BN-Si2N2O composite ceramic and preparation method thereof

A technology of composite ceramics and hexagonal boron nitride, which is applied in the field of boron nitride-based ceramic materials and its preparation, can solve the problems of low efficiency, difficulty in preparation, and high preparation cost, and achieve excellent dielectric properties, low thermal expansion coefficient, and high temperature. Effect of Strength and Thermal Shock Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

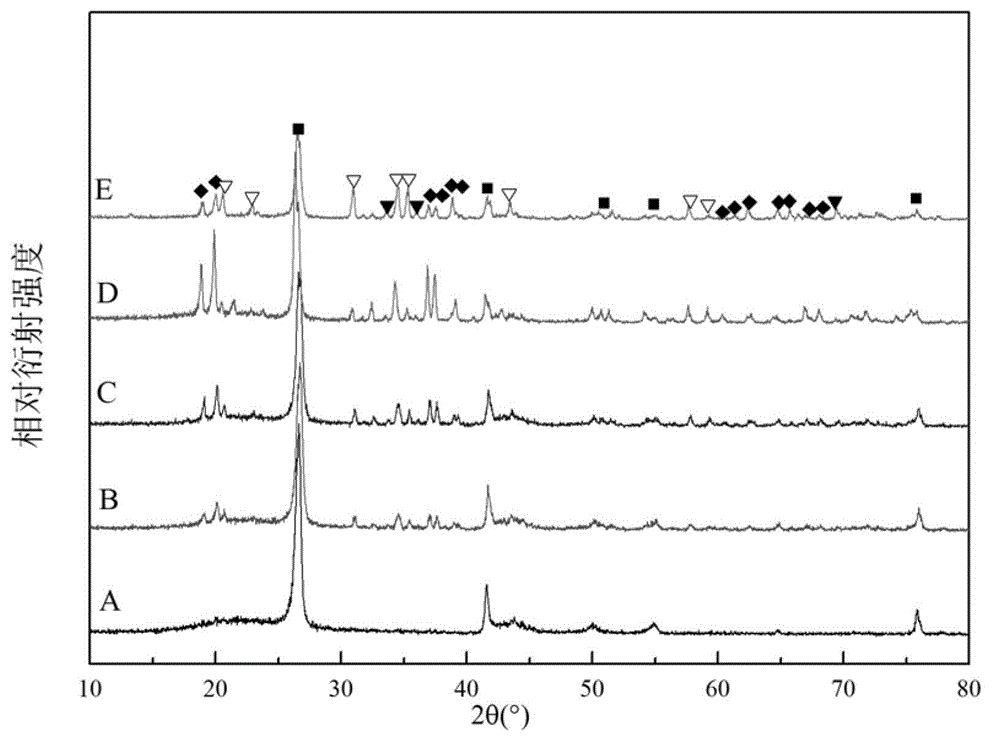

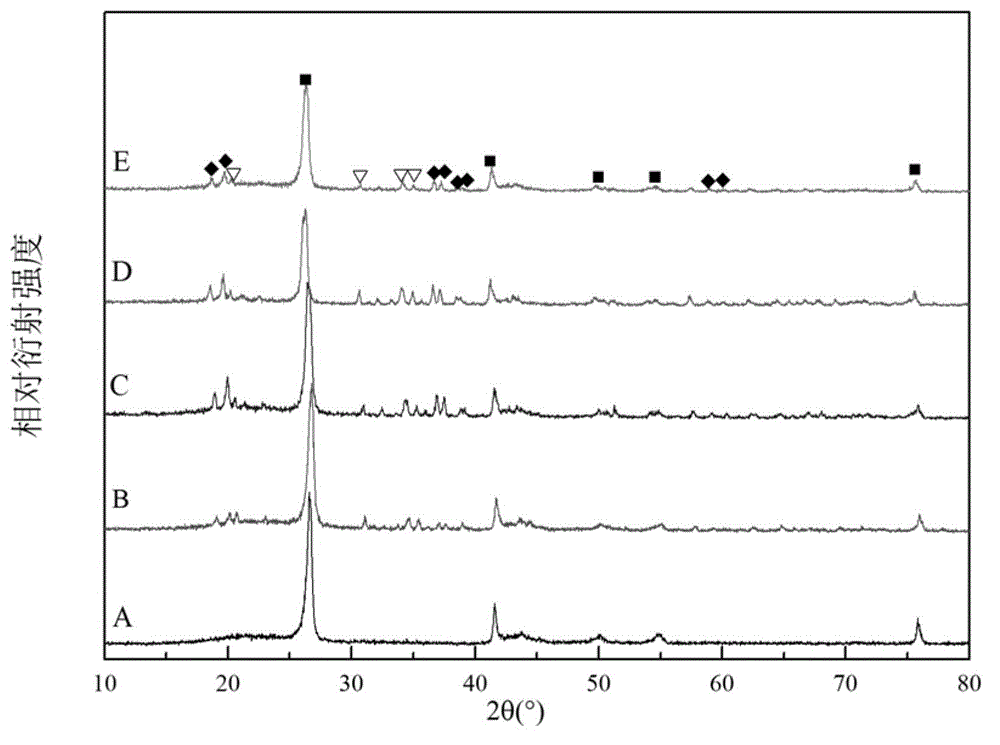

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: This implementation mode is a kind of BN-Si 2 N 2 O composite ceramics are made of 15% to 40% of amorphous nano-silicon dioxide, 5% to 30% of silicon nitride powder and 30% to 80% of hexagonal boron nitride powder by volume percentage; and wherein the nitrogen The volume ratio of silicon oxide powder to amorphous nano-silicon oxide is less than 1.

[0016] The sum of the volume fractions of amorphous nano-silicon dioxide, silicon nitride powder and hexagonal boron nitride powder described in this embodiment is 100%.

[0017] The BN-Si described in this embodiment 2 N 2 O composite ceramics contain Si 2 N 2 O, Si 2 N 2 O in BN-Si 2 N 2 O composite ceramic plays the role of improving the high temperature strength and thermal shock resistance of the material, and improving the high temperature dielectric wave transmission performance; so the BN-Si described in this embodiment 2 N 2 O composite ceramics can meet the requirements of...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the amorphous nano-silica is amorphous nano-silica powder or silica sol; wherein the amorphous nano-silica The average particle size of silicon oxide powder is 0.9 μm to 3 μm; the amorphous SiO in the silica sol 2 The particle mass fraction is 30%, and the amorphous SiO in the silica sol 2 The average particle diameter of the particles is 9nm-13nm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the average particle size of the silicon nitride powder is 1 μm to 1.5 μm; the average particle size of the hexagonal boron nitride powder is 0.9 μm~1.5μm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com