Method for preparing impregnated scandium-tungsten diffusion type cathode material

A cathode material and impregnation-type technology, which is applied in the field of rare earth refractory metal cathode materials, can solve the problems of affecting the quality of the reduced powder, the growth of powder particles, and the lack of uniform doping, etc., to achieve strong process repeatability, simplify the preparation process, The effect of avoiding the introduction of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this experiment, the precursor powder was prepared on the EYELA Spray Dryer SD-1000 spray dryer. Dissolve 13.2335 grams of ammonium metatungstate and 0.1865 grams of scandium nitrate in water respectively, then add the scandium nitrate solution into the ammonium metatungstate solution and mix, the solution concentration is 20g / L, the feeding speed is 400ml / h, and the inlet temperature is 150 ℃, the outlet temperature is stable at 95 ℃, and the blast speed is 0.4m 3 / min for experiments. The obtained precursor powder was decomposed at 550° C. for 2 hours in the air atmosphere to obtain a composite oxide powder. The powder was kept in a hydrogen reduction furnace at 600°C for 2 hours, and then the temperature was raised to 800°C for 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 1% of the total mass. Press the doped tungsten powder made by the above method at a pressure of 1t / cm 2 Press and sinter at 1500°C for 1...

Embodiment 2

[0022] In this experiment, the precursor powder was prepared on the EYELA Spray Dryer SD-1000 spray dryer. Dissolve 12.7305 grams of ammonium metatungstate and 0.9330 grams of scandium nitrate in water respectively, then add the scandium nitrate solution into the ammonium metatungstate solution and mix, the solution concentration is 20g / L, the feeding speed is 400ml / h, and the inlet temperature is 150 °C, the outlet temperature is stable at 95 °C, and the blast speed is 0.6m 3 / min for experiments. The obtained precursor powder was decomposed at 550° C. for 2 hours in the air atmosphere to obtain a composite oxide powder. The powder was kept in a hydrogen reduction furnace at 500°C for 2 hours, and then the temperature was raised to 950°C for 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 5% of the total mass. Press the doped tungsten powder made by the above method at a pressure of 1t / cm 2 Press and sinter at 1500°C for...

Embodiment 3

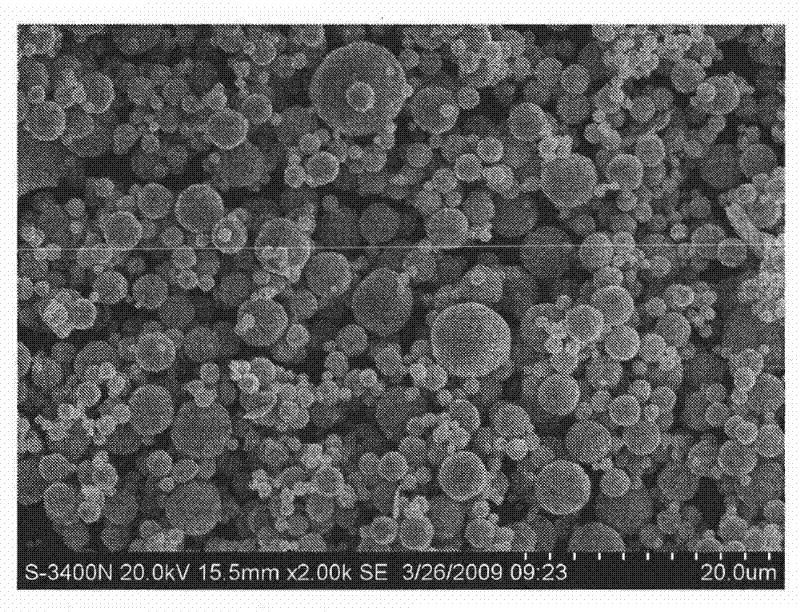

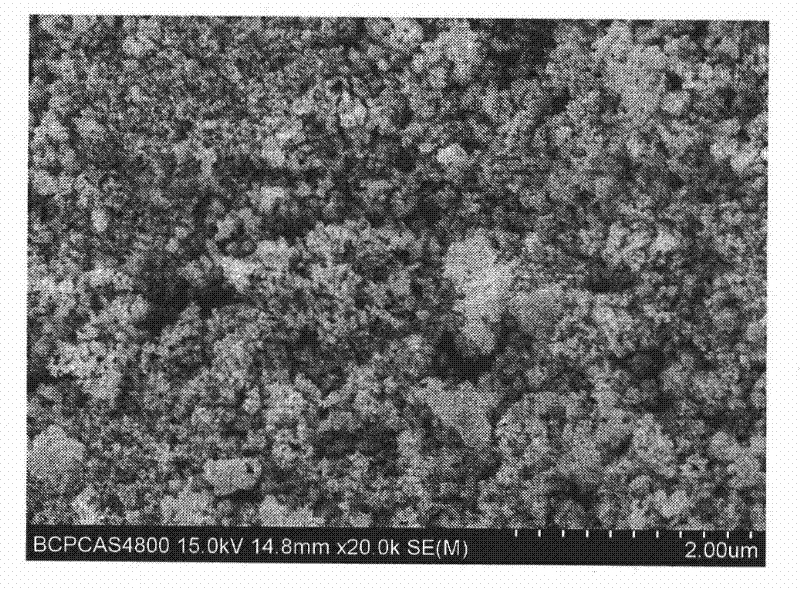

[0024] In this experiment, the precursor powder was prepared on the EYELA Spray Dryer SD-1000 spray dryer. Dissolve 12.7305 grams of ammonium metatungstate and 0.9330 grams of scandium nitrate in water respectively, then add the scandium nitrate solution into the ammonium metatungstate solution and mix, the solution concentration is 20g / L, the feeding speed is 400ml / h, and the inlet temperature is 150 ℃, the outlet temperature is stable at 95 ℃, and the blast speed is 0.4m 3 / min for experiments. The obtained precursor powder was decomposed at 550° C. for 2 hours in the air atmosphere to obtain a composite oxide powder. Precursor powder map see figure 1 . The powder was kept in a hydrogen reduction furnace at 500°C for 2 hours, and then the temperature was raised to 950°C for 2 hours. Cool down to room temperature to obtain Sc 2 o 3 Doped tungsten powder, where Sc 2 o 3 Accounting for 5% of the total mass, the particle morphology is shown in figure 2 , powder XRD see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com