Patents

Literature

35 results about "Scandium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scandium(III) nitrate, Sc(NO₃)₃, is an ionic compound. It is an oxidizer, as all nitrates are. It is applied in optical coatings, catalysts, electronic ceramics and the laser industry.

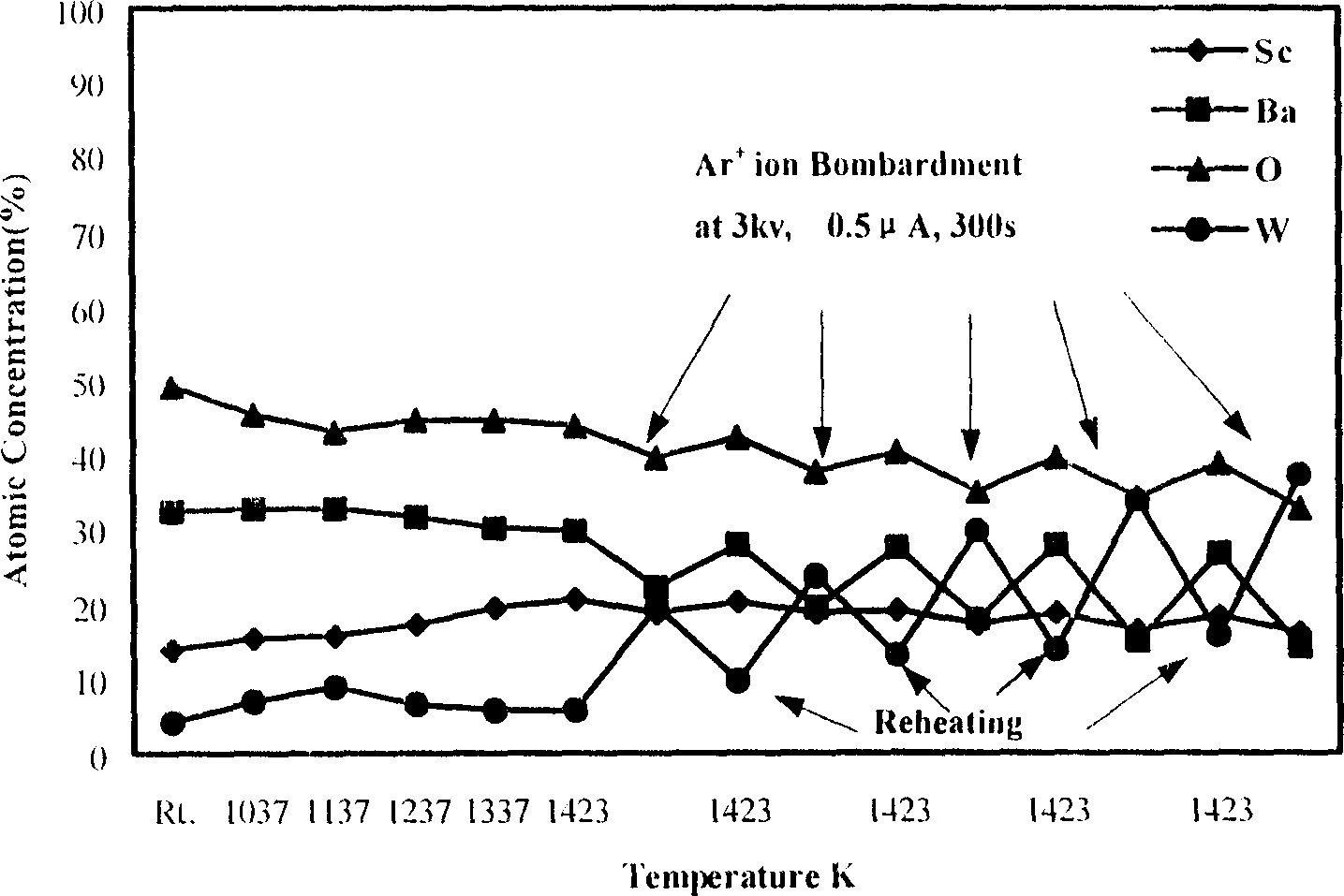

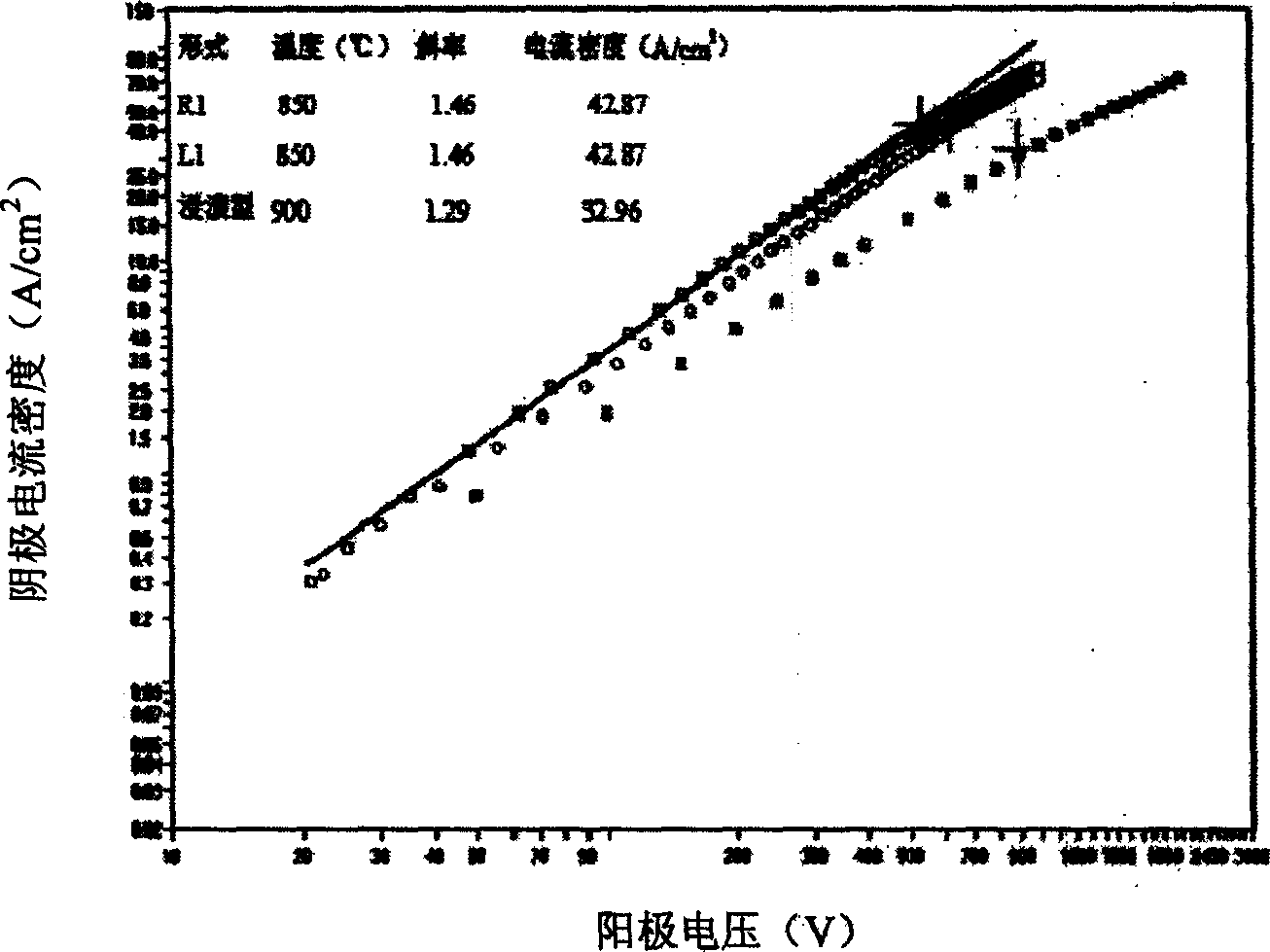

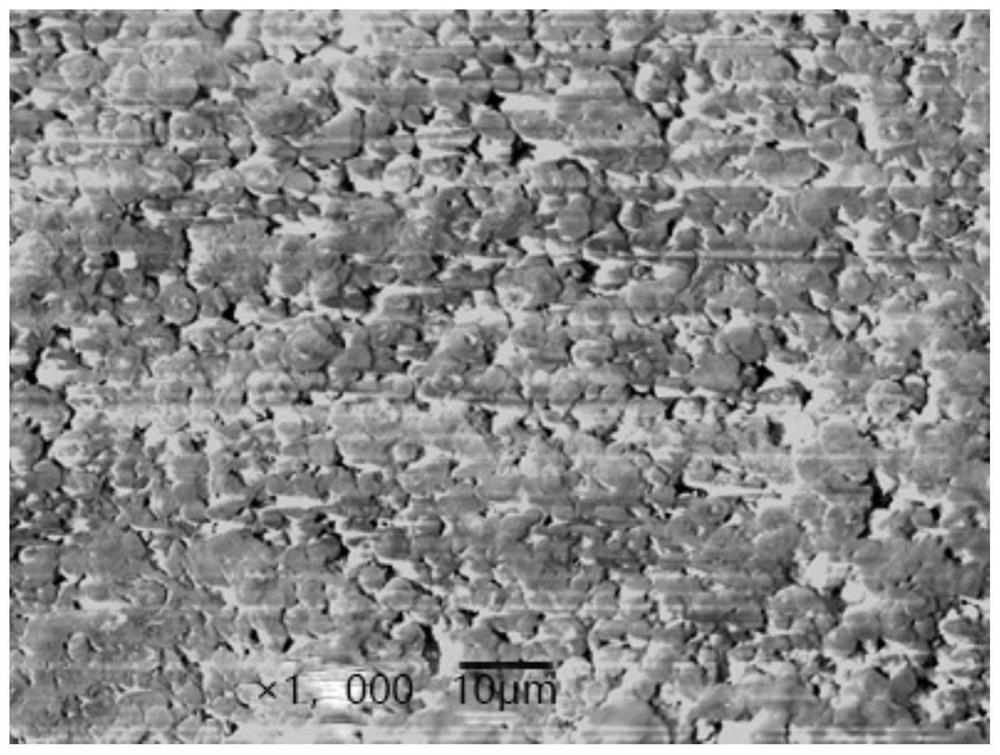

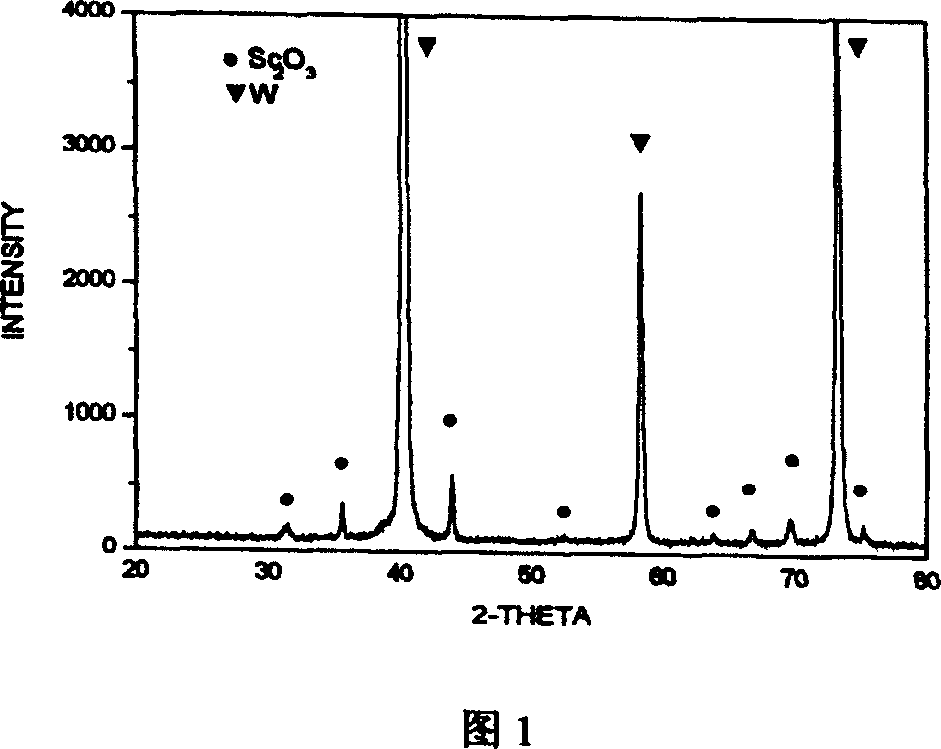

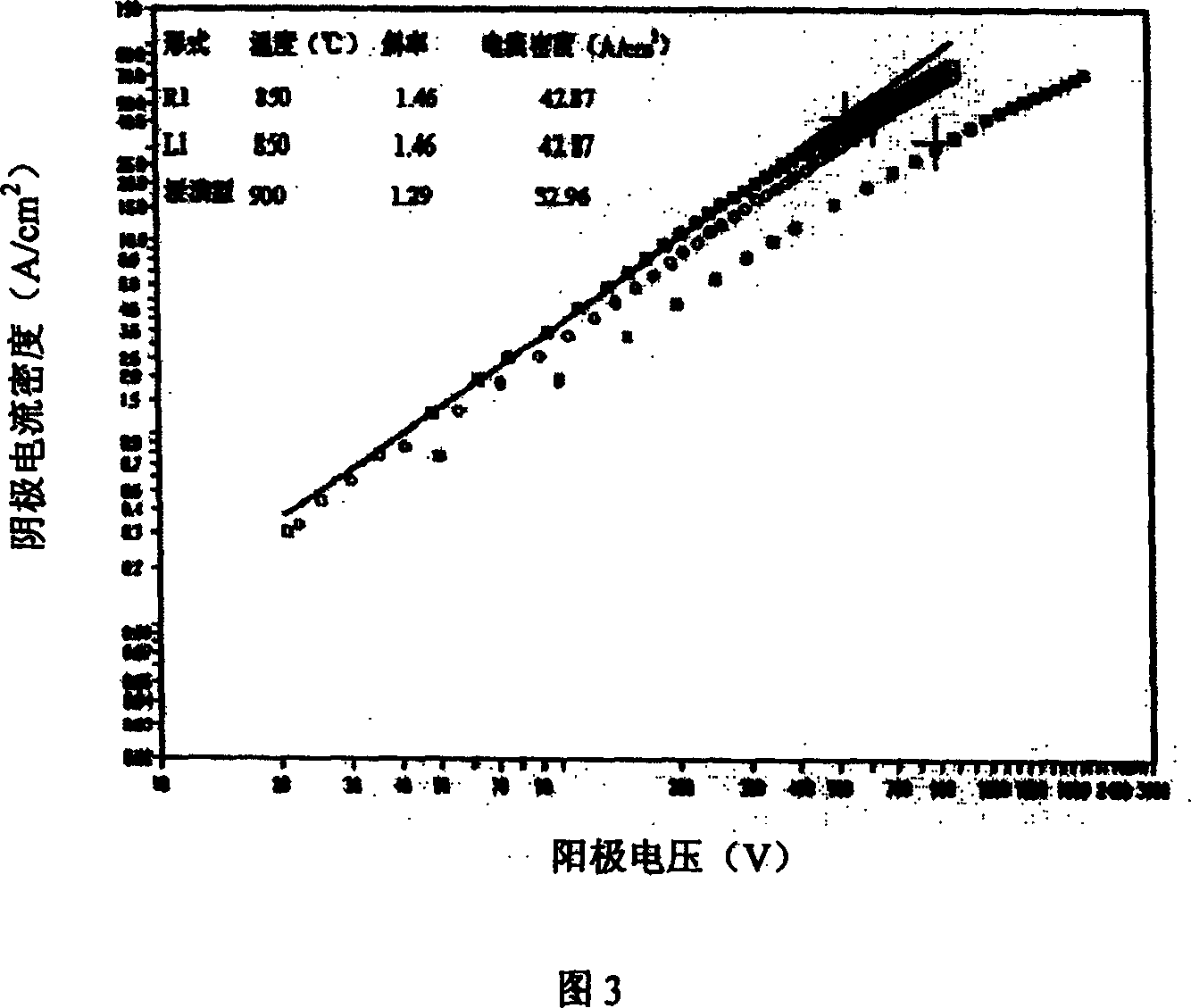

High-current density electronic emission body rareearth-Sc-W based material and mfg. method thereof

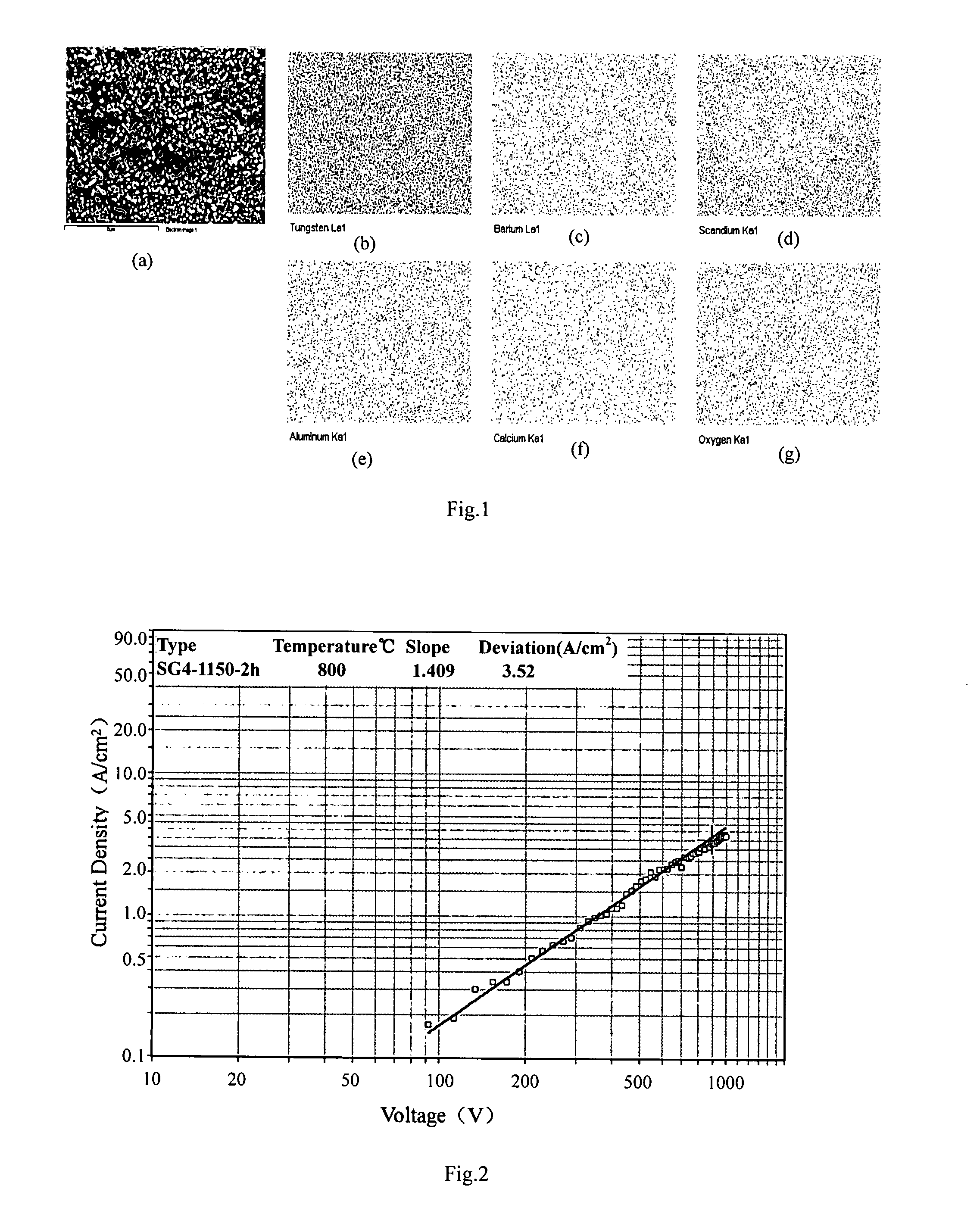

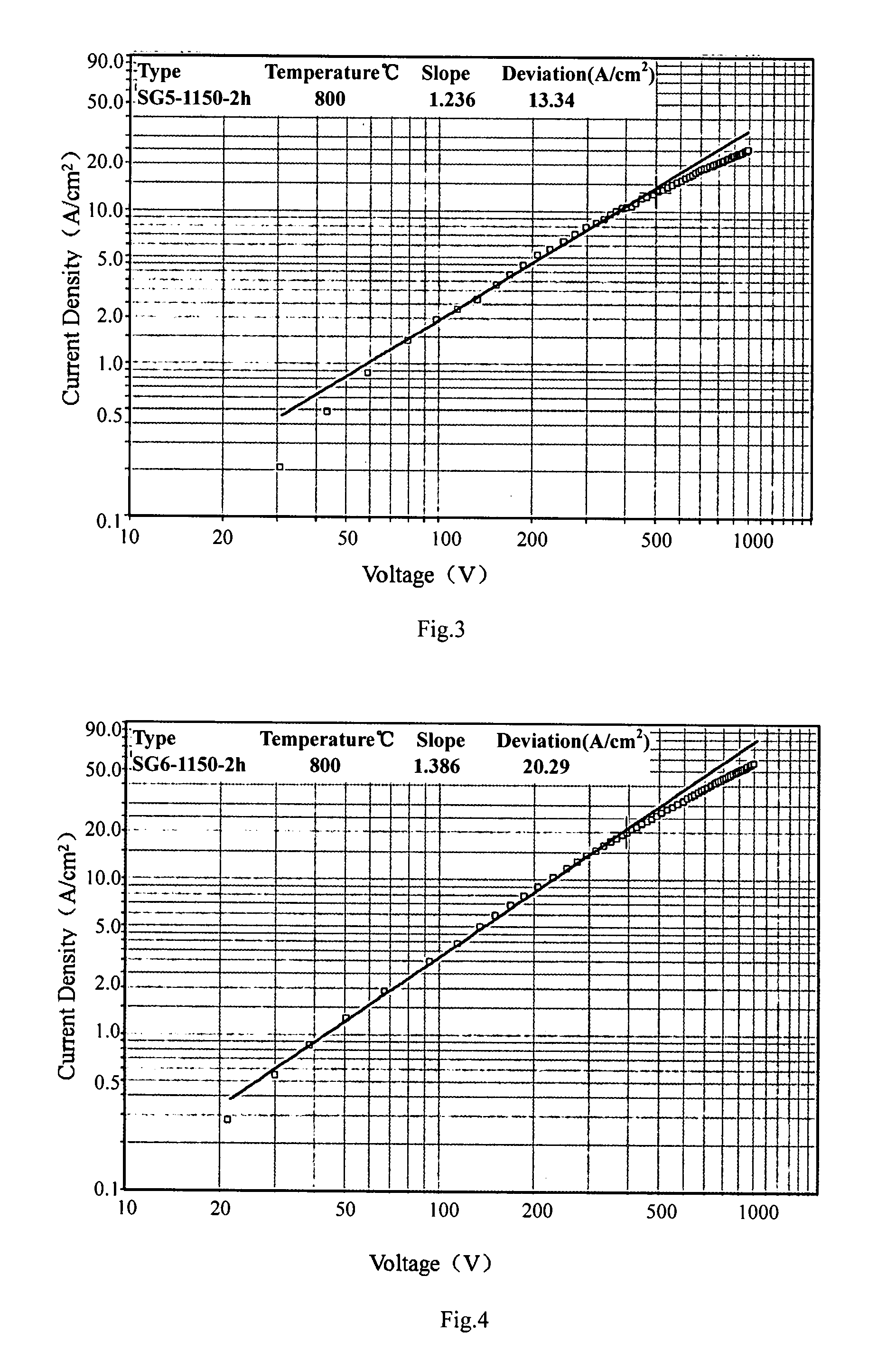

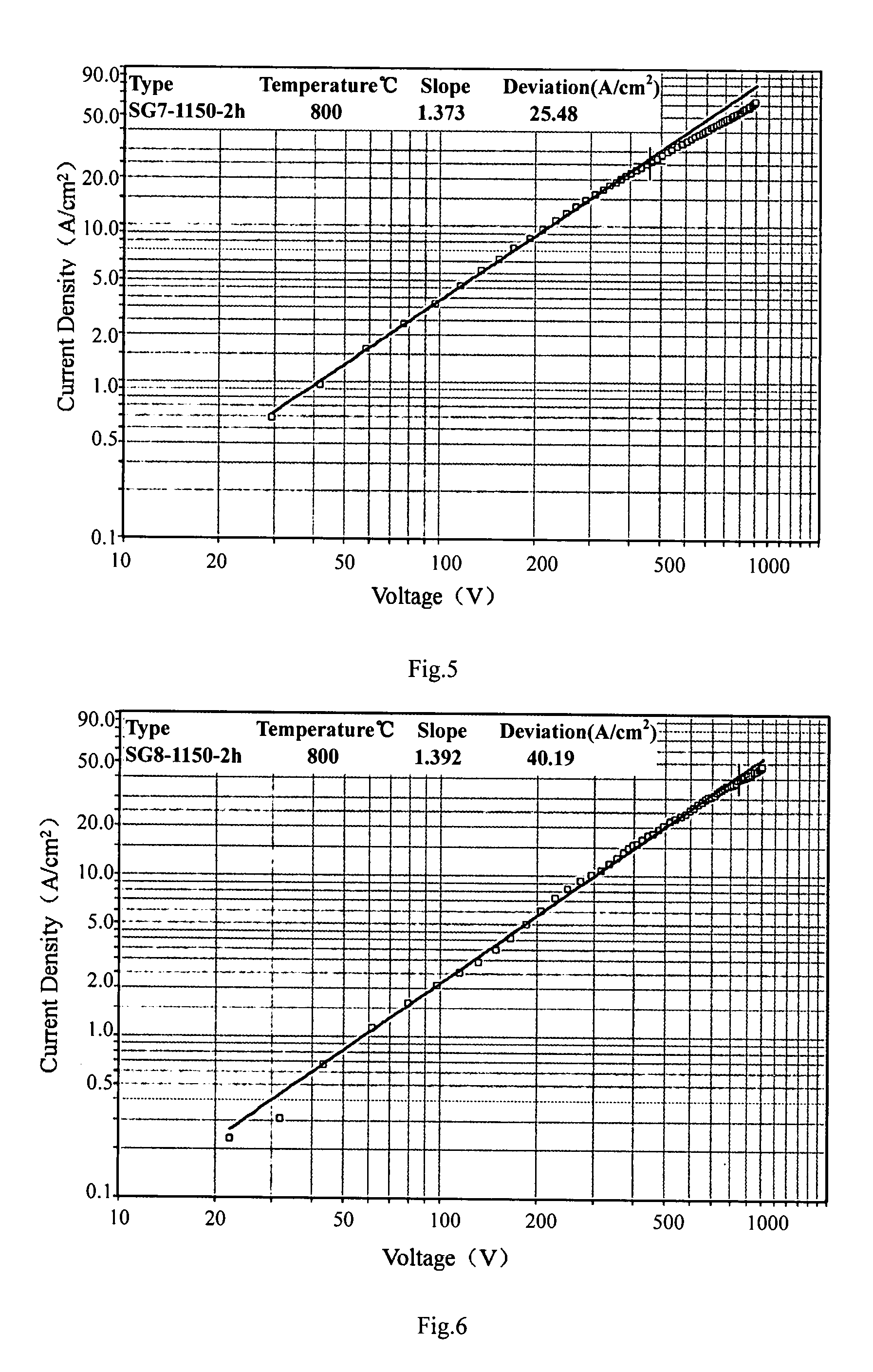

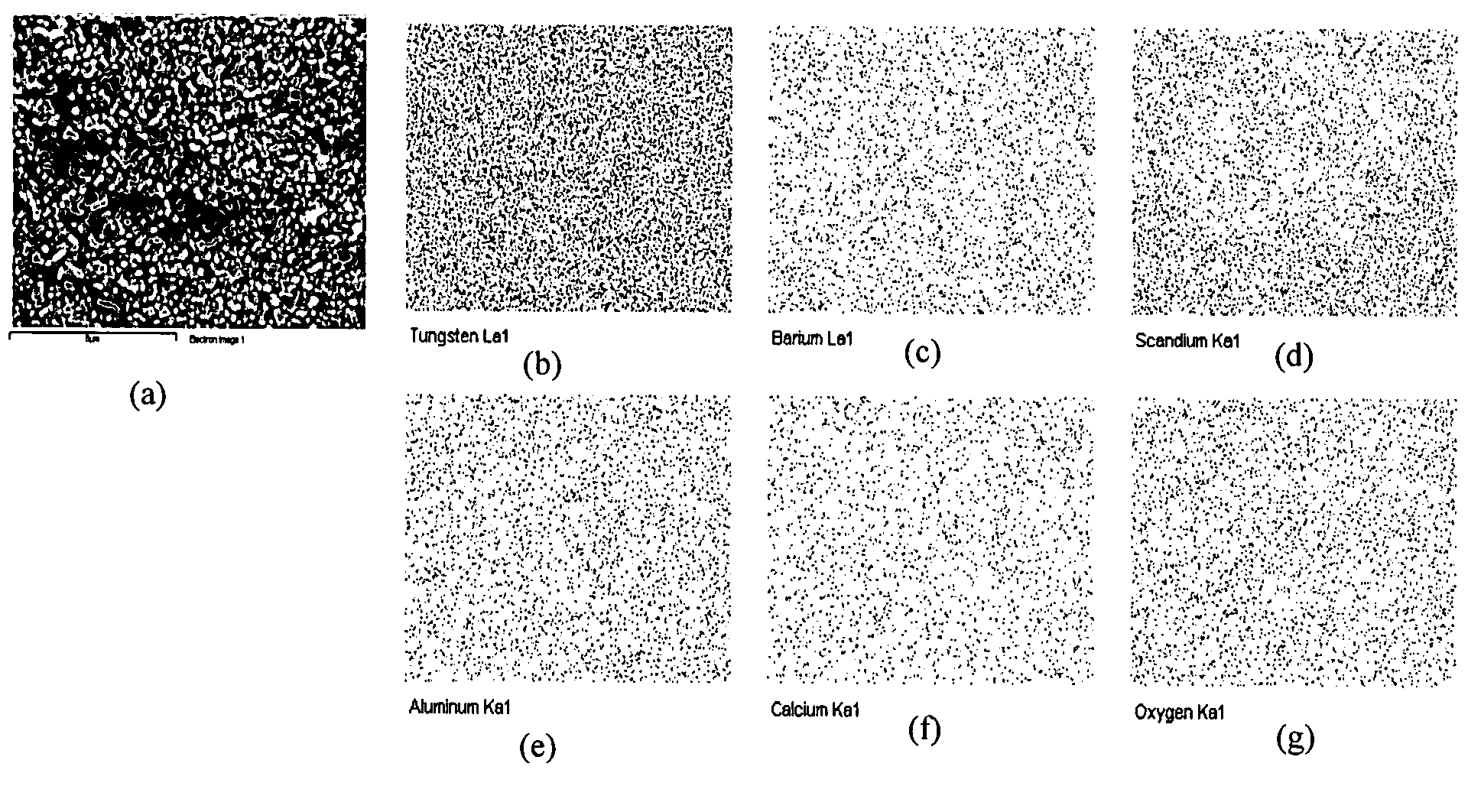

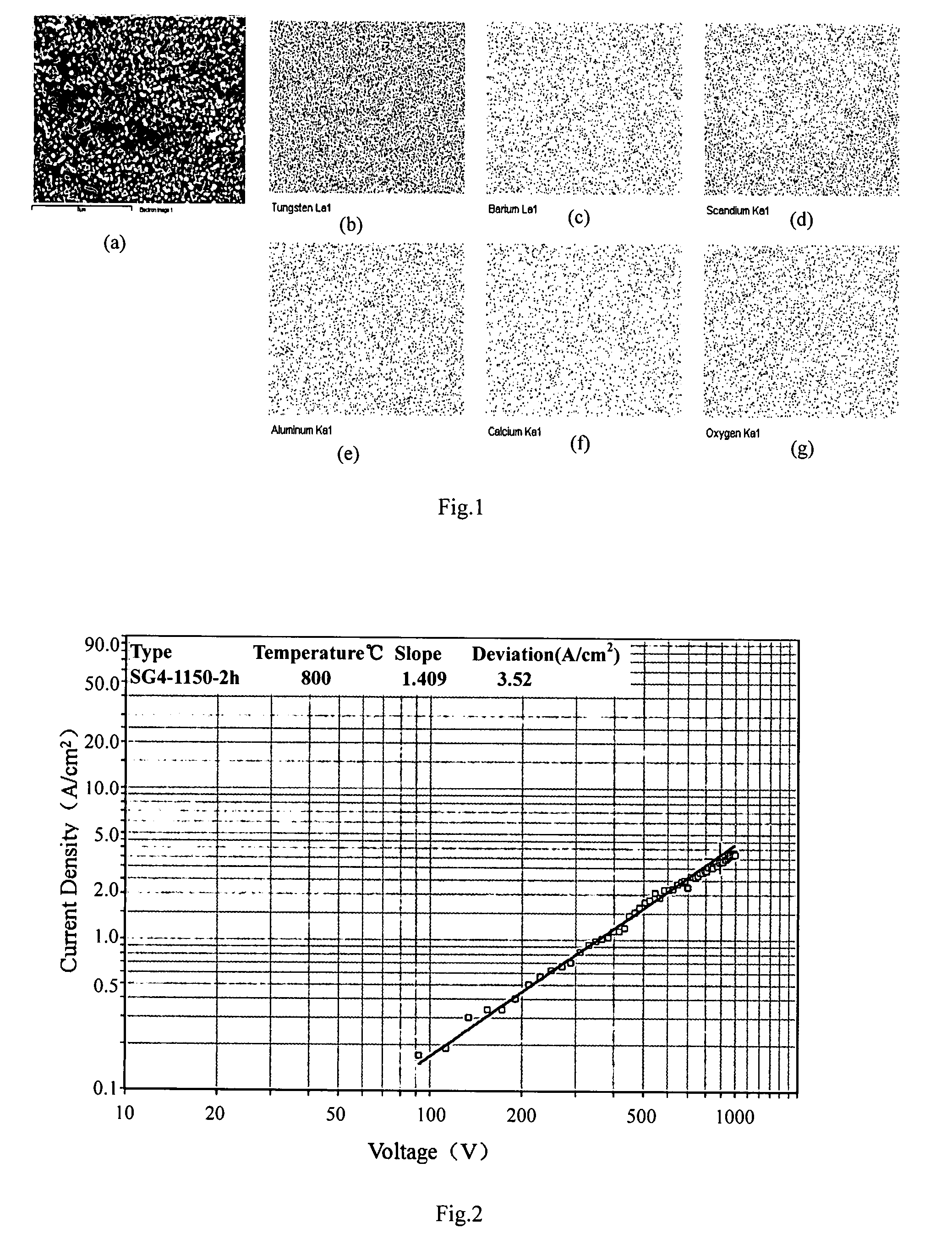

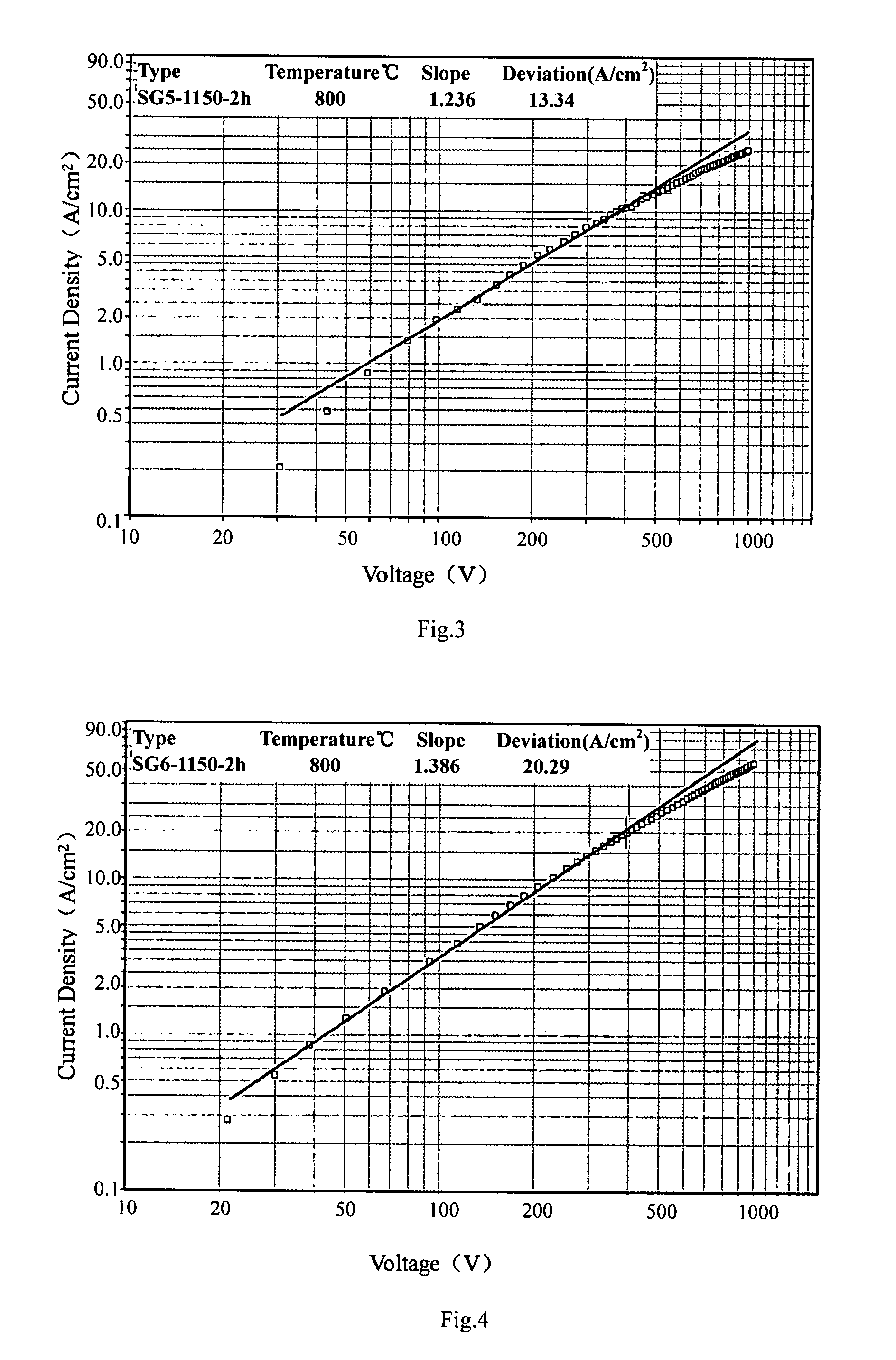

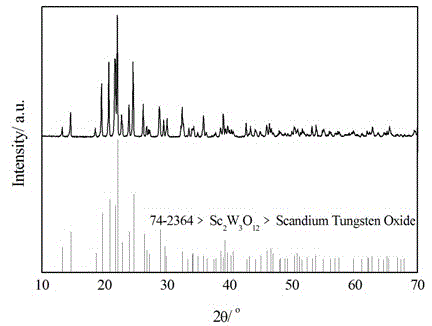

InactiveCN1402291AEvenly distributedImprove high temperature resistanceDischarge tube cold cathodesDischarge tube solid thermionic cathodesHigh current densityHigh resistance

A ScW-base rare-earth material as high-current-density electronic emitter (cathode) contains scandium oxide, rhenium and tungsten. It is prepared through proportionally mixing blue tungsten with aqueous solution of scandium nitrate, adding the aqueous solution of ammonium rhenate, reduction reaction in hydrogen at 500-650 deg.C for 0.5-1.5 hr, maintaing 800-1000 deg.c for 1-3 hr, powder metallurgy, dipping in solution of aluminate, ultrasonic washing at annealing. Its advantages are high emission uniformity and high resistance to high temp and ion bombardment.

Owner:BEIJING UNIV OF TECH

Process using water tolerant lewis acids in catalytic hydration of alkylene oxides to alkylene glycols

ActiveUS20050014980A1Efficient preparationEfficient CatalysisOxygen-containing compound preparationOrganic compound preparationRare earthTriflic acid

Water tolerant Lewis acids are used in a process for the preparation of alkylene glycols by catalytic hydration of the corresponding alkylene oxide. The water tolerant Lewis acids can be a metal salt of a non-coordinating or weakly coordinating anion and a Group IIIB, rare earth or lanthanide, actinide or Group IVB cation. Optionally, carbon oxide may also be present. Examples of such water tolerant Lewis acids are scandium triflate, europium triflate, hafnium triflate, yttrium triflate, lanthanum triflate and ytterbium triflate. The catalyst may contain a coordinating anion instead, examples of which are scandium sulfate [Sc2(SO4)3], scandium chloride [ScCl3], scandium acetate [Sc(OAc)3] and scandium nitrate [Sc(NO3)3]. The catalysts may also contain both a non-coordinating or weakly coordinating anion and a coordinating anion, examples of which are scandium triflate sulfate [Sc(CF3SO3) (SO4)], scandium triflate chloride [Sc(CF3SO3)2Cl], scandium triflate acetate [Sc(CF3SO3)2(OAc)] and scandium triflate nitrate [Sc(CF3SO3)2(NO3)]

Owner:SAUDI BASIC IND CORP SA

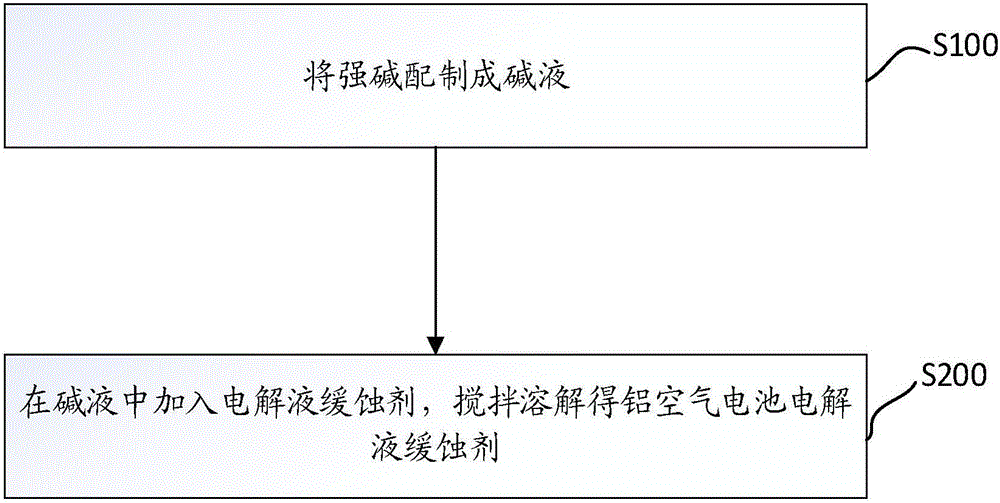

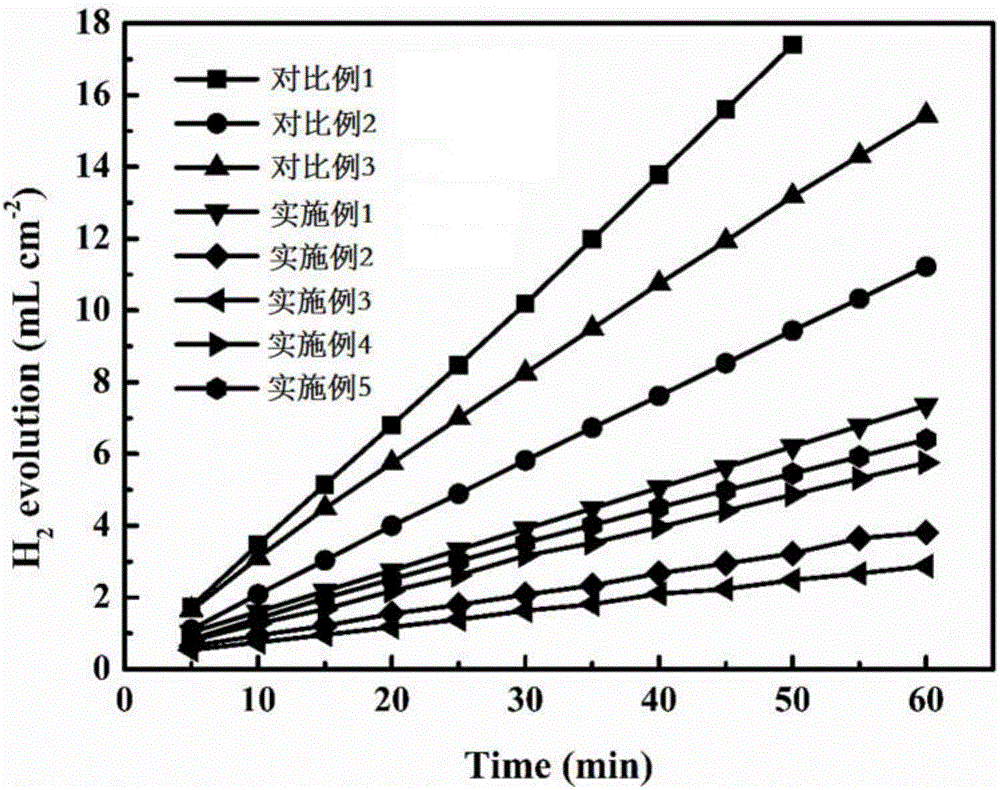

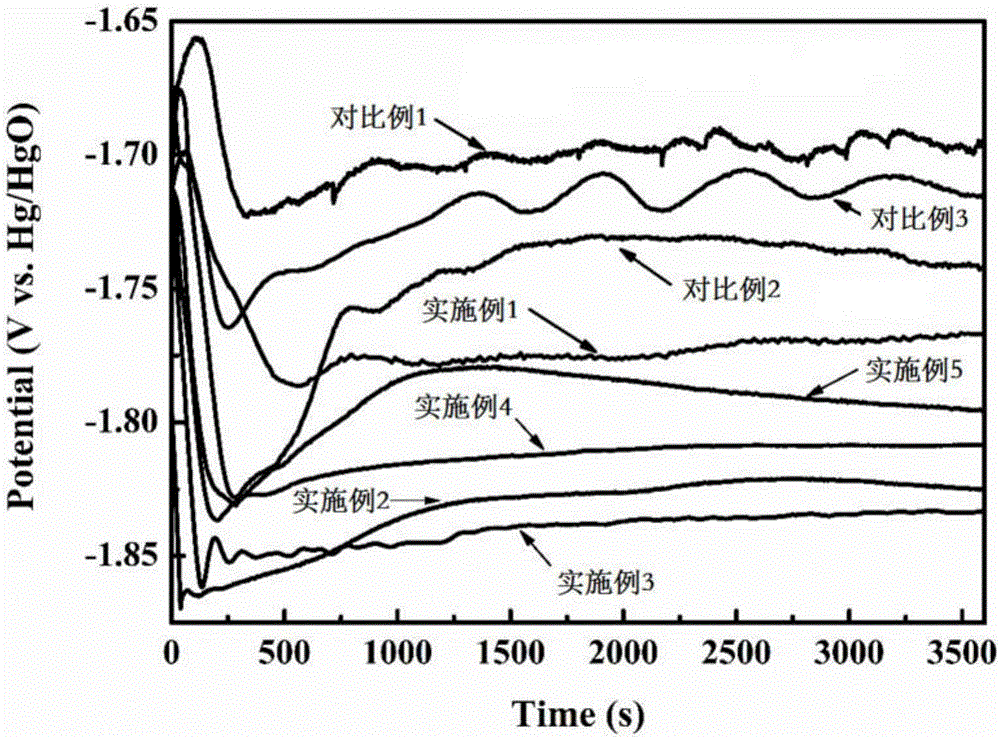

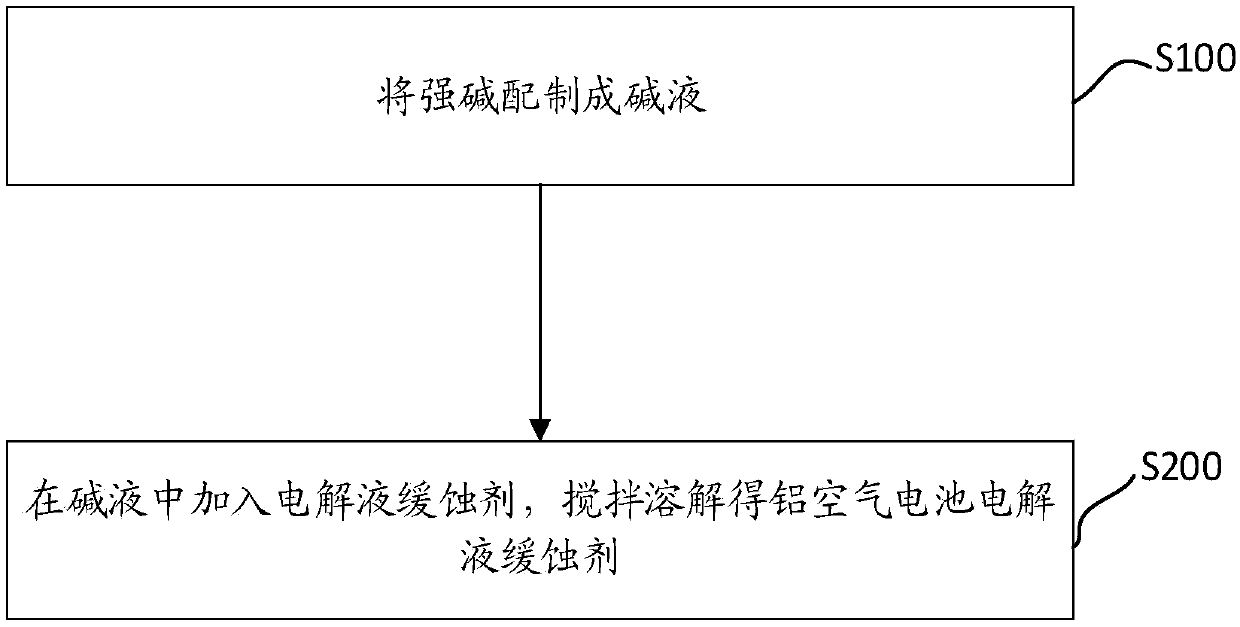

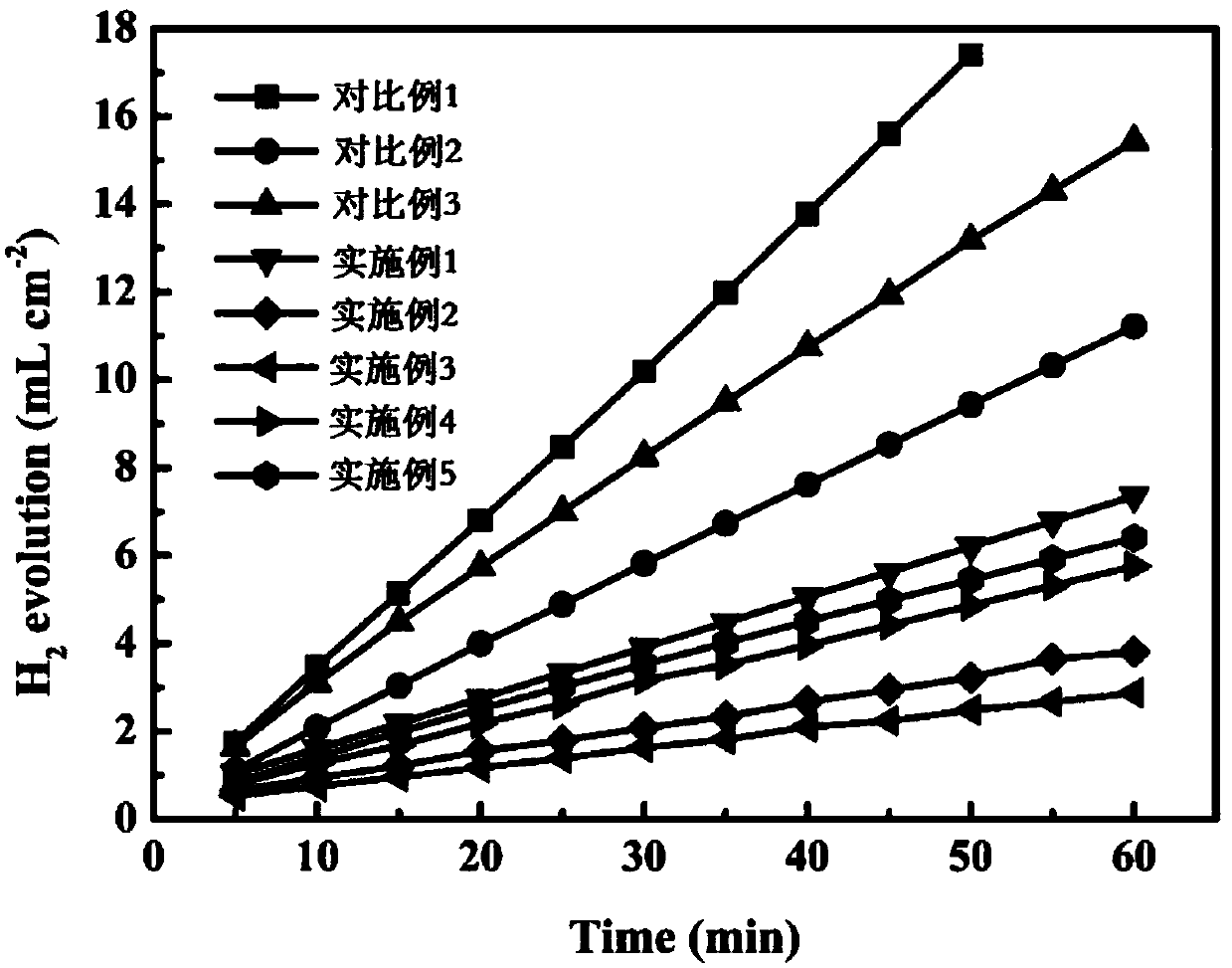

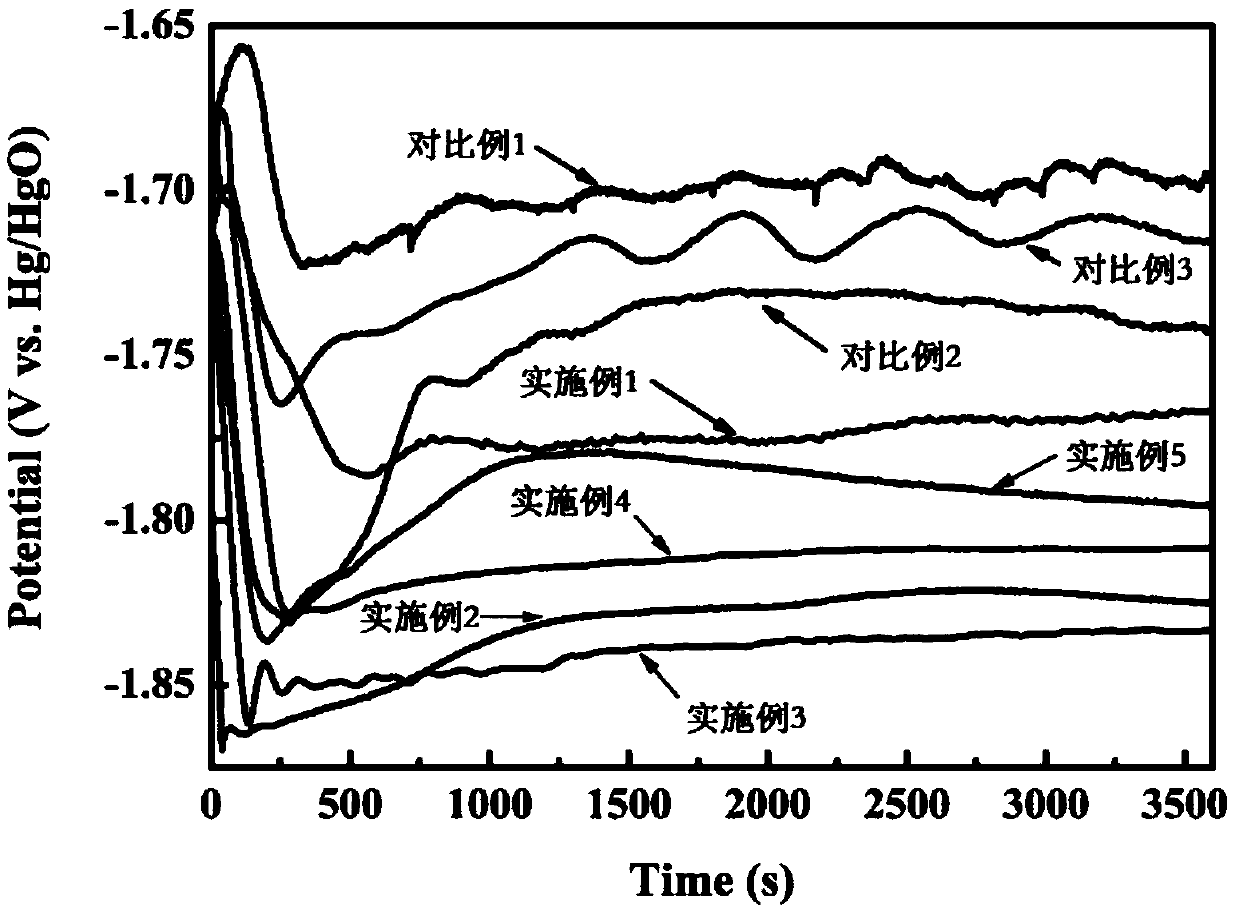

Electrolyte corrosion inhibitor, aluminum-air battery electrolyte and preparation method of aluminum-air battery electrolyte

InactiveCN105870545AGood corrosion inhibition effectFacilitate depositionFuel and primary cellsBenzotriazoleManganate

The invention relates to an electrolyte corrosion inhibitor, an aluminum-air battery electrolyte and a preparation method of the aluminum-air battery electrolyte. The electrolyte corrosion inhibitor mainly comprises an inorganic phase type corrosion inhibitor and an organic adsorption type corrosion inhibitor, wherein the inorganic phase type corrosion inhibitor is selected from at least one of zinc acetate, manganate and scandium nitrate; the organic adsorption type corrosion inhibitor is selected from at least one of benzotriazole, a natural amino acid and a cationic surfactant; and the molar ratio of the inorganic phase type corrosion inhibitor and the organic adsorption type corrosion inhibitor is (1-5,000) to (1-1,000). The electrolyte corrosion inhibitor is prepared on the basis of the property of an electrolyte solution, has the advantages of the phase type corrosion inhibitor and the adsorption type corrosion inhibitor, and is a multifunctional additive with good overall performance.

Owner:CENT SOUTH UNIV

Process using water tolerant Lewis acids in catalytic hydration of alkylene oxides to alkylene glycols

InactiveUS6916963B2Oxygen-containing compound preparationOrganic compound preparationRare earthTriflic acid

Water tolerant Lewis acids are used in a process for the preparation of alkylene glycols by catalytic hydration of the corresponding alkylene oxide. The water tolerant Lewis acids can be a metal salt of a non-coordinating or weakly coordinating anion and a Group IIIB, rare earth or lanthanide, actinide or Group IVB cation. Optionally, carbon oxide may also be present. Examples of such water tolerant Lewis acids are scandium triflate, europium triflate, hafnium triflate, yttrium triflate, lanthanum triflate and ytterbium triflate. The catalyst may contain a coordinating anion instead, examples of which are scandium sulfate [Sc2(SO4)3], scandium chloride [ScCl3], scandium acetate [Sc(OAc)3] and scandium nitrate [Sc(NO3)3]. The catalysts may also contain both a non-coordinating or weakly coordinating anion and a coordinating anion, examples of which are scandium triflate sulfate [Sc(CF3SO3) (SO4)], scandium triflate chloride [Sc(CF3SO3)2Cl], scandium triflate acetate [Sc(CF3SO3)2(OAc)] and scandium triflate nitrate [Sc(CF3SO3)2(NO3)].

Owner:SAUDI BASIC IND CORP SA

Chestnut shell active carbon and preparation method thereof

InactiveCN103551109AWell-developed pore structureWell-developed structureOther chemical processesCerium nitrateHazardous substance

Chestnut shell active carbon is prepared by the following raw materials by weight: 120-140 parts of chestnut shell, 3-5 parts of zinc chloride, 4-6 parts of Arabic gum, 4-6 parts of periston, 25-30 parts of bentonite, 10-15 parts of alumina, 20-25 parts of pumice, 2-4 parts of lanthanum chloride, 2-4 parts of cerium chloride, 2-4 parts of scandium chloride, 2-4 parts of yttrium chloride, 2-4 parts of praseodymium chloride, 1-3 parts of lanthanum nitrate, 1-3 parts of cerium nitrate, 1-2 parts of scandium nitrate, 1-2 parts of yttrium nitrate, 1-2 parts of praseodymium nitrate, 4-5 parts of modified diatomite, and a proper amount of water. Chestnut shell is used as a raw material, so as that the active carbon has advantages of developed aperture structure, big specific surface area, high adsorption speed, and good adsorption capability on various solutes and dissociation gases; lanthanum chloride is used for activation so as to form active carbon, which has big gaps and strong adsorption capability, is suitable for absorbing organic matters in air and water and removing harmful substances like formaldehyde, is low in cost, and is suitable for industrialization production.

Owner:BENGBU PIONEER FILTER

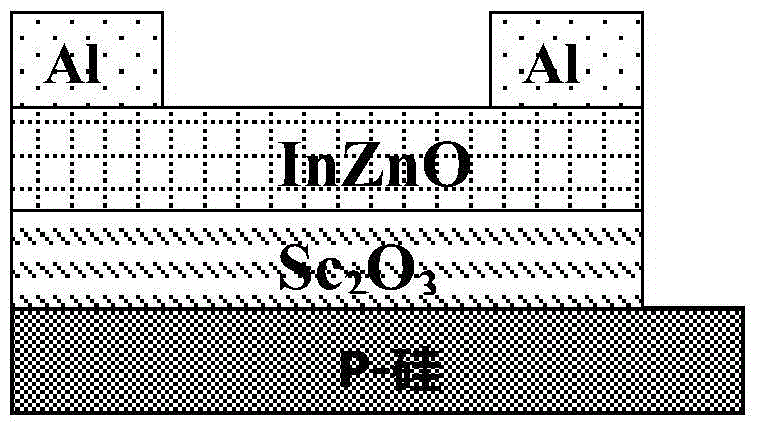

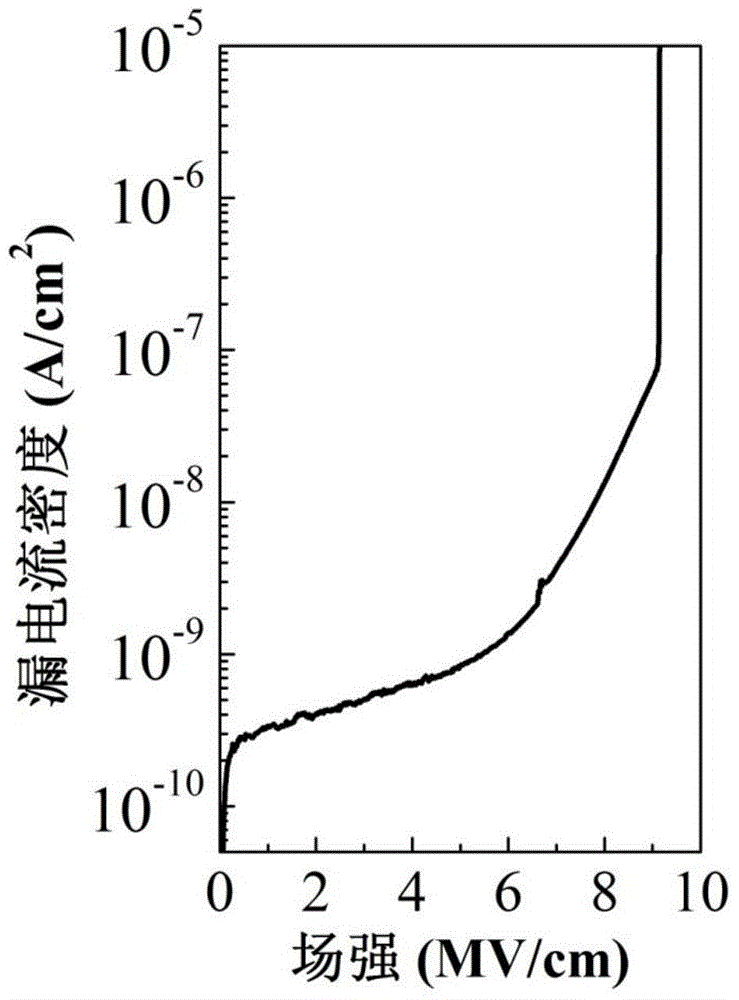

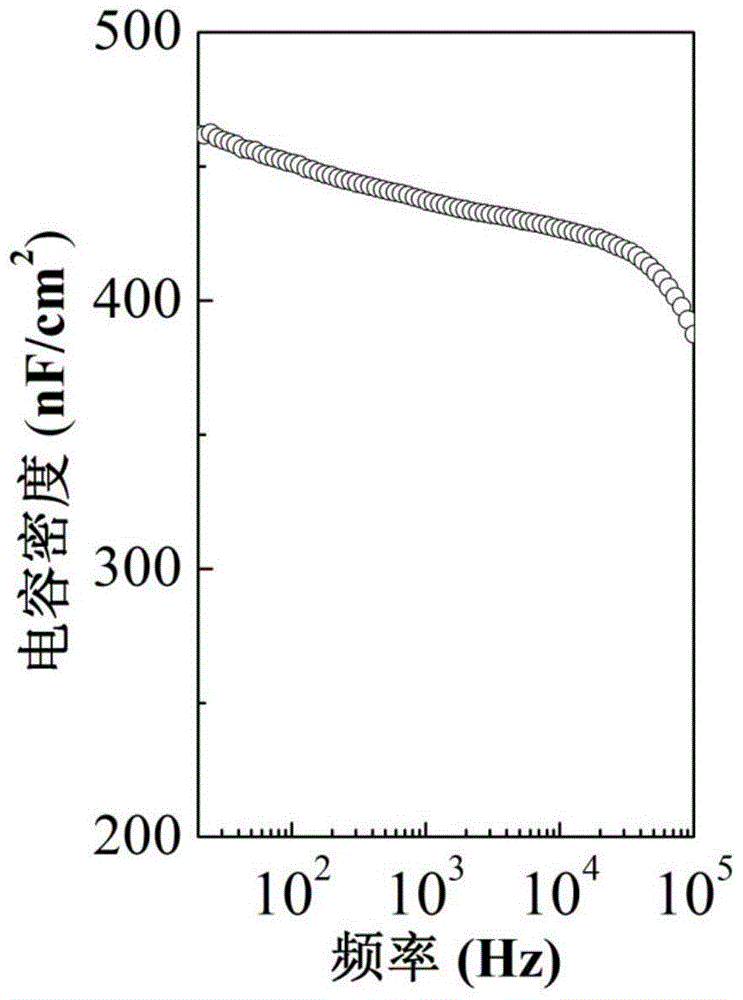

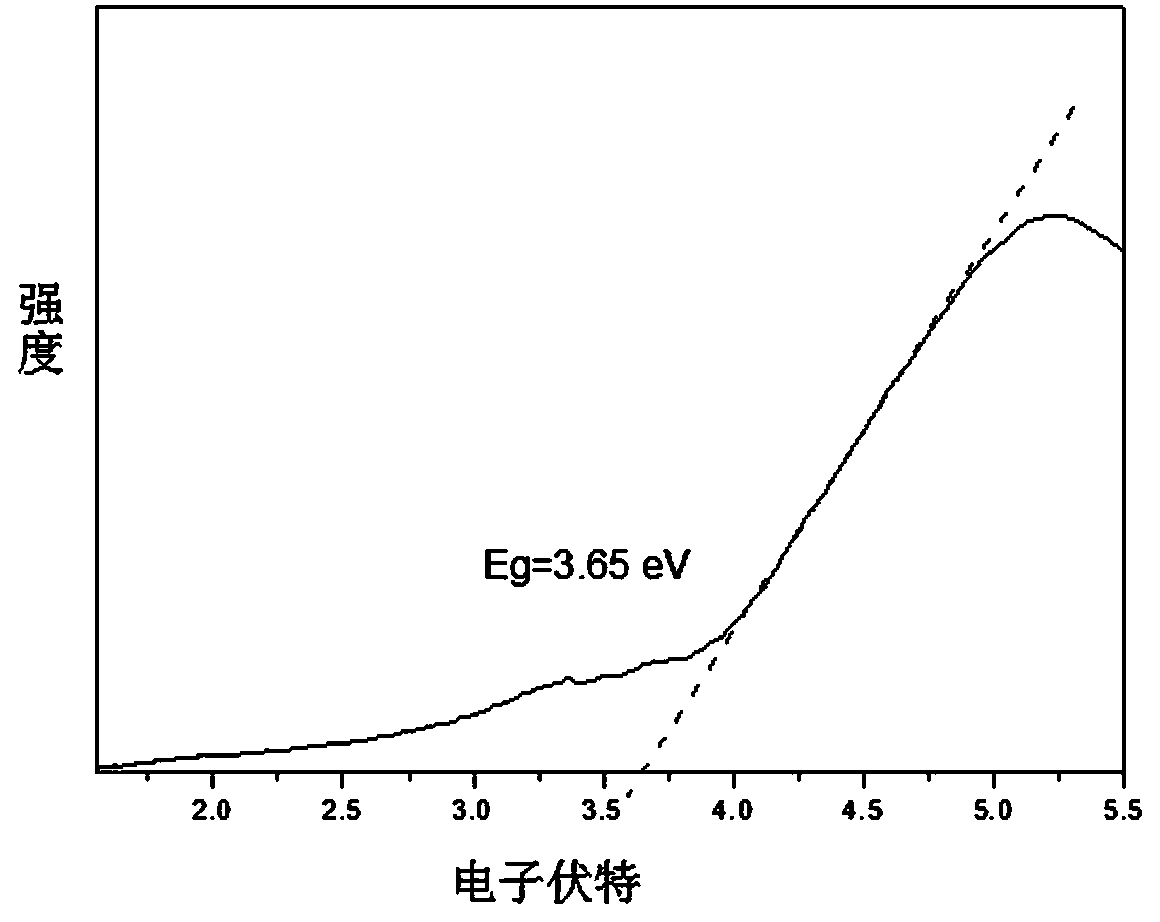

Method for preparing thin-film transistor based on scandia high-k dielectric layer

InactiveCN104934327AImprove transmittanceMeet size requirementsSemiconductor/solid-state device manufacturingSemiconductor devicesEvaporationZinc nitrate

The invention belongs to the technical field of semiconductor thin film transistor preparation technology and relates to a method for preparing a thin-film transistor based on a scandia high-k dielectric layer. According to the method, firstly, scandium nitrate is dissolved in de-ionized water and the obtained solution is stirred to form a precursor solution. The precursor solution is applied onto the cleaned surface of a low-resistance silicon substrate through the spin-coating process and the spin-coating thickness is 5-10 nm. After that, a thin film generated through the spin-coating process is baked and annealed to obtain a Sc2O3 film sample. Then, the zinc nitrate and the indium nitrate are respectively dissolved in de-ionized water and stirred to form an IZO aqueous solution. The IZO aqueous solution is applied onto the surface of the Sc2O3 film sample through the spin-coating process. After the spin-coating process, the film sample is cured and annealed at a low temperature to obtain an IZO channel layer. Finally, a metal source and a drain electrode are prepared on the IZO channel layer by means of a stainless steel mask through the vacuum thermal-evaporation process, so that a thin-film transistor can be obtained. According to the overall technical scheme of the invention, the method has the advantages of low cost, simple process, reliable principle, good product performance, environment-friendly preparation and broad application prospect. By utilizing the method, the large-area preparation of high-performance thin-film transistors is realized.

Owner:QINGDAO UNIV

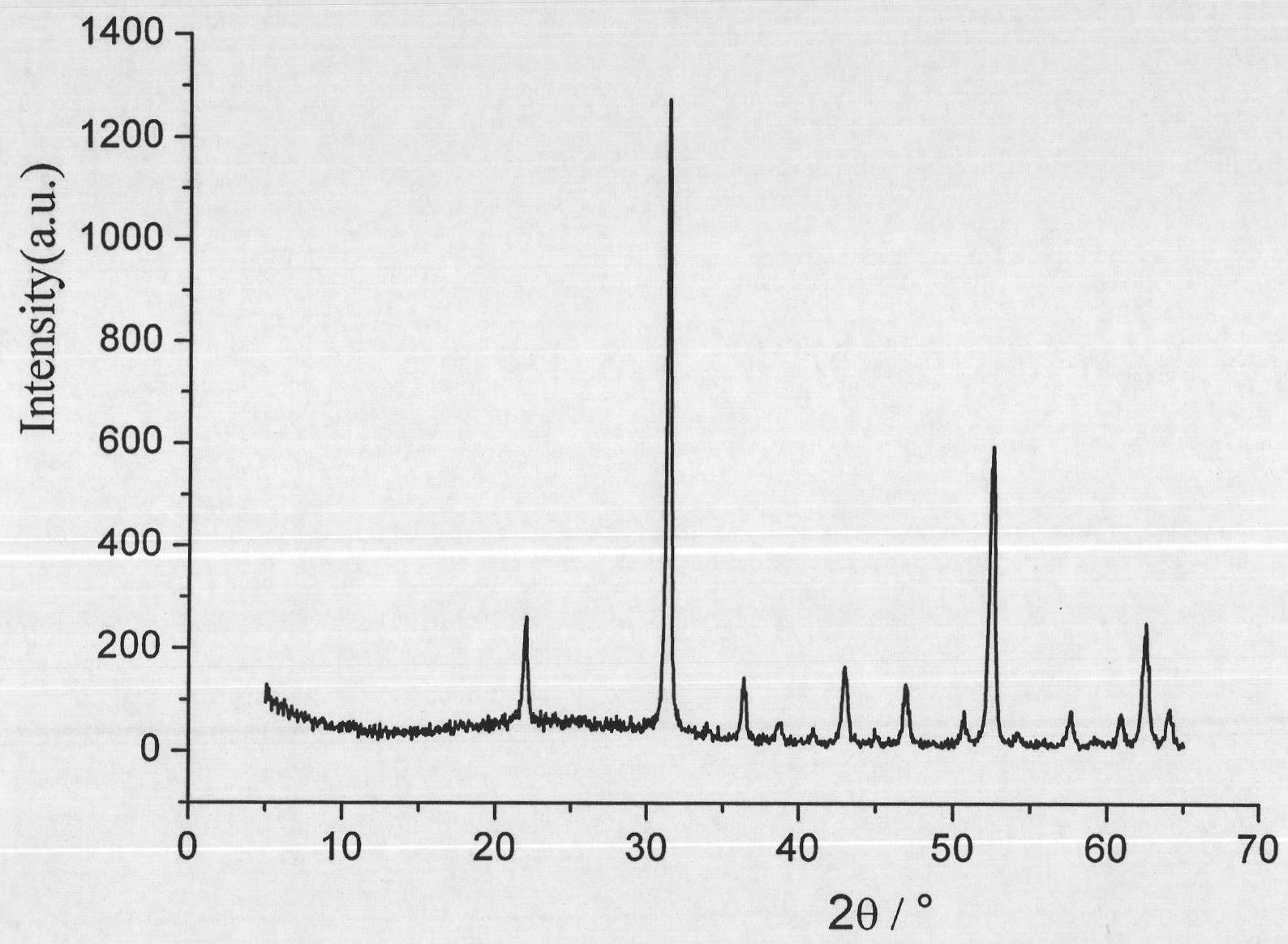

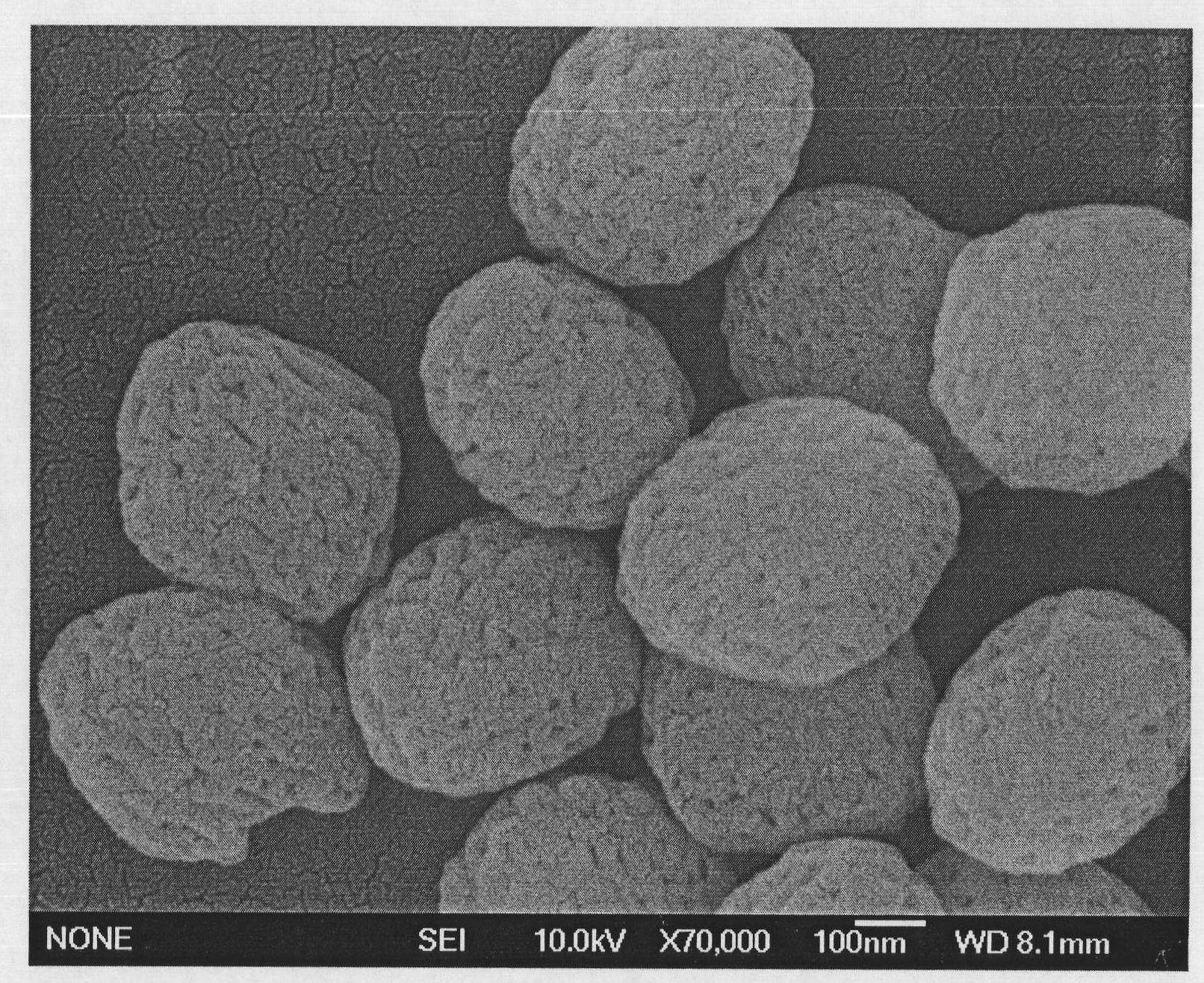

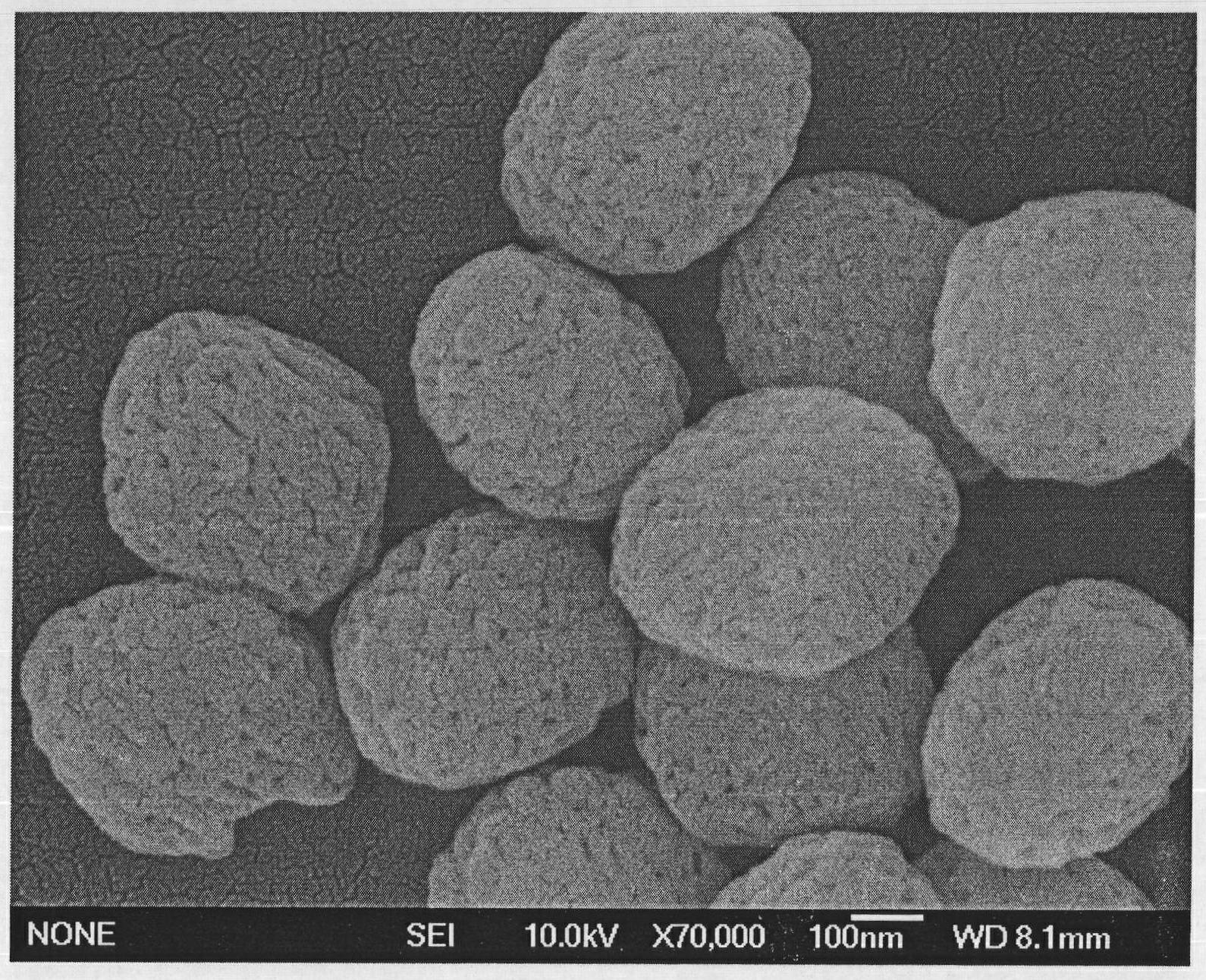

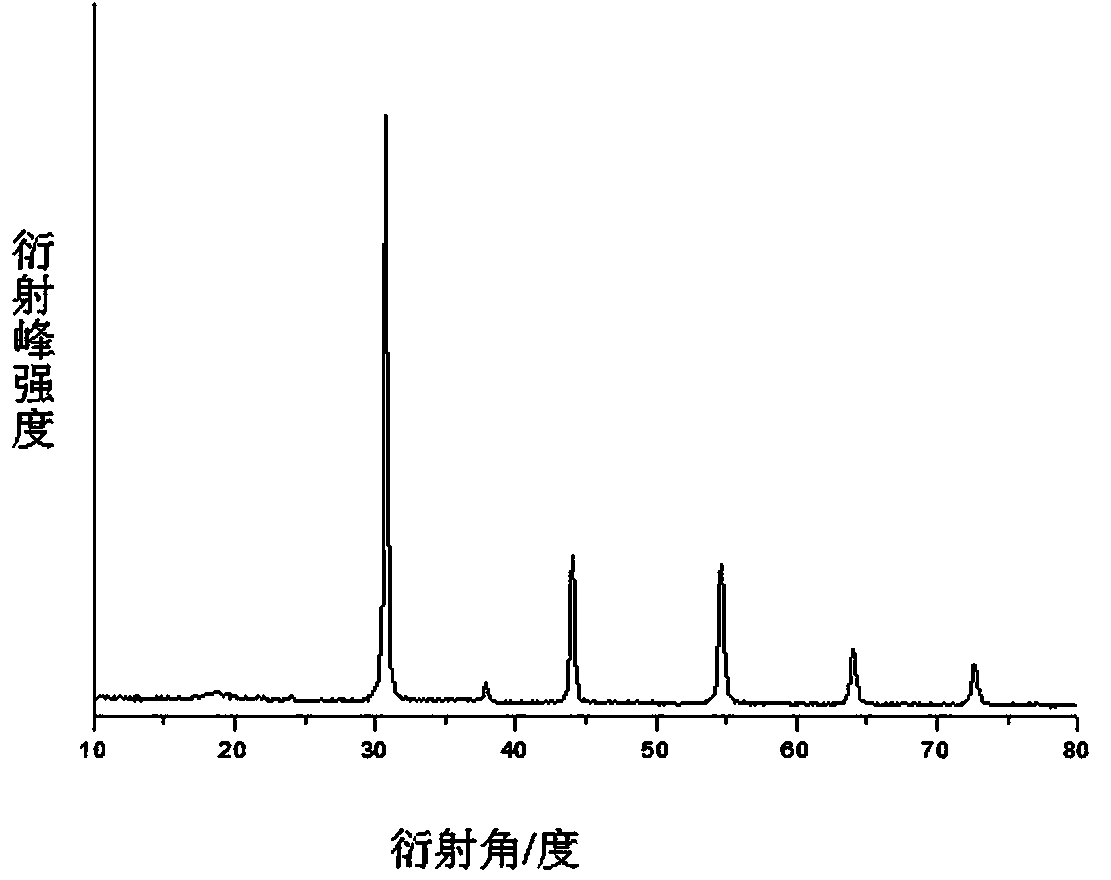

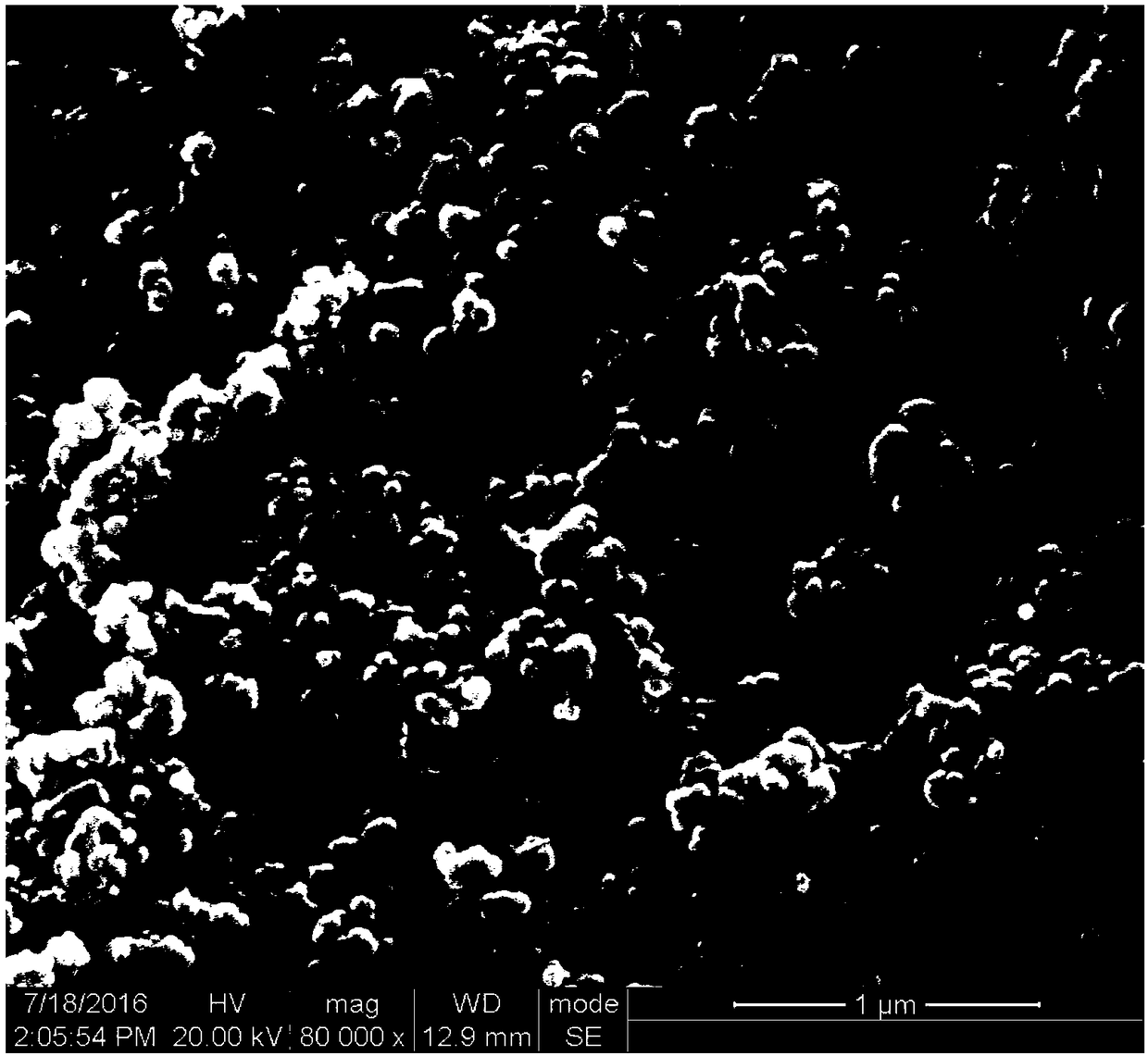

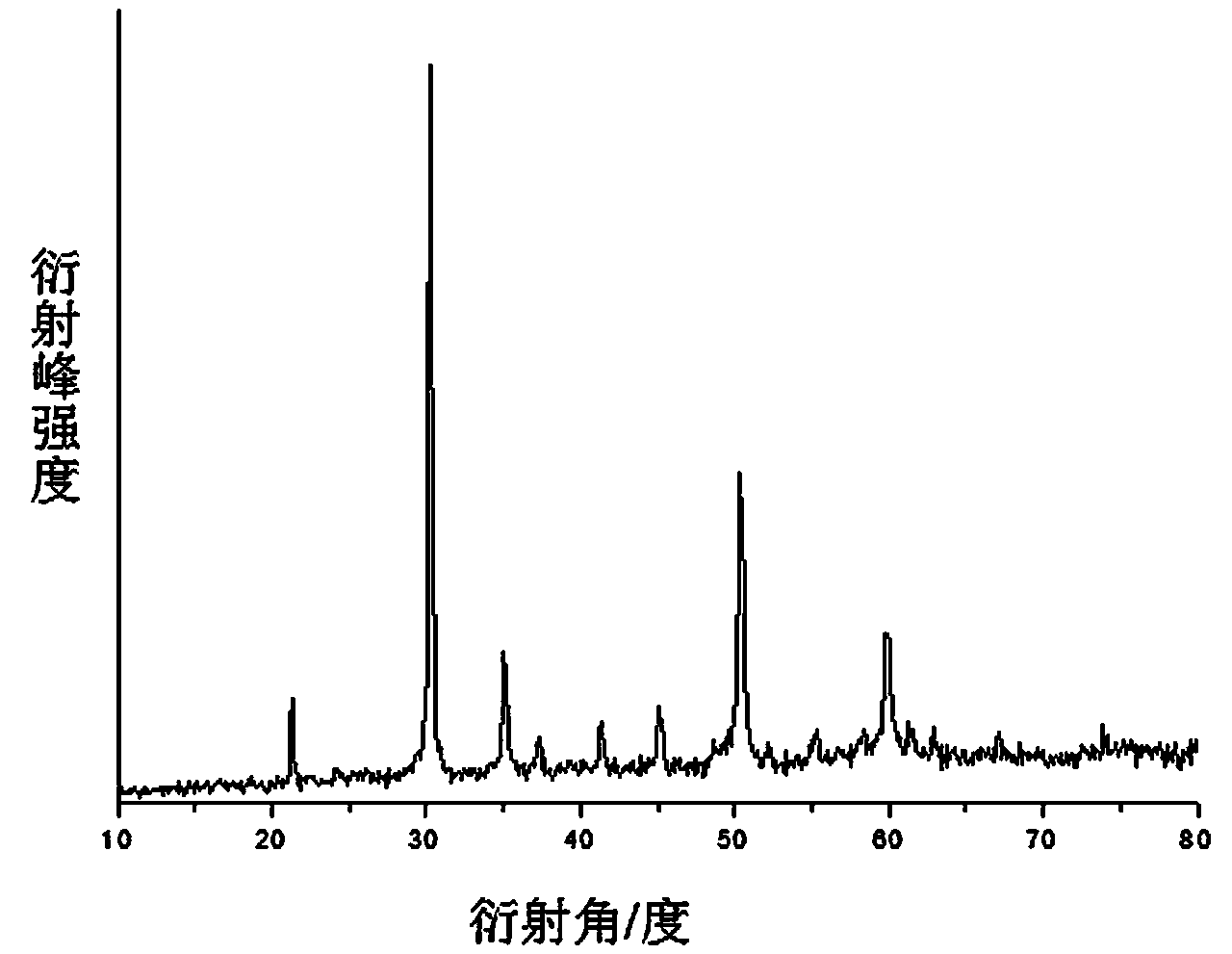

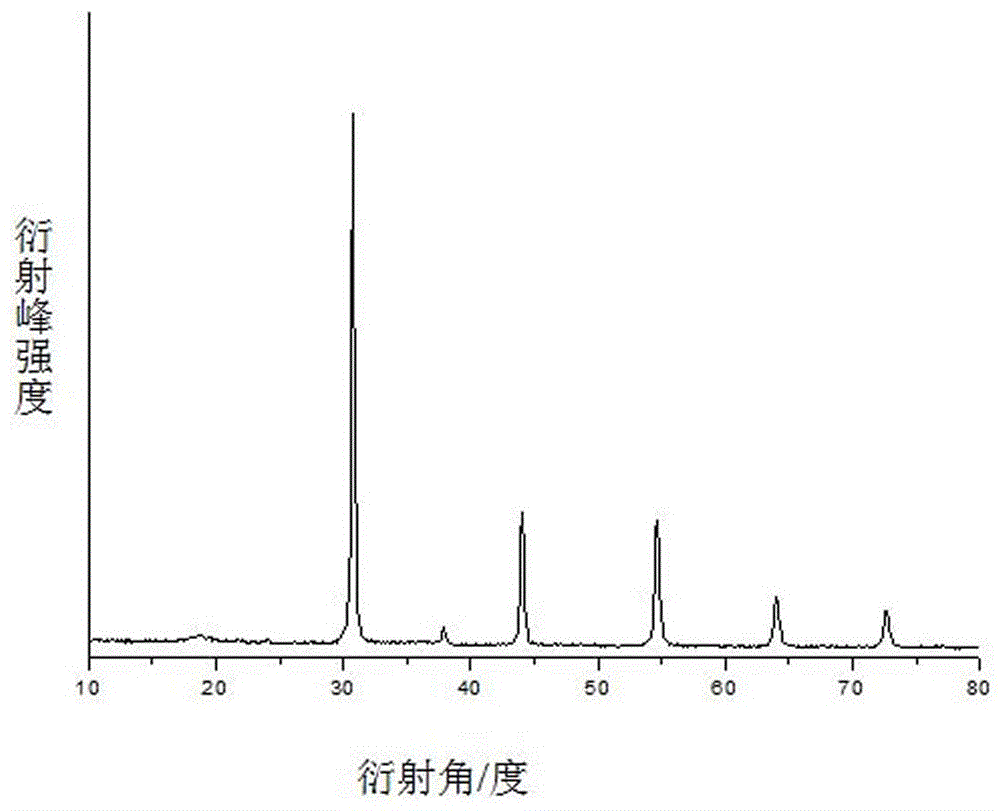

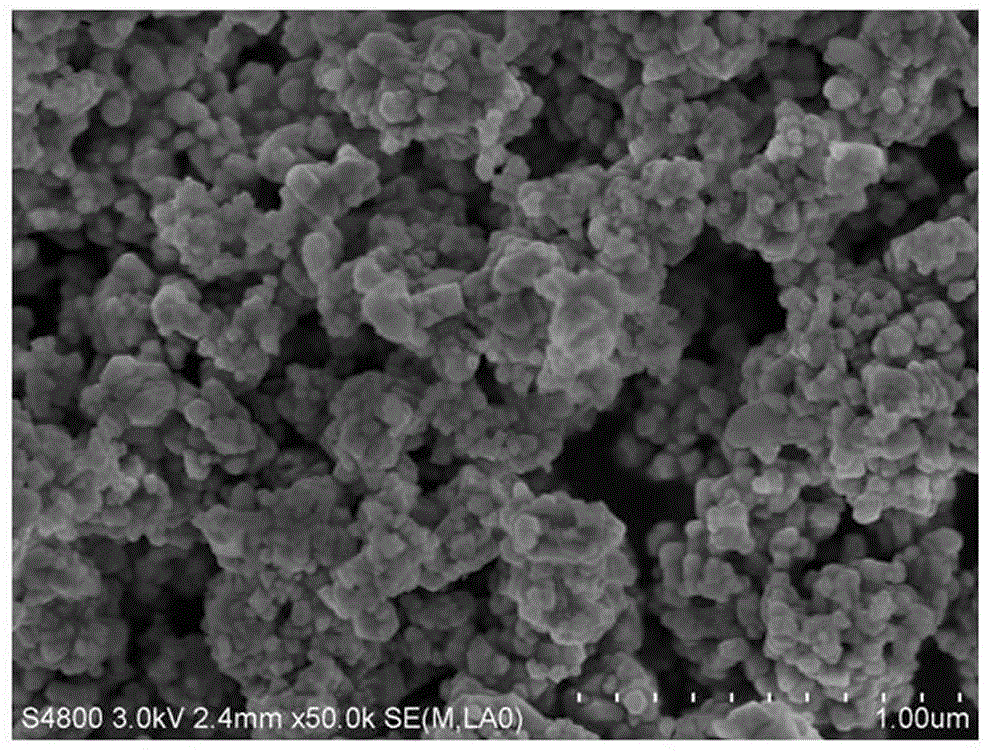

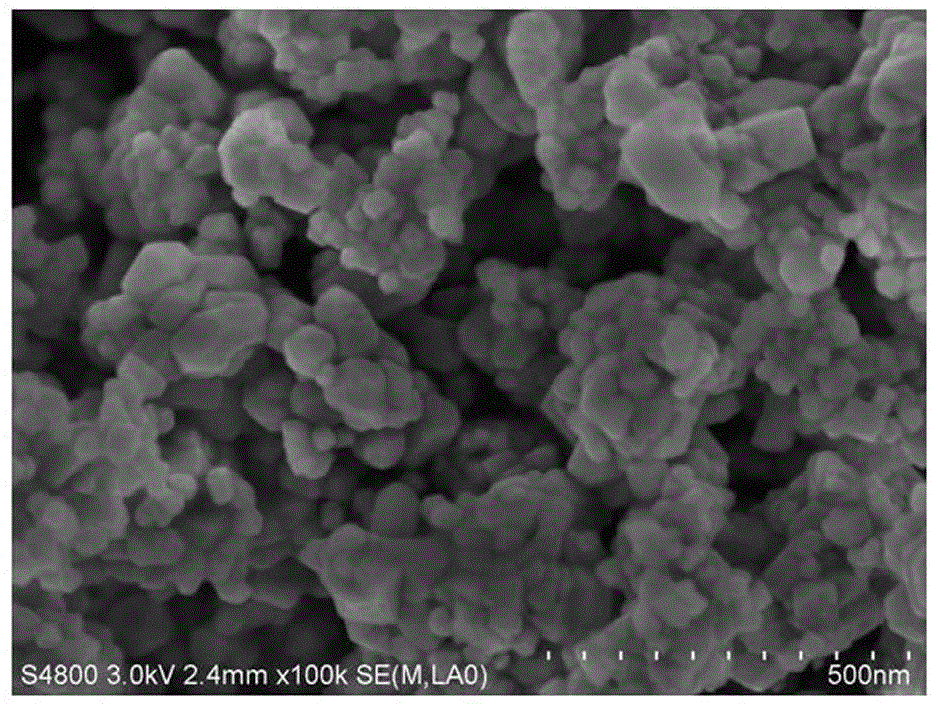

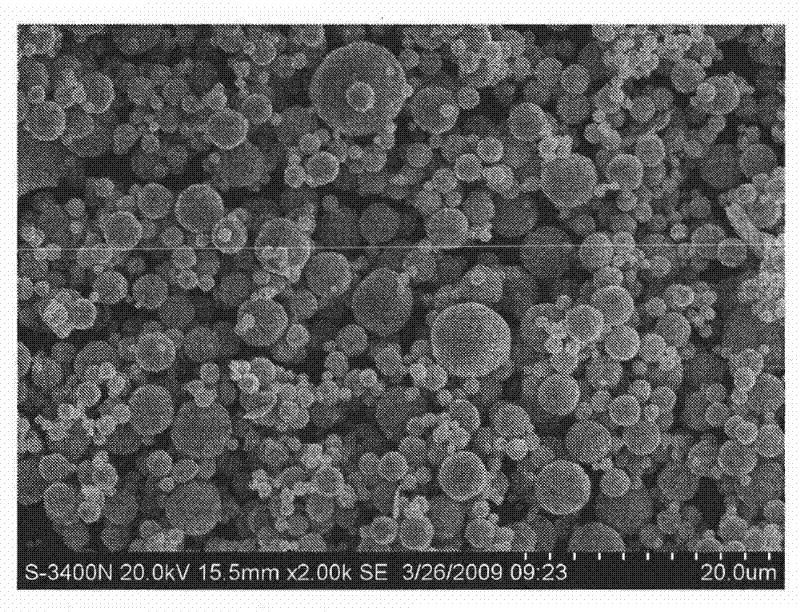

Porous cubic phase scandium oxide powder and preparation method thereof

ActiveCN102070177APorousNarrow particle size distributionRare earth metal compoundsSodium acetateDispersity

The invention provides porous cubic phase scandium oxide powder and a preparation method thereof. In the invention, hexamine is used as a precipitator and added to a scandium nitrate solution to obtain hydroxyl scandium oxide precipitate by utilizing a uniform precipitating method in the presence of sodium acetate and polyethylene glycol 1000, and then the precipitate is collected and calcined at high temperature to prepare and obtain porous walnut-shaped cubic phase scandium oxide powder with uniform size and good dispersity. The multi-hole cubic phase scandium oxide powder has the characteristics of porosity and narrow particle size distribution and also has better property in the application of gas sensing and catalysis and important application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

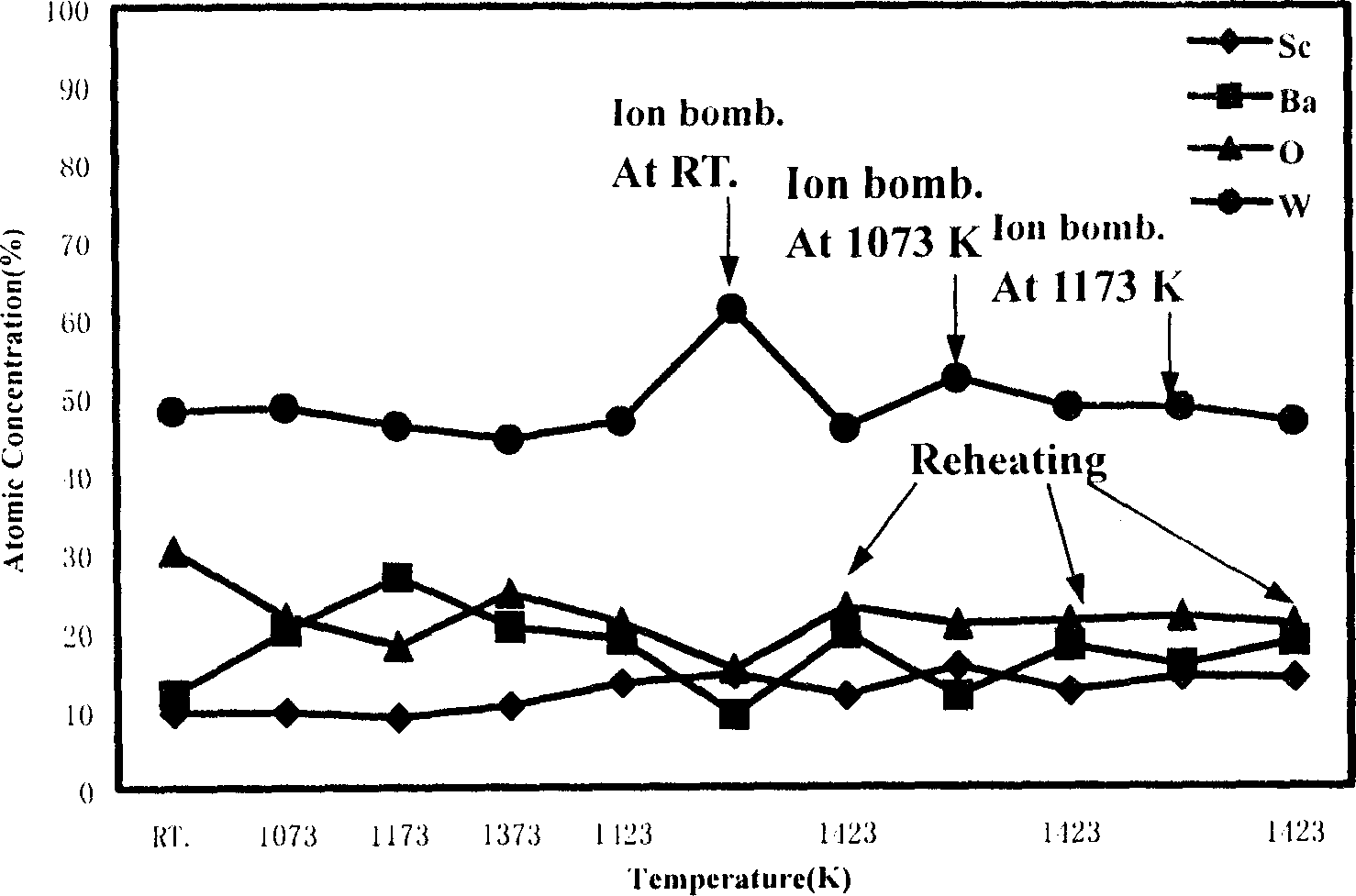

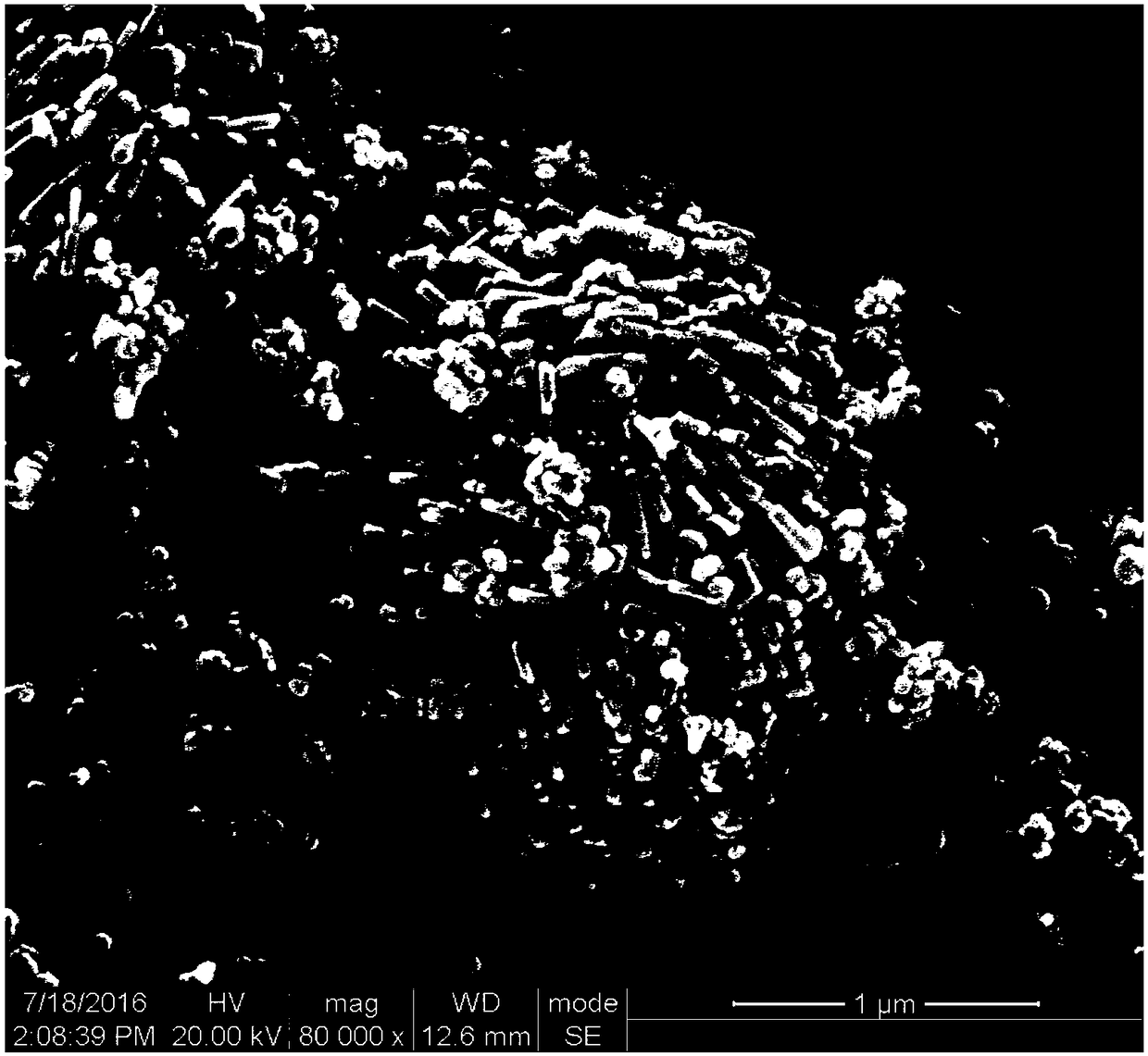

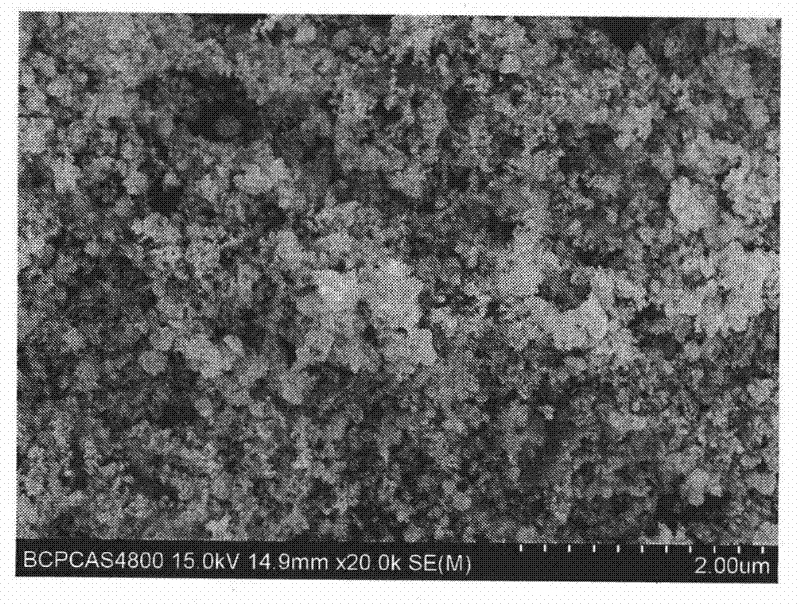

Method of manufacturing a pressed scandate dispenser cathode

InactiveUS20080025864A1Reduce energy costsImprove launch performanceOther chemical processesTungsten oxides/hydroxidesCross-linkWater baths

In a method of manufacturing a pressed scandate dispenser cathode, firstly, scandium nitrate, barium nitrate, calcium nitrate, aluminum nitrate and ammonium metatungstate (AMT) are dissolved in de-ionized water, respectively, and then mixed with a solution of a cross-link agent such as citric acid and H2O2. After water bathing, the mixed aqueous solution turns into gel, and the powders are obtained after the gel calcination. Secondly, the calcined powders are reduced by hydrogen. Finally, the reduced powders are pressed into shapes and then sintered in the furnace with the atmosphere of hydrogen or by Spark Plasma Sintering (SPS 3.202-MK-V) in vacuum.

Owner:BEIJING UNIV OF TECH

Method of manufacturing a pressed scandate dispenser cathode

InactiveUS7722804B2Improve launch performanceImprove electron emission performanceOther chemical processesMolybdeum compoundsCross-linkMetallurgy

In a method of manufacturing a pressed scandate dispenser cathode, firstly, scandium nitrate, barium nitrate, calcium nitrate, aluminum nitrate and ammonium metatungstate (AMT) are dissolved in de-ionized water, respectively, and then mixed with a solution of a cross-link agent such as citric acid and H2O2. After water bathing, the mixed aqueous solution turns into gel, and the powders are obtained after the gel calcination. Secondly, the calcined powders are reduced by hydrogen. Finally, the reduced powders are pressed into shapes and then sintered in the furnace with the atmosphere of hydrogen or by Spark Plasma Sintering (SPS 3.202-MK-V) in vacuum.

Owner:BEIJING UNIV OF TECH

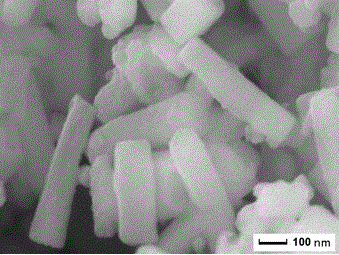

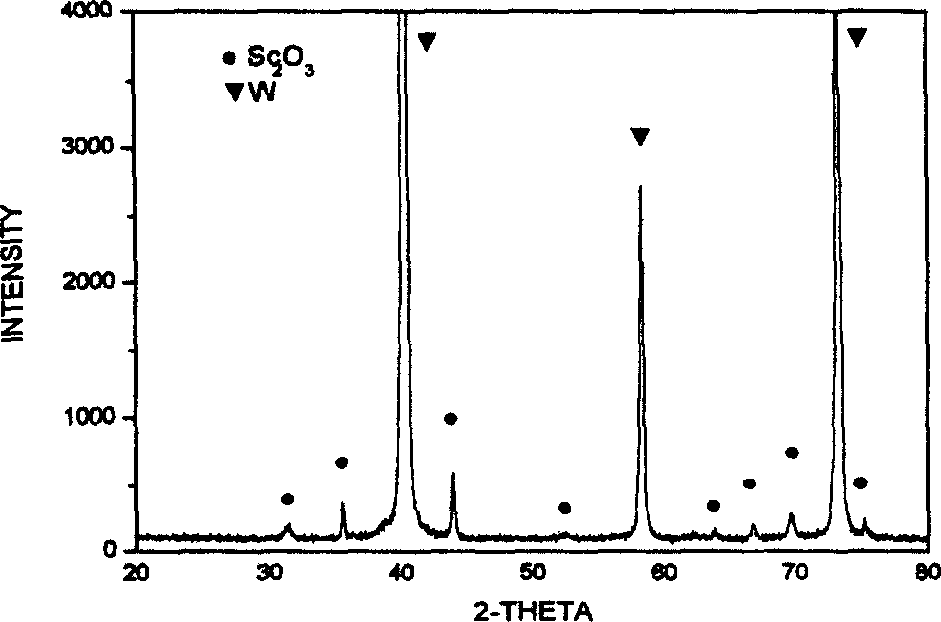

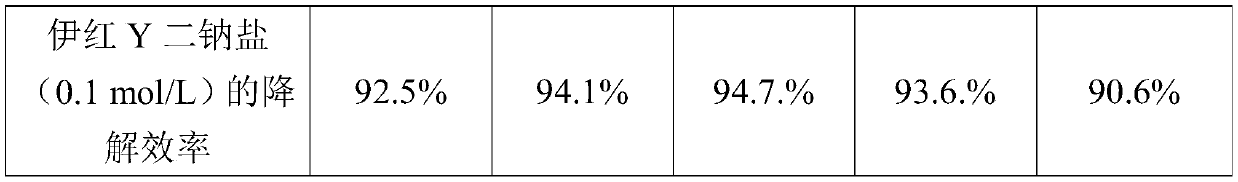

Preparation method for rod-like Sc2W3O12 negative thermal expansion material

ActiveCN102745747ASimple procedureEasy to operateNanotechnologyTungsten compoundsThermal dilatationPhysical chemistry

The present invention relates to a negative thermal expansion material, and particularly to a preparation method for a rod-like Sc2W3O12 negative thermal expansion material. According to the present invention, a hydrothermal method is adopted to synthesize a negative thermal expansion compound Sc2W3O12 at a low temperature, wherein raw materials comprise Sc(NO3)3.xH2O (analytically pure grade), H40N10O41W12.xH2O (chemically pure grade), and HNO3 (analytically pure grade). The preparation method comprises: respectively dissolving scandium nitrate and ammonium wolframate in deionized water according to a molar ratio of Sc<3+> to W<6+> of 2:3; adopting a double-addition method in a dropwise manner to mixing the resulting two solutions; adding a nitric acid solution to the resulting mixing solution to adjust the pH value to 3-5 while constantly stirring, and uniformly stirring at a temperature of 60-80 DEG C; transferring the resulting mixed solution to a reaction kettle with a polytetrafluoroethylene liner, carrying out sealing heating for 10-15 hours at a temperature of 150-180 DEG C; after completing the reaction, carrying out centrifugal dewatering by using a centrifuge, discarding the supernatant, repeatedly washing and centrifugating 3 times, and then drying at a temperature of 80-110 DEG C to obtain a precursor; placing the precursor in a muffle furnace, and heating at a temperature of 540-800 DEG C to obtain the final product Sc2W3O12. The method of the present invention has advantages of simple procedure, easy operation and easy industrialization.

Owner:JIANGSU UNIV

Method for preparing barium scandium tantalate powder

InactiveCN104386750ASimple process routeReduce manufacturing costTantalum compoundsCross-linkBarium salt

The invention discloses a method for preparing barium scandium tantalate powder. The method comprises the steps of thoroughly dissolving a barium salt, a tantalum salt, a scandium salt and different cross-linking agents, which serve as raw materials, into a methanol-water mixture solution, then, carrying out cross-linking reaction at a certain temperature, then, mixing with a molten salt, grinding, so as to thoroughly mix uniformly, carrying out high-temperature reaction, then, cooling to room temperature, and then, carrying out water washing and drying, thereby obtaining the barium scandium tantalate powder, wherein the barium salt is either or a mixture of barium chloride and barium nitrate, the tantalum salt is either or a mixture of tantalum pentachloride and pentaethoxy tantalum, the scandium salt is either or a mixture of scandium chloride and scandium nitrate, the cross-linking agents are either or a mixture of urea and citric acid, and the molten salt is a mixture of sodium chloride and barium chloride. The method has the advantages that the preparation procedures are simplified, the preparation cost is low, the pollution to an environment cannot be caused, industrialized large-scale preparation is facilitated, and the prepared product can be applied to the fields of ferroelectrics, photoelectricity, photocatalytic hydrogen generation, fuel cells and the like.

Owner:BOHAI UNIV

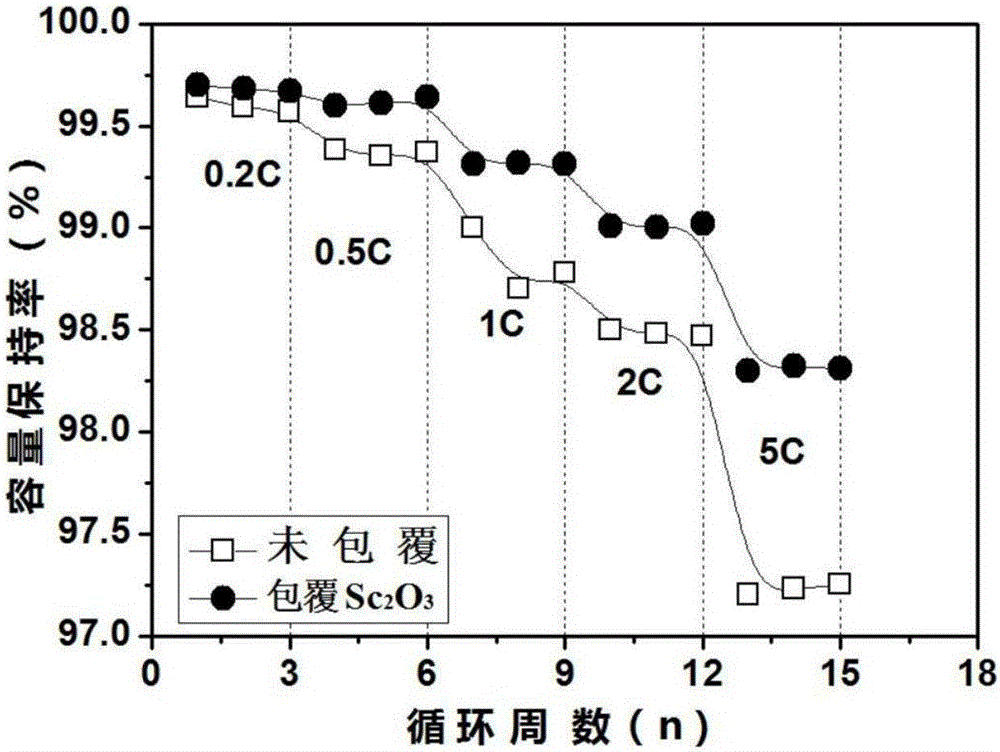

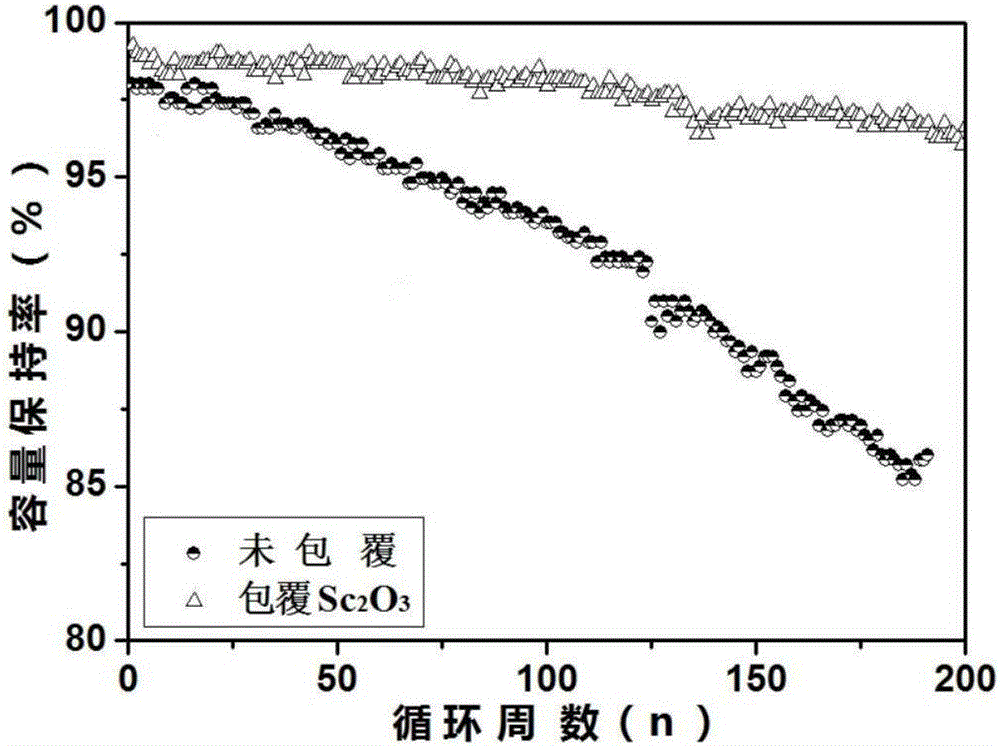

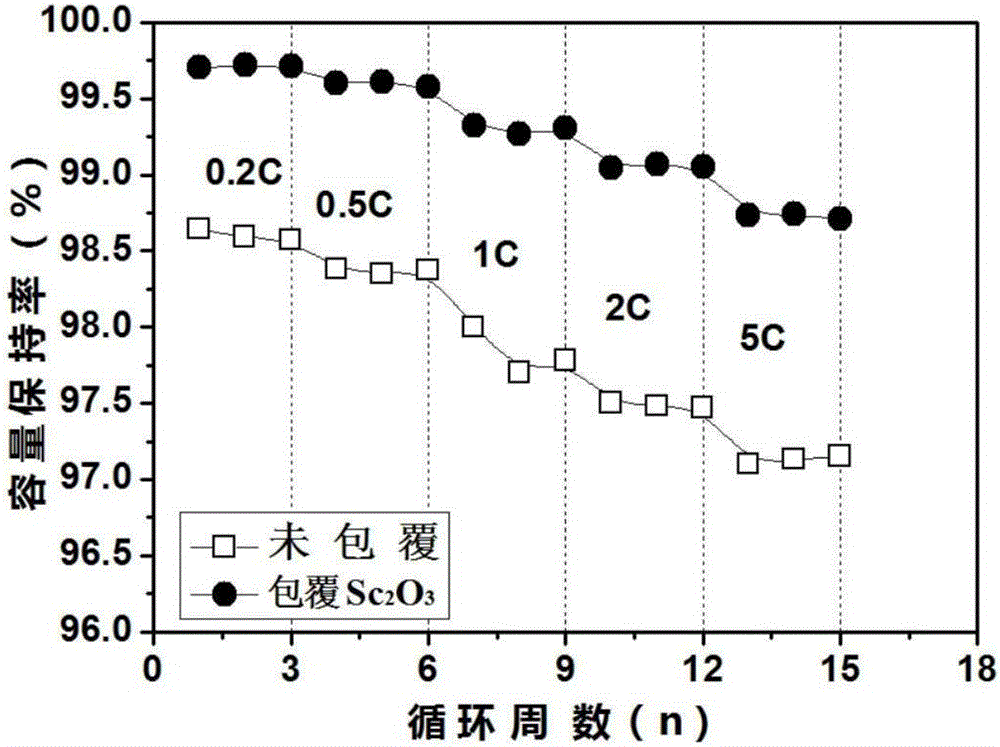

High-stability scandium oxide coated positive electrode material of manganese-based lithium ion battery and preparation method of positive electrode material

InactiveCN106129370AReduce interface resistanceReduce erosionCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a metal oxide coated positive electrode material of a manganese-based lithium ion battery and a preparation method of the positive electrode material. The preparation method comprises the following steps of weighing corresponding acetate of a metal element according to a ratio of substances corresponding to the metal element of the positive electrode material of the manganese-based lithium ion battery, adding an oxalic acid precipitant during stirring at a room temperature to obtain an oxalate precursor, and sintering the oxalate precursor to obtain the positive electrode material; weighing Sc(NO<3>)<3>.6H<2>O, dispersing positive electrode material powder in a scandium nitrate solution, stirring and drying the solution to obtain a precursor of a Sc<2>O<3> coated positive electrode material of the lithium ion battery; and performing thermal processing on the precursor of the Sc<2>O<3> coated positive electrode material of the lithium ion battery to obtain the Sc<2>O<3> coated positive electrode material of the manganese-based lithium ion battery. By the preparation method, the corrosion of an electrolyte to the positive electrode material is reduced, and higher cycle performance is achieved; moreover, a compact and uniform coating layer is formed on a surface of an active material, the consumption of lithium ions is reduced, and the capacity and the rate performance are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

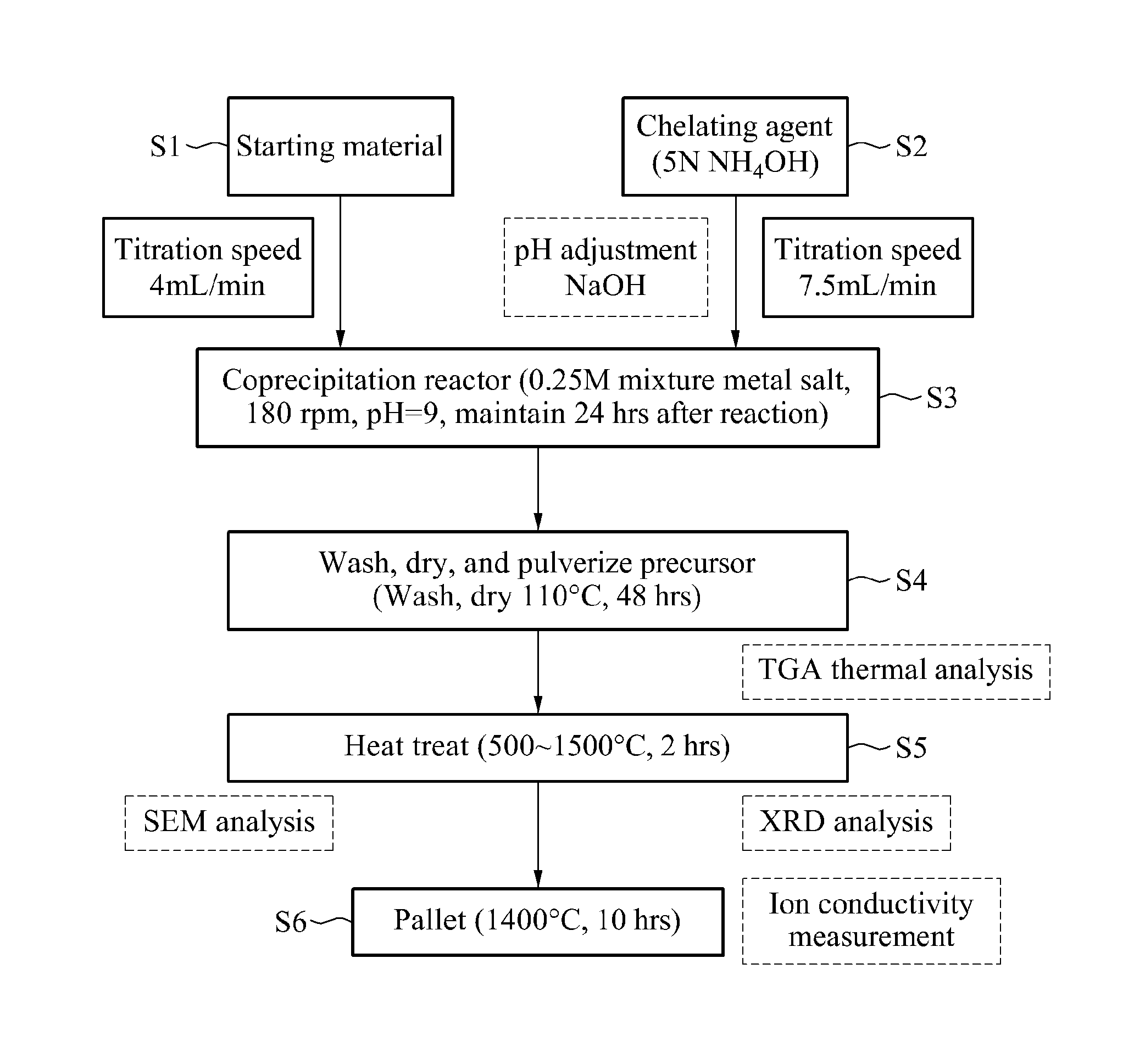

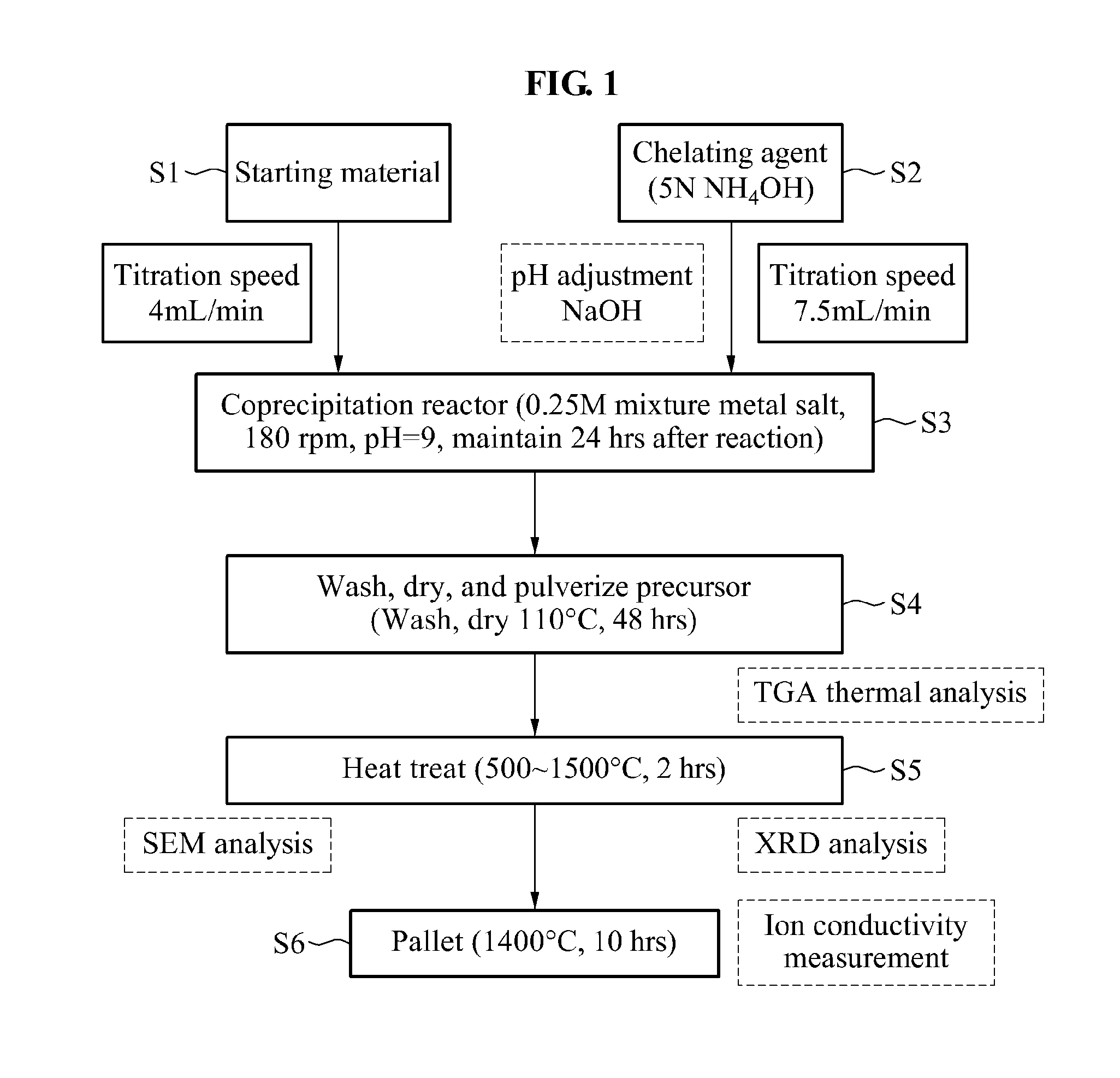

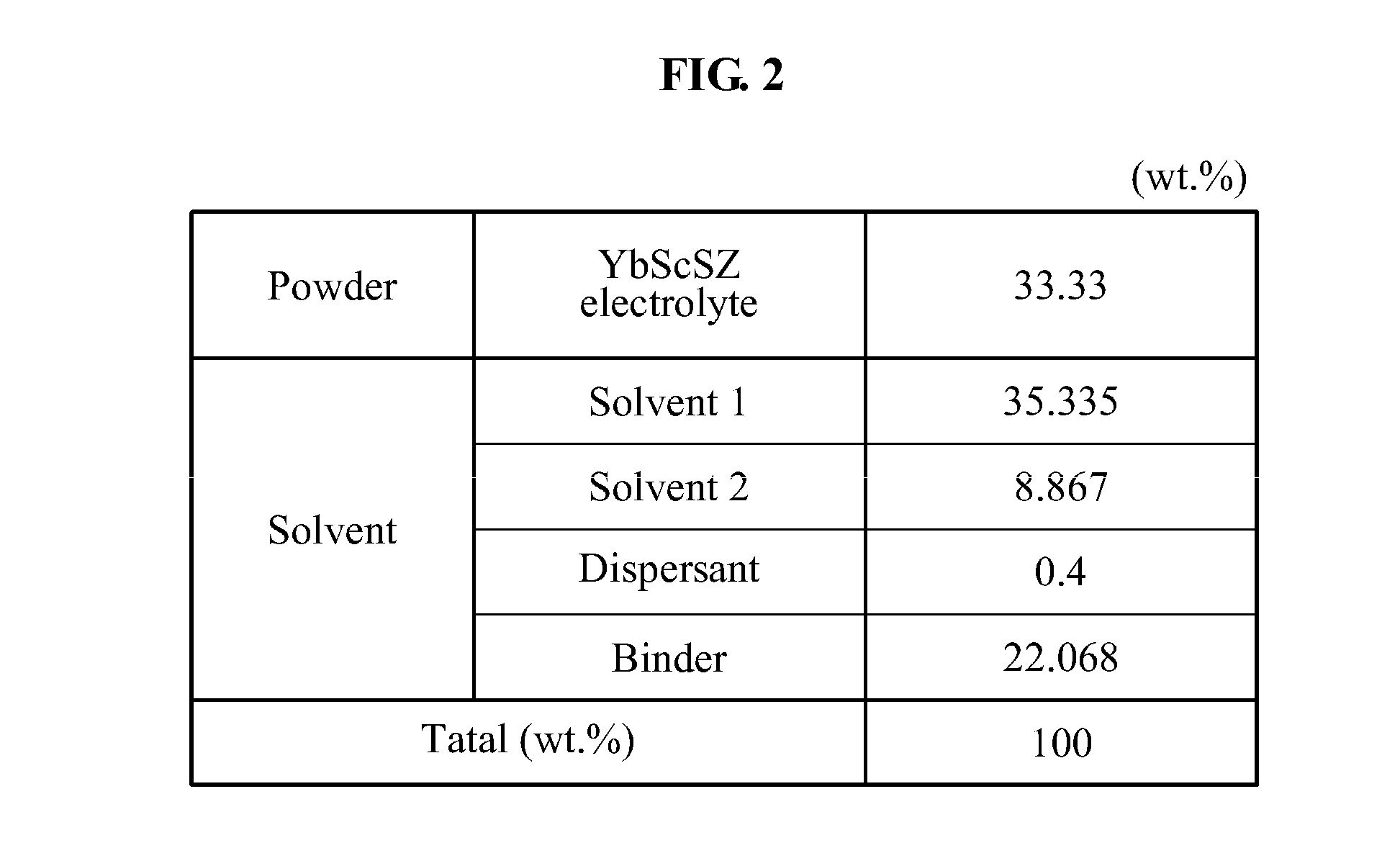

Method for preparing solid electrolyte for solid oxide fuel cell, and method for preparing unit cell

InactiveUS20160079623A1Low costImprove output performanceFinal product manufactureElectrolytesFuel cellsFiltration

Provided are a method for preparing a solid electrolyte material for a cheap solid oxide fuel cell capable of implementing high ion conductivity at a medium-low temperature of 800° C. or lower, and a method for preparing a unit cell of a solid oxide fuel cell by using the same. The method for preparing a solid electrolyte material for a solid oxide fuel cell comprises: providing a starting material comprising ytterbium nitrate [Yb(NO3)3.H2O], scandium nitrate [Sc(NO3)3.H2O] and zirconium oxychloride [ZrOCl2.H2O] in a ratio of 6:4:90 by mol; forming a mixture metal salt aqueous solution by dissolving the starting material; forming a precursor by mixing the mixture metal salt aqueous solution and a chelating agent and coprecipitating the obtained mixture; washing the precursor by providing ultrapure water multiple times; filtering the washed precursor by using a vacuum filtration apparatus; and forming a solid electrolyte powder by heat treating the filtered precursor.

Owner:KOREA INST OF IND TECH

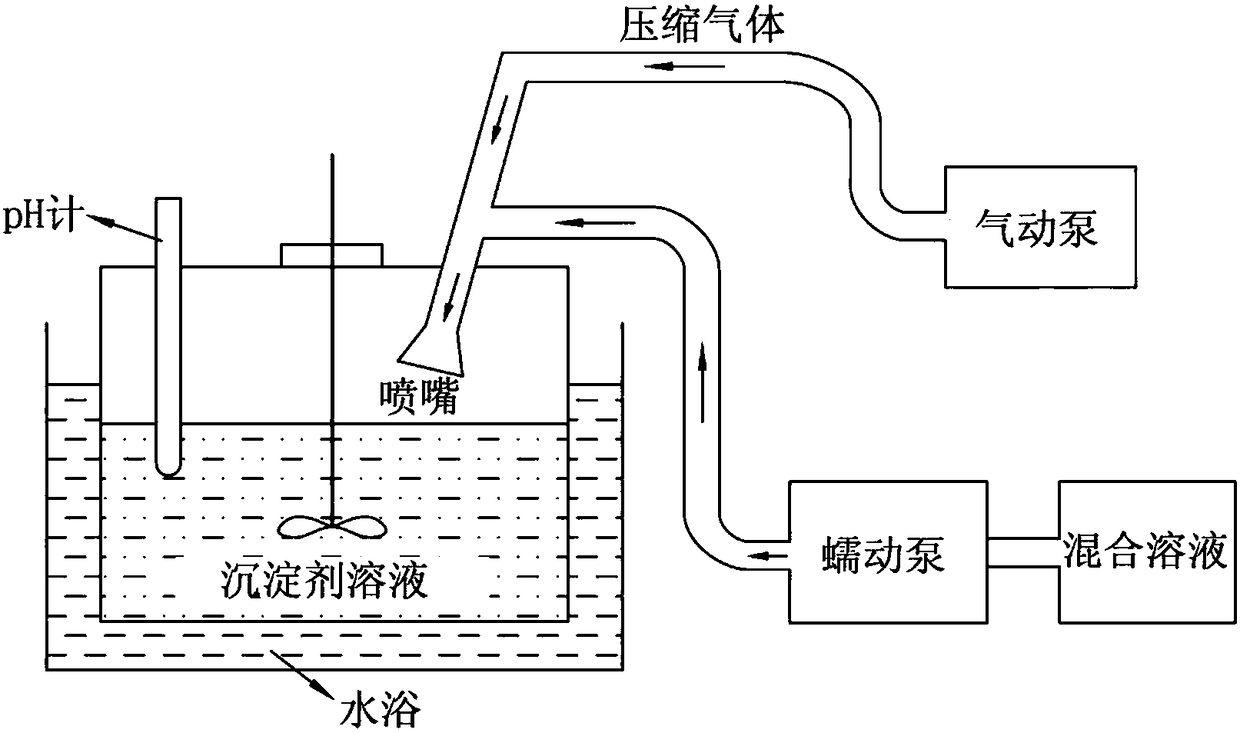

Rapid preparation method of Ho:Sc2O3 nano-crystal powder

ActiveCN108069453AIncrease the drop rateEvenly dispersedRare earth metal oxides/hydroxidesNanotechnologyPeristaltic pumpHolmium

The invention discloses a rapid preparation method of a Ho:Sc2O3 nano-crystal powder. The rapid preparation method of the Ho:Sc2O3 nano-crystal powder comprises the steps of, firstly, preparing cationsalt solution, specifically, dissolving scandium oxide and holmium oxide into nitric acid to obtain scandium oxide solution and holmium oxide solution, uniformly mixing the scandium oxide solution and the holmium oxide solution to obtain the cation salt solution; secondly, preparing precipitant solution, specifically, preparing ammonium bicarbonate solution and at the meantime, adding in ammoniumhydroxide, then adding in ammonium sulfate dispersant to obtain the precipitant solution; thirdly, performing atomizing and precipitation processes, specifically, through a peristaltic pump, sprayingthe precipitant solution into the cation salt solution inside an ultrasonic device via a pneumatic atomizing nozzle to obtain a Ho:Sc2O3 precipitation precursor; fourthly, performing precipitation, filtering and washing processes; fifthly, calcinating the precipitation precursor to obtain the Ho:Sc2O3 nano-crystal powder. The prepared Ho:Sc2O3 nano-crystal powder is high in purity and dispersionand narrow in size distribution and reaches an average grain size of around 100 nm.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Production for powdery diffused cathode base material containing scandium

A process for preparing the dispersed Sc-contained powder used as the raw material of cathode includes such steps as respectively dissolving scandium nitrate and ammonium metatungstate in water, mixing, adding the solution of citric acid and glycol, water-bath heating to 60-90 deg.C while stirring to obtain sol, baking at 80-150 deg.C to obtain gel, and thermal decomposing at 500-600 deg.C for 0.5-1 hr and then at 850-1000 deg.C for 1-2 hr.

Owner:BEIJING UNIV OF TECH

Ho-Doped transparent scandia ceramic and preparation method thereof

The invention discloses Ho-doped transparent scandia ceramic and a preparation method thereof. The preparation method includes: adding scandia powder into electronic dilute nitric acid to obtain scandium nitrate, adding scandia powder and scandium nitrate solution into a ball milling tank, adding little alumina powder and lithium fluoride powder as sintering aids, wherein doping quantity of alumina is 0-0.2 at.% and doping quantity of lithium fluoride is 0.8-1.2 at.%, grinding with alumina milling balls to obtain a slurry, drying, screening to obtain ceramic powder, pressing the ceramic powderinto discs, performing repeated heating, sintering and cooling at certain temperatures respectively in a muffle furnace, a vacuum sintering furnace and a hot isostatic pressure furnace, and loweringthe temperature to room temperature to obtain prefabricated parts; calcining the prefabricated parts in the muffle furnace, annealing, and polishing to obtain the finished ceramic. Alumina is used herein to assist lithium fluoride to act as the sintering aids, so that the Ho-doped transaprent scandia ceramic is attained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

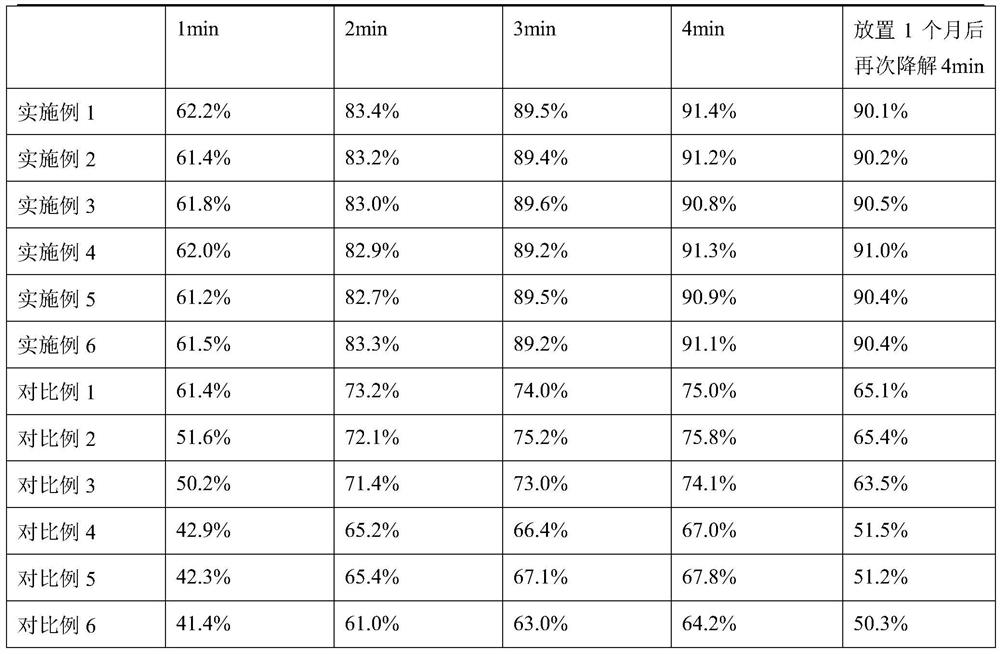

Photocatalyst composite coating and preparation method thereof

PendingCN111774061AHigh catalytic activityImprove stabilityMolten spray coatingOrganic-compounds/hydrides/coordination-complexes catalystsCerium nitratePolyvinyl alcohol

The invention belongs to the technical field of photocatalytic coatings, and provides a photocatalyst composite coating, which comprises the following components in parts by mass: 5-15 parts of ferroferric oxide, 70-90 parts of nano titanium dioxide, 2-5 parts of cerium nitrate, 1-2 parts of magnesium oxide, 1-4 parts of scandium nitrate and 1-20 parts of polyvinyl alcohol. By means of the technical scheme, the problem that in the prior art, the VOCs removal rate is low is solved.

Owner:河北弘盛源科技有限公司

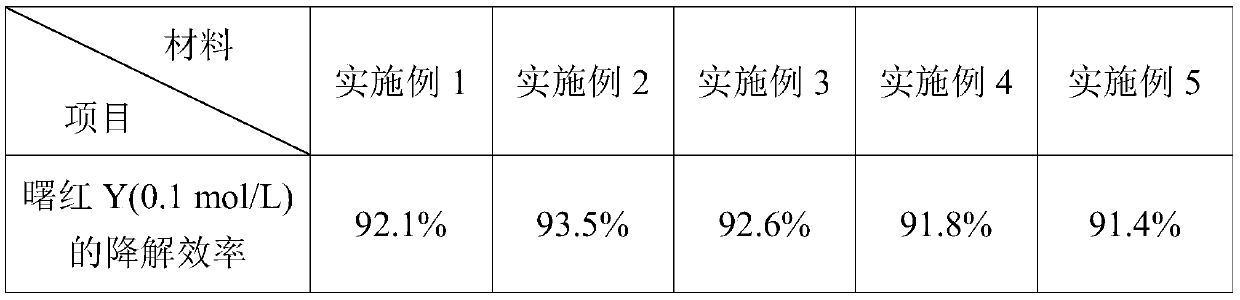

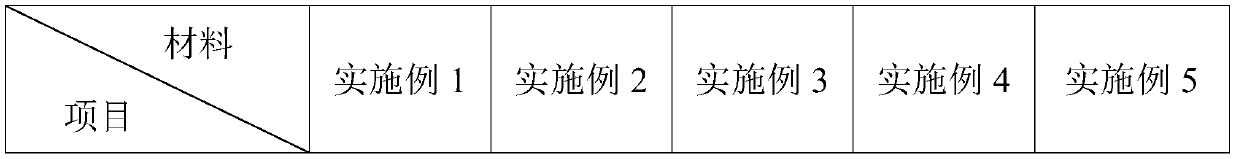

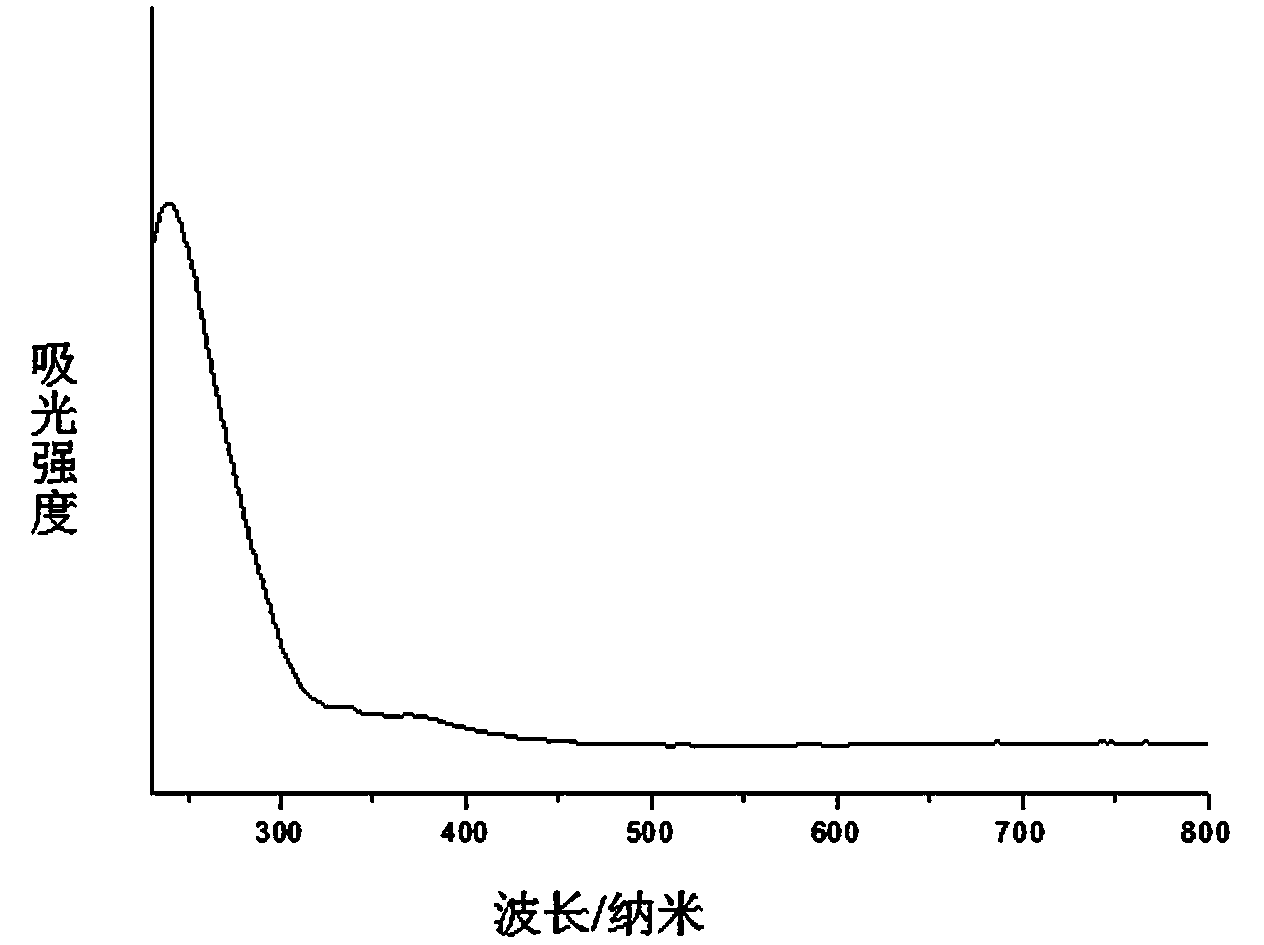

Scandium doping zinc oxide-bismuth vanadium oxide composite photodegradation material and preparation method thereof

InactiveCN110420631ALarge specific surface areaSmall sizeWater/sewage treatment by irradiationWater treatment compoundsRare-earth elementZinc hydroxide

The invention relates to the technical field of photodegradation materials, and discloses a scandium doping zinc oxide-bismuth vanadium oxide composite photodegradation material and a preparation method thereof. A formula includes the following experiment raw materials: zinc hydroxide, citric acid, scandium nitrate hexahydrate, bismuth trichloride, sodium vanadate, sodium hydroxide, and the like.In the scandium doping zinc oxide-bismuth vanadium oxide composite photodegradation material and the preparation method thereof, ZnO is doped with a rare earth element Sc to form Zn0.92-0.97Sc0.03-0.08O, the Sc makes the size of a ZnO crystal reduce, the specific surface area of the ZnO is increased, the diffusion time of photoelectron e<->-hole h+ is shortened during a photocatalysis process, thereby improving the degradation efficiency of a photocatalyst to organic dye, active oxygen is generated by the action of the ZnO and water and oxygen under illumination, the recombination velocity ofBiVO4 photocatalyst electron-hole is reduced, the number of photoelectron e<-> is increased, the organic dye can capture electron e<->, its activation energy is reduced, and the catalytic efficiency and the degradation efficiency of photocatalytic materials to organic dye pollutants are improved.

Owner:厦门珉瑶贸易有限公司

Preparation method for rod-like Sc2W3O12 negative thermal expansion material

ActiveCN102745747BSimple procedureEasy to operateNanotechnologyTungsten compoundsThermal dilatationTungstate

The invention relates to a negative thermal expansion material, in particular to a preparation method of a rod-shaped Sc2W3O12 negative thermal expansion material. The invention adopts the hydrothermal method to synthesize the negative thermal expansion compound Sc2W3O12 at low temperature, and the raw materials used are: Sc(NO3)3 xH2O (analytical pure), H40N10O41W12 xH2O (chemical pure), HNO3 (analytical pure). Dissolve scandium nitrate and ammonium tungstate in deionized water at a molar ratio of Sc3+:W6+ of 2:3, mix the two solutions of scandium nitrate and ammonium tungstate by double drop method, and add to the mixed solution under constant stirring Adjust pH=3~5 with nitric acid solution, stir evenly at 60~80°C; transfer the mixed solution into a reaction kettle lined with polytetrafluoroethylene, seal and heat at 150~180°C for 10~15h, and the reaction is complete Finally, use a centrifuge for centrifugal dehydration, pour off the supernatant, wash and centrifuge repeatedly for 3 times, and then dry at 80-110°C to obtain the precursor; place the precursor in a muffle furnace and heat it at 540-800°C The final product Sc2W3O12 is obtained. The method has the advantages of simple procedure, easy operation and industrialization.

Owner:JIANGSU UNIV

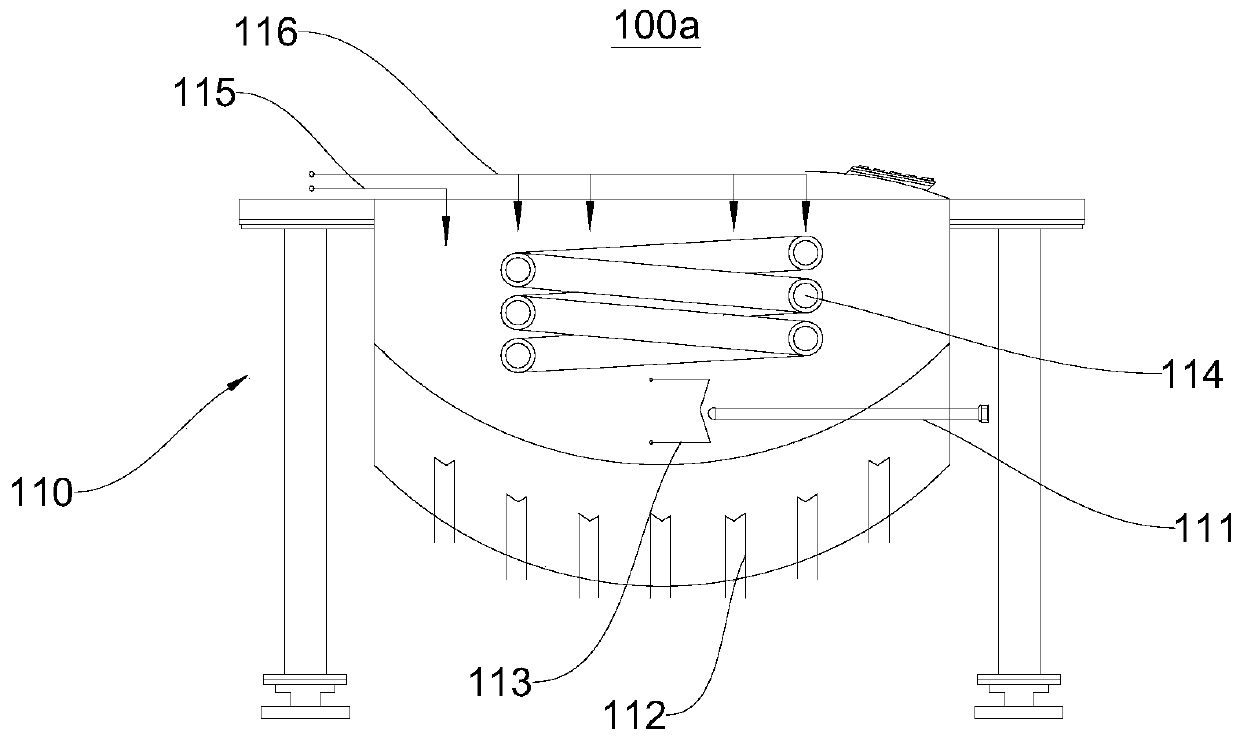

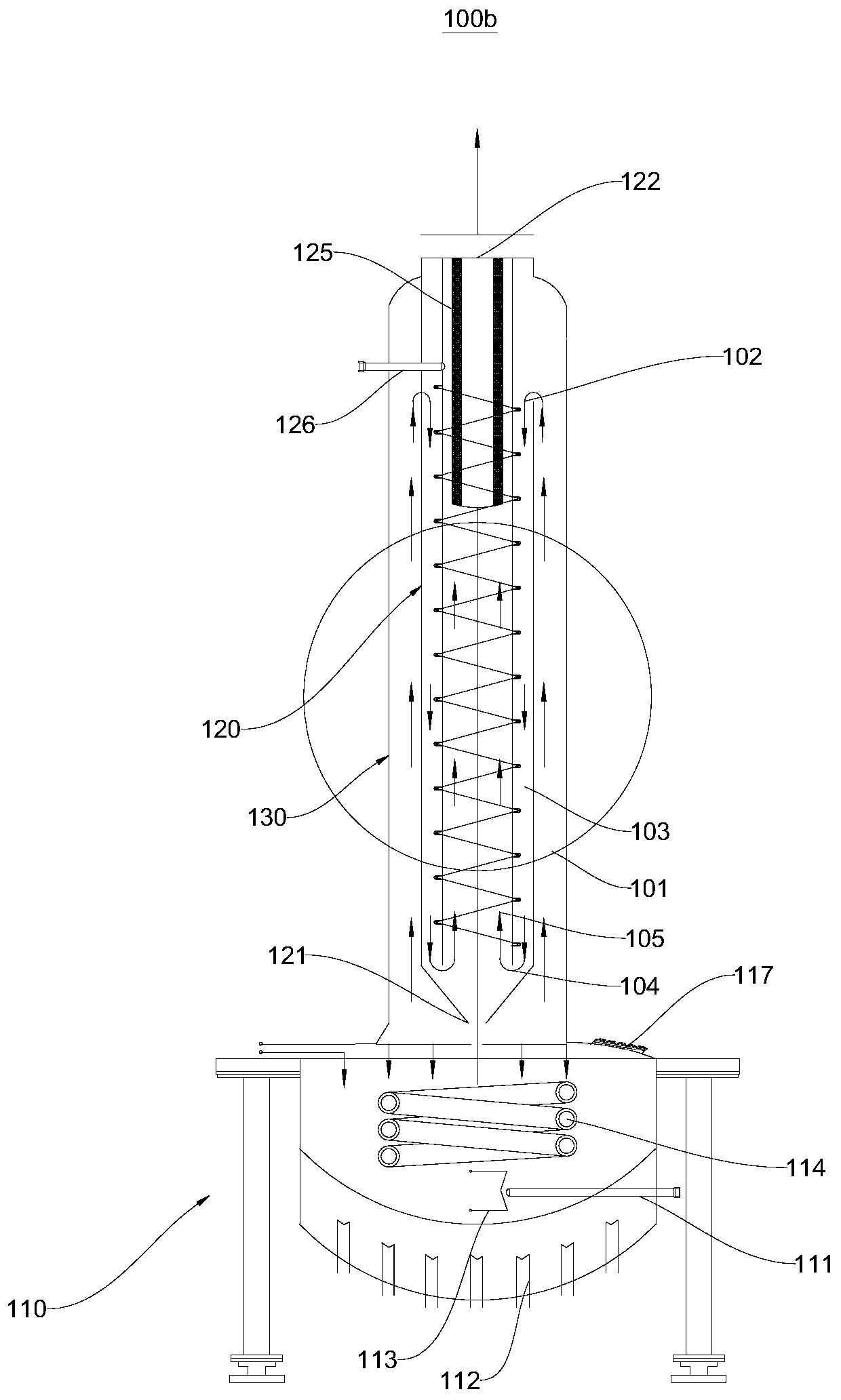

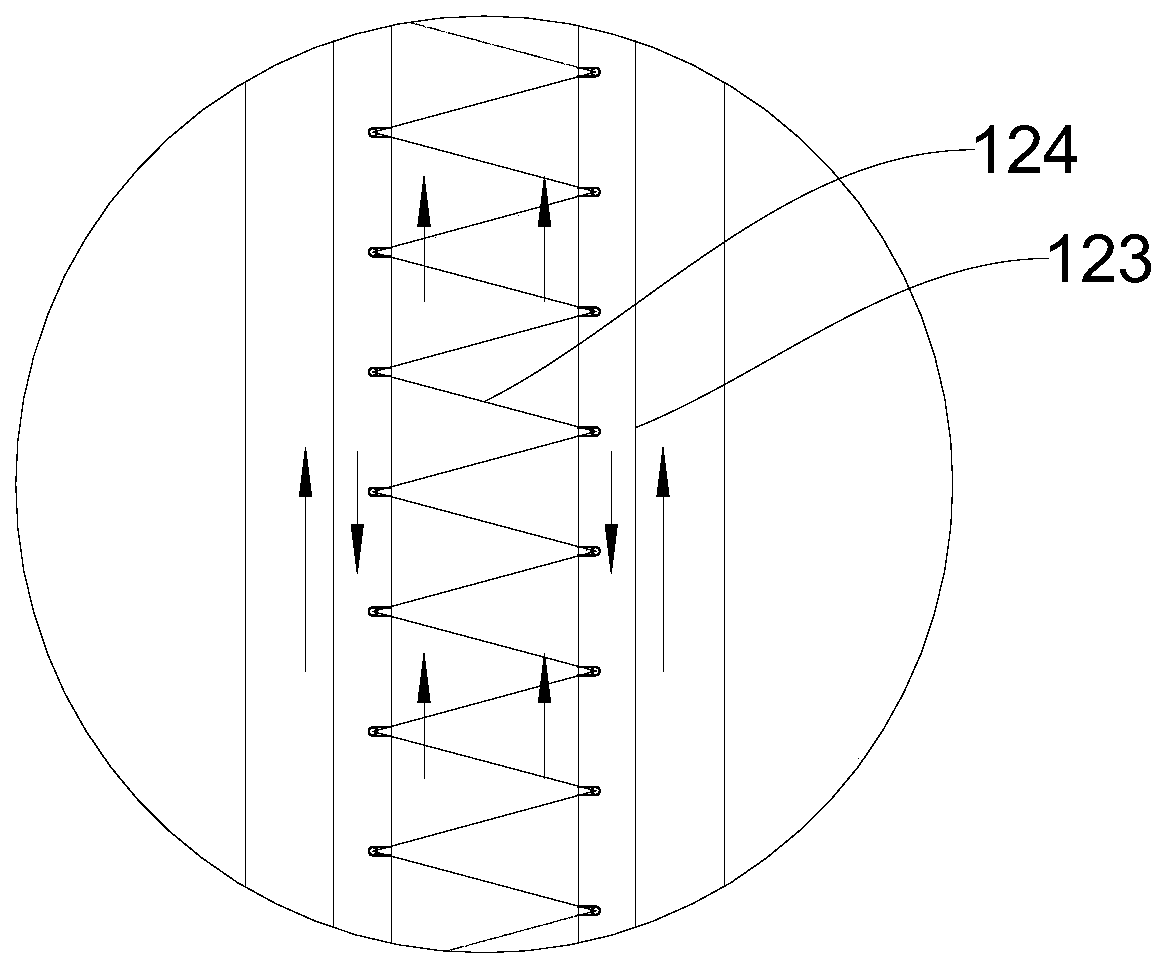

Generator and method for preparing nitrous oxide by degrading ammonium nitrate in wet way

InactiveCN110329999APrecise temperature controlPrecise control of reaction temperatureNitrous oxidesReaction temperatureNitrous oxide

The invention provides a generator and method for preparing nitrous oxide by degrading ammonium nitrate in a wet way, and relates to the technical field of chemical equipment. The generator is characterized in that a heating controller, a cooling controller and a quenching controller are correspondingly used for controlling the work of a heating assembly, a material cooling heat exchanger and a quenching heat exchanger; the heating assembly, the material cooling heat exchanger and the quenching heat exchanger are coordinative to work to achieve the purpose of accurately controlling the reaction temperature, and thus the phenomenon of excessively high temperature in a kettle in the reaction process is avoided. The method is applicable to the generator, and the circumstance of excessively high temperature caused by heat dissipating is prevented.

Owner:欧中电子材料(重庆)有限公司

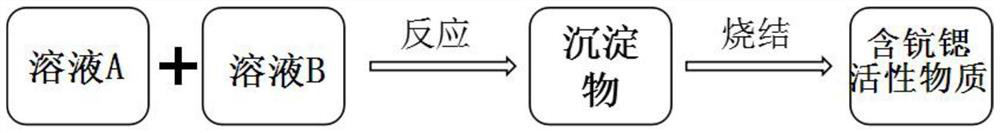

Scandium-strontium-containing active material for thermal cathode material

PendingCN111739771AEnhanced electron emission capabilityEasy to operateTransit-tube cathodesDischarge tube solid thermionic cathodesCalcium nitrate tetrahydrateRare-earth element

The invention discloses a scandium-strontium-containing active substance for a thermal cathode material. The scandium-strontium-containing active substance is prepared by the following steps of addinga solution A prepared from ammonium carbonate or / and ammonium bicarbonate into a solution B prepared from scandium nitrate hexahydrate, strontium nitrate, aluminum nitrate nonahydrate, barium nitrateand calcium nitrate tetrahydrate, reacting to obtain a precipitate, and sintering the precipitate. A precursor raw material reacts in a solution to obtain a precipitate, the scandium-strontium-containing active substance is obtained through sintering, the scandium-strontium-containing active substance with high electron emission capacity is obtained by introducing rare earth elements scandium andstrontium, so that the electron emission capacity of the thermal cathode material is improved, and the preparation process is simple, the cost is low, and the popularization and application values are relatively high.

Owner:西安稀有金属材料研究院有限公司

Production for powdery diffused cathode base material containing scandium

A process for preparing the dispersed Sc-contained powder used as the raw material of cathode includes such steps as respectively dissolving scandium nitrate and ammonium metatungstate in water, mixing, adding the solution of citric acid and glycol, water-bath heating to 60-90 deg.C while stirring to obtain sol, baking at 80-150 deg.C to obtain gel, and thermal decomposing at 500-600 deg.C for 0.5-1 hr and then at 850-1000 deg.C for 1-2 hr.

Owner:BEIJING UNIV OF TECH

Polymer electrolyte membrane, membrane electrode assembly, polymer electrolyte fuel cell, and process for producing polymer electrolyte membrane

ActiveUS20220238902A1Improve featuresIncreased durabilitySolid electrolytesFuel cellsPolyelectrolytePolymer electrolytes

Provided is a polymer electrolyte membrane comprising: (a) a polyelectrolyte having an ion exchange capacity of from 0.5 to 3.0 meq / g; and (b) at least one scandium compound selected from the group consisting of scandium oxide, scandium acetate, scandium sulfate, scandium nitrate, and scandium carbonate, wherein a polyethylene glycol (PEG)-derived compound in the polymer electrolyte membrane has a total content of 10 ppm or less.

Owner:ASAHI KASEI KK

Preparation method for scandium yttrium aluminate powder

InactiveCN104229858ASimple process routeReduce manufacturing costRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsMethanol waterFuel cells

The invention discloses a preparation method for scandium yttrium aluminate powder. The preparation method comprises the following steps: fully dissolving yttrium salts, scandium salts and different cross-linking agents as raw materials in a methanol and water mixing solution; then performing a cross-linking reaction on the mixture at certain temperature; mixing the reacted mixture with fused salts and grinding for fully and uniformly mixing the mixture; finally, performing high-temperature calcination treatment and washing drying to obtain the scandium yttrium aluminate powder, wherein the mole ratio of the yttrium salts to the scandium salts to the fused salts to the cross-linking agents is 1:1:2:10-200; the yttrium salts are one of yttrium chloride and yttrium nitrate or the mixture of the yttrium chloride and the yttrium nitrate; the scandium salts are one of scandium chloride or scandium nitrate or the mixture of the scandium chloride and the scandium nitrate; the cross-linking agents are one of urine or citric acid or the mixture of the urine and the citric acid. The preparation method disclosed by the invention has the advantages of simplicity, convenience, feasibility, high purity, low impurity content, low preparation cost of products and suitability for batch production. The prepared products can be applied to the fields of ferroelectricity, photoelectricity, photocatalysis, fuel cells and the like.

Owner:BOHAI UNIV

Electrolyte corrosion inhibitor, aluminum-air battery electrolyte and preparation method thereof

The invention relates to an electrolyte corrosion inhibitor, an aluminum-air battery electrolyte and a preparation method of the aluminum-air battery electrolyte. The electrolyte corrosion inhibitor mainly comprises an inorganic phase type corrosion inhibitor and an organic adsorption type corrosion inhibitor, wherein the inorganic phase type corrosion inhibitor is selected from at least one of zinc acetate, manganate and scandium nitrate; the organic adsorption type corrosion inhibitor is selected from at least one of benzotriazole, a natural amino acid and a cationic surfactant; and the molar ratio of the inorganic phase type corrosion inhibitor and the organic adsorption type corrosion inhibitor is (1-5,000) to (1-1,000). The electrolyte corrosion inhibitor is prepared on the basis of the property of an electrolyte solution, has the advantages of the phase type corrosion inhibitor and the adsorption type corrosion inhibitor, and is a multifunctional additive with good overall performance.

Owner:CENT SOUTH UNIV

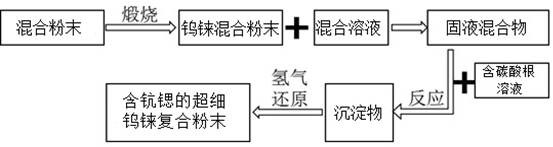

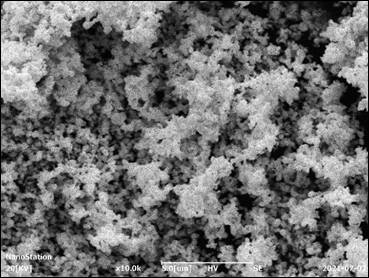

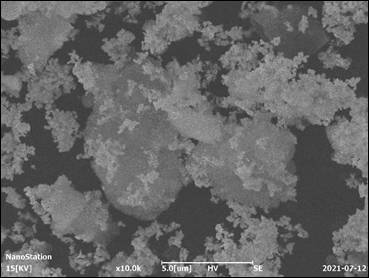

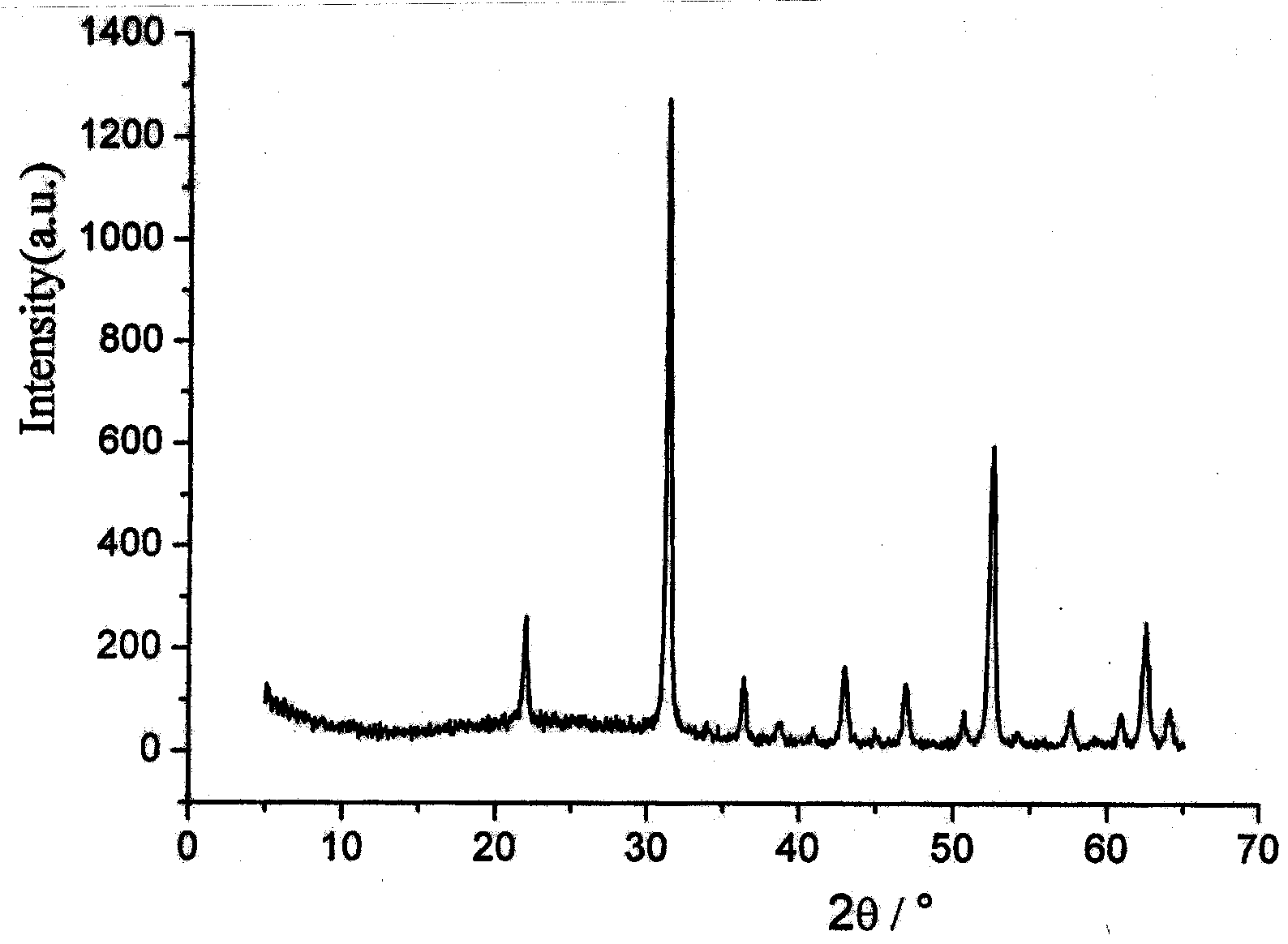

Preparation method and application of ultrafine tungsten-rhenium composite powder containing scandium and strontium

The invention discloses a method for preparing ultrafine tungsten-rhenium composite powder containing scandium and strontium. The method comprises: 1. Ball milling tungsten oxide powder, ammonium perrhenate powder and carbon black to obtain tungsten-rhenium mixed powder; 2. Adding tungsten-rhenium mixed powder into the mixed solution to obtain a solid-liquid mixture; 3. Adding a solution containing carbonate to the solid-liquid mixture to react to obtain a precipitate; 4. Sintering to obtain ultrafine tungsten-rhenium composite powder containing scandium and strontium; The invention also discloses the application of one-step sintering of superfine tungsten-rhenium composite powder containing scandium and strontium to obtain hot cathode material. The present invention uses tungsten oxide powder and ammonium perrhenate powder as the source of tungsten and rhenium, uses scandium nitrate hexahydrate and strontium nitrate as the source of scandium and strontium, and uses a solid-liquid mixing method to combine carbon and hydrogen for two-step reduction without the need to prepare a matrix and The precursor active material has a simple and efficient method; the application process of the invention is simple, the production cycle is short, the cost is low, and the electron emission performance of the hot cathode material is improved.

Owner:西安稀有金属材料研究院有限公司

Porous cubic phase scandium oxide powder and preparation method thereof

ActiveCN102070177BPorousNarrow particle size distributionRare earth metal compoundsDispersitySodium acetate

The invention provides porous cubic phase scandium oxide powder and a preparation method thereof. In the invention, hexamine is used as a precipitator and added to a scandium nitrate solution to obtain hydroxyl scandium oxide precipitate by utilizing a uniform precipitating method in the presence of sodium acetate and polyethylene glycol 1000, and then the precipitate is collected and calcined at high temperature to prepare and obtain porous walnut-shaped cubic phase scandium oxide powder with uniform size and good dispersity. The multi-hole cubic phase scandium oxide powder has the characteristics of porosity and narrow particle size distribution and also has better property in the application of gas sensing and catalysis and important application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method for zirconia ceramic bushing applied to optical fibers

The invention relates to a preparation method for a zirconia ceramic bushing applied to optical fibers. The preparation method is characterized by comprising the following steps: weighing magnesium nitrate, cerium nitrate, scandium nitrate, calcium nitrate and lanthanum nitrate according to a mass ratio of 1: 2: 2: 0.5: 1; then adding deionized water; and carrying out uniform mixing to prepare mixed nitrate solution with a concentration of 25%. The preparation method can prepare the zirconia ceramic bushing with low cost, high mechanical strength and excellent anti-aging properties.

Owner:NINGBO TOPTEK ADVANCED CERAMICS CO LTD

A kind of preparation method of barium scandium tantalate powder

InactiveCN104386750BSimple process routeReduce manufacturing costTantalum compoundsCross-linkBarium salt

The invention discloses a method for preparing barium scandium tantalate powder. The method comprises the steps of thoroughly dissolving a barium salt, a tantalum salt, a scandium salt and different cross-linking agents, which serve as raw materials, into a methanol-water mixture solution, then, carrying out cross-linking reaction at a certain temperature, then, mixing with a molten salt, grinding, so as to thoroughly mix uniformly, carrying out high-temperature reaction, then, cooling to room temperature, and then, carrying out water washing and drying, thereby obtaining the barium scandium tantalate powder, wherein the barium salt is either or a mixture of barium chloride and barium nitrate, the tantalum salt is either or a mixture of tantalum pentachloride and pentaethoxy tantalum, the scandium salt is either or a mixture of scandium chloride and scandium nitrate, the cross-linking agents are either or a mixture of urea and citric acid, and the molten salt is a mixture of sodium chloride and barium chloride. The method has the advantages that the preparation procedures are simplified, the preparation cost is low, the pollution to an environment cannot be caused, industrialized large-scale preparation is facilitated, and the prepared product can be applied to the fields of ferroelectrics, photoelectricity, photocatalytic hydrogen generation, fuel cells and the like.

Owner:BOHAI UNIV

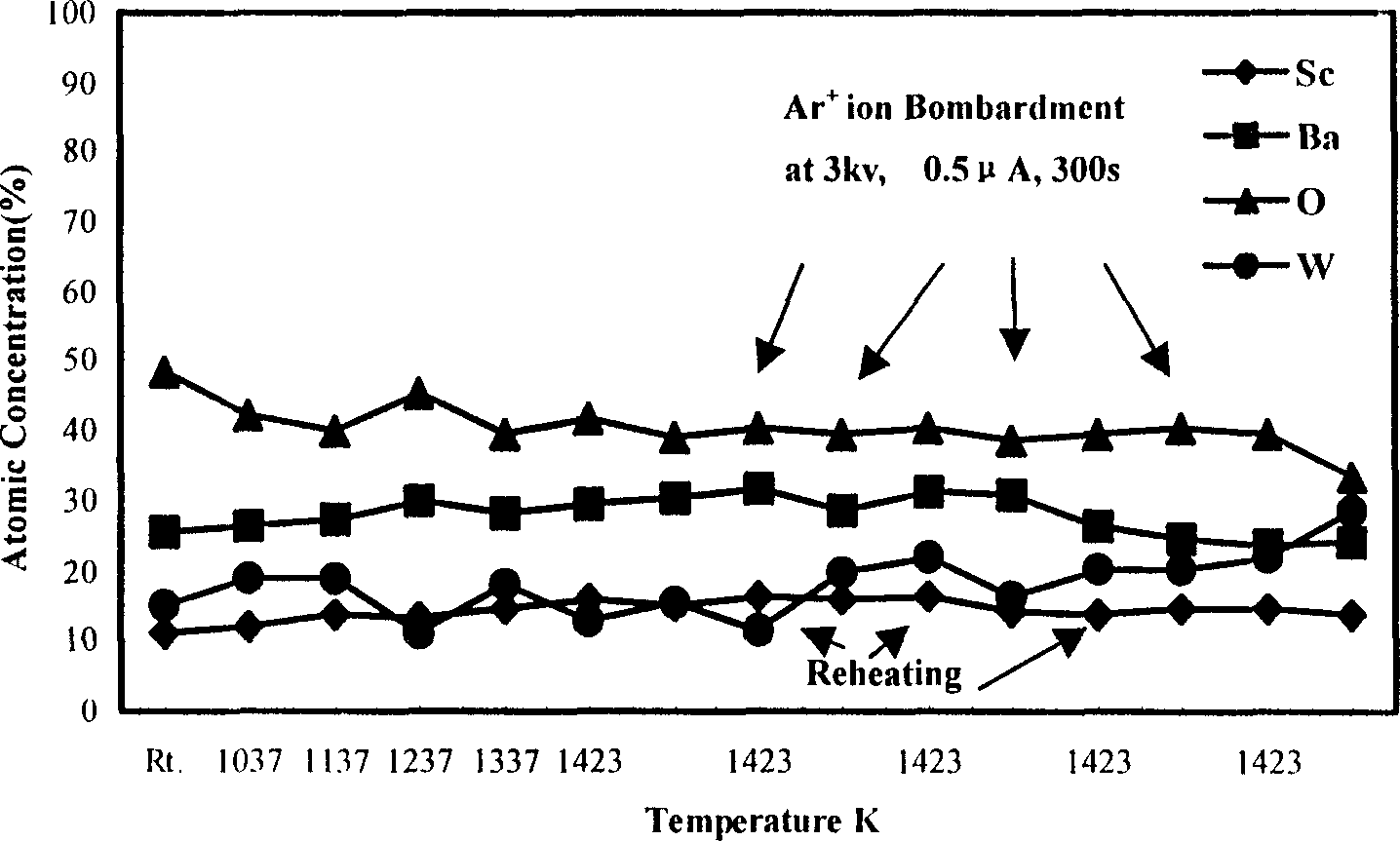

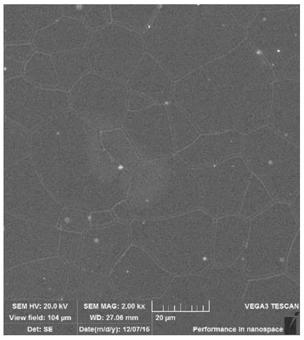

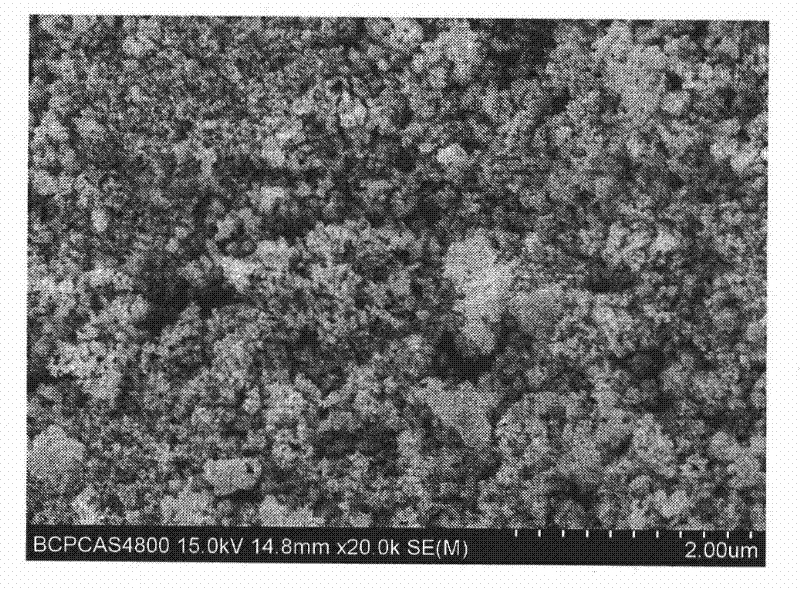

Method for preparing impregnated scandium-tungsten diffusion type cathode material

InactiveCN101764006BSimple manufacturing processAvoid introducingCold cathode manufactureTungstateHydrogen atmosphere

The invention discloses a method for preparing an impregnated scandium-tungsten diffusion type cathode material, and belongs to the technical field of refractory metal cathode materials. The method for preparing the impregnated scandium-tungsten diffusion type cathode material comprises the following steps: 1) dissolving ammonium meta-tungstate and scandium nitrate into water to form solution respectively, adding the scandium nitrate solution into the ammonium meta-tungstate solution for mixing, controlling the concentration of the mixed solution to between 20 and 40 g / L, and adopting spray drying to prepare precursor powder of the cathode material, wherein the feeding speed is 400 ml / h; the blowing rate is 0.4 to 0.6 cubic meters per minute; the inlet temperature is 150 DEG C; and the outlet temperature is stabilized at 95 DEG C; 2) decomposing the precursor powder prepared by the spray drying at the temperature of between 500 and 550 DEG C for 2 hours in the atmosphere so as to obtain composite oxide powder; and 3) reducing in the hydrogen atmosphere in two steps: preserving the heat to between 500 and 600 DEG C for 1 to 2 hours, and then raising the temperature to between 800 and 950 DEG C and preserving the heat for 1 to 2 hours to obtain the precursor-doped tungsten powder. The method for preparing the impregnated scandium-tungsten diffusion type cathode material simplifies the preparation technology for the precursor powder, avoids the introduction of impurity elements in the preparation process, and has the advantages of strong repeatability, simple technology, and convenient mass production. The prepared cathode material has excellent emission characteristics at 850 DEG C.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com