Production for powdery diffused cathode base material containing scandium

A technology for diffusing cathodes and powder raw materials, applied in the field of rare earth refractory metal cathode materials, can solve the problems of extremely difficult to fully cover the matrix frame, slow diffusion of scandium oxide, difficult emission recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

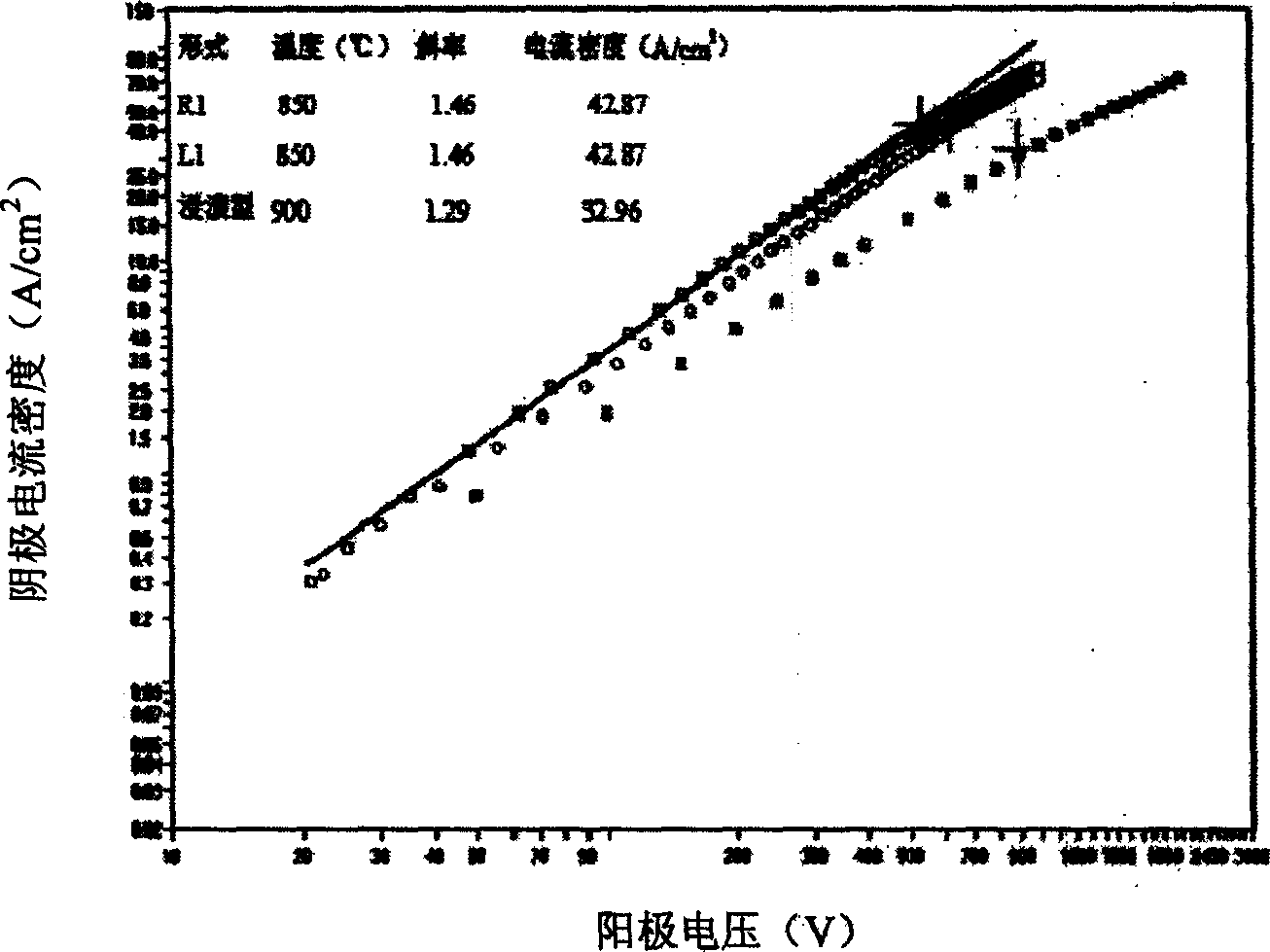

example 1

[0016] Example 1. Dissolve 1.6748 grams of scandium nitrate, 12.7305 grams of ammonium metatungstate, and 10 grams of citric acid in water respectively, then mix the scandium nitrate solution and ammonium metatungstate solution, stir while slowly adding the citric acid solution, and then add 4ml Ethylene glycol solution. The mixed solution was placed in a water bath at 60°C until the solution became a sol. The colloid is dried and aged at 80°C to form a yellow powder. The powder is heated and kept at 550°C for 2 hours in the atmosphere, and then reduced in a hydrogen furnace. The first reduction temperature is 600°C and the time is 1 hour; the second step The reduction temperature is 850° C. and the reduction time is 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 Accounting for 1% of the total mass, the particle size distribution curve of the powder is shown in Table 1. The powder was made into a porous body by the convent...

example 2

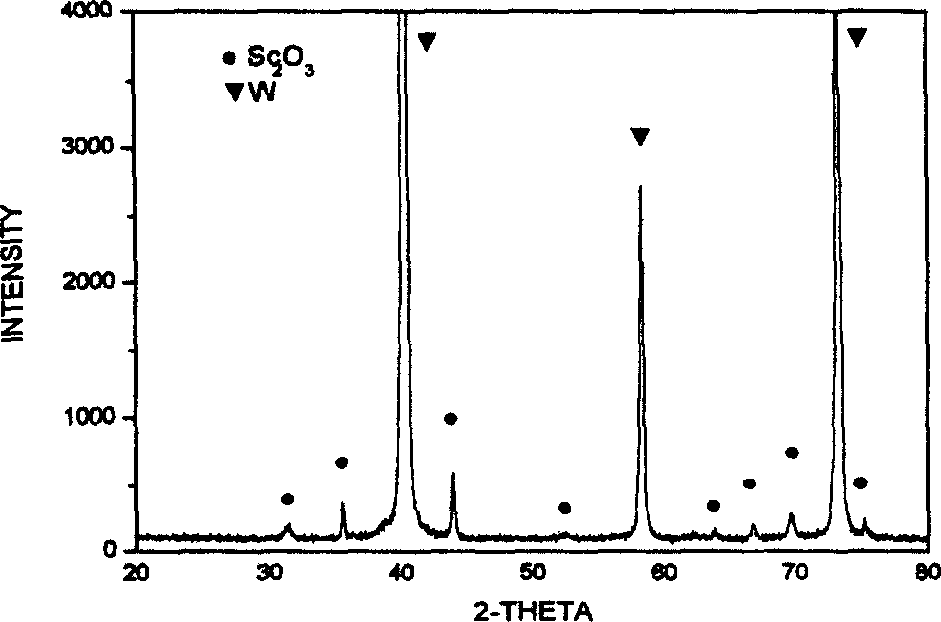

[0017] Example 2. Dissolve 1.6748 grams of scandium nitrate, 12.7305 grams of ammonium metatungstate, and 10 grams of citric acid in water respectively, then mix the scandium nitrate solution and ammonium metatungstate solution, stir while slowly adding the citric acid solution, and then add 4ml Ethylene glycol solution. The mixed solution was placed in a water bath at 60°C until the solution became a sol. The colloid is dried and aged at 90°C to form a yellow powder, and the powder is heated and kept at 550°C for 2 hours in an atmospheric atmosphere, and then reduced in a hydrogen furnace. The first reduction temperature is 500°C and the time is 1 hour; the second step The reduction temperature is 1000° C. and the reduction time is 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 Accounting for 5% of the total mass, see powder XRD figure 1 , the particle morphology see figure 2 . The powder is made into a porous body ac...

example 3

[0018] Example 3. Dissolve 1.6748 grams of scandium nitrate, 12.7305 grams of ammonium metatungstate, and 10 grams of citric acid in water respectively, then mix the scandium nitrate solution and ammonium metatungstate solution, stir while slowly adding the citric acid solution, and then add 6ml Ethylene glycol solution. The mixed solution was placed in a water bath at 80°C until the solution became a sol. The colloid is dried and aged at 120°C to form a yellow powder. The powder is heated and kept at 550°C for 2 hours in the atmosphere, and then reduced in a hydrogen furnace. The first reduction temperature is 500°C and the time is 1 hour; the second step The reduction temperature is 1000° C. and the reduction time is 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 5% of the total mass. The powder was made into a porous body by the conventional powder metallurgy method, impregnated with barium calcium aluminate to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com