Assembly type brick membrane

A brick membrane and assembly technology, which is applied in construction, infrastructure engineering, etc., can solve problems such as long construction period, many types of materials, and complex structural forms, and achieve the effects of increasing contact area, stable structure, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

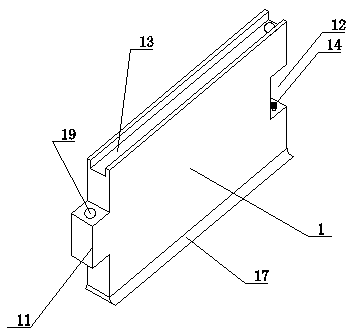

Embodiment 1

[0030]A prefabricated brick membrane base, comprising a prefabricated base 1 with a length of 1-3m. The upper and lower center of a bump 11 is provided with a through first installation hole 19, and the middle part of the right side of the prefabricated base 1 is provided with an inwardly recessed first groove 12. The size of the first bump 11 and the first groove 12 is Similarly, the top of the prefabricated base 1 is provided with a first strip groove 13, and the bottom of the right side of the prefabricated base 1 is poured with a first T-shaped steel bar 14, and the first T-shaped steel bar 14 is set upside down. The top of the T-shaped steel bar 14 protrudes upwards from the bottom center of the first groove 12, and the top of the first T-shaped steel bar 14 is fixedly welded with a first threaded sleeve 15, on the first threaded sleeve 15 of the first T-shaped steel bar 14 Also be provided with the first extension rod 16, the bottom car of the first extension rod 16 has ...

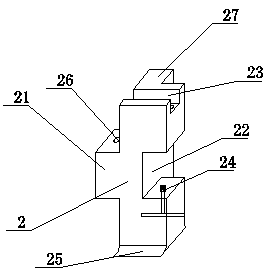

Embodiment 2

[0032] A prefabricated brick membrane base reinforced column, comprising a prefabricated reinforced column 2 with a length of 300-500 mm, a second convex block 21 protruding outward is provided in the middle of the left side of the prefabricated reinforced column 2, and the second convex block 21 The center of the upper and lower sides is provided with a through second installation hole 28, and the middle part of the right side of the prefabricated reinforcement column 2 is provided with an inwardly recessed second groove 22, and the size of the second protrusion 21 and the second groove 22 are the same. The top of the prefabricated reinforcement column 2 is provided with a second strip groove 23, and the bottom of the right side of the prefabricated reinforcement column 2 is poured with a second T-shaped steel bar 24, and the second T-shaped steel bar 24 is set upside down, and the second T-shaped steel bar 24 is placed upside down. The top of steel bar 24 stretches out the bo...

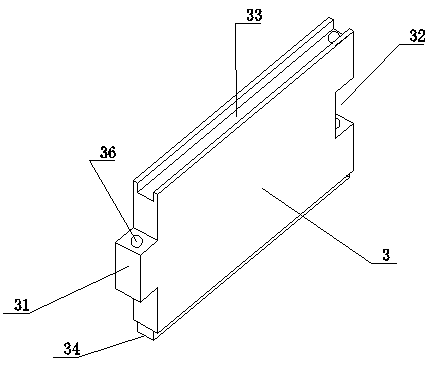

Embodiment 3

[0034] A prefabricated brick membrane standard part, comprising a prefabricated standard part 3, the prefabricated standard part 3 is in the shape of a cuboid, the middle part of the left side of the prefabricated standard part 3 is provided with a third protrusion 31 protruding outwards, and the right side of the prefabricated standard part 1 The middle part of the side is provided with a third groove 32 sunken inward, the size of the third bump 31 and the third groove 32 are the same, the top of the prefabricated standard part 3 is provided with a third strip groove 33, the prefabricated The bottom of the standard part 3 is provided with a first strip-shaped protrusion 34, the size of the first strip-shaped protrusion 34 and the third strip-shaped groove 33 are the same, and the right side of the prefabricated standard part 3 passes through the third strip-shaped groove 33 successively The surface, the upper and lower sides of the third groove 32, and the first strip-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com