High-stability scandium oxide coated positive electrode material of manganese-based lithium ion battery and preparation method of positive electrode material

A technology for coating manganese-based lithium and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc. problems, to achieve good cycle performance, reduce lithium ion consumption, and reduce the effect of interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

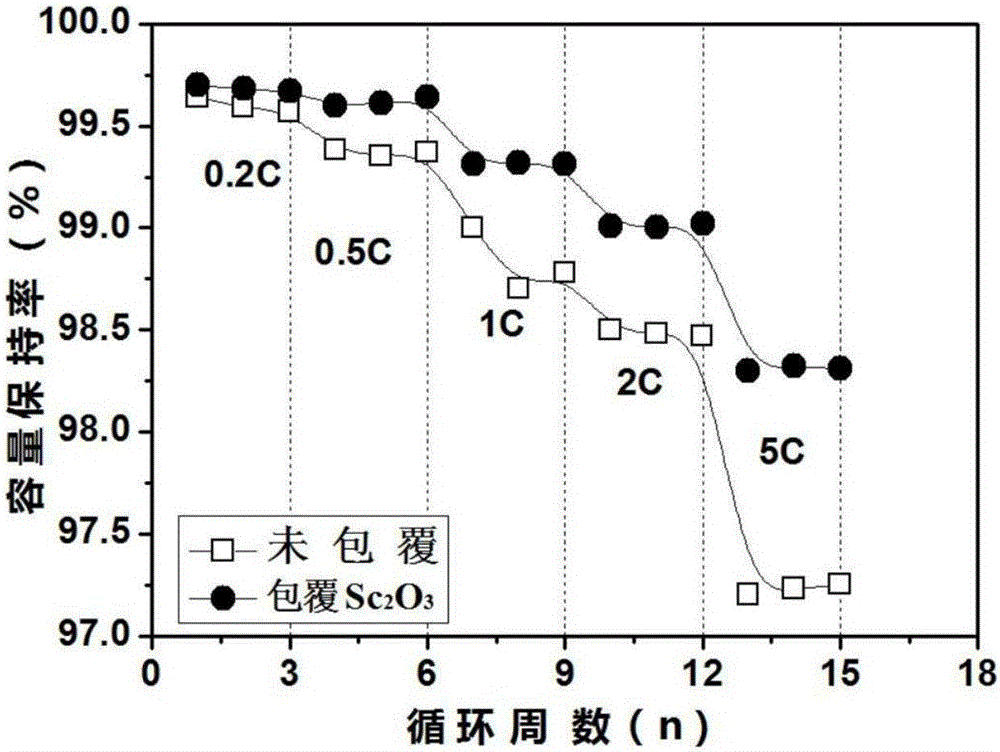

[0025] Mass fraction 0.5% Sc 2 o 3 Preparation of coated lithium nickel manganese oxide

[0026] 2.09g LiCH 3 COO·2H 2 O, 2.13g Ni(CH 3 COO) 2 2H 2 O, 7.35g Mn(CH 3 COO) 2 4H 2 O was dissolved in 200mL deionized water, and 1.8g of oxalic acid was dissolved in 200mL deionized water to form an oxalic acid solution. The metal salt solution was quickly poured into the oxalic acid solution for 6 hours of stirring, and then evaporated at 80°C for 10 hours to obtain the precursor precipitation. Precipitate the precursor in the air at 900°C for 12h, and anneal at 700°C for 18h to obtain LiNi 0.5 mn 1.5 o 4 matrix. Weigh 0.09g Sc(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to prepare scandium nitrate solution, LiNi 0.5 mn 1.5 o 4 Disperse the matrix powder into scandium nitrate solution, stir at room temperature for 0.5h with a magnetic stirrer, dry at 80°C for 10h, and then heat-treat at 600°C for 3h to obtain the target high-performance Sc 2 o 3 Co...

Embodiment 2

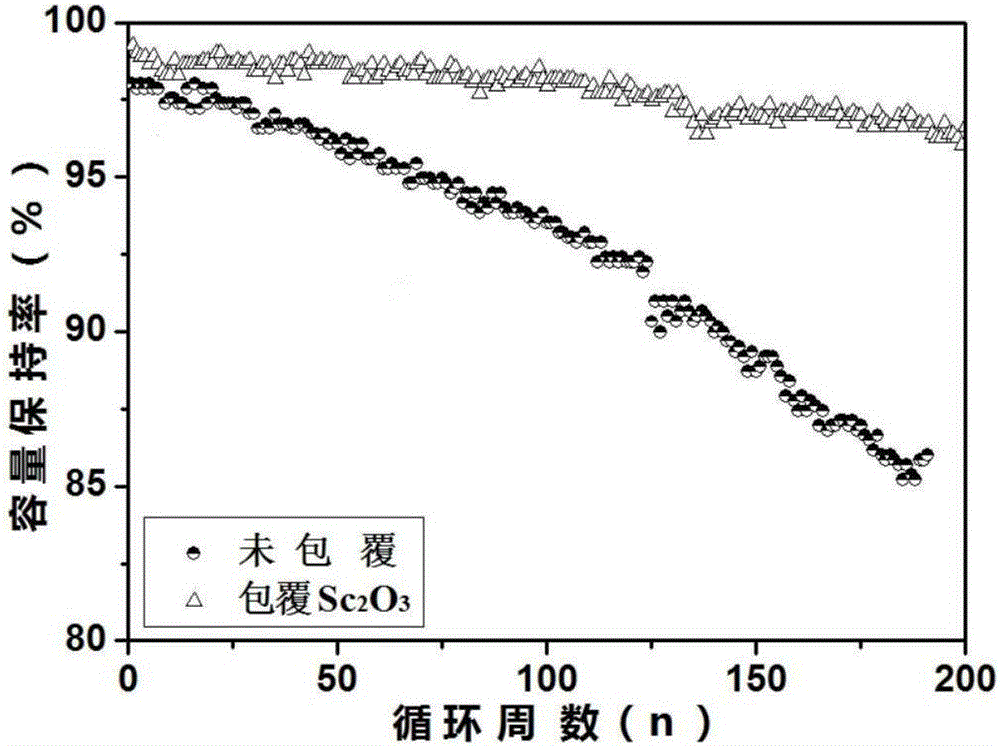

[0029] Mass fraction 1% Sc 2 o 3 Coated lithium-rich layered lithium-ion battery cathode material Li 1.2 Ni 0.25 mn 0.75 o 2 preparation of

[0030] 2.52g LiCH 3 COO·2H 2 O, 1.06g Ni(CH 3 COO) 2 2H 2 O, 3.67g Mn(CH 3 COO) 2 4H 2 O was dissolved in 200 mL of deionized water, and 1.98 g of oxalic acid was dissolved in 100 mL of deionized water to form an oxalic acid solution. The metal salt solution was quickly poured into the oxalic acid solution for 6 hours of stirring, and then evaporated at 80°C for 10 hours to obtain the precursor precipitation. The precursor was calcined at 820 °C for 18 h in air to prepare the lithium-rich layered material Li1.2 Ni 0.25 mn 0.75 o 2 matrix. Weigh 0.09g Sc(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to prepare scandium nitrate solution, and Li 1.2 Ni 0.25 mn 0.75 o 2 The matrix powder was dispersed into scandium nitrate solution, stirred at room temperature for 0.5 h with a magnetic stirrer, dried at 9...

Embodiment 3

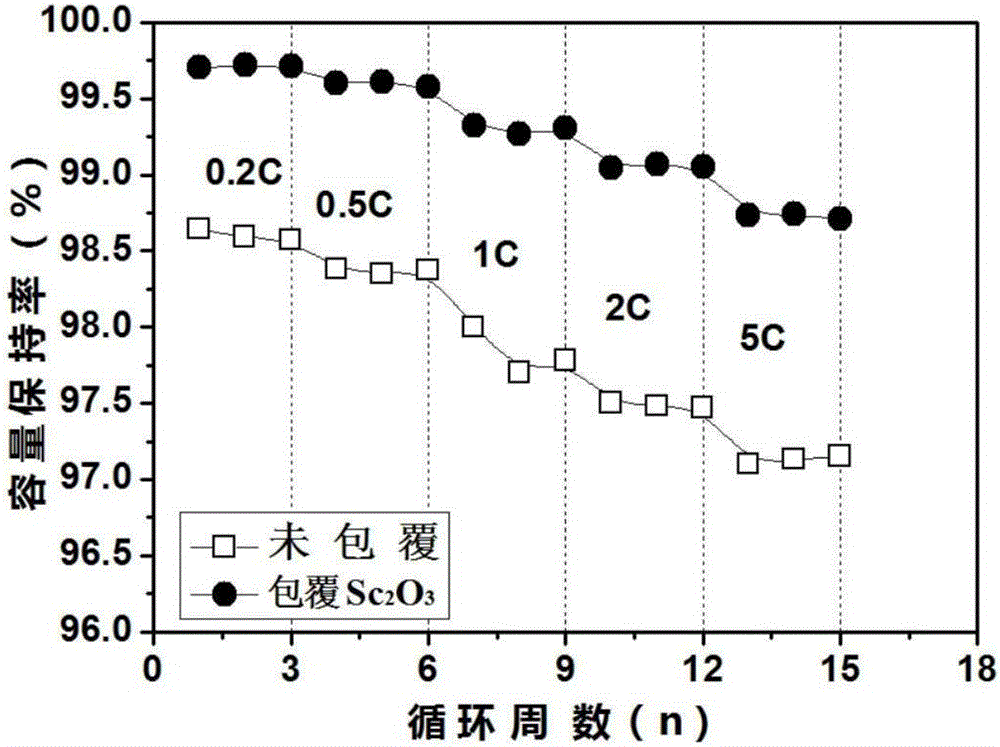

[0033] Mass fraction 2% Sc 2 o 3 Coated ternary material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 preparation of

[0034] 2.09g LiCH 3 COO·2H 2 O, 1.4g Ni(CH 3 COO) 2 2H 2 O, 1.62g Mn(CH 3 COO) 2 4H 2 O, 1.41g Co(CH 3 COO) 2 4H 2 O was dissolved in 200 mL of deionized water, and 2.7 g of oxalic acid was dissolved in 100 mL of deionized water to form an oxalic acid solution. The metal salt solution was quickly poured into the oxalic acid solution for 6 hours of stirring, and then evaporated at 80°C for 10 hours to obtain the precursor precipitation. The precursor was calcined at 850 °C for 20 h in the air to prepare the ternary material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 matrix. Weigh 0.19g Sc(NO 3 ) 3 ·6H 2 O was dissolved in 10 mL of deionized water to prepare scandium nitrate solution, LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Disperse the matrix powder into scandium nitrate solution, stir at room temperature for 0.5h with a magnetic stirrer, dry at 100°C for 9h, and then heat-treat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com