Wheel hub electrophoretic coating hanger

A technology for coating electrophoresis and wheel hubs, applied in the directions of electrophoresis plating, coating, electrolytic coatings, etc., can solve the problems of many contact surfaces between the wheel hub and the hanger, easy to damage the electrophoresis paint film, and increase the workload of refinishing, so as to reduce the Refinishing workload, good fixation, and the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

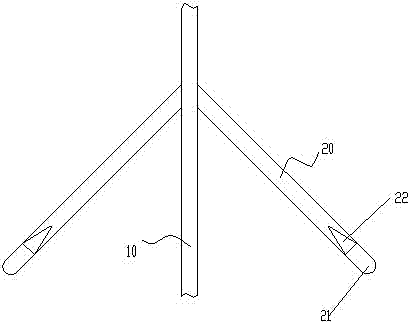

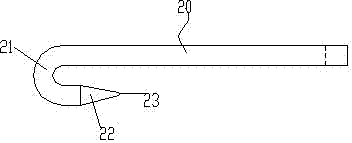

[0024] combine figure 1 , 2 Be explained:

[0025] The hub coating electrophoresis hanger includes a main pole 10 and a pair of hanging poles 20, the main pole 10 is a round steel column, and the hanging pole 20 is fixed on the main pole 10 obliquely downward from the main pole 10, so The hanging rod 20 is composed of a linear main body and an end portion provided with a bending portion 21 away from the main rod 10. The free end of the end portion is a pointed portion 22, and the base of the pointed portion 22 is connected to the hanging portion. The minimum distance between the main bodies of the rods 20 is less than or equal to the minimum distance between them and the inner bottom of the bending portion 21, and the included angle between the main rod and the hanging rod is 25°C.

Embodiment 2

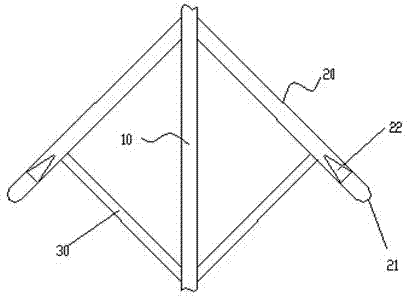

[0027] combine image 3 Be explained:

[0028] The difference from Embodiment 1 is that the hanging rod 20 is supported by a supporting rod 30, the supporting rod 30 is inclined upwards and its two ends are respectively welded to the main rod 10 and the hanging rod 20, and the angle between the main rod and the hanging rod is 15°C.

[0029] On the basis of the above embodiments, in order to further increase the stability of the electrophoresis rack, the electrophoresis rack can be provided with a base as a modification, or the electrophoresis rack can be hung on the top of the electrophoresis space.

[0030] As a modification of the present invention, a pair of hanging bars may be replaced by bent hanging bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com