Assembly welding process method for aluminum structure ceiling of driver cab of motor train unit

A technology of aluminum structure roof and process method, which is applied in the direction of vehicle parts, manufacturing tools, welding equipment, etc., and can solve the problems of large fluctuations in the quality of products produced by the aluminum structure of the driver's cab, large free deformation of the top position of the driver's cab, and problems in the driver's cab assembly. Long manufacturing cycle and other issues, to achieve the effect of ensuring the length, width, height and arc size of the car roof, reducing the development and production cycle, shortening the synthesis time and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

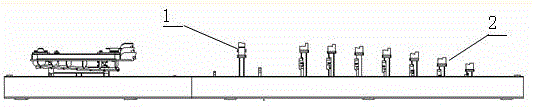

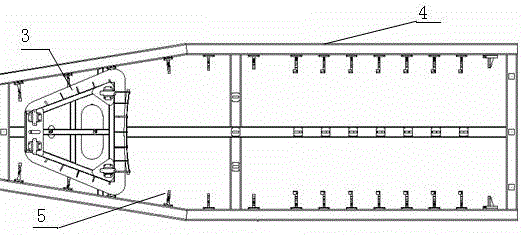

[0024] refer to figure 1 , figure 2 The assembly welding tooling involved in the present invention includes a reinforcing beam positioning structure 1, a roof curved beam positioning structure 2, a roof front window frame positioning structure 3, a clamp main frame 4, a roof longitudinal beam positioning structure 5, a reinforcing beam positioning structure, The roof curved beam positioning structure, the roof front window frame positioning structure, and the roof longitudinal beam positioning structure are respectively fixed on the fixture main frame.

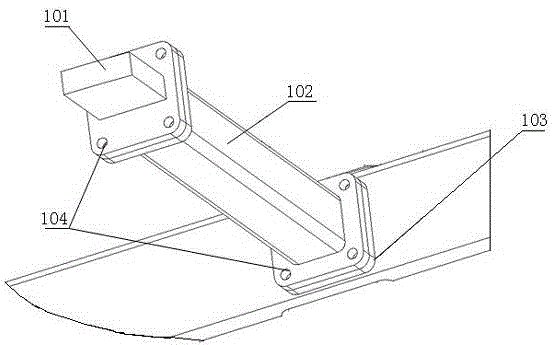

[0025] refer to image 3 , the reinforcing beam positioning structure includes a conformal positioning block 101, a connection support column 102, and a positioning mounting seat 103, the connection support column 102 is fixed on the positioning mounting seat 103 with bolts, and the conformal positioning block 101 is fixed on the connection support column 102 with bolts , 104 is a bolt connection hole, and the positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com