Method for remotely monitoring damage of interlayer structure of wind power blade

A wind power blade and interlayer structure technology, which is applied in wind power generation, wind power generator components, wind turbines, etc., can solve the problem of high installation cost of wind power blades, and achieve the effects of saving manpower and material resources, high sensitivity, and strengthening the mechanical properties of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] In the following, in conjunction with the drawings, specific implementations of the present invention are given as follows:

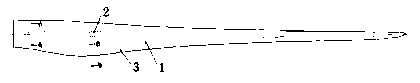

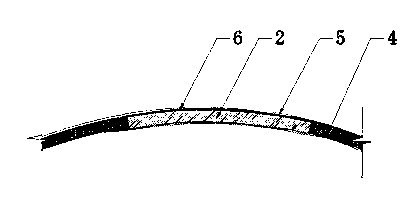

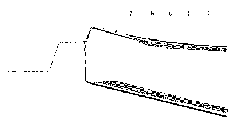

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a method for remotely monitoring the structural damage between layers of wind power blades is to lay a structure with good shape conformability and obvious response to load changes on the structural member spar cap 2 and trailing edge beam 3 of the wind power blade 1. Carbon fiber smart layer 6 made of carbon fiber composite material; the carbon fiber smart layer 6 is respectively laid on the outer skin 4 of the wind turbine blade 1 on the lower spar cap 2 and the outer skin 5 on the lower rear edge beam 3, on both sides of the spar cap 2 The core material 4 is used to fill, and the bottom of the trailing edge beam 3 is also filled with the core material 4. The upper and lower halves of the wind turbine blade 1 are bonded with adhesive; a sensitivity is estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com