Photocatalyst composite coating and preparation method thereof

A composite coating and photocatalyst technology, which can be used in coatings, separation methods, chemical instruments and methods, etc., can solve problems such as low VOCs removal rate, enhance purification efficiency and durability, reduce forbidden band width, and reduce waste gas treatment. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

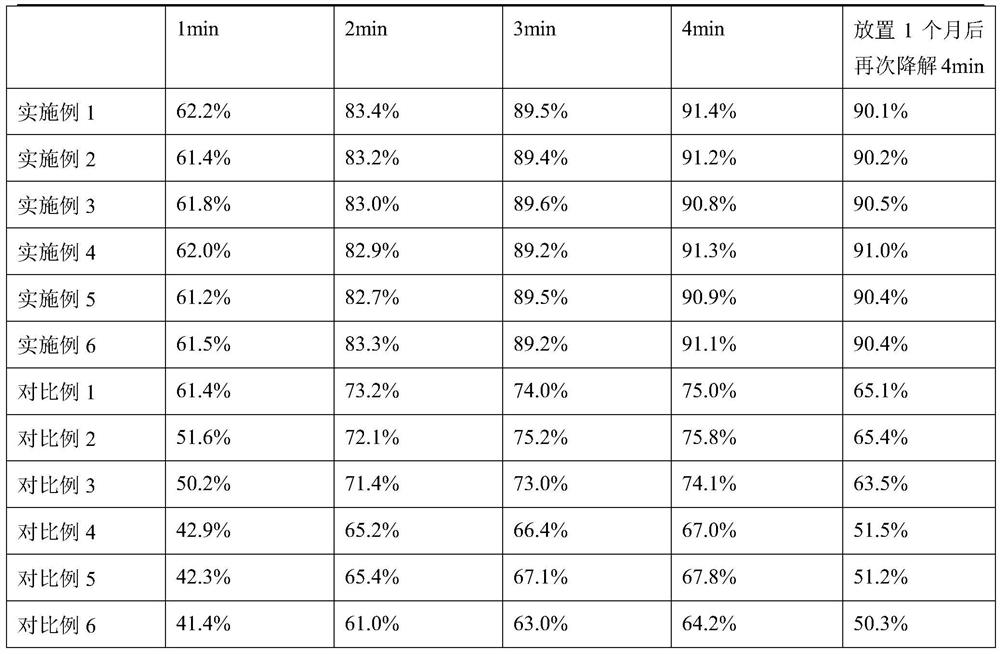

Examples

Embodiment 1

[0025] A photocatalyst composite coating, in parts by mass, said composite coating comprising: 5 parts of ferric oxide, 90 parts of nano-titanium dioxide, 2 parts of cerium nitrate, 2 parts of magnesium oxide, 1 part of scandium nitrate, 20 parts of poly Vinyl alcohol, 6 parts of adhesion promoter, the adhesion promoter includes dodecyl phosphate, azo polyurethane, and sodium silicate with a mass ratio of 1:1:1.5.

[0026] The preparation method of above-mentioned photocatalyst composite coating, comprises the steps:

[0027] A. Weigh each component according to the above-mentioned parts by mass, grind and granulate to obtain plasma sprayed particles;

[0028] B. Clean and sandblast the surface of the substrate; use plasma spraying equipment to spray the plasma sprayed particles on the substrate, and the temperature of the substrate during spraying is 100°C to form a photocatalyst composite coating, and the resulting substrate containing the photocatalyst composite coating is ...

Embodiment 2

[0031] A photocatalyst composite coating, in parts by mass, the composite coating includes: 15 parts of ferric oxide, 70 parts of nano-titanium dioxide, 5 parts of cerium nitrate, 1 part of magnesium oxide, 4 parts of scandium nitrate, 1 part of poly Vinyl alcohol, 12 parts of adhesion promoter, the adhesion promoter includes dodecyl phosphate, azo polyurethane, and sodium silicate with a mass ratio of 1:0.5:2.

[0032] The preparation method of above-mentioned photocatalyst composite coating, comprises the steps:

[0033] A. Weigh each component according to the above-mentioned parts by mass, grind and granulate to obtain plasma sprayed particles;

[0034] B. Clean and sandblast the surface of the substrate; use plasma spraying equipment to spray plasma sprayed particles on the substrate to form a photocatalyst composite coating; the thickness of the coating is 1.5 μm; the substrate is aluminum alloy.

[0035] The gases used in the plasma spraying process are argon and hydro...

Embodiment 3

[0037] A photocatalyst composite coating, in parts by mass, said composite coating comprising: 10 parts of ferric oxide, 80 parts of nano-titanium dioxide, 3 parts of cerium nitrate, 1.5 parts of magnesium oxide, 2 parts of scandium nitrate, 10 parts of poly Vinyl alcohol, 8 parts of adhesion promoter, the adhesion promoter includes dodecyl phosphate, azo polyurethane, and sodium silicate with a mass ratio of 1:0.8:1.8.

[0038] The preparation method of above-mentioned photocatalyst composite coating, comprises the steps:

[0039] A. Weigh each component according to the above-mentioned parts by mass, grind and granulate to obtain plasma sprayed particles;

[0040] B. Clean and sandblast the surface of the substrate; spray plasma spray particles on the substrate by plasma spraying equipment to form a photocatalyst composite coating; the thickness of the coating is 1.2 μm; the substrate is magnesium alloy.

[0041] The gases used in the plasma spraying process are argon and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com