Method for preparing thin-film transistor based on scandia high-k dielectric layer

A technology of thin-film transistors and dielectric layers, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to achieve the effects of reliable principles, reduced production costs, and cheap processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

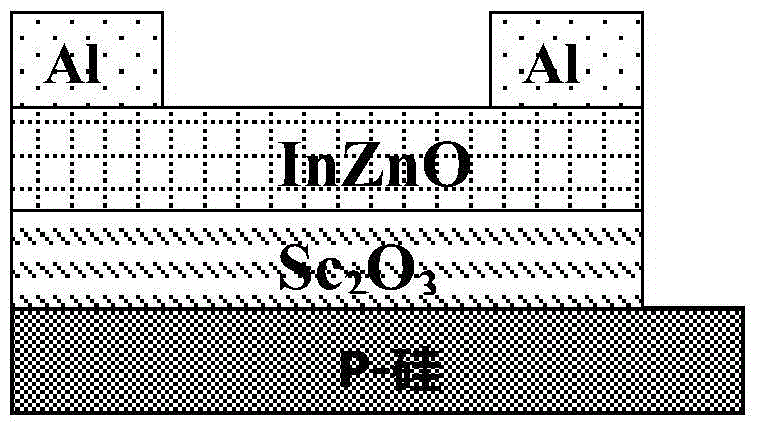

[0022] The scandium nitrate, zinc nitrate and indium nitrate powders involved in this embodiment are all purchased from Aldrich Company, and the purity is greater than 98%; its bottom gate structure is based on ultra-thin scandium oxide (Sc 2 o 3 ) is a high-k dielectric layer and the preparation process of an all-aqueous thin film transistor with an indium zinc oxide (IZO) film as a channel layer is:

[0023] (1) Prepare ultra-thin Sc by spin-coating with aqueous sol method 2 o 3 High-k dielectric films:

[0024] Step 1: Select commercially purchased single-sided polished low-resistance silicon as the substrate (resistance value less than 0.0015 Ω·cm) and the gate electrode, and clean the low-resistance silicon substrate with hydrofluoric acid, acetone, and alcohol ultrasonically for 10 times each. Minutes, and then rinsed repeatedly with deionized water, then blow dry with high-purity nitrogen;

[0025] Step 2: Weigh 10mL of deionized water, dissolve scandium nitrate in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com