Method for preparing neodymium/gadolinium/scandium/aluminum garnet doped nanometer powder

A technology of nano-powder and garnet, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low efficiency and long time consumption, and achieve the effects of reduced time, good dispersion and simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

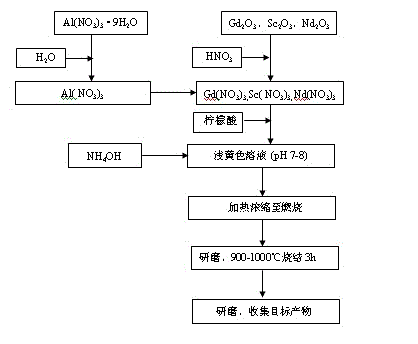

[0028] Example 1: The concrete processing step of the embodiment of the present invention is as follows:

[0029] 1. Weigh a certain quality of gadolinium oxide, neodymium oxide and scandium oxide, dissolve them completely with dilute nitric acid and constant volume respectively; weigh a certain quality of aluminum nitrate nonahydrate, and dissolve them with double distilled water;

[0030] 2. According to (Gd 1-x Nd x ) 3 sc 2 Al 3 o 12 Middle Nd 3+ Doping concentration, use a pipette to measure a certain volume of gadolinium nitrate, neodymium nitrate, scandium nitrate and aluminum nitrate solutions, mix these nitrate solutions evenly into an appropriate volume of solution, Gd(NO 3 ) 3 , Nd(NO 3 ) 3 , Sc(NO 3 ) 3 , Al(NO 3 ) 3 The molar concentrations are: (0.12-0.12 x )mol / L, 0.12 x mol / L, 0.08mol / L, 0.12mol / L( x =0.01, 0.015, 0.02).

[0031] 3. Weigh a certain mass of citric acid and add it to the above mixed nitrate solution and stir until com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com