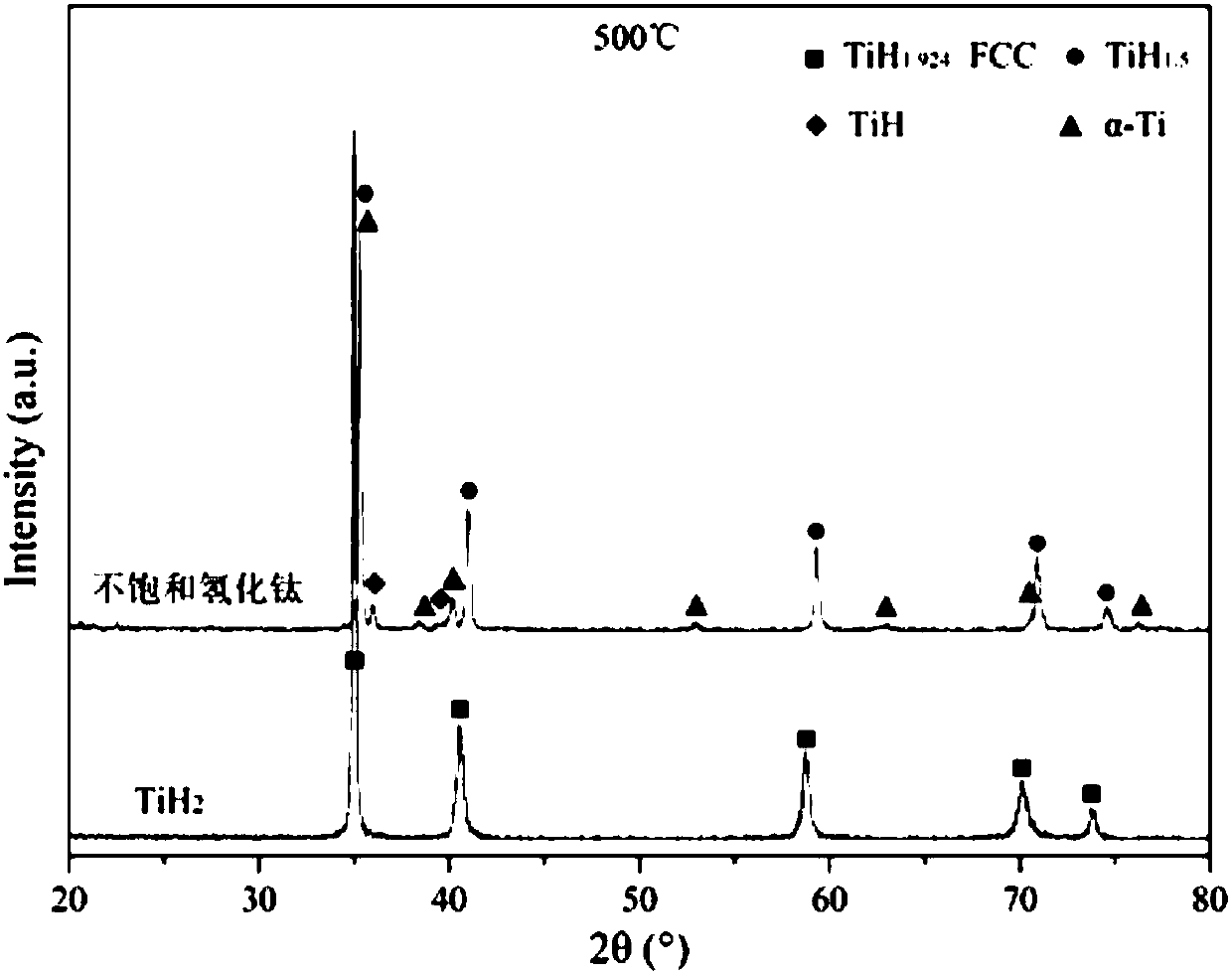

[0034] TiH passed through a 200-mesh sieve (particle size2 Put the powder in the hydrogen absorption / dehydrogenation reactor 3 of the PCT equipment, open the reactor joint of the gas storage tank 2 and the control valve on the vacuum joint, close the control valve of the hydrogen source joint, and turn on the vacuum pump 5 for hydrogen absorption / dehydrogenation. Vacuumize the hydrogen reactor to a pressure of 0.01Pa, then turn on the heating furnace 4 to heat the hydrogen absorption / dehydrogenation reactor and continue vacuuming to keep the pressure at 0.01Pa. When the temperature of the hydrogen absorption / dehydrogenation reactor reaches 500°C Then heat at this temperature for 180 minutes to carry out incomplete dehydrogenation to obtain unsaturated titanium hydride powder.

[0035] Carry out XRD phase analysis to the unsaturated titanium hydride powder prepared in this embodiment, its XRD collection of patterns is as follows figure 2 As shown, by analyzing the XRD pattern,...

Embodiment 2

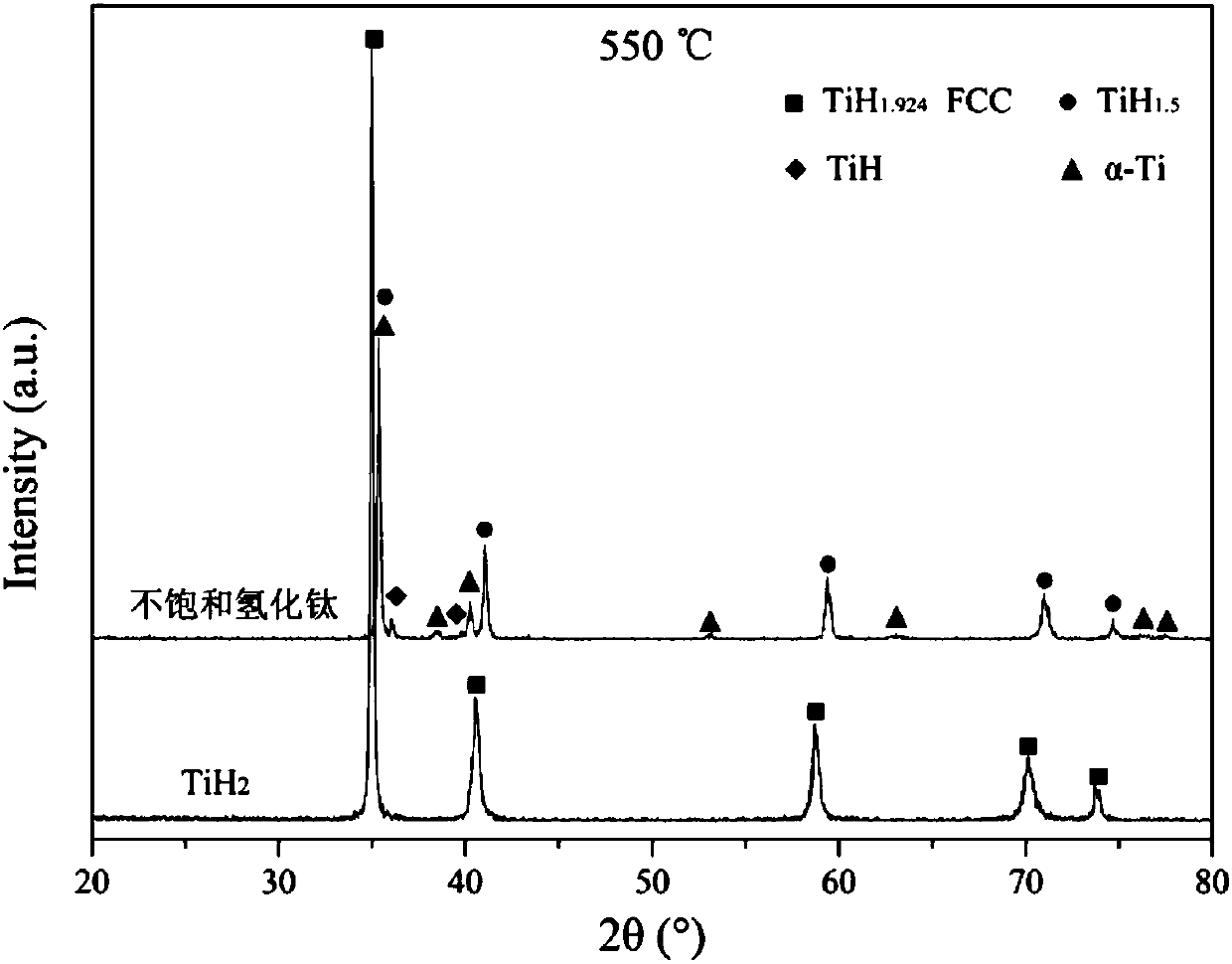

[0037] TiH passed through a 200-mesh sieve (particle size2 Put the powder in the hydrogen absorption / dehydrogenation reactor 3 of the PCT equipment, open the reactor joint of the gas storage tank 2 and the control valve on the vacuum joint, close the control valve of the hydrogen source joint, and turn on the vacuum pump 5 for hydrogen absorption / dehydrogenation. The hydrogen reactor is evacuated to a pressure of 100Pa, then the heating furnace 4 is turned on to heat the hydrogen absorption / dehydrogenation reactor and the vacuum is continued to keep the pressure at 100Pa. When the temperature of the hydrogen absorption / dehydrogenation reactor reaches 550°C, the Heating at this temperature for 45 minutes carries out incomplete dehydrogenation to obtain unsaturated titanium hydride powder.

[0038] Carry out XRD phase analysis to the unsaturated titanium hydride powder prepared in this embodiment, its XRD collection of patterns is as follows image 3 As shown, by analyzing the X...

Embodiment 3

[0040] TiH passed through a 200-mesh sieve (particle size2 Put the powder in the hydrogen absorption / dehydrogenation reactor 3 of the PCT equipment, open the reactor joint of the gas storage tank 2 and the control valve on the vacuum joint, close the control valve of the hydrogen source joint, and turn on the vacuum pump 5 for hydrogen absorption / dehydrogenation. Vacuumize the hydrogen reactor to a pressure of 0.01Pa, then turn on the heating furnace 4 to heat the hydrogen absorption / dehydrogenation reactor and continue vacuuming to keep the pressure at 0.01Pa. When the temperature of the hydrogen absorption / dehydrogenation reactor reaches 600°C Then heat at this temperature for 15 minutes to carry out incomplete dehydrogenation to obtain unsaturated titanium hydride powder.

[0041] Carry out XRD phase analysis to the unsaturated titanium hydride powder that present embodiment prepares, and XRD collection of illustrative plates is as follows Figure 4 As shown, by analyzing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com