Ho-Doped transparent scandia ceramic and preparation method thereof

A technology of transparent oxidation and scandium oxide, which is applied in the field of Ho-doped transparent scandium oxide ceramics and its preparation, can solve the problems of long time consumption, high cost, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

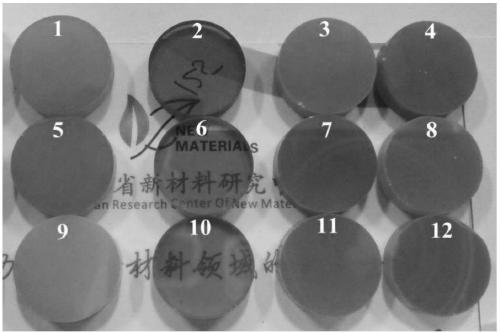

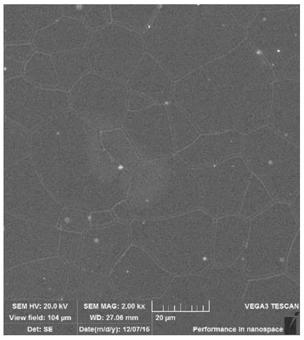

Image

Examples

Embodiment 13

[0044] (1) According to the mass volume ratio of 80g:1000ml, adding the oxidized di oxide powder of 4N purity into the electronic grade dilute nitric acid with a concentration of 22vol.%, stirring while heating until completely dissolving, obtaining the di nitrate solution;

[0045] (2) Add the scandium oxide powder of 4N purity and the Di nitrate solution into the ball mill tank, then add a small amount of alumina powder of 4N purity and lithium fluoride powder of 4N purity as sintering aids, wherein Ho 3+ See Table 2 for the doping concentration, alumina doping amount, and lithium fluoride doping amount. Use 3N pure alumina ball milling balls as the grinding medium and mix uniformly with a uniform speed planetary ball mill to obtain a slurry; the uniform speed planetary ball mill described in step (2) The speed is 220rpm. Each of the Di oxide powder, Scandium oxide powder, Aluminum oxide powder and Lithium fluoride powder has an average particle diameter of less than 1 micro...

Embodiment 14

[0049] (1) According to the mass volume ratio of 100g:800ml, the dioxidized powder of 4N purity is added in the electronic grade dilute nitric acid with a concentration of 18vol.%, and stirred until completely dissolved while heating to obtain the dinitrate solution;

[0050] (2) Add the scandium oxide powder of 4N purity and the Di nitrate solution into the ball mill tank, then add a small amount of alumina powder of 4N purity and lithium fluoride powder of 4N purity as sintering aids, wherein Ho 3+ See Table 2 for the doping concentration, alumina doping amount, and lithium fluoride doping amount. Use 3N pure alumina ball milling balls as the grinding medium and mix uniformly with a uniform speed planetary ball mill to obtain a slurry; the uniform speed planetary ball mill described in step (2) The speed is 180rpm. Each of the Di oxide powder, Scandium oxide powder, Aluminum oxide powder and Lithium fluoride powder has an average particle diameter of less than 1 micron. (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com