Ultra-wide apron conveyer

A technology of ultra-wide slats and conveyors, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of high use cost, waste of space, large conveying volume, etc., achieve large conveying volume, high material efficiency, reduce manufacturing and The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

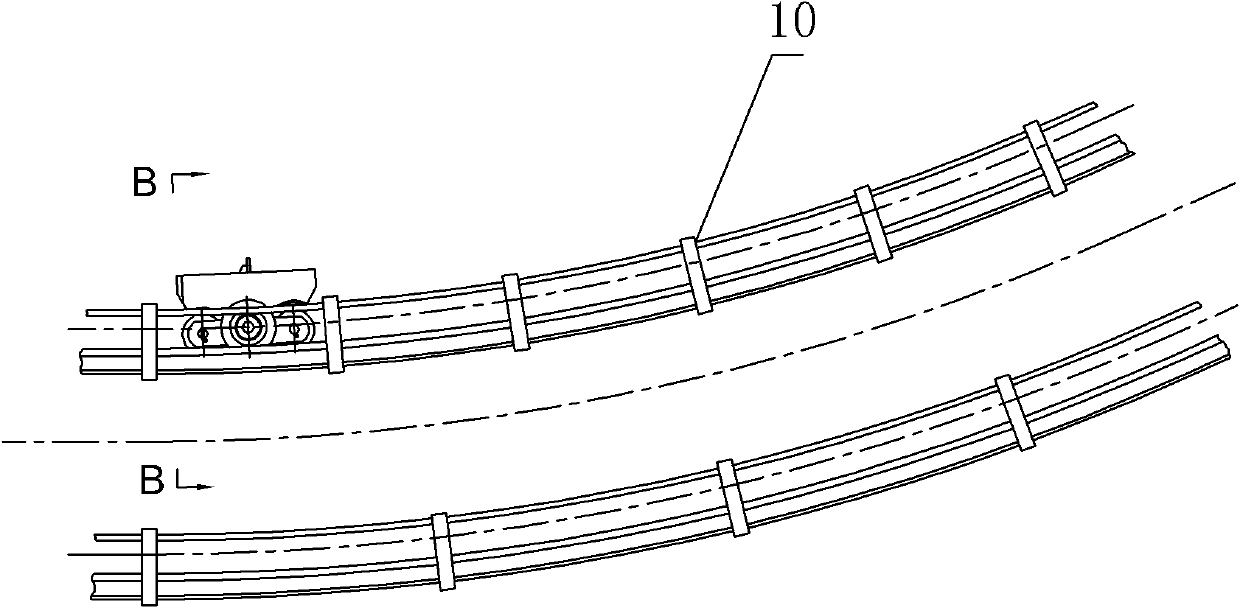

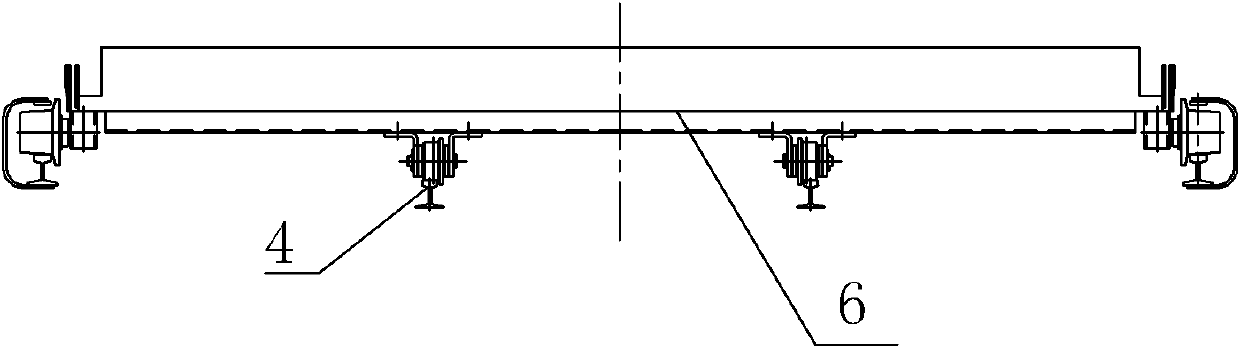

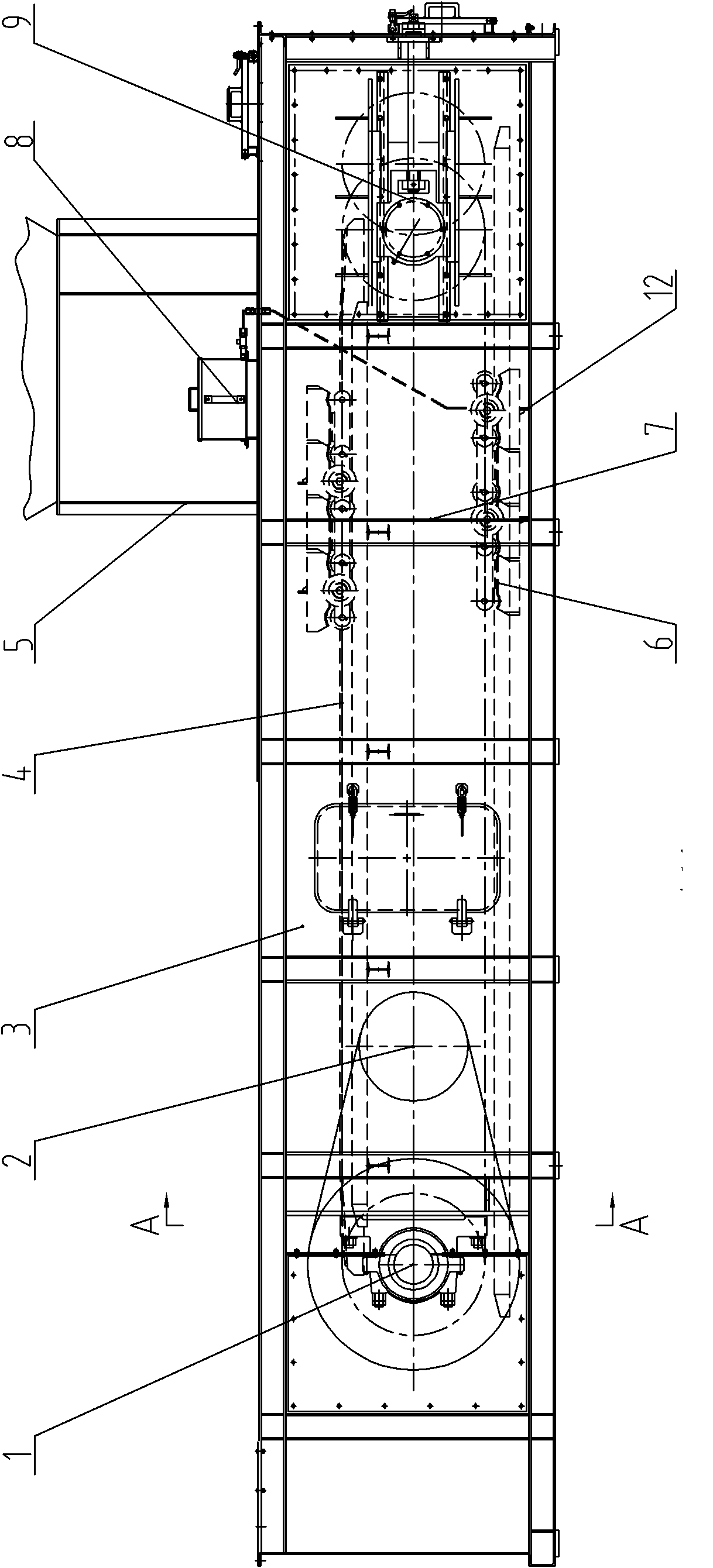

[0016] The structure of the present invention is as follows: an ultra-wide slat conveyor, comprising a head 1, a tail 9, an intermediate casing 3, a slat 6, a chain and a rail group 4, and is characterized in that: between the slat 6 and the rail group 4 Rollers 11 are provided, and the rail group 4 is a plurality of parallel rails, which are welded on the intermediate support 7 . The rail group 4 consists of 2-8 parallel rails. The intermediate casing 3 is provided with a material guide trough 13 . A plurality of parallel and concentric arc-shaped steel rail groups 4 are arranged in the bending section of the conveyor, and parallel guard rails 10 are installed on the steel rails on both sides thereof. A rib plate 12 is provided at the lower part of the scale plate 6 . The net width of the scale plate 6 is greater than 1 meter.

[0017] Example:

[0018] Design a 2-meter-wide slat, press it with a special mold or directly cast it, and set up 4 parallel rails to support the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com