Patents

Literature

119results about "Nitrous oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

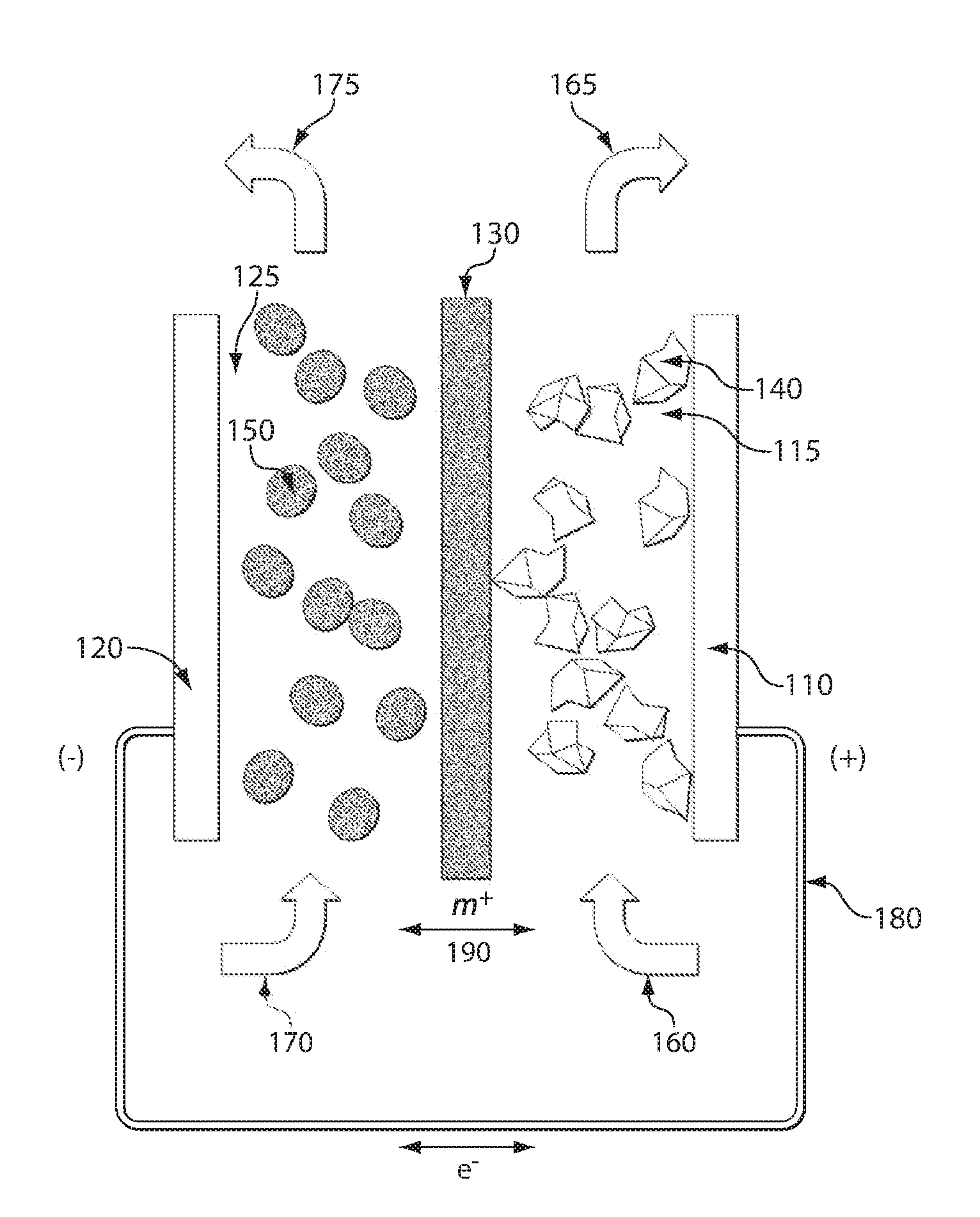

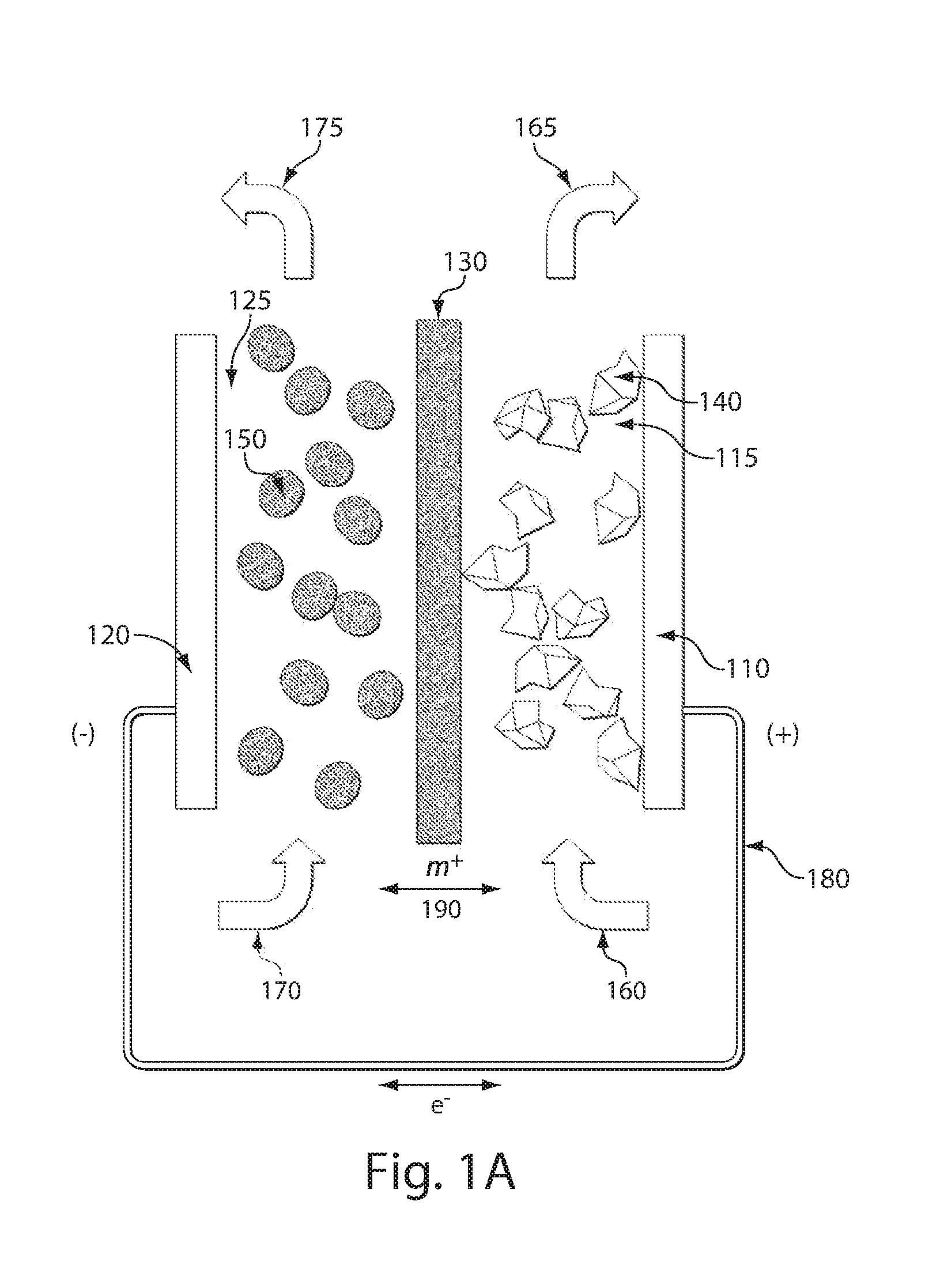

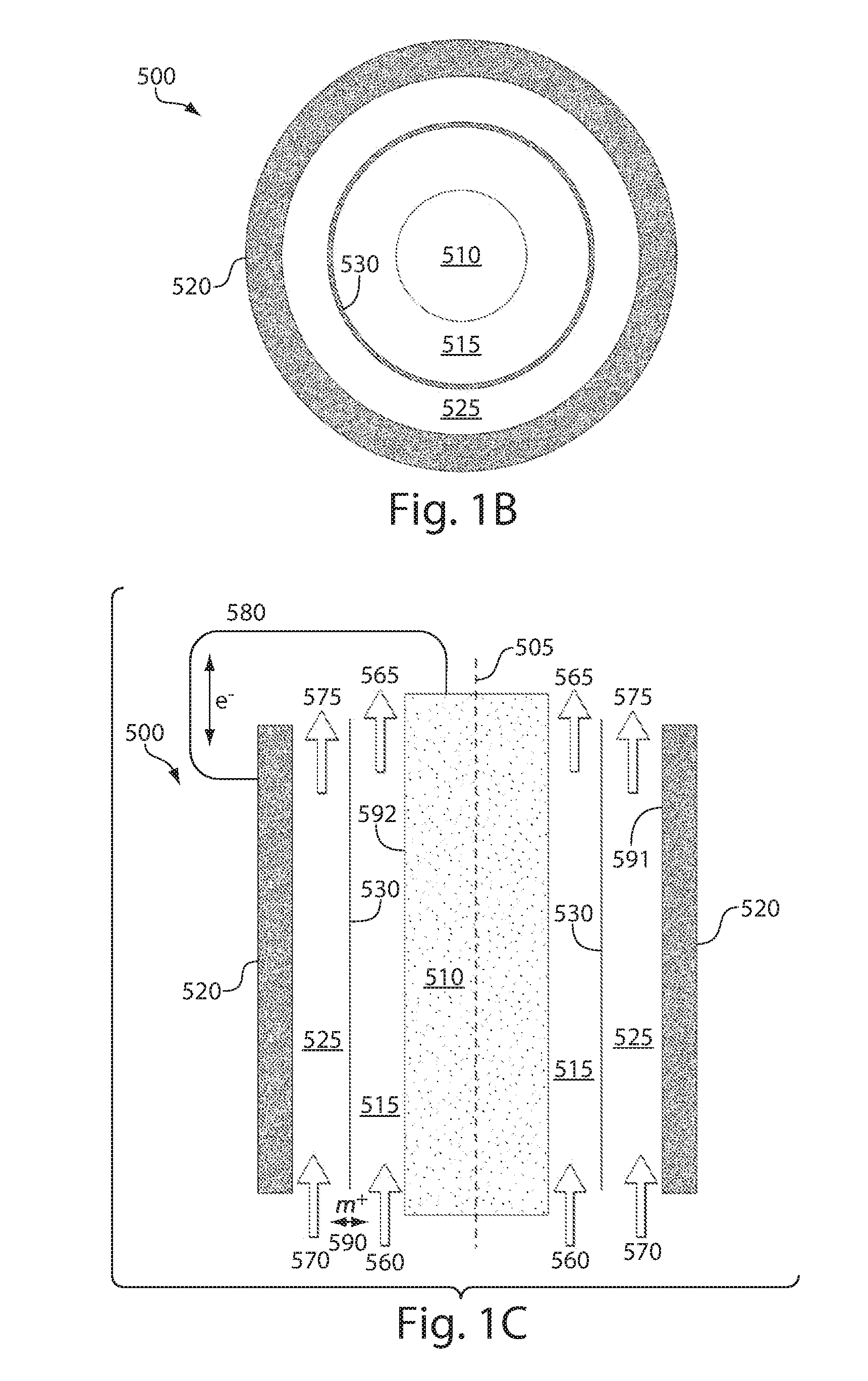

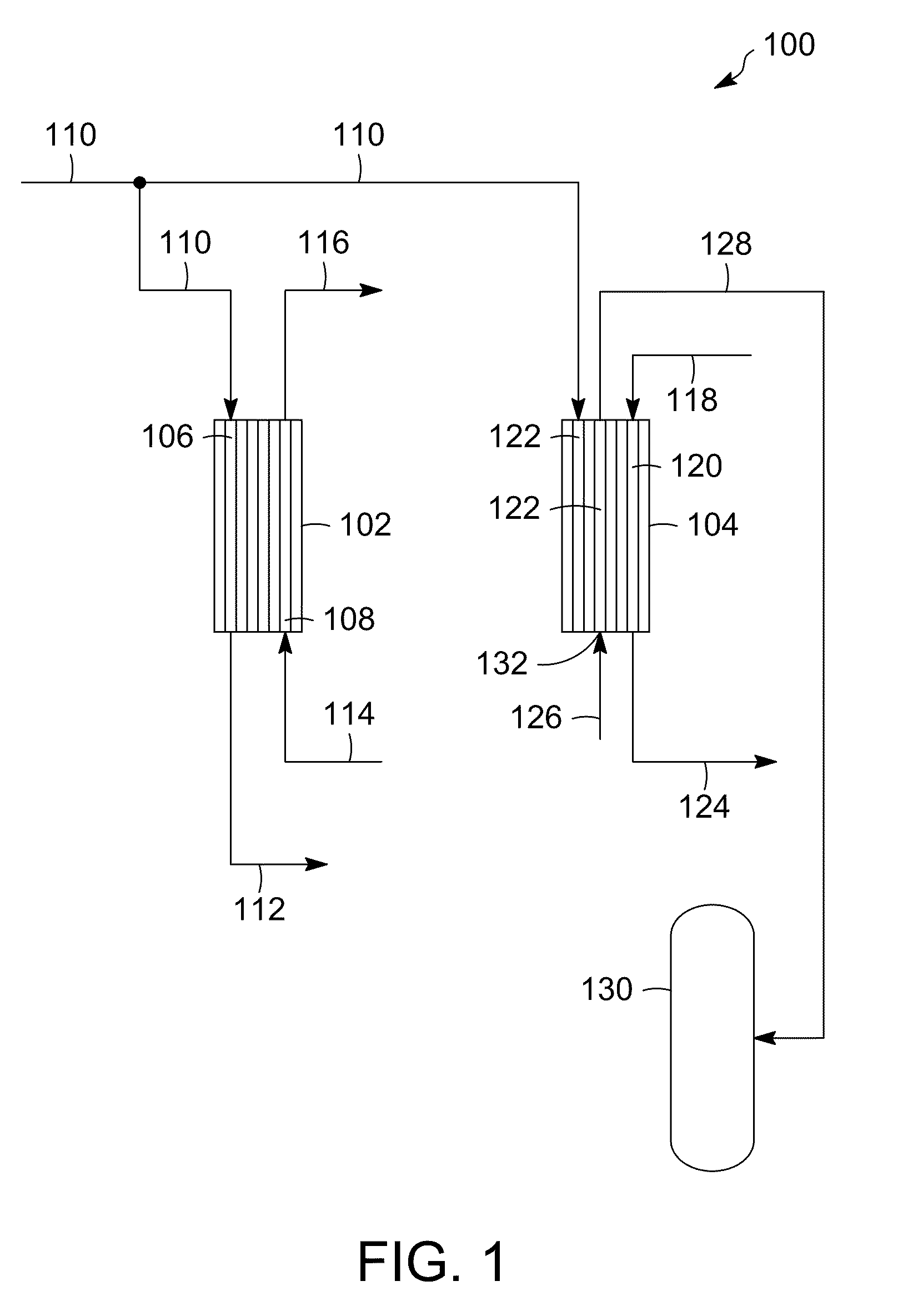

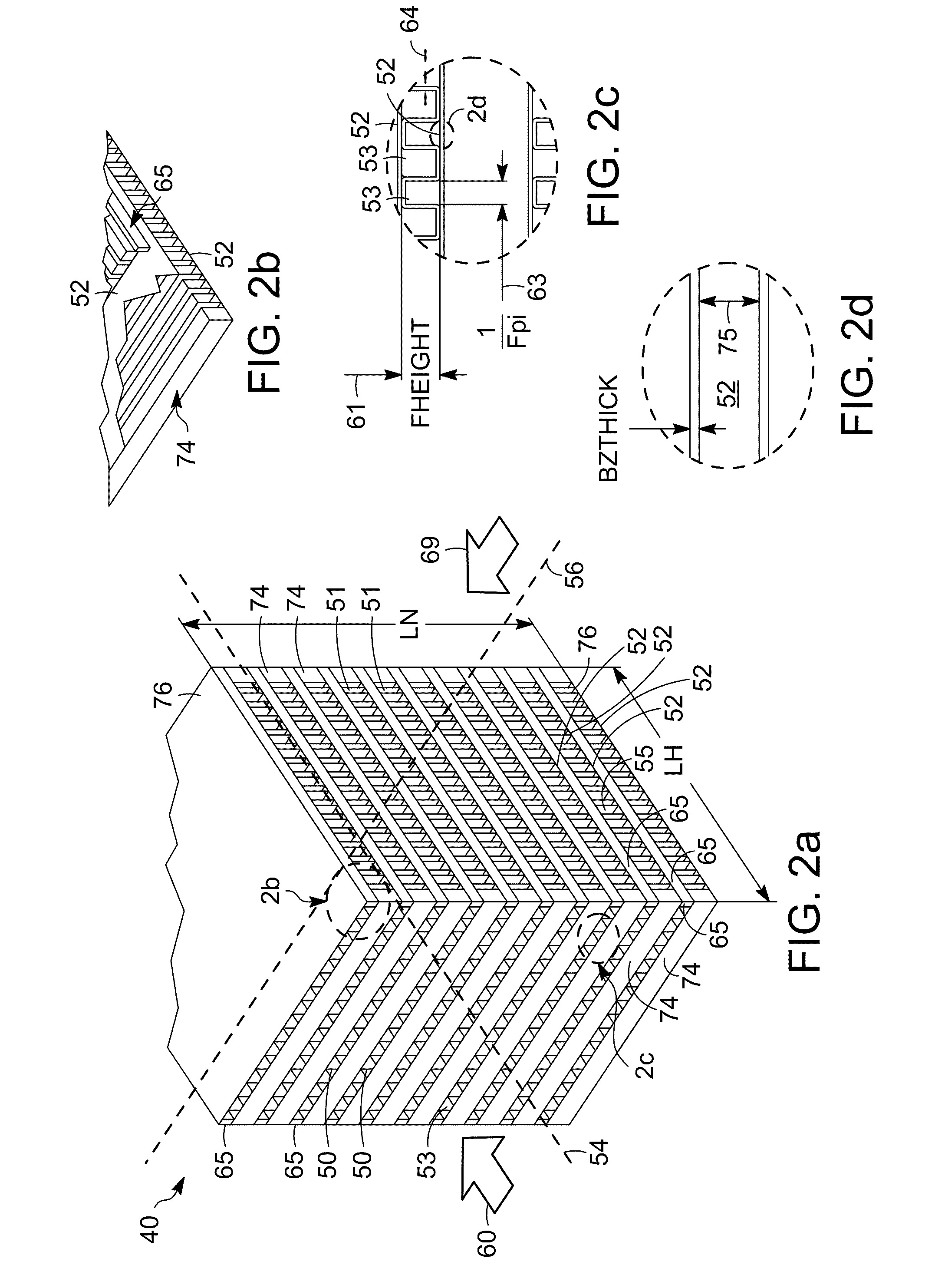

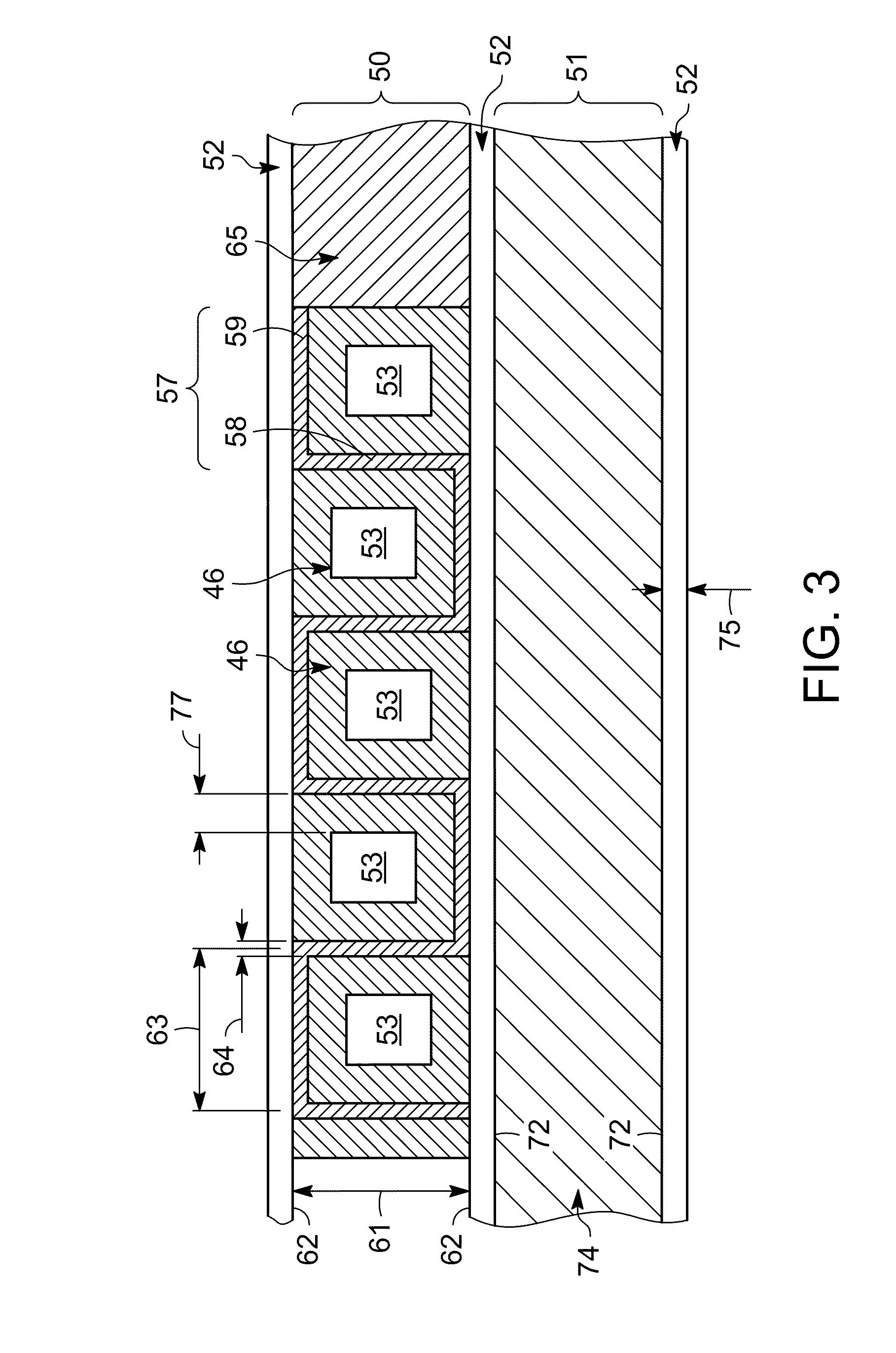

High energy density redox flow device

ActiveUS20110200848A1Avoid accumulationHigh enough specific energyOrganic chemistryFlow propertiesElectrochemical responseHigh energy

Redox flow devices are described in which at least one of the positive electrode or negative electrode-active materials is a semi-solid or is a condensed ion-storing electroactive material, and in which at least one of the electrode-active materials is transported to and from an assembly at which the electrochemical reaction occurs, producing electrical energy. The electronic conductivity of the semi-solid is increased by the addition of conductive particles to suspensions and / or via the surface modification of the solid in semi-solids (e.g., by coating the solid with a more electron conductive coating material to increase the power of the device). High energy density and high power redox flow devices are disclosed. The redox flow devices described herein can also include one or more inventive design features. In addition, inventive chemistries for use in redox flow devices are also described.

Owner:MASSACHUSETTS INST OF TECH +2

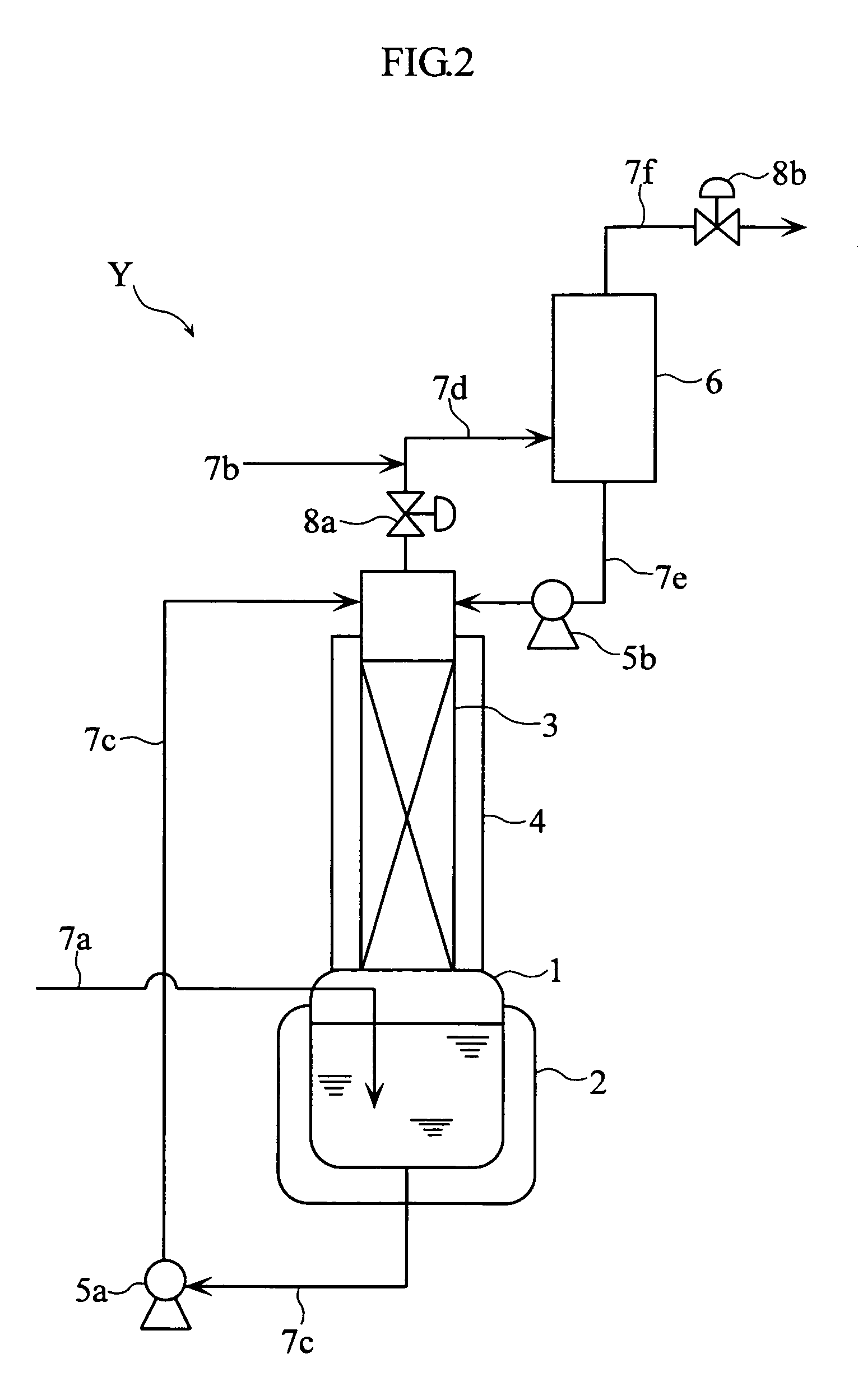

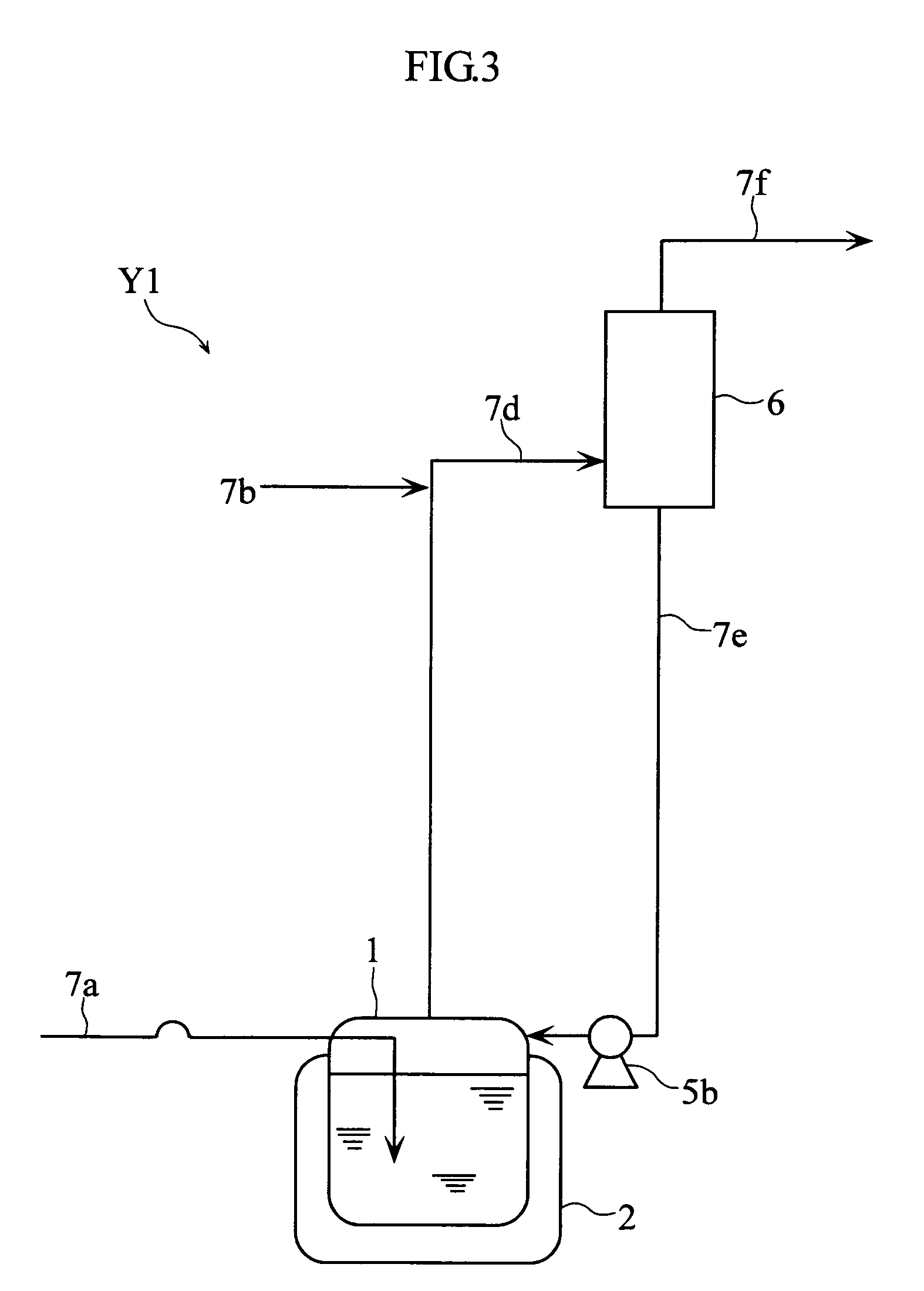

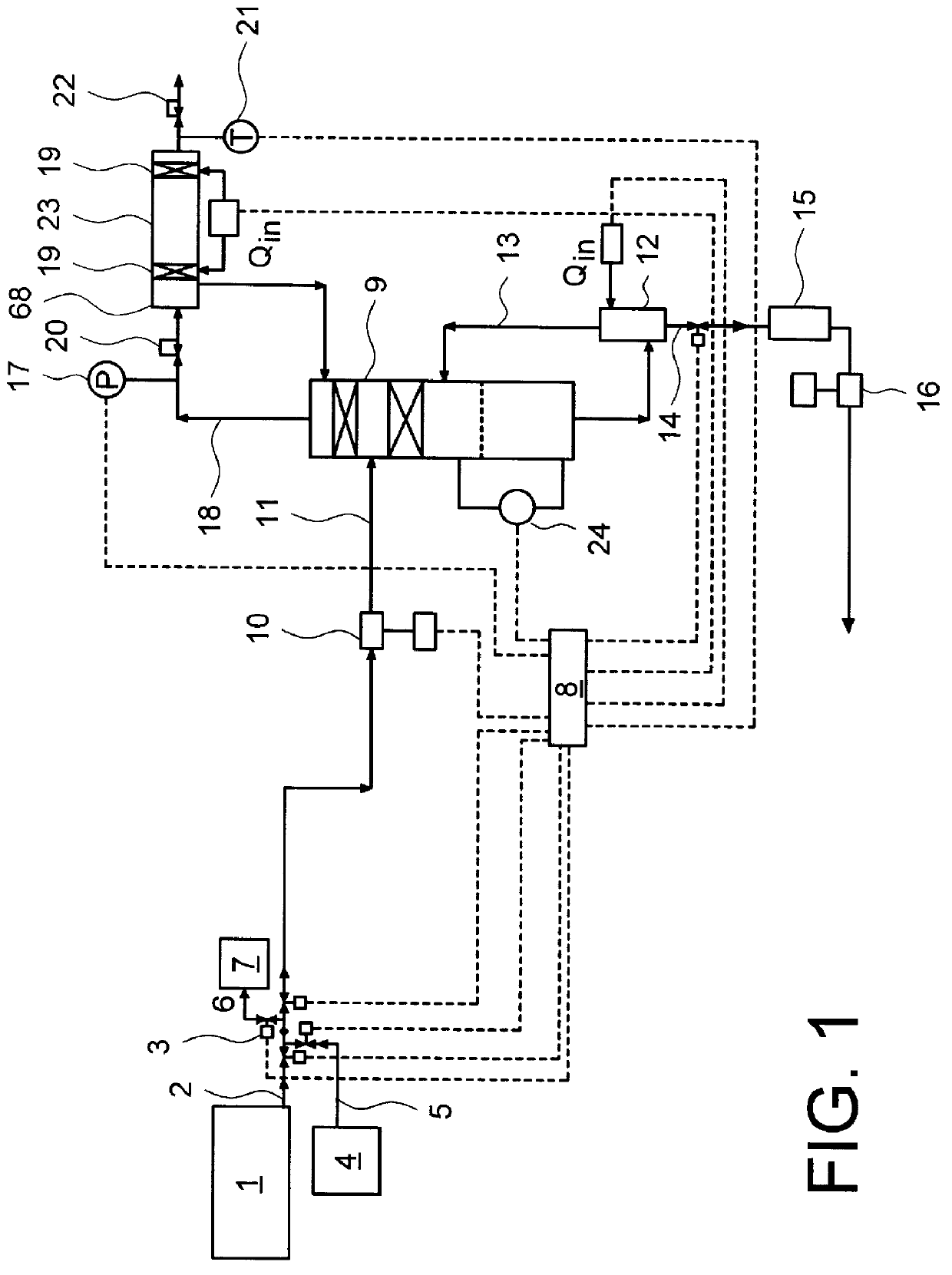

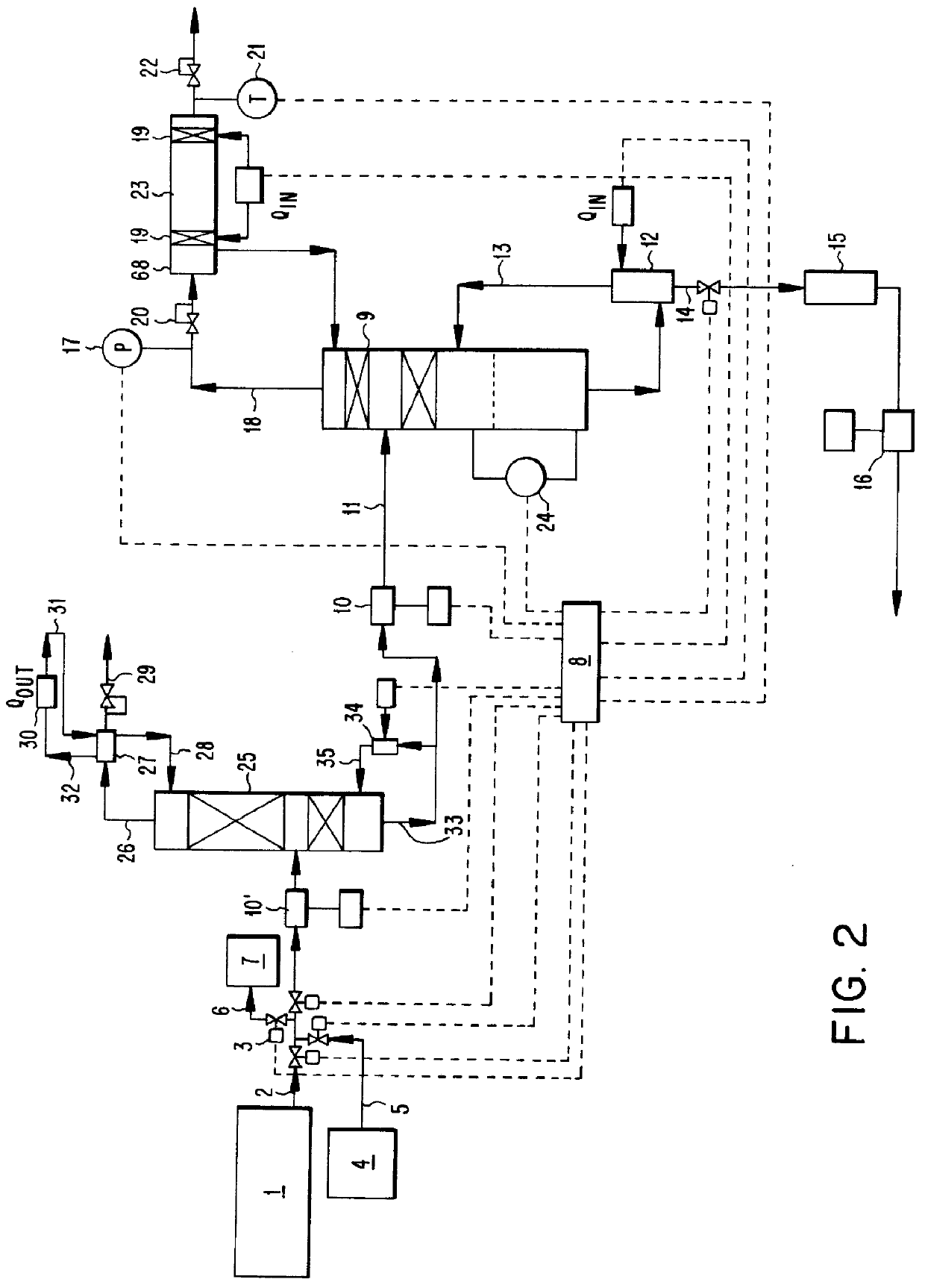

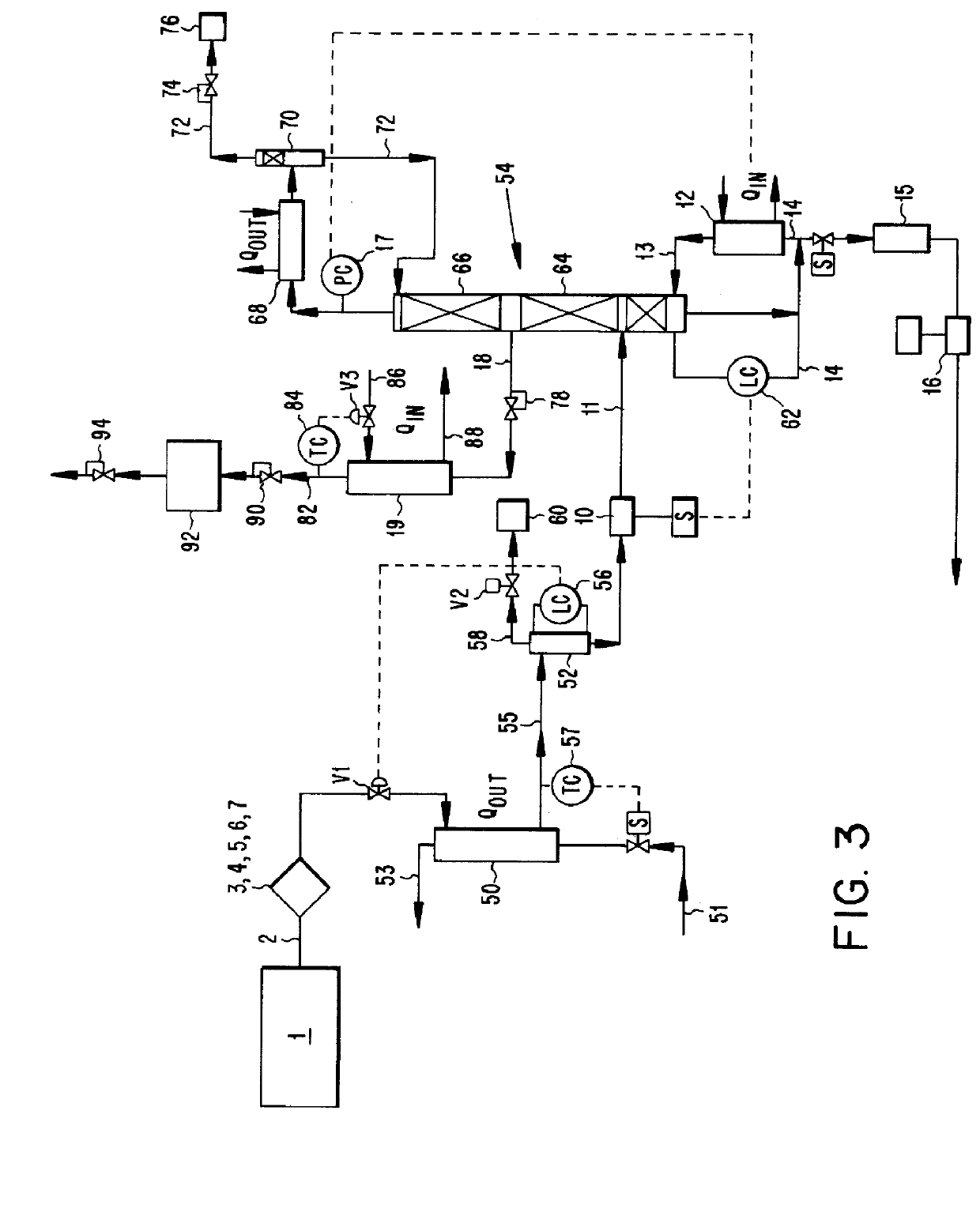

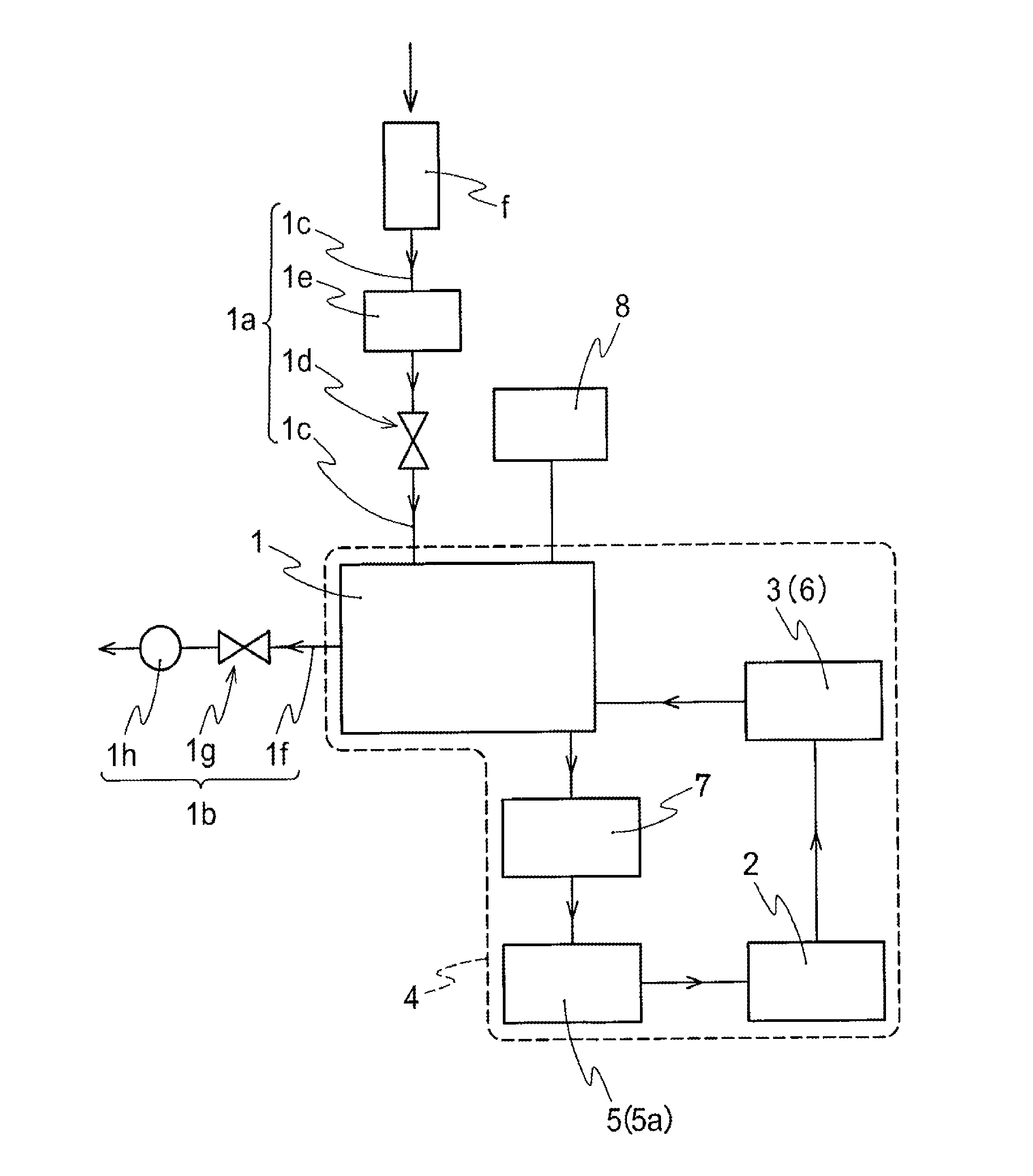

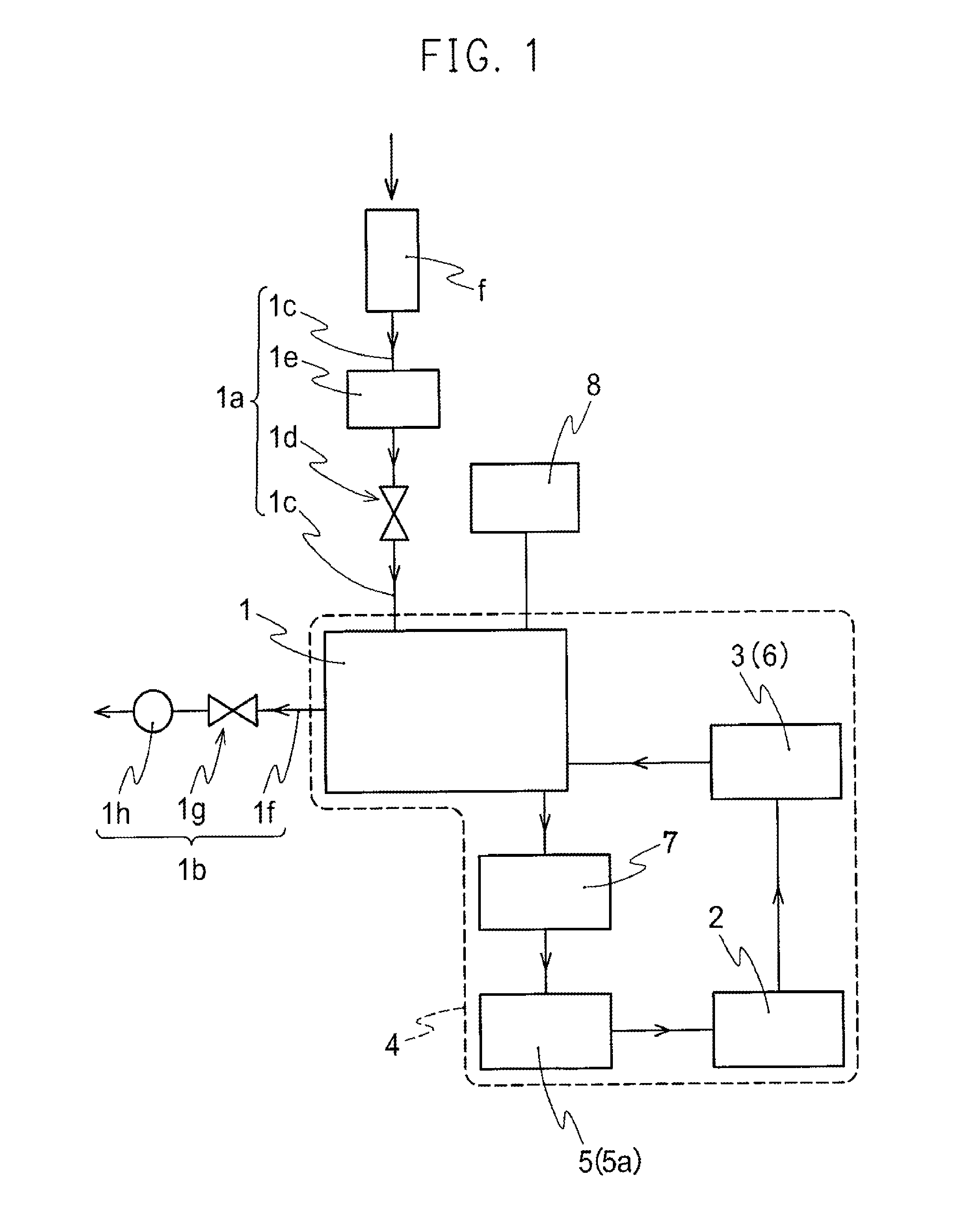

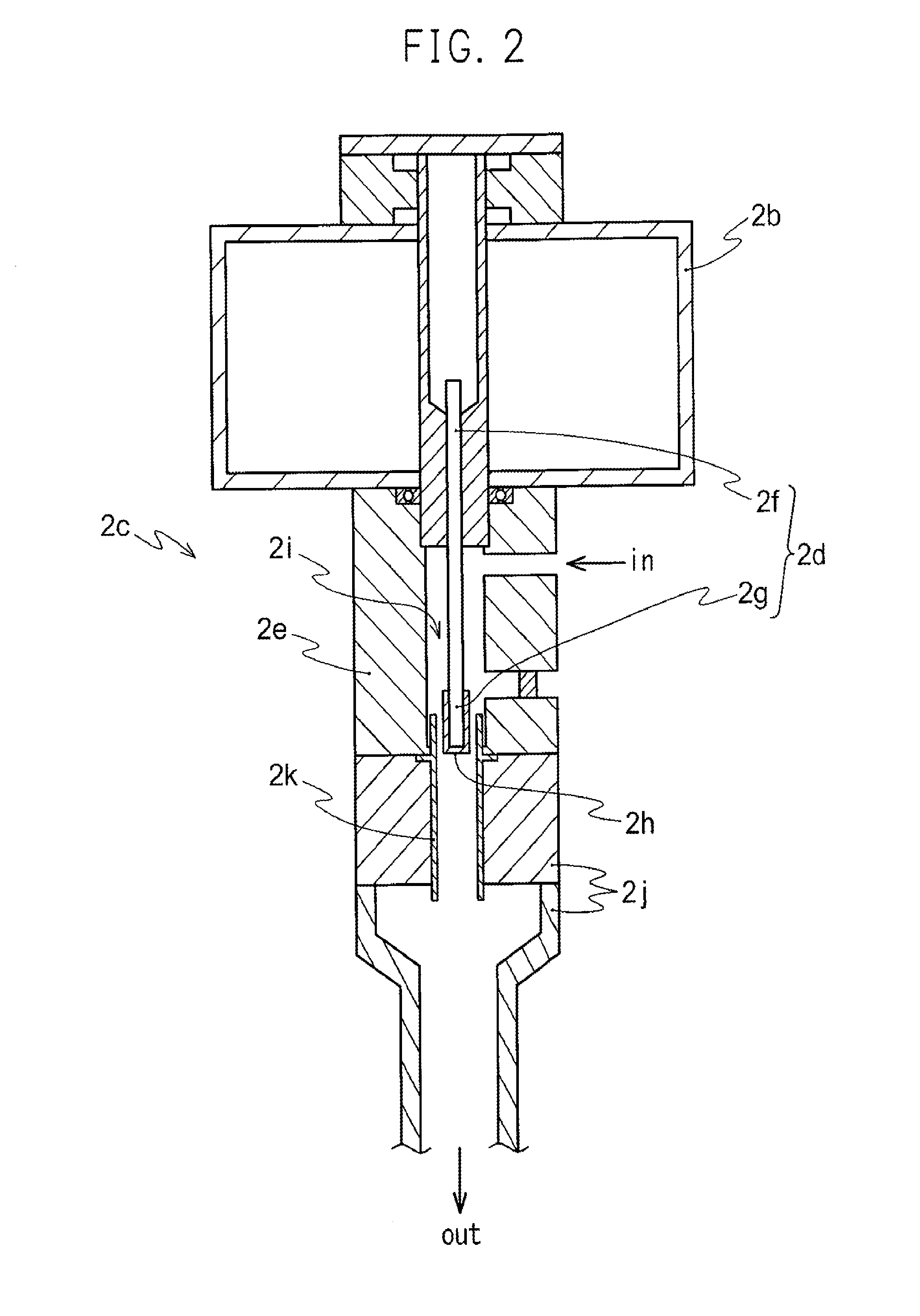

Method for purification of nitrogen oxide and apparatus for purification of nitrogen oxide

ActiveUS7776305B2Efficient purificationImprove securityNitric oxideNitrous oxidesNitrogen oxidesRadiochemistry

A nitrogen oxide purifying apparatus includes a gas absorption vessel (1) and a condenser (6), where the vessel receives an absorption solution containing liquefied N2O4 for absorbing NO and also receives a source gas to vary the temperature and / or pressure of the source gas and the absorption solution, while the condenser receives a gas from the gas absorption vessel (1) to vary the temperature and / or pressure of the gas. In the gas absorption vessel (1), the absorption solution containing liquefied N2O4 may be applied to the source gas containing NO, so that NO is absorbed in the absorption solution. Then the absorption-solution is heated and / or depressurized to generate an intermediate gas containing a relatively large amount of NO and a smaller amount of NO2 from the absorption solution. In the condenser (6), the intermediate gas is cooled and / or pressurized to give condensed N2O3 and / or condensed N2O4.

Owner:SUMITOMO SEIKA CHEM CO LTD

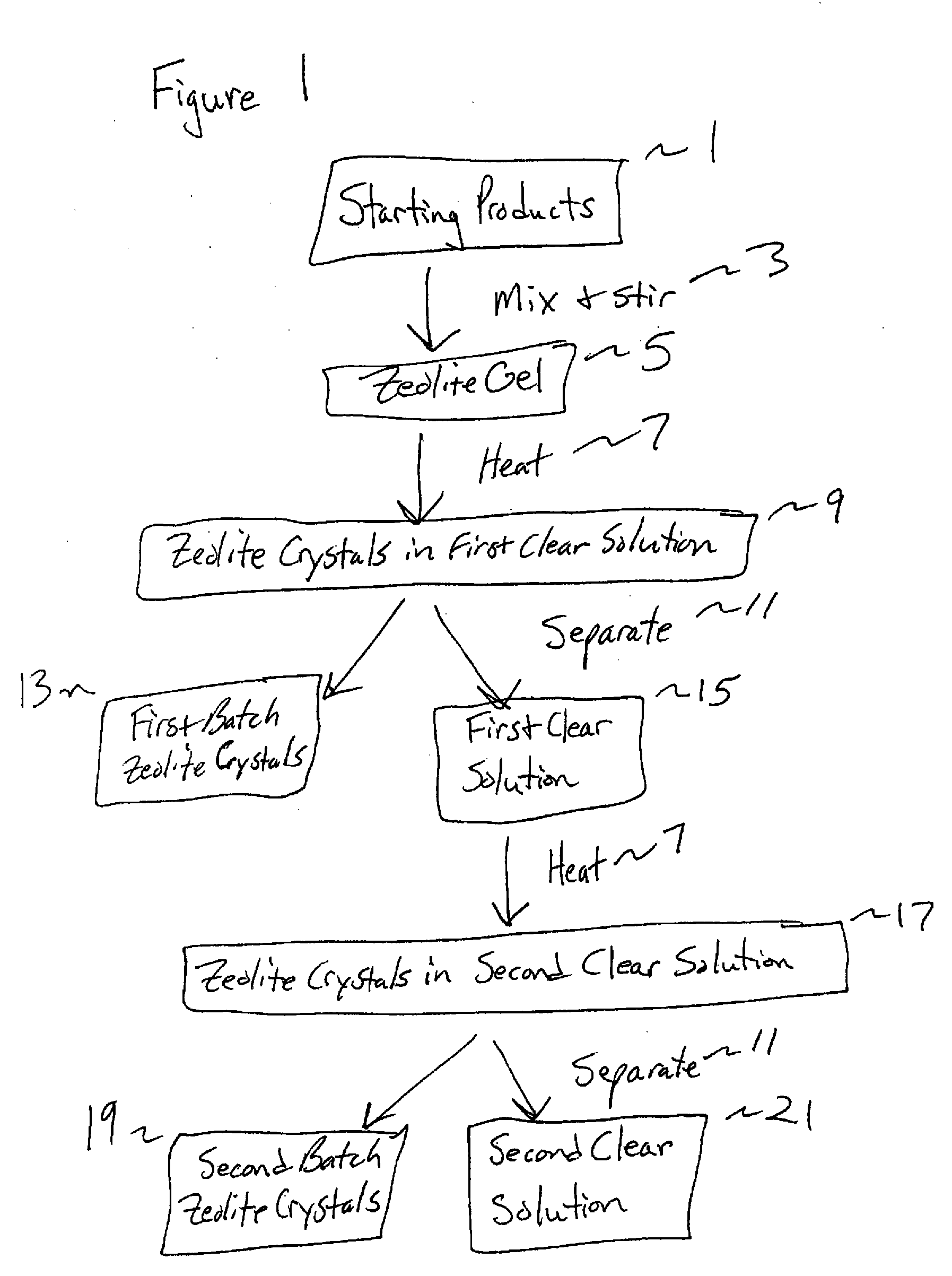

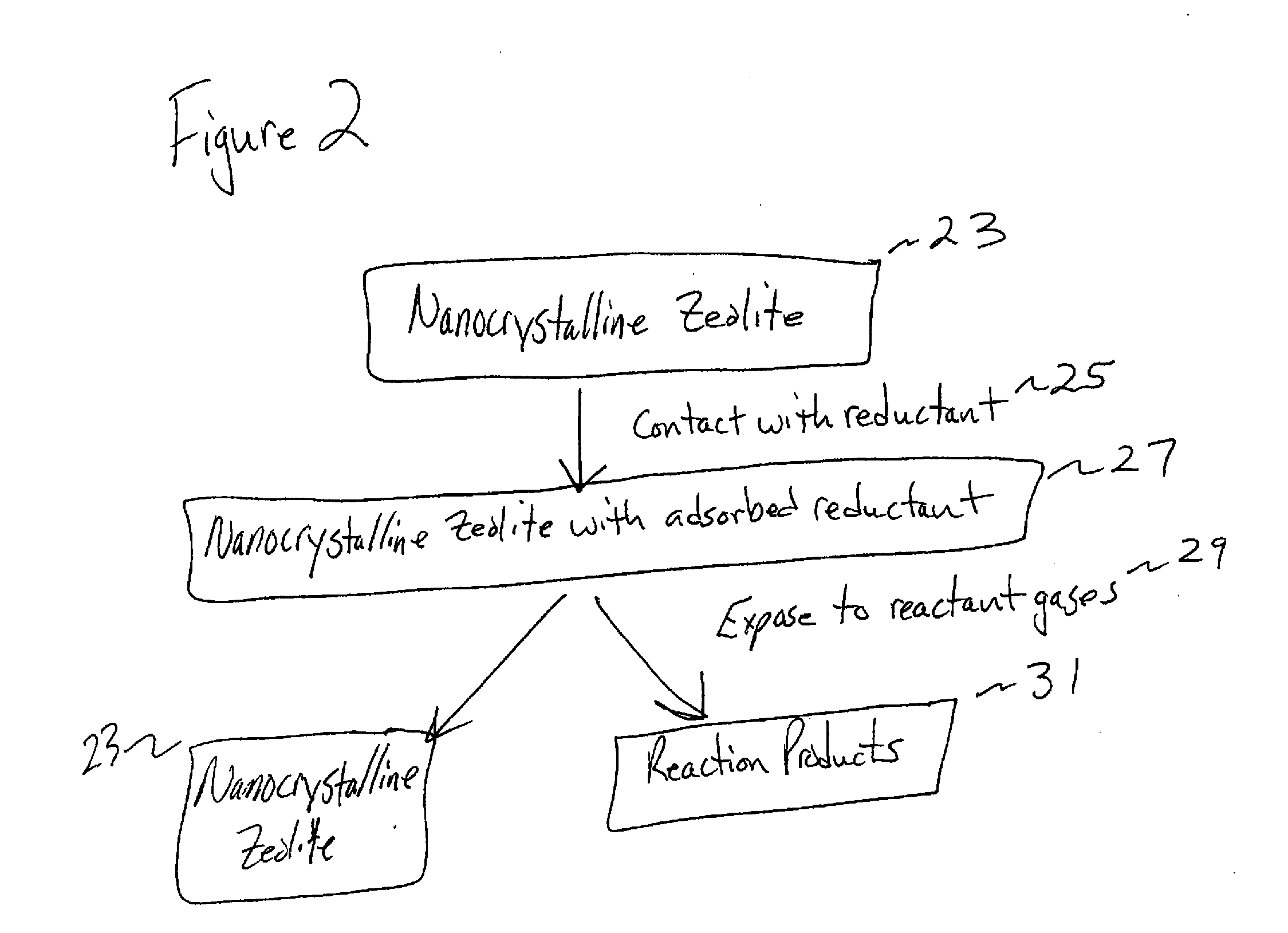

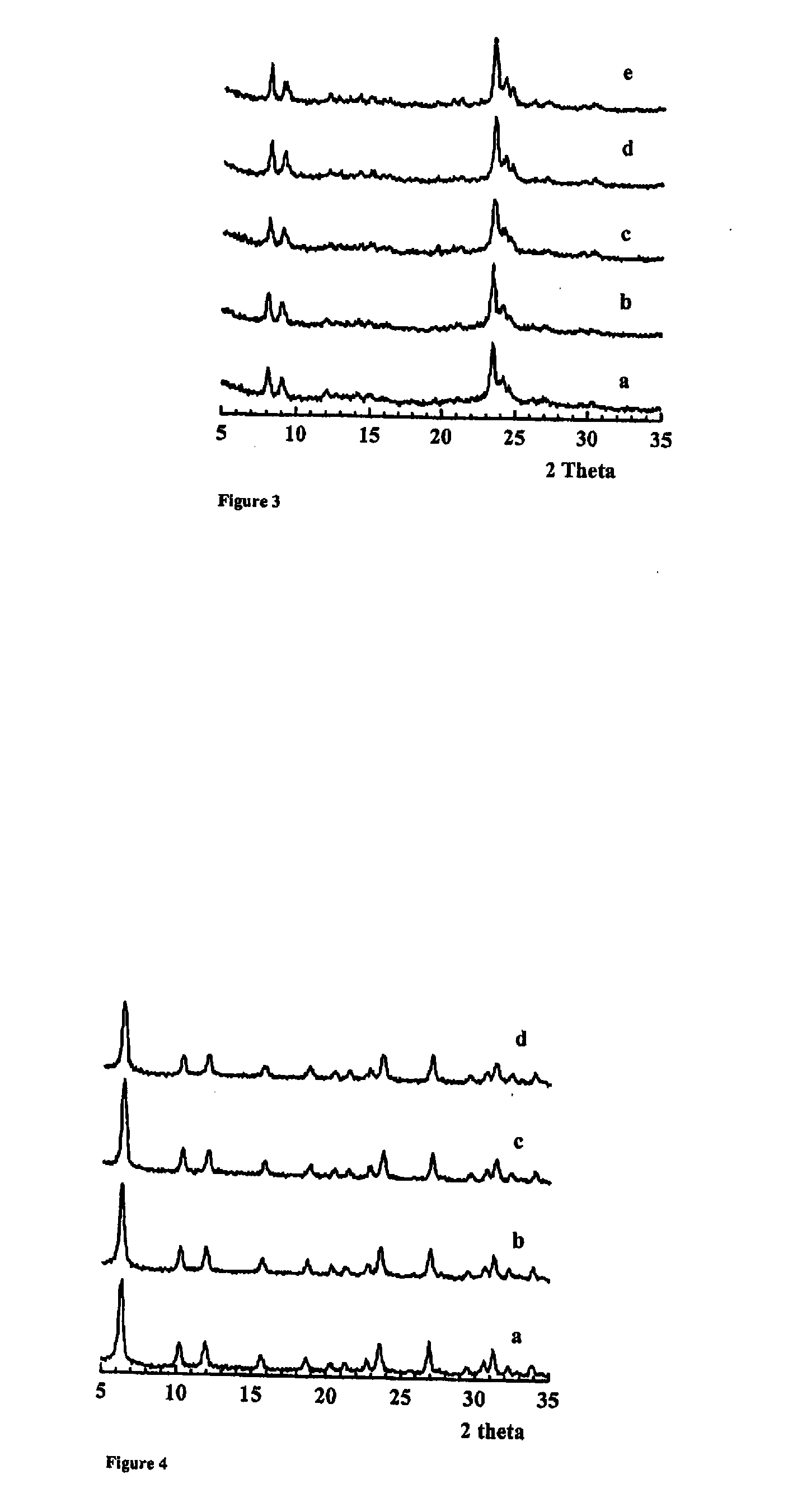

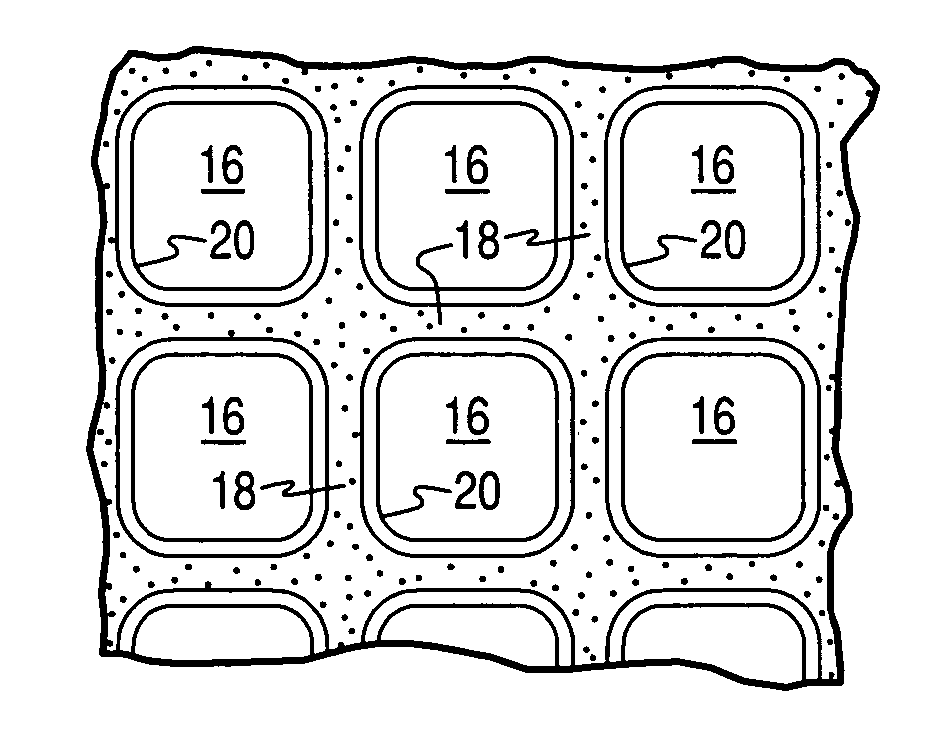

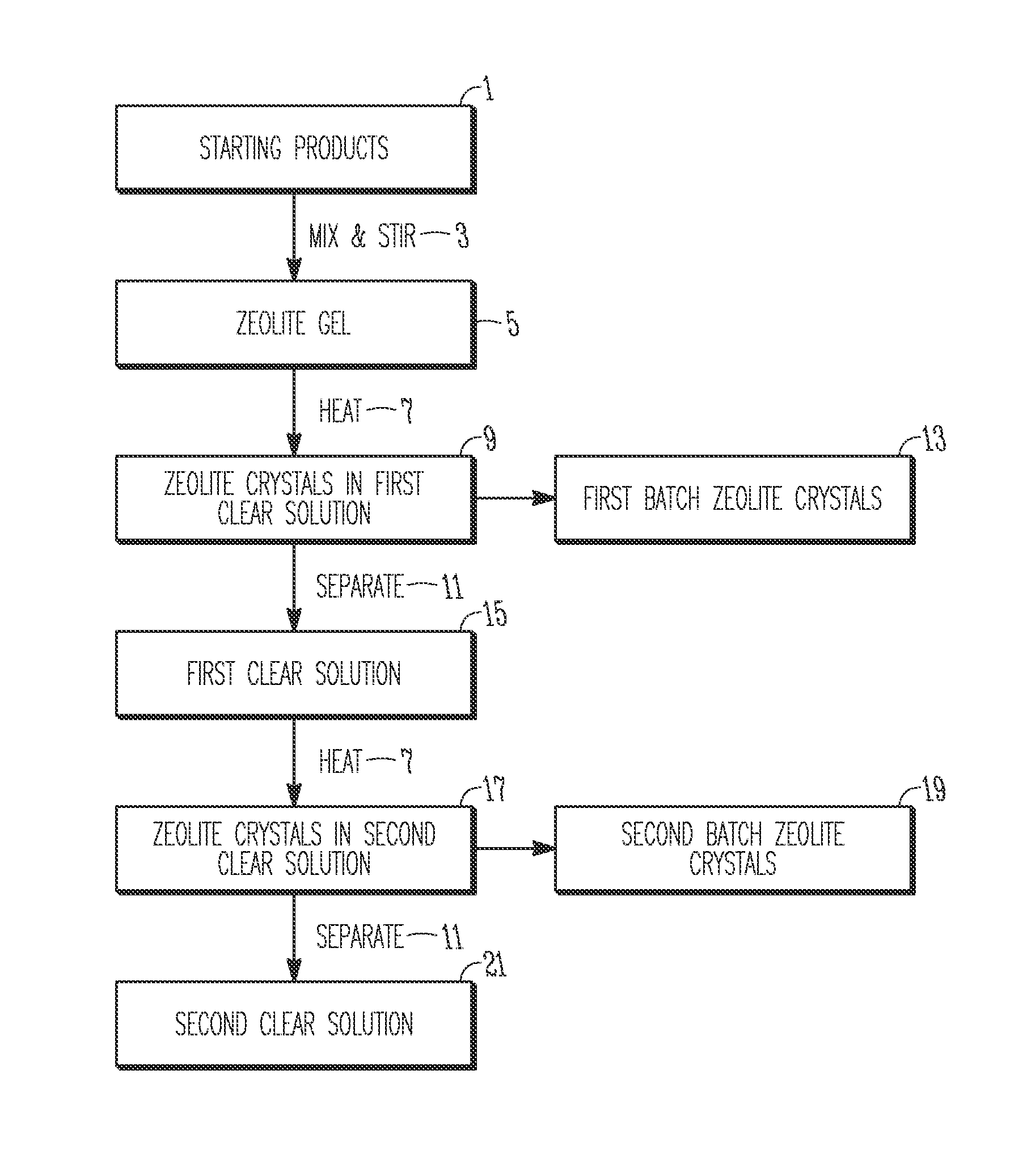

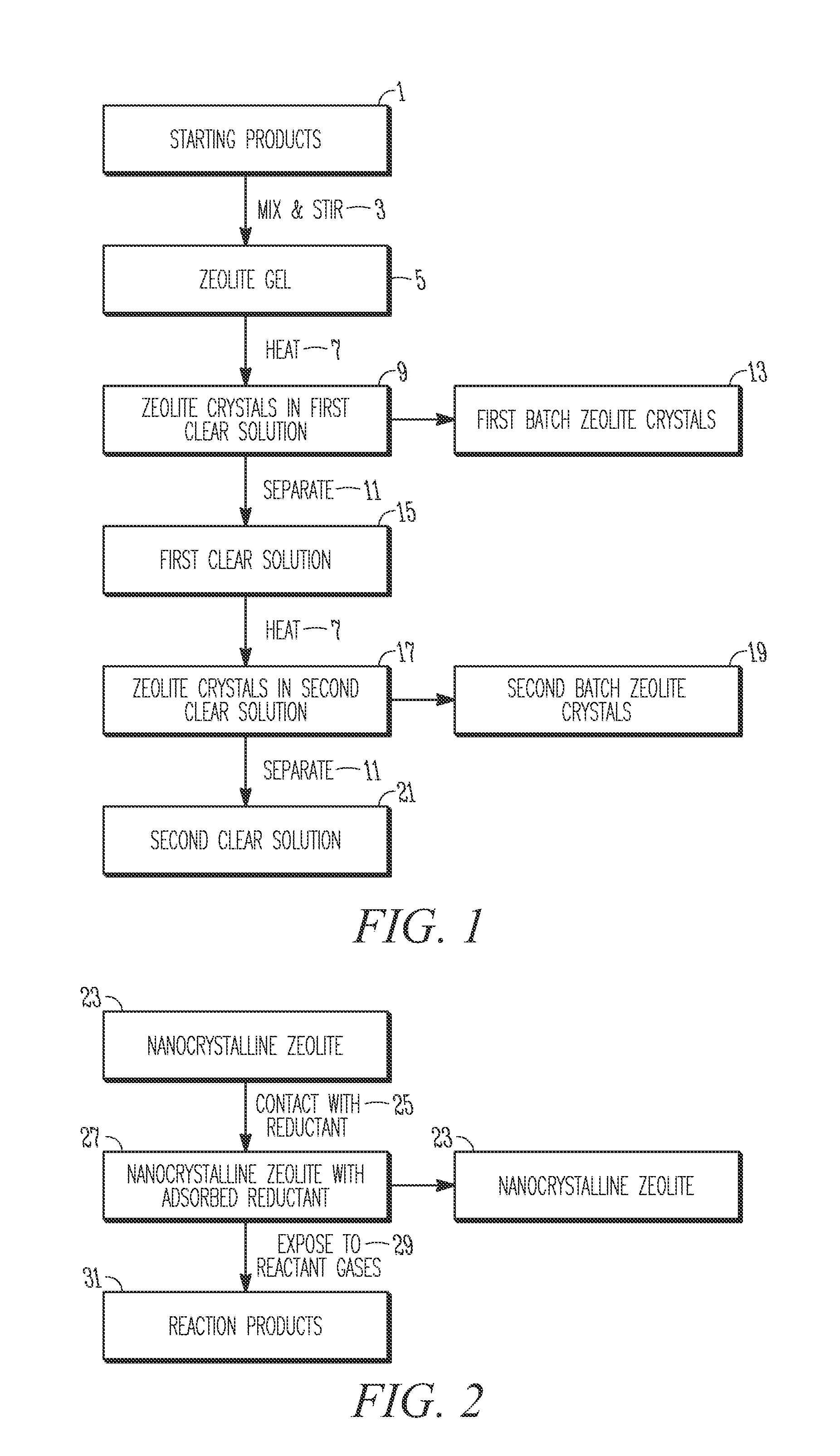

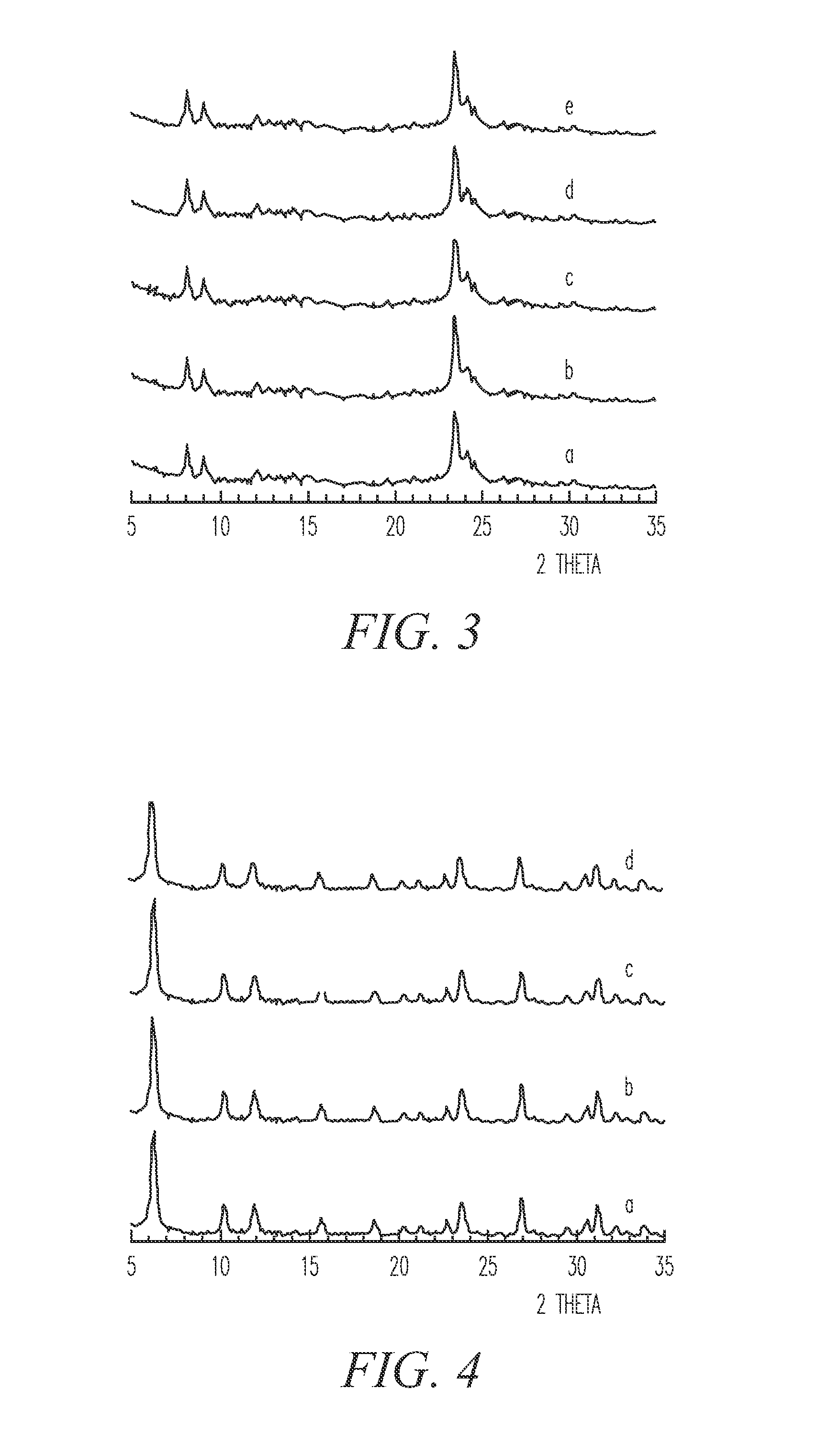

Synthesis and use of nanocrystalline zeolites

InactiveUS20070071666A1High yieldMore consistent crystal sizeNitrous oxide captureMaterial nanotechnologySolventHydrolysis

Embodiments of the present invention relate to a method for synthesizing nanocrystalline zeolites, the method comprising contacting starting products that comprise a solvent, a silicon source, a cation base, an organic template, and an aluminum source, or any combination thereof sufficient to produce a zeolite gel by hydrolysis, heating the zeolite gel sufficient to produce a first batch of zeolite crystals and a first clear solution, separating the first batch of zeolite crystals from the first clear solution, heating the first clear solution sufficient to produce a second batch of zeolite crystals and second clear solution and separating the second batch of zeolite crystals from the second clear solution. In addition, embodiments relate to a method of using nanocrystalline zeolites, the method comprising contacting a nanocrystalline zeolite with a reductant sufficient to produce a nanocrystalline zeolite with adsorbed reductant and exposing the nanocrystalline zeolite with adsorbed reductant to reactant gases sufficient to obtain reaction products and the nanocrystalline zeolite.

Owner:UNIV OF IOWA RES FOUND

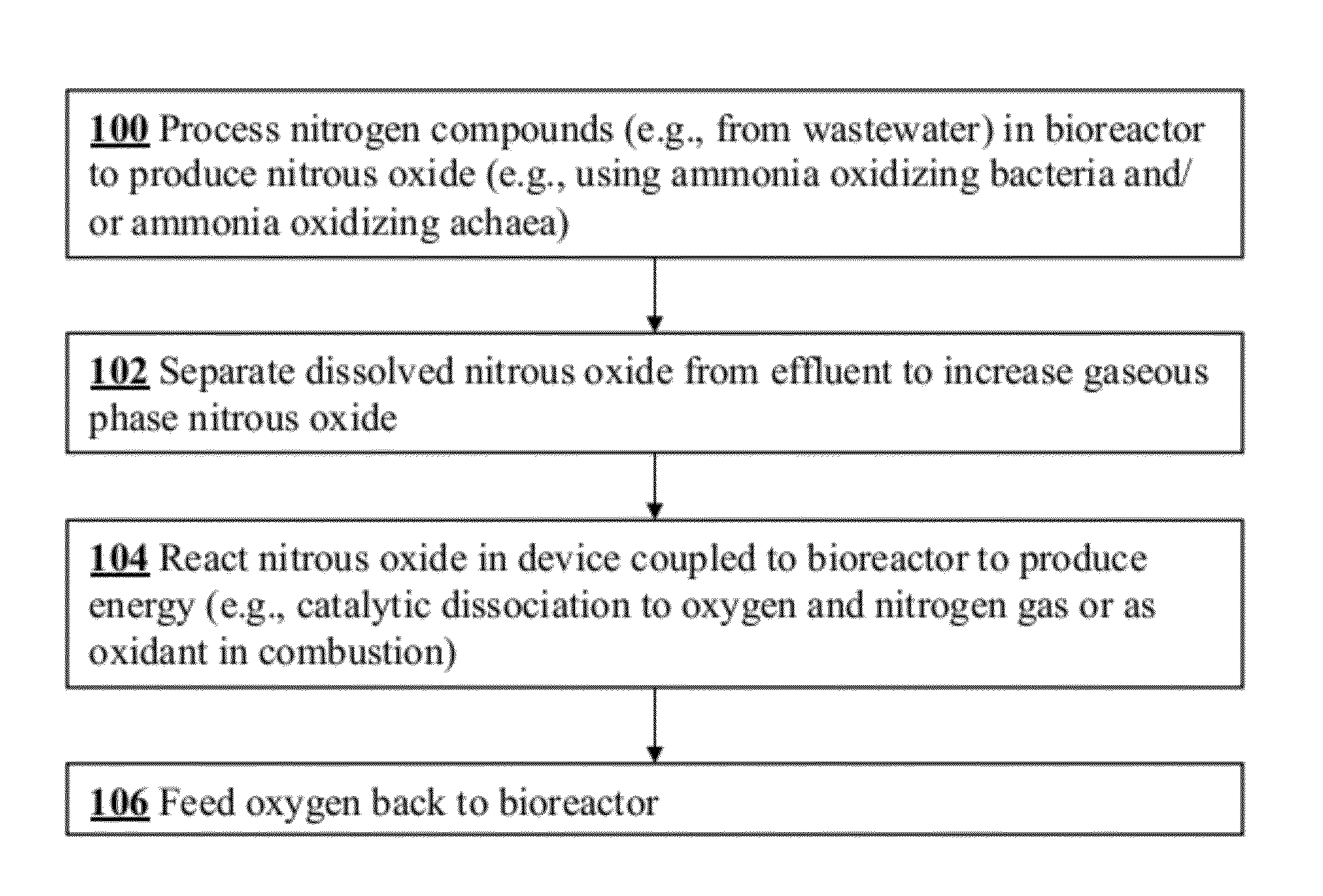

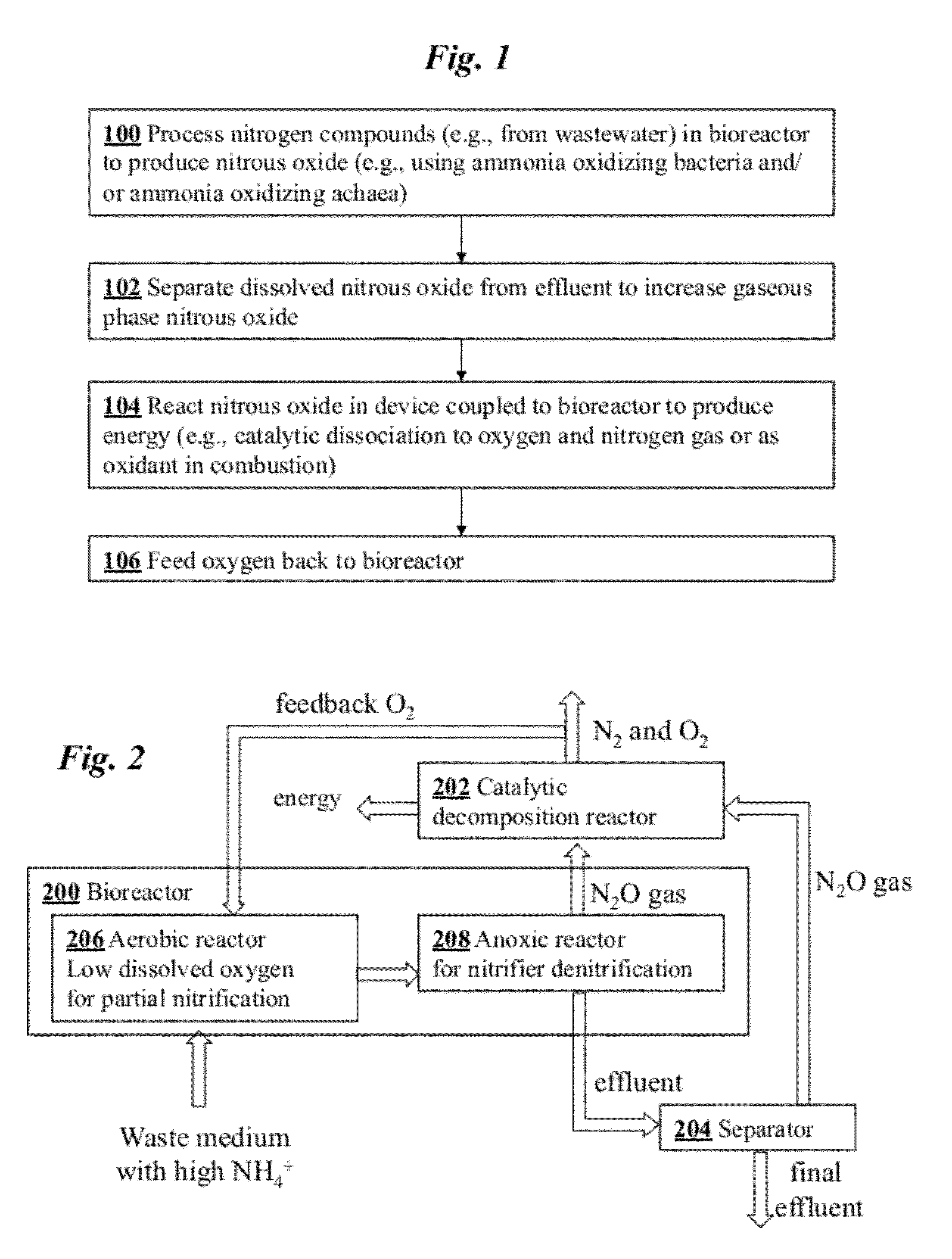

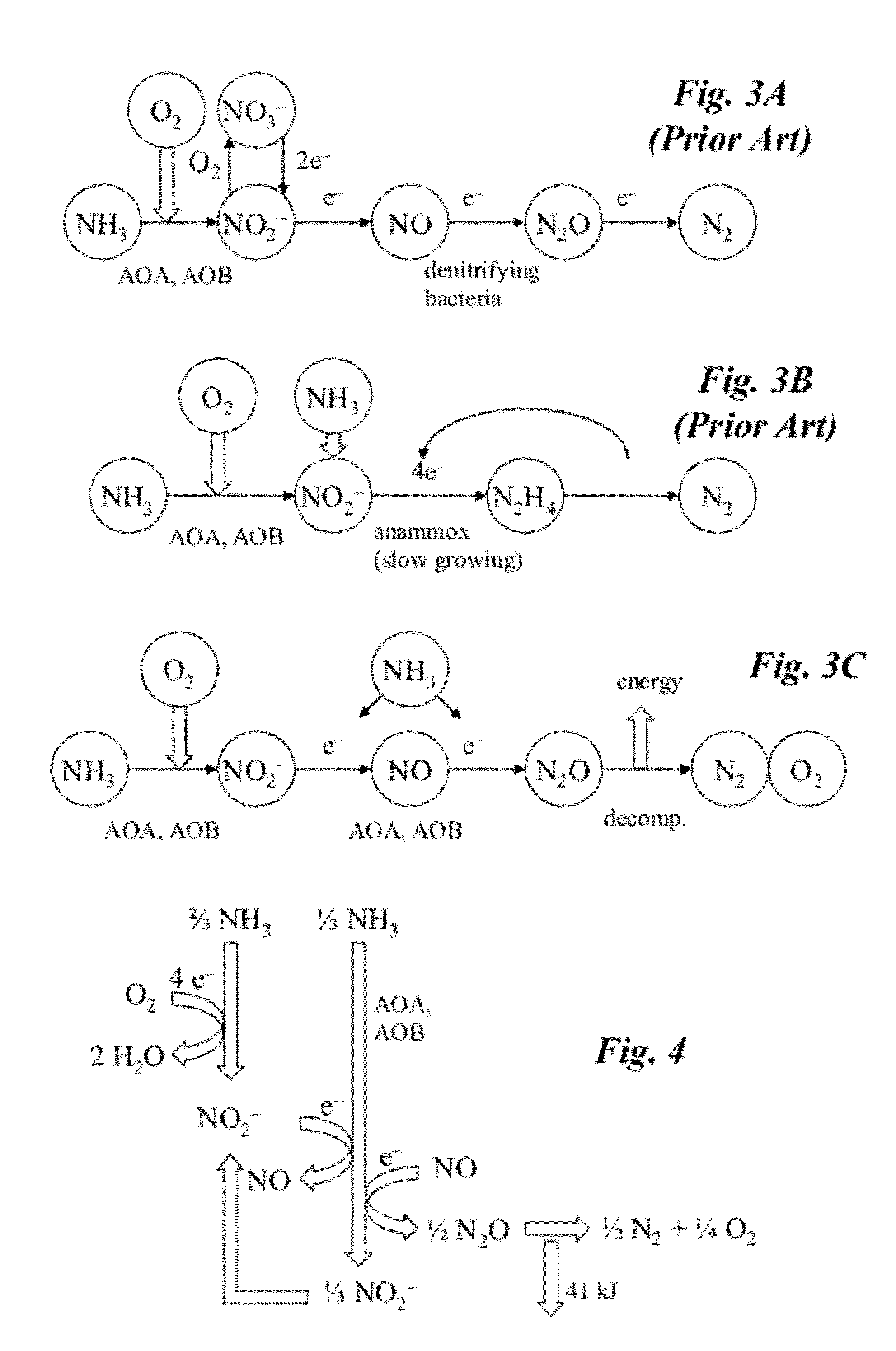

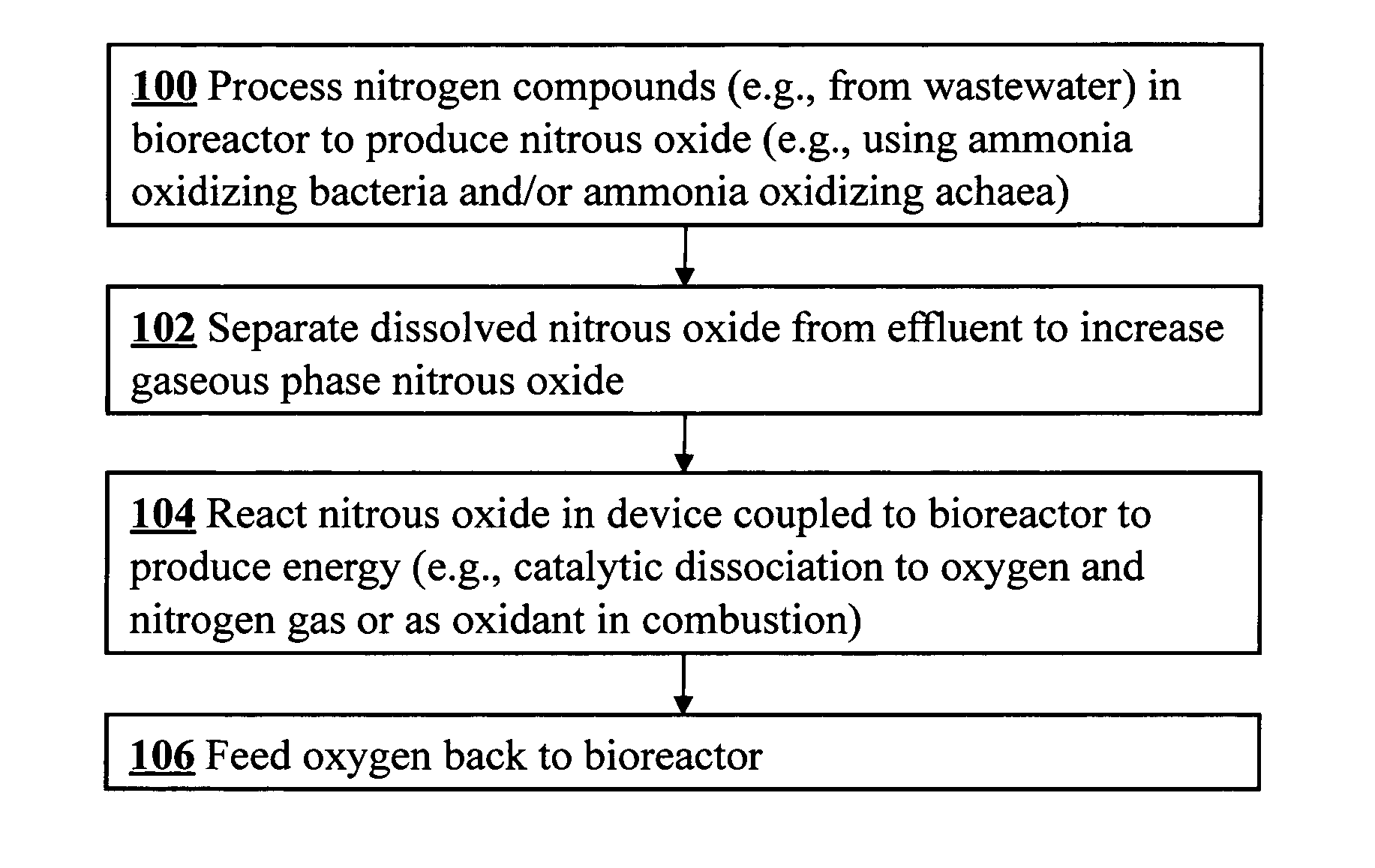

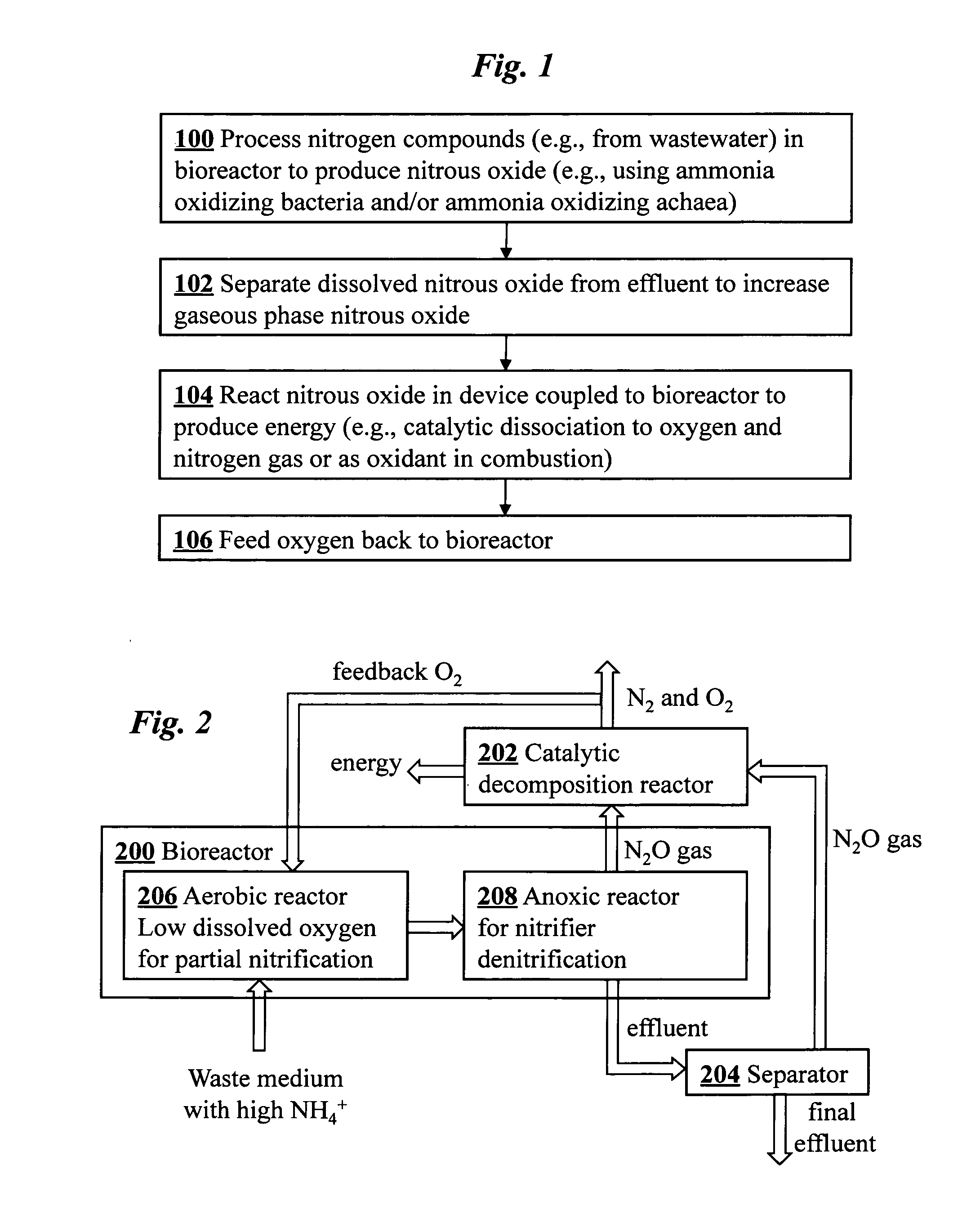

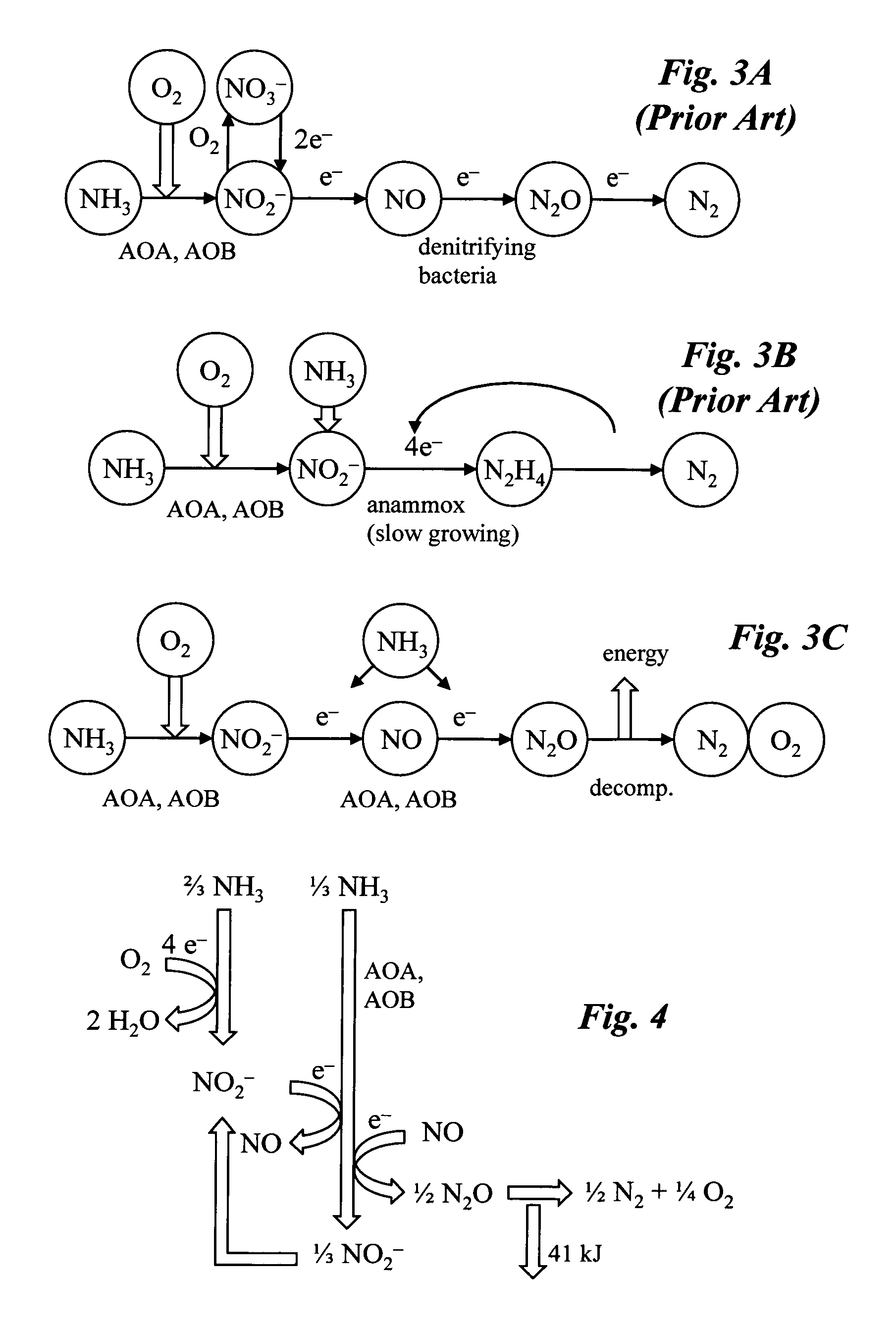

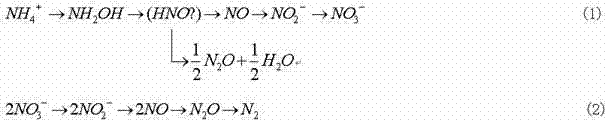

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

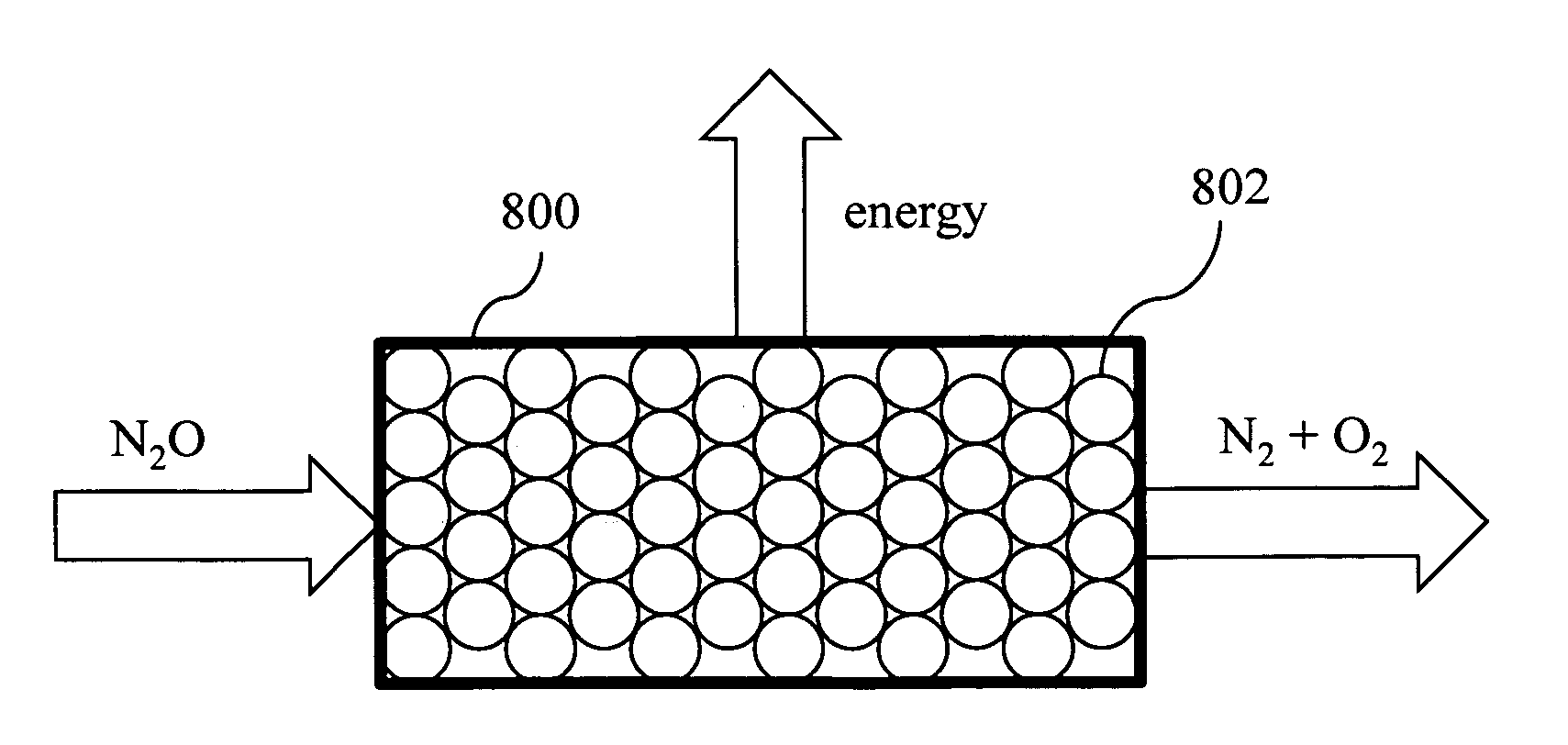

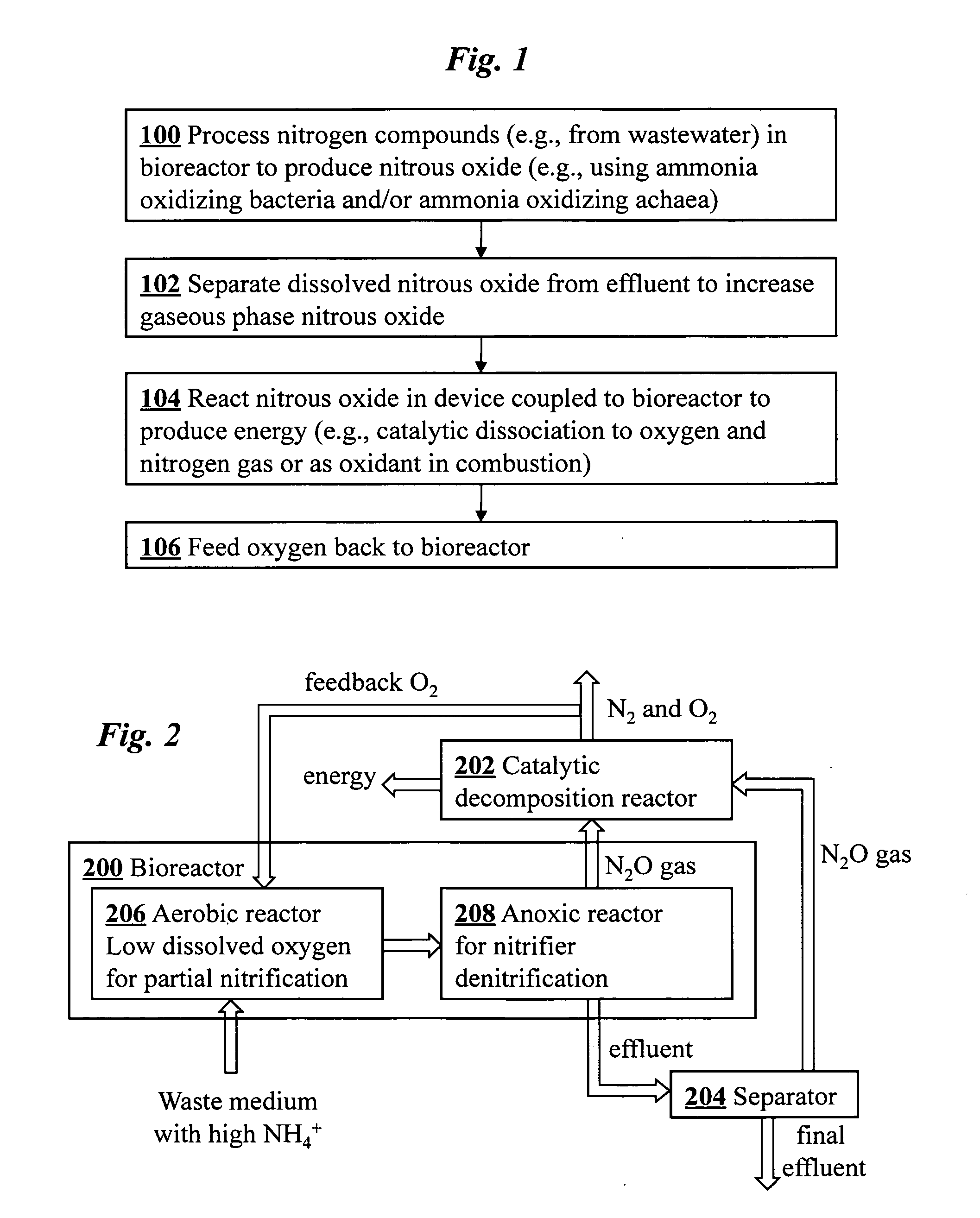

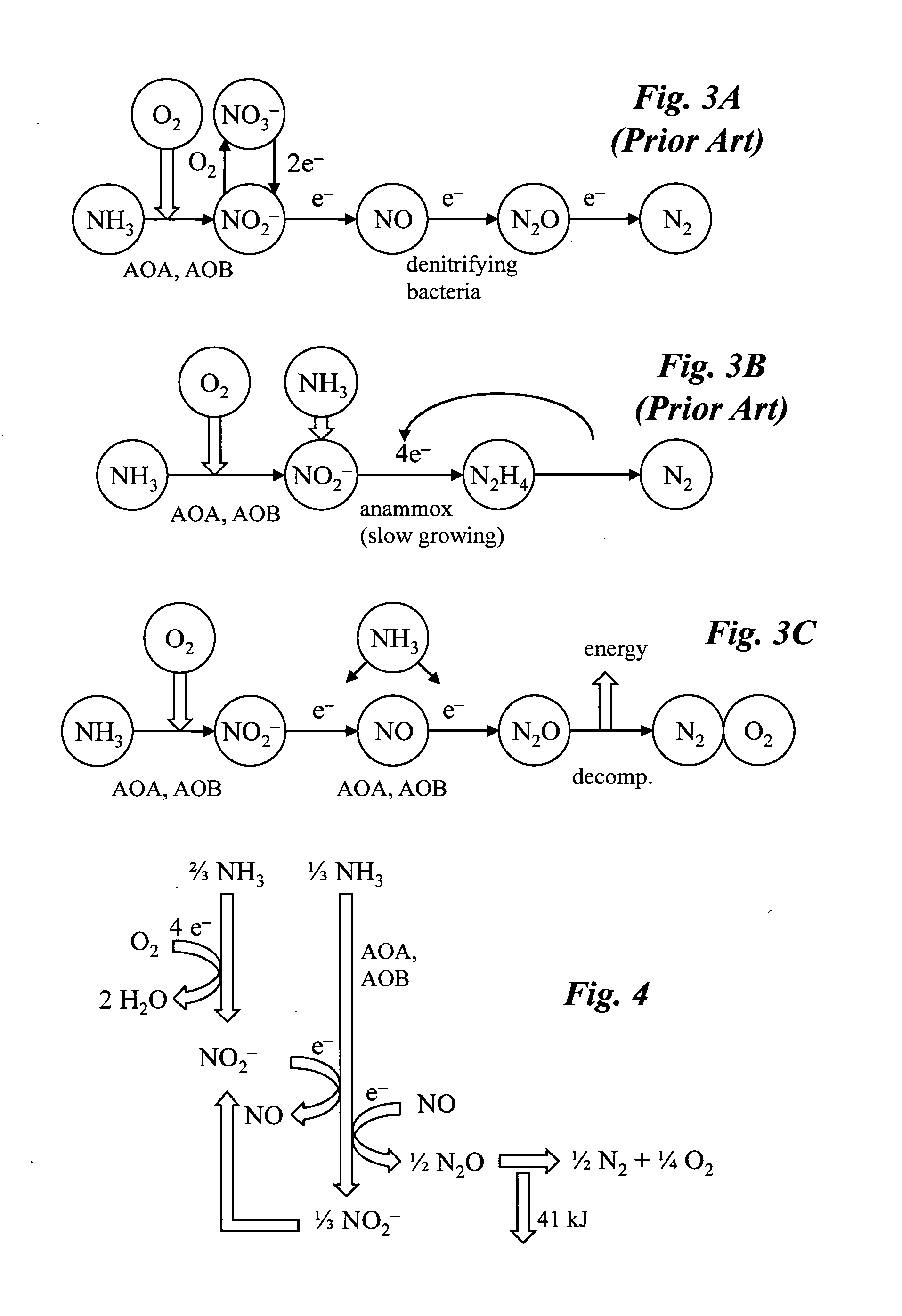

InactiveUS20120309071A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionGas phase

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

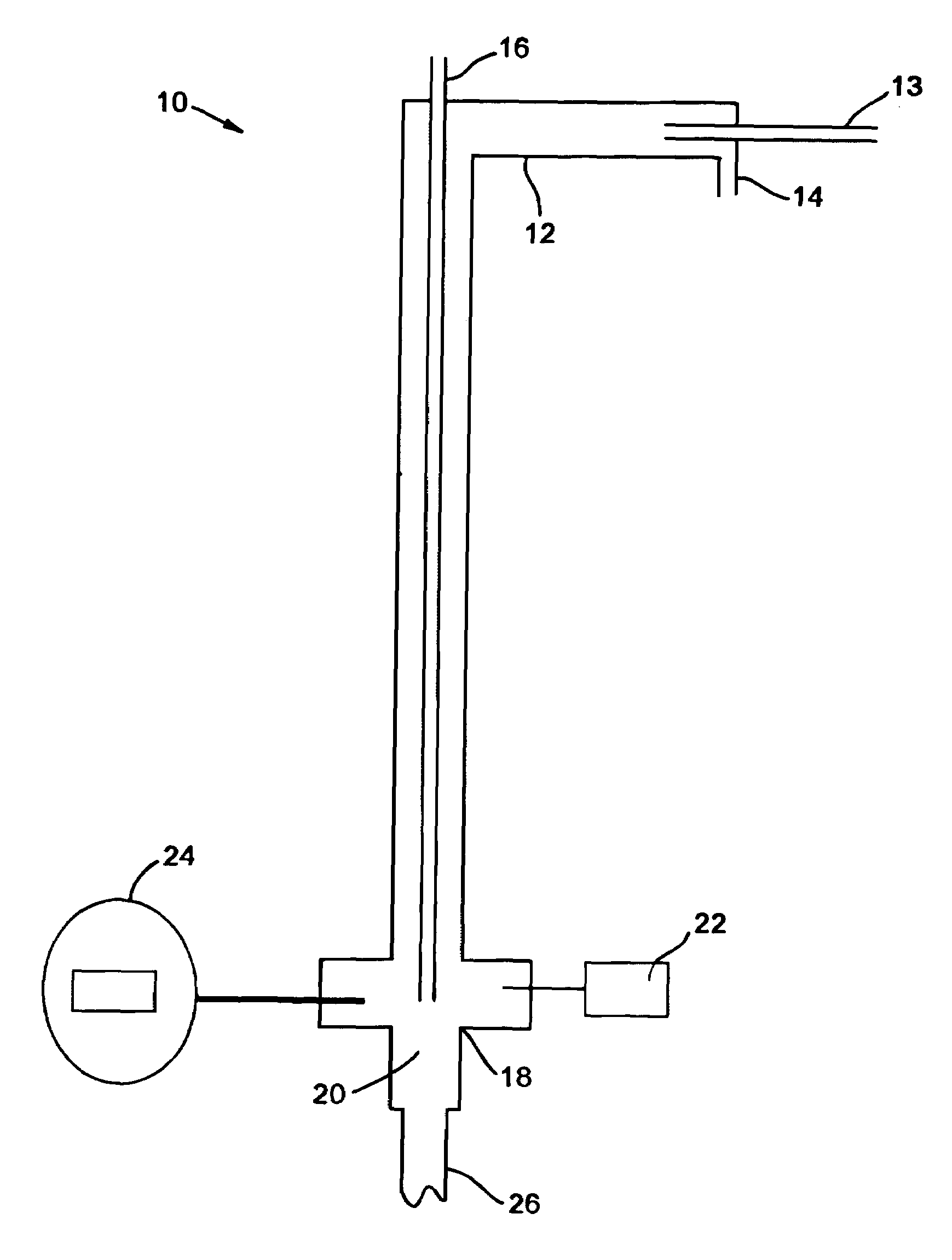

InactiveUS20110207061A1Treatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorFiber

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas.Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane. The bioreactor may have various designs including a two-stage bioreactor, a hollow-fiber membrane bioreactor, or a sequencing batch reactor. The bioreactor may involve Fe(II)-mediated reduction of nitrite to nitrous oxide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

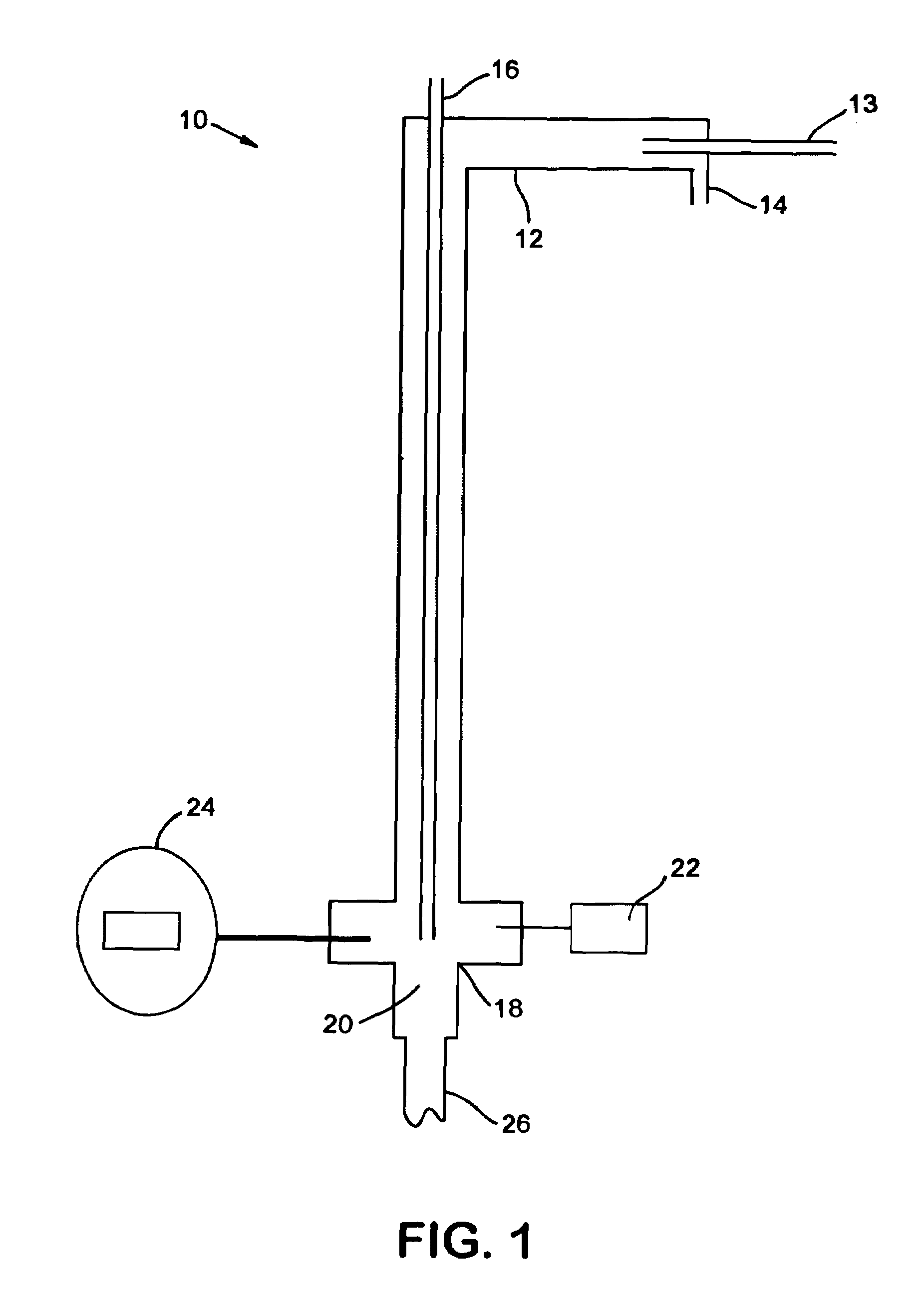

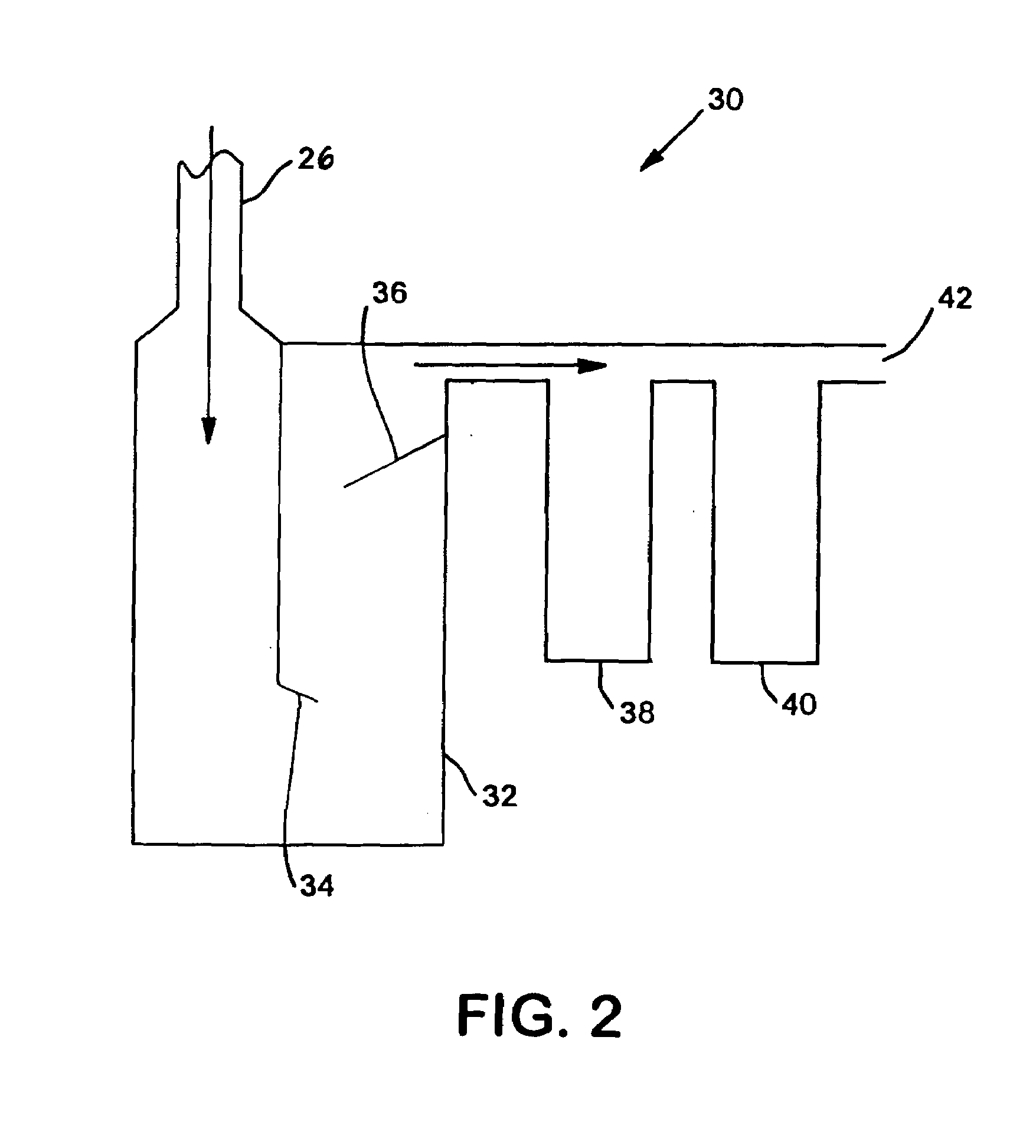

System and method for delivery of a vapor phase product to a point of use

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronic specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

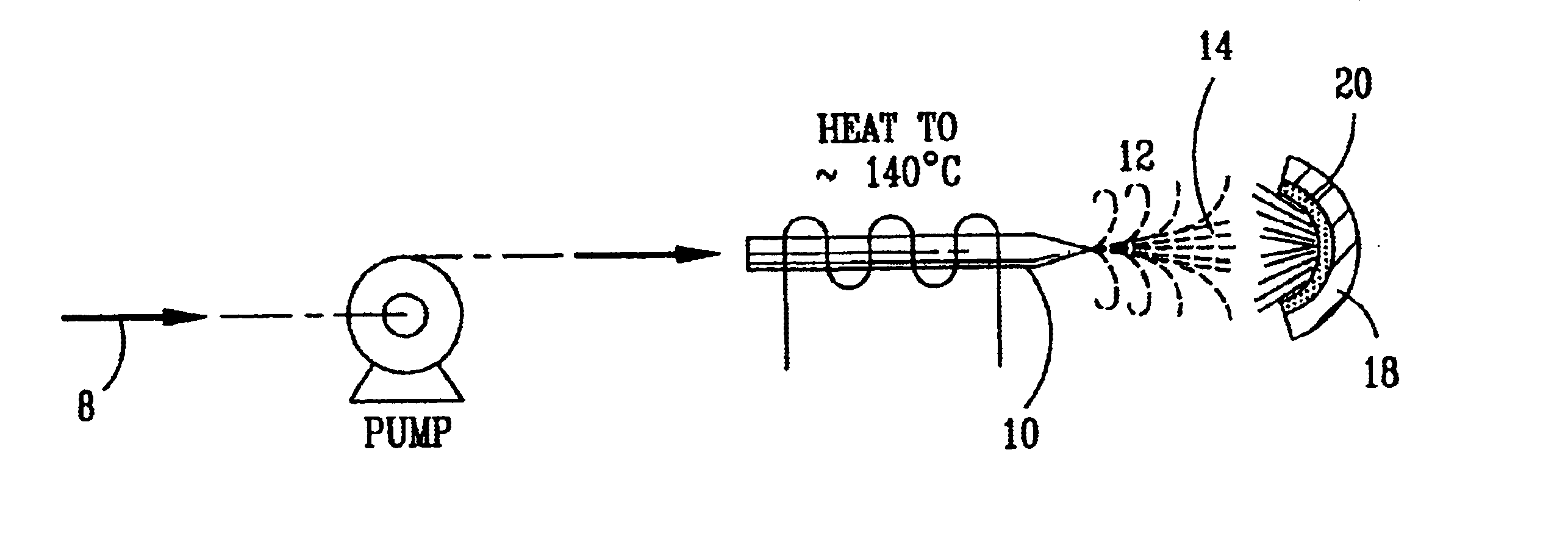

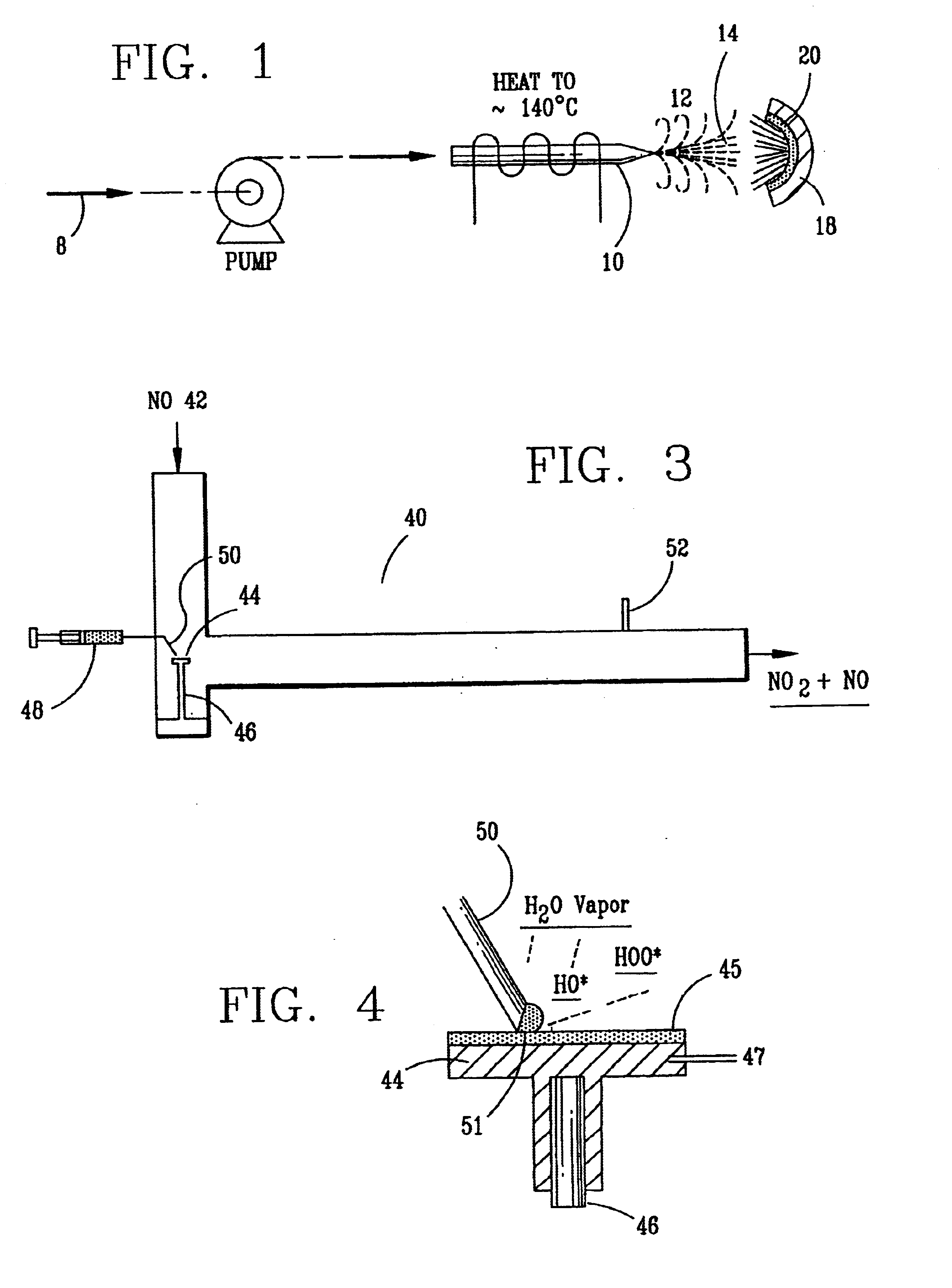

High temperature decomposition of hydrogen peroxide

InactiveUS6793903B1Easy to disassembleReduce nitrogen oxide emissionsDispersed particle separationNitric oxideNitrogen dioxideGas phase

Nitric oxide (NO) is oxidized into nitrogen dioxide (NO2) by the high temperature decomposition of a hydrogen peroxide solution to produce the oxidative free radicals, hydroxyl and hydroperoxyl. The hydrogen peroxide solution is impinged upon a heated surface in a stream of nitric oxide where it decomposes to produce the oxidative free radicals. Because the decomposition of the hydrogen peroxide solution occurs within the stream of the nitric oxide, rapid gas-phase oxidation of nitric oxide into nitrogen dioxide occurs.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATION OF

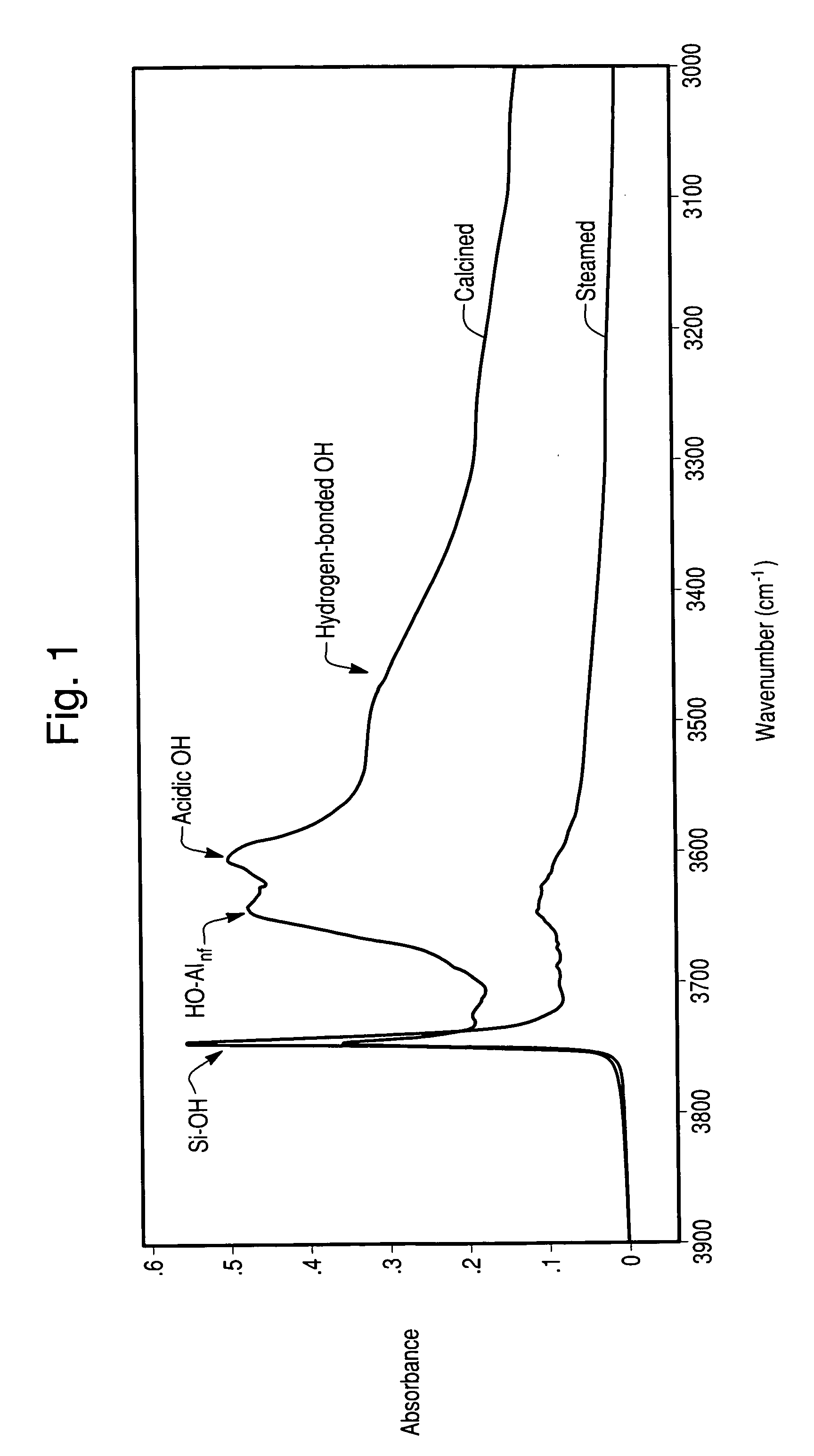

Hydrothermally stable Ag-zeolite traps for small olefin hydrocarbon molecules

InactiveUS20070129236A1Good hydrothermal stabilityHigh-temperature steamingMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsHydrocotyle bowlesioidesHydrocarbon

Owner:BASF CATALYSTS LLC

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

InactiveUS20100272626A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionAmmonia-oxidizing bacteria

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The bioreactor may use communities of autotrophic microorganisms such as those capable of nitrifier denitrification, ammonia oxidizing bacteria, and / or ammonia oxidizing archaea. A portion of the N2O dissolved in aqueous effluent from the bioreactor may be separated to increase the amount of gas phase N2O product. The amount of the gas phase N2O in a gas stream may also be concentrated prior to undergoing the chemical reaction. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Production of gaseous chloramine

InactiveUS7070751B2Prevent scalingSimple streamlined designCombination devicesExhaust apparatusChloramine BGas phase

The present invention provides a reactor for the gas-phase reaction of commercially available gases in the presence of an inert carrier gas to form product gas. The reactor has a streamlined, compact configuration and at least one solids collection and removal system downstream of the reactor, where solids are efficiently removed from the product gas stream, leaving high purity product gas. The removal system allows for a simple reactor design, which is easy to clean and operates continuously over longer periods of time.

Owner:BRISTOL MYERS SQUIBB CO

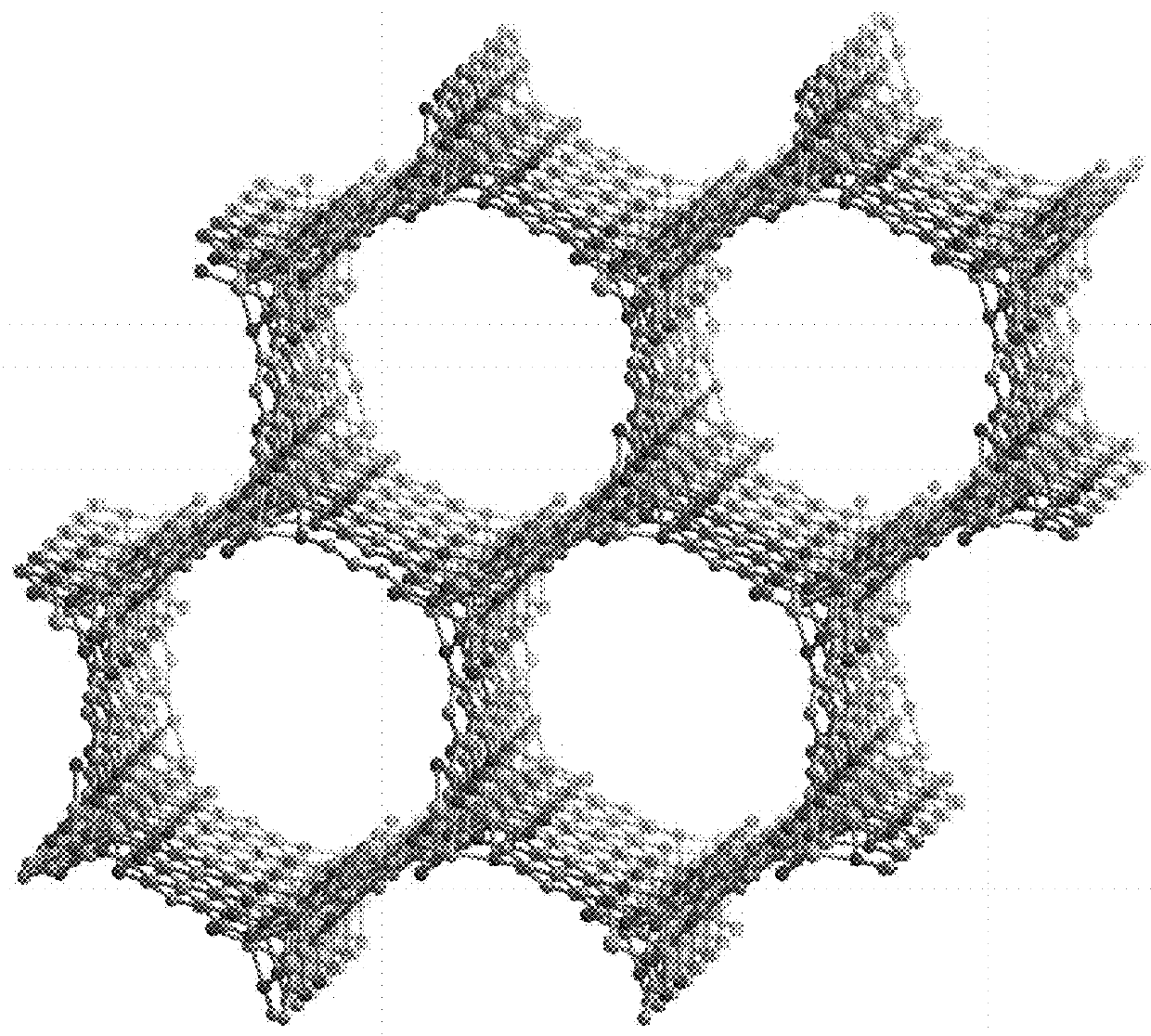

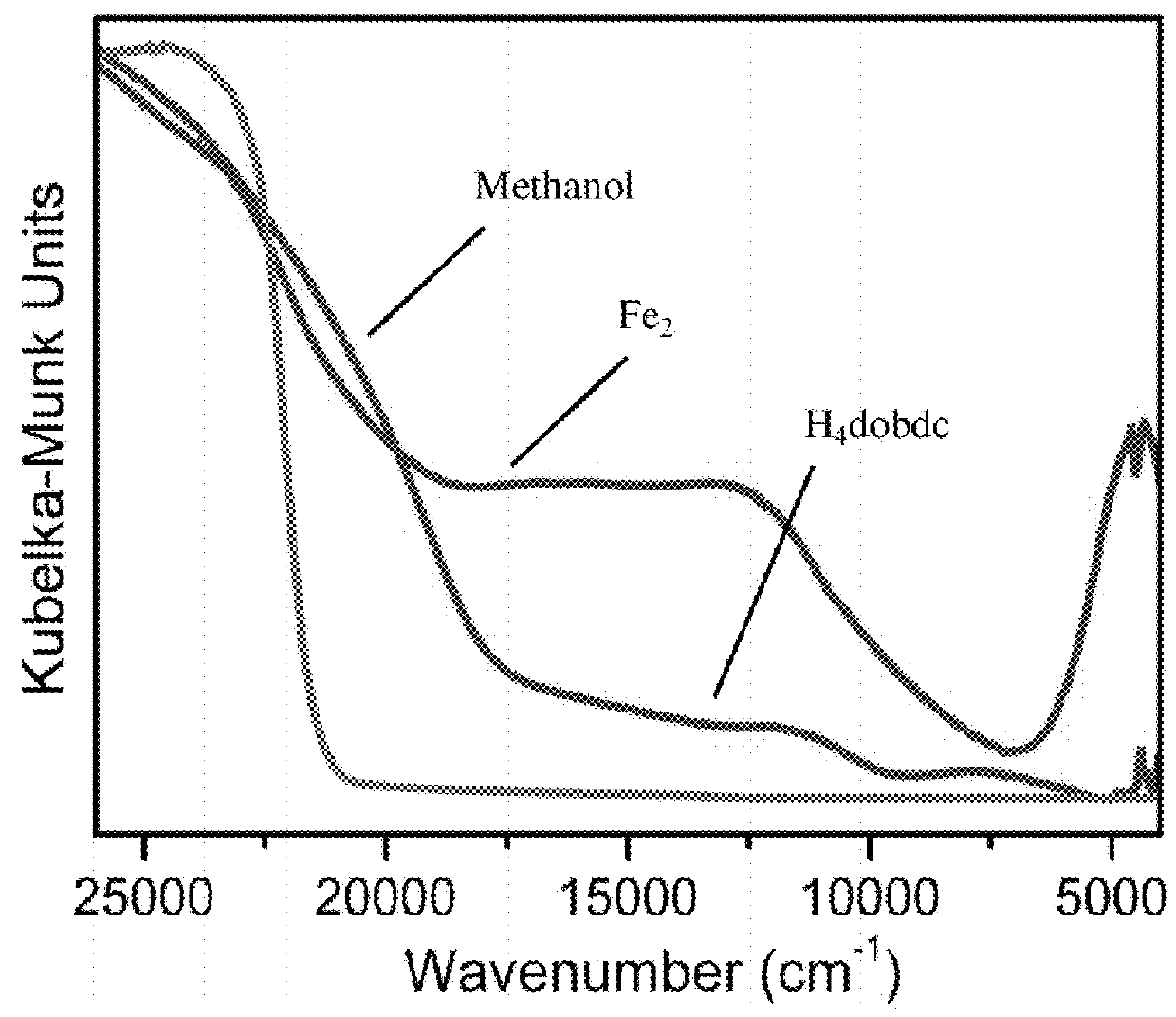

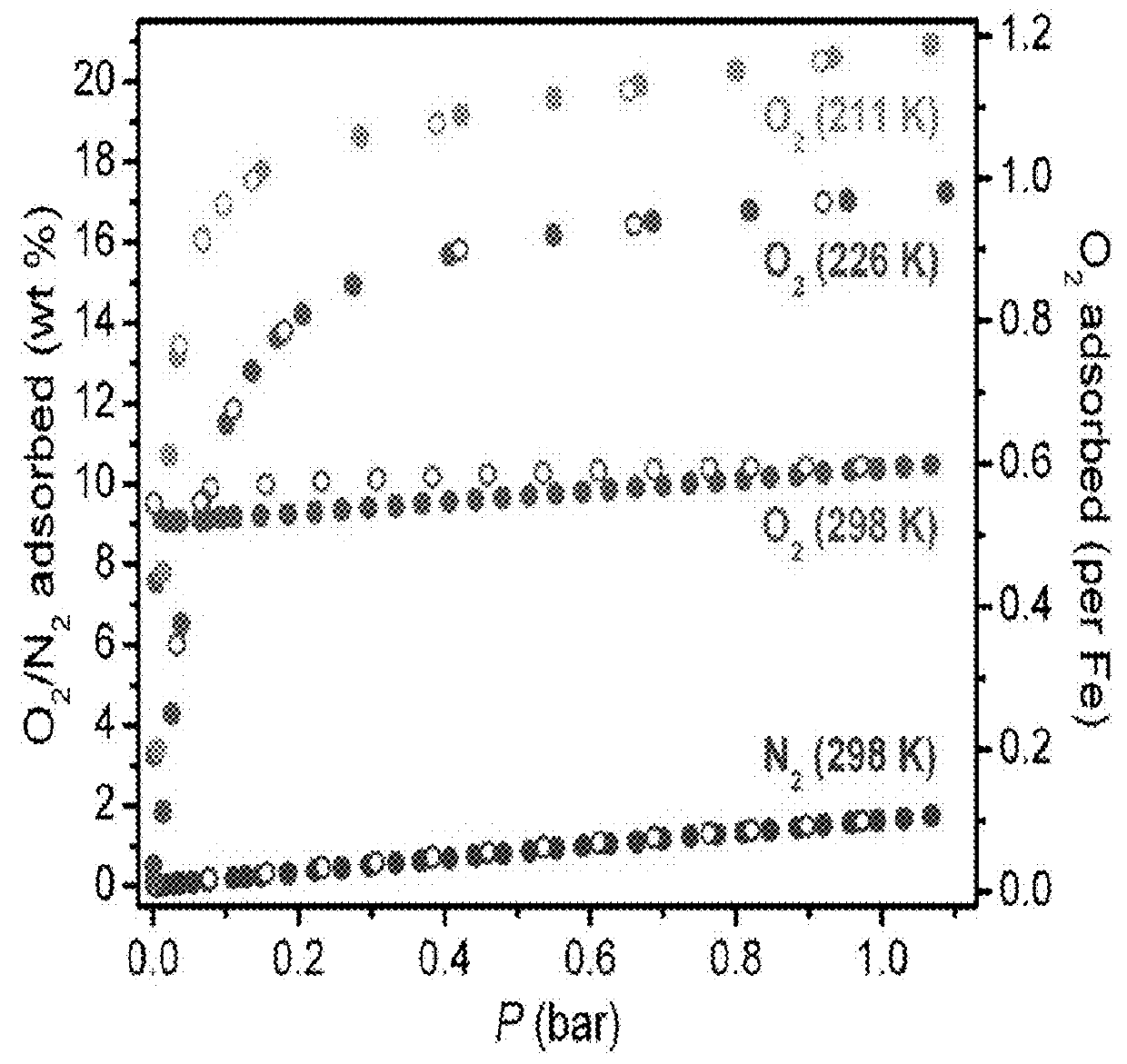

Gas separations with redox-active metal-organic frameworks

ActiveUS20130053585A1Incredible separation propertyNitrous oxide capturePreparation by oxidation reactionsHigh densityElectron transfer reactions

Fe2(dobdc) has a metal-organic framework with a high density of coordinatively-unsaturated FeII centers lining the pore surface. It can be effectively used to separate O2 from N2 and in a number of additional separation applications based on selective, reversible electron transfer reactions. In addition to being an effective O2 separation material, it can be used for many other processes, including paraffin / olefin separation, nitric oxide / nitrous oxide separation, acetylene storage, and as an oxidation catalyst.

Owner:RGT UNIV OF CALIFORNIA

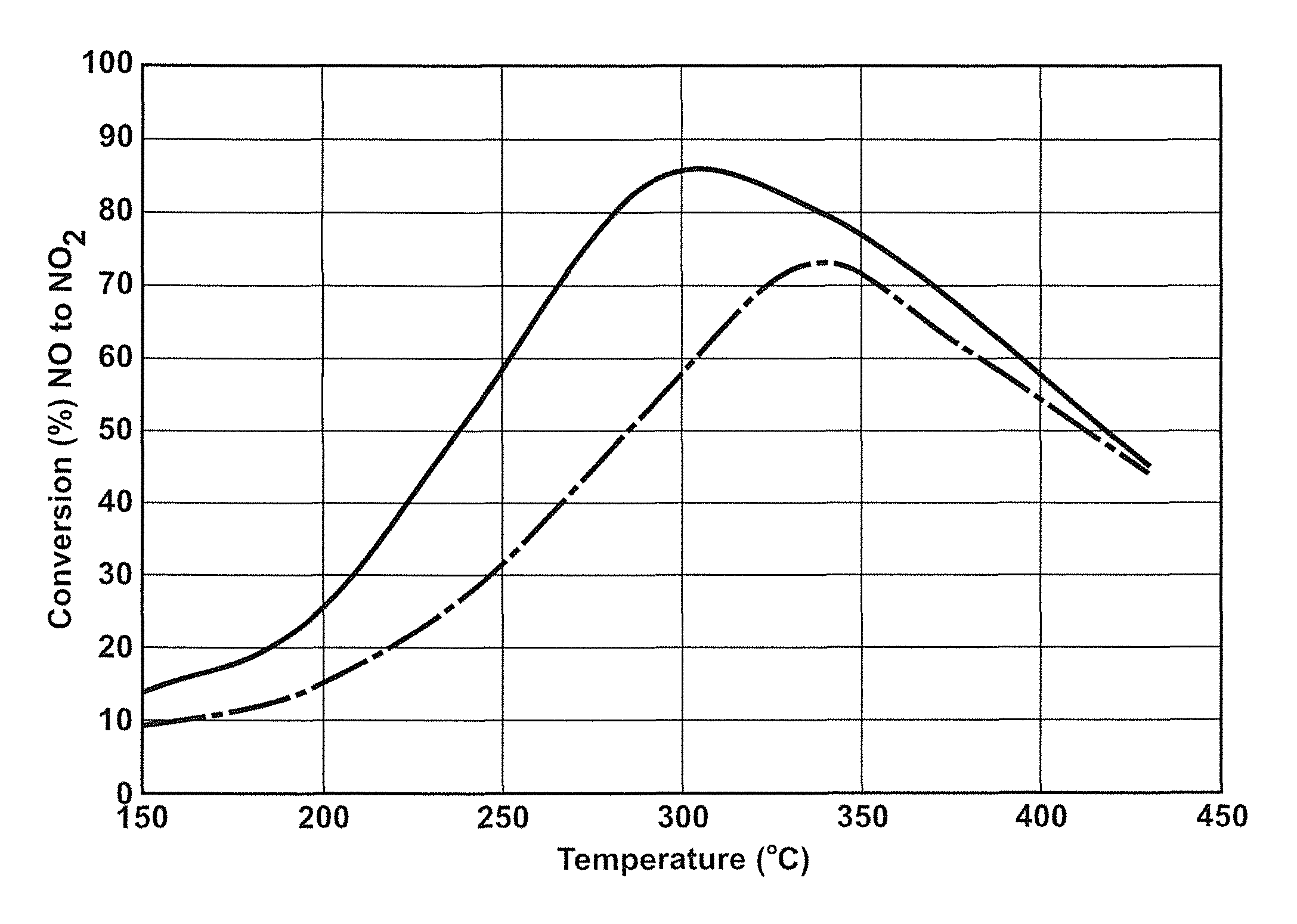

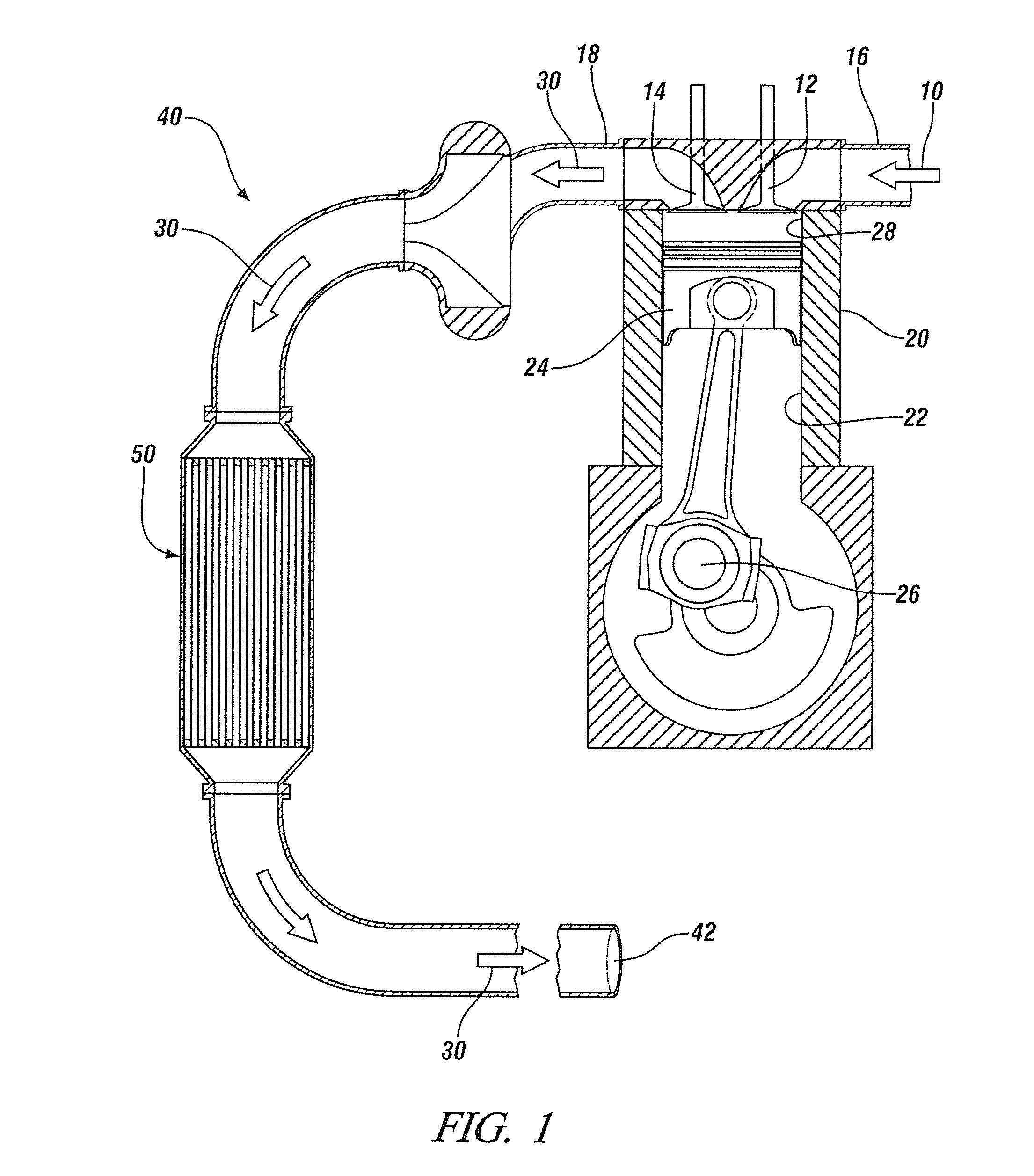

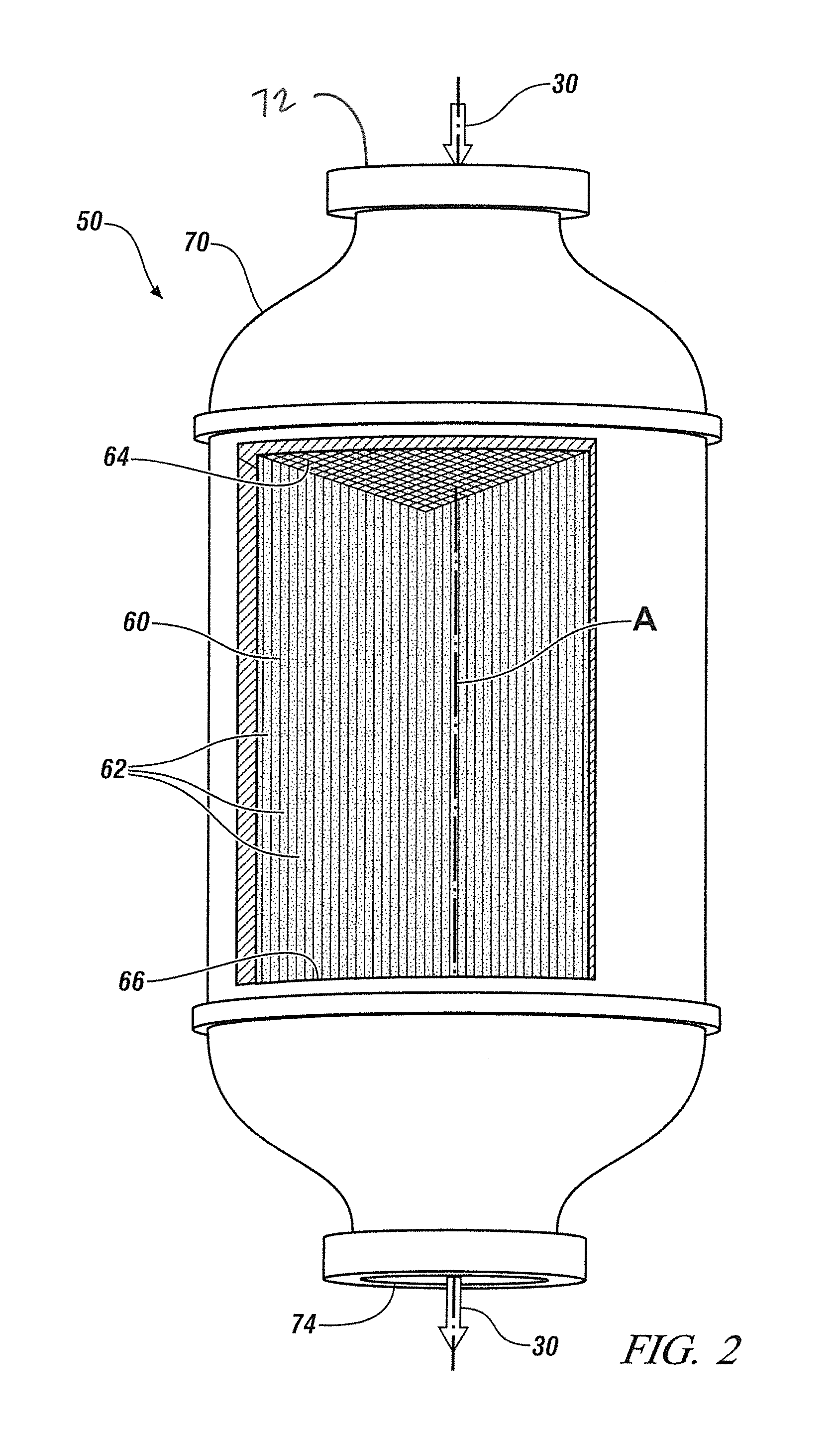

Mn, Ce and Zr MIXED OXIDES OXIDATION CATALYST

ActiveUS20120036834A1Great proportionImprove performanceOrganic chemistryMachines/enginesMixed oxideSulfur

The oxidation of nitrogen oxide (NO) in an oxygen-containing exhaust gas flow from a diesel or other lean-burn engine may be catalyzed using particles of co-precipitated and calcined manganese (Mn), cerium (Ce) and zirconium (Zr) mixed oxides. In preferred embodiments, the molar ratios of Mn, Ce and Zr to the total amount of base metals in the ternary mixed oxide catalyst are in the range of 0.25-0.35, 0.40-0.50 and 0.20-0.25, respectively. Further, this ternary mixed oxide catalyst is less susceptible to sulfur poisoning than previously-disclosed binary mixed oxide catalysts. The ternary mixed oxide catalyst may also be regenerated—and the inhibiting effect of SO2 reversed—by briefly exposing the catalyst to a reducing exhaust gas environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

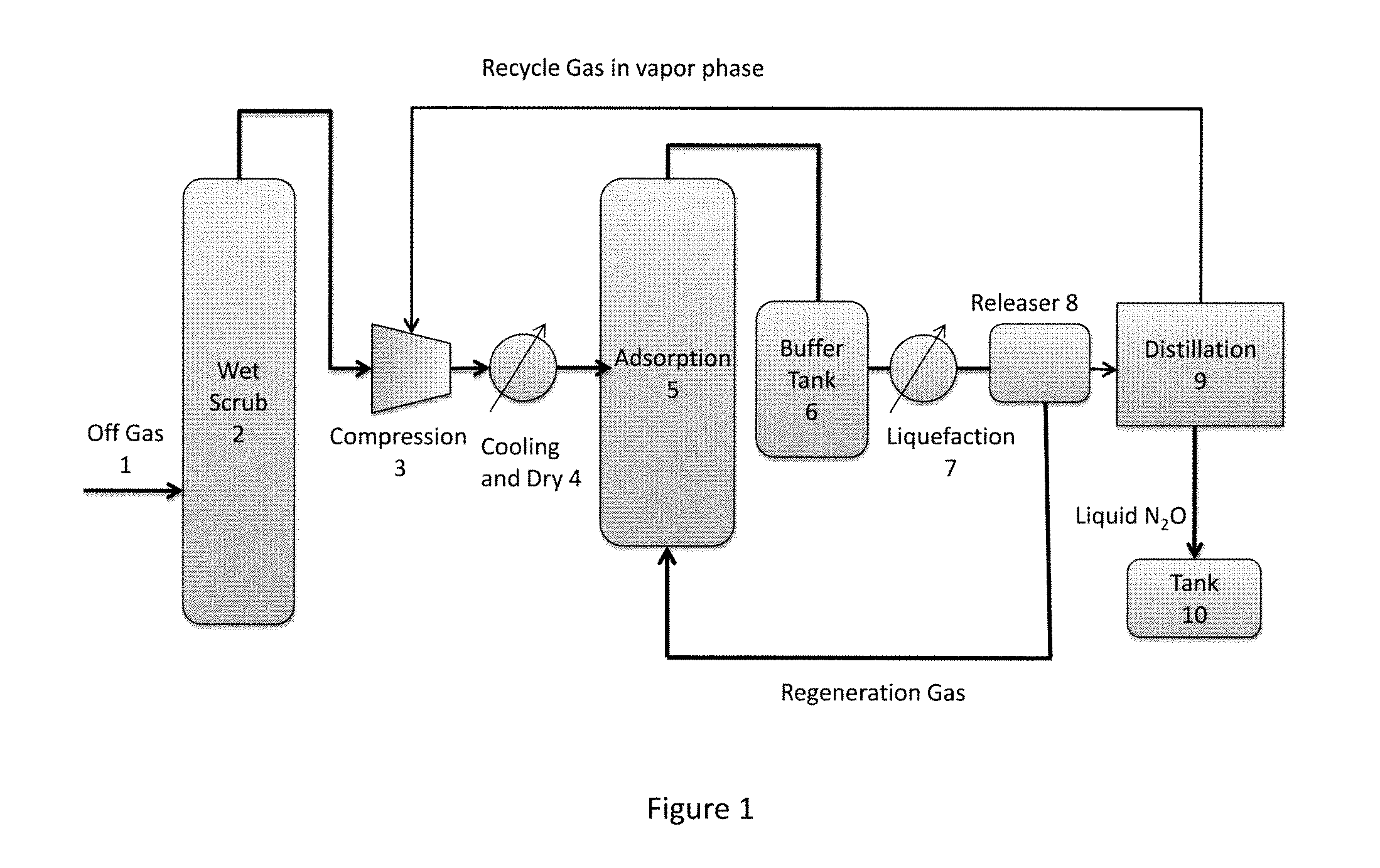

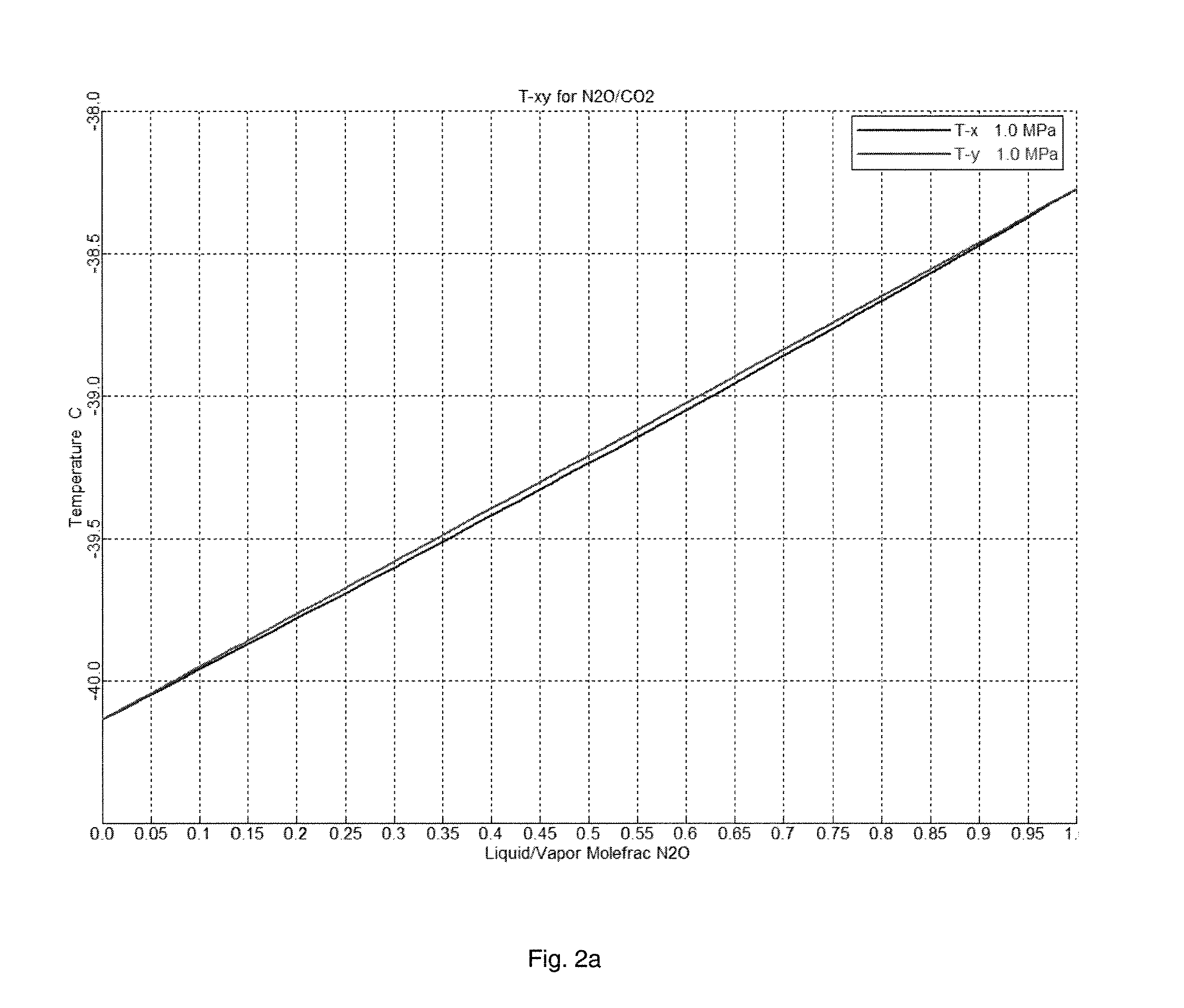

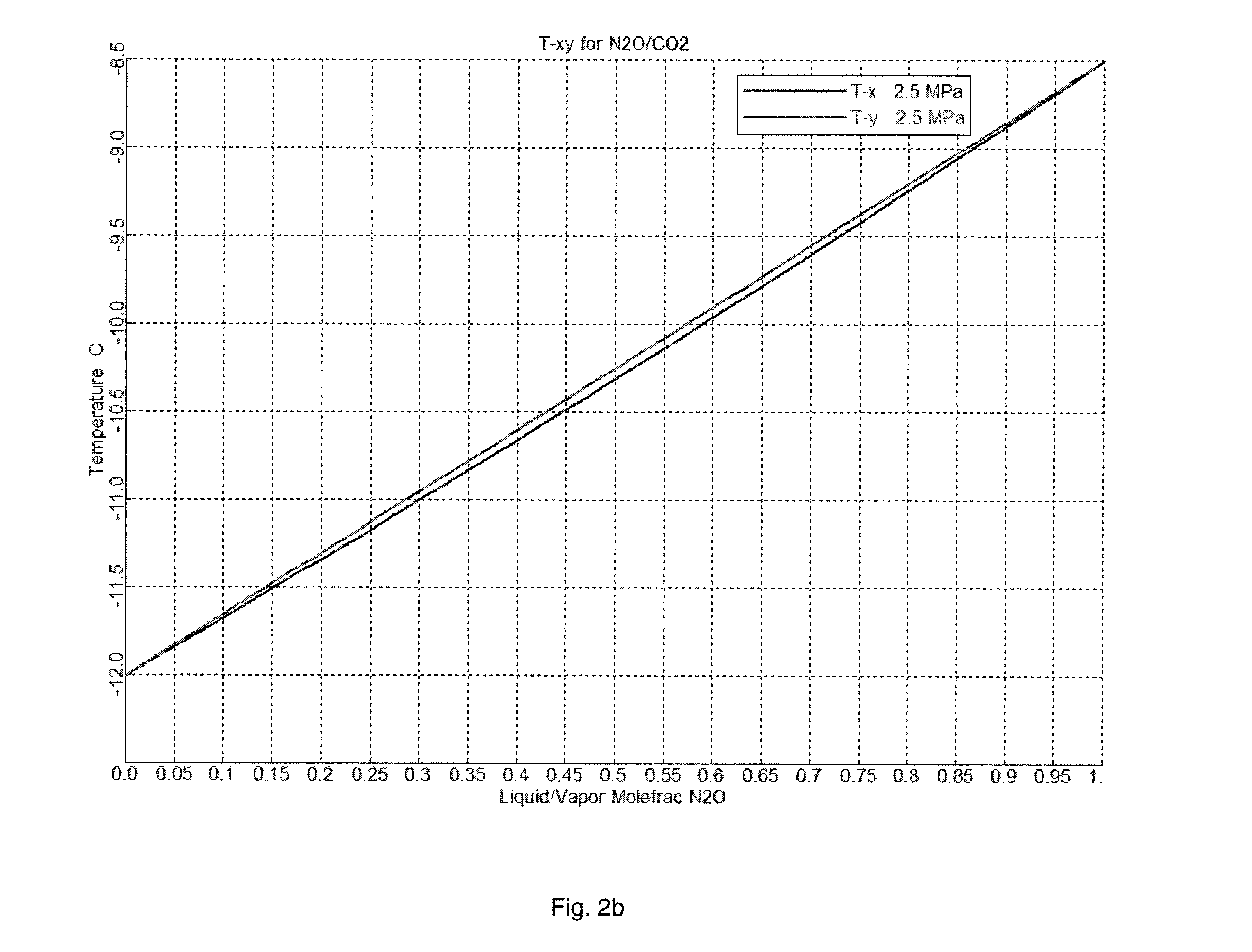

Process for Recovery and Purification of Nitrous Oxide

This invention is aimed at recovering and purifying nitrous oxide from the gas stream containing N2O to produce different grade of nitrous oxide by combination of unit operation including, but not limited to, wet scrubbing, adsorption, liquefaction, flash distillation or continuous distillation with reflux.

Owner:VERSUM MATERIALS US LLC

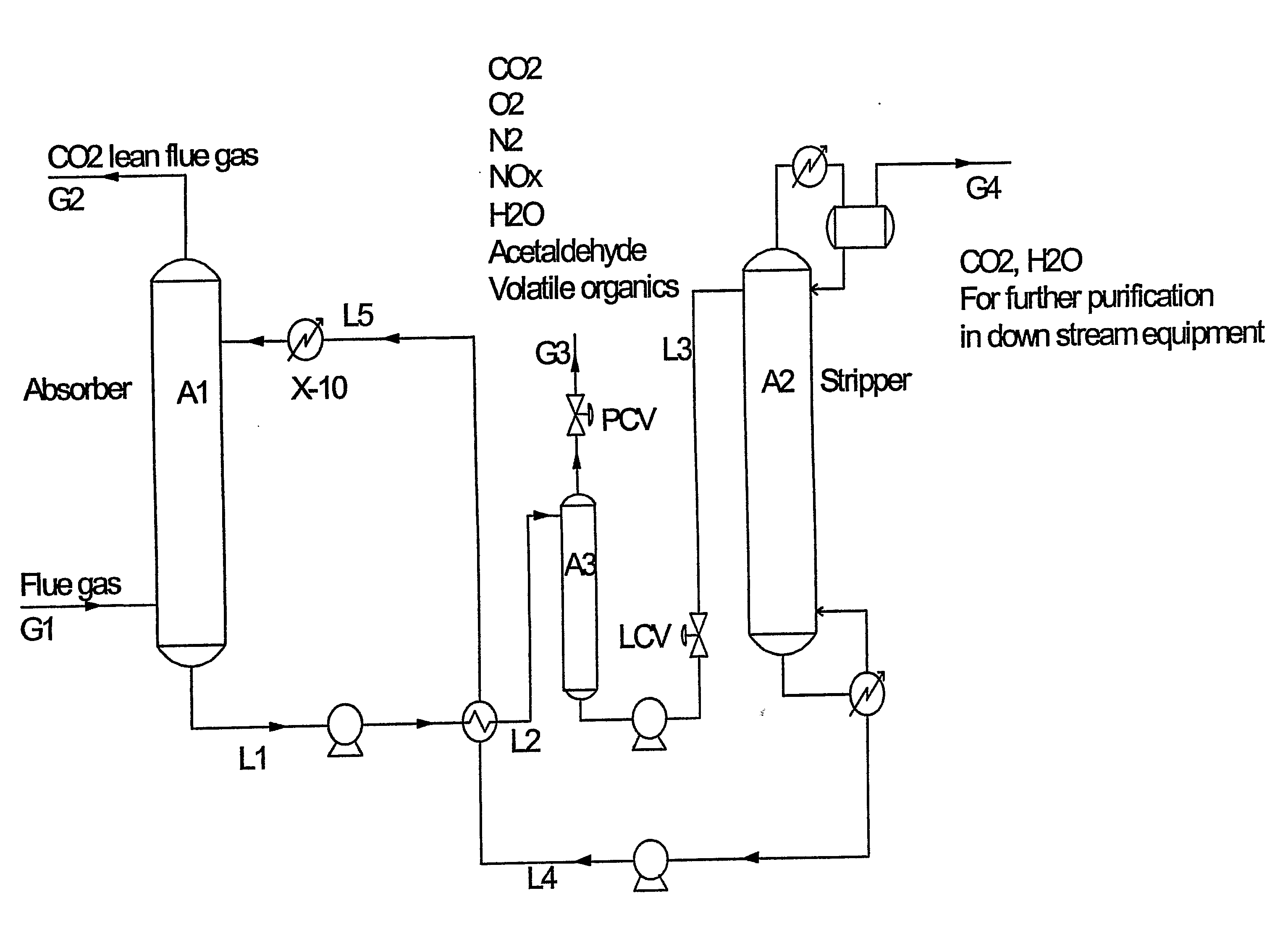

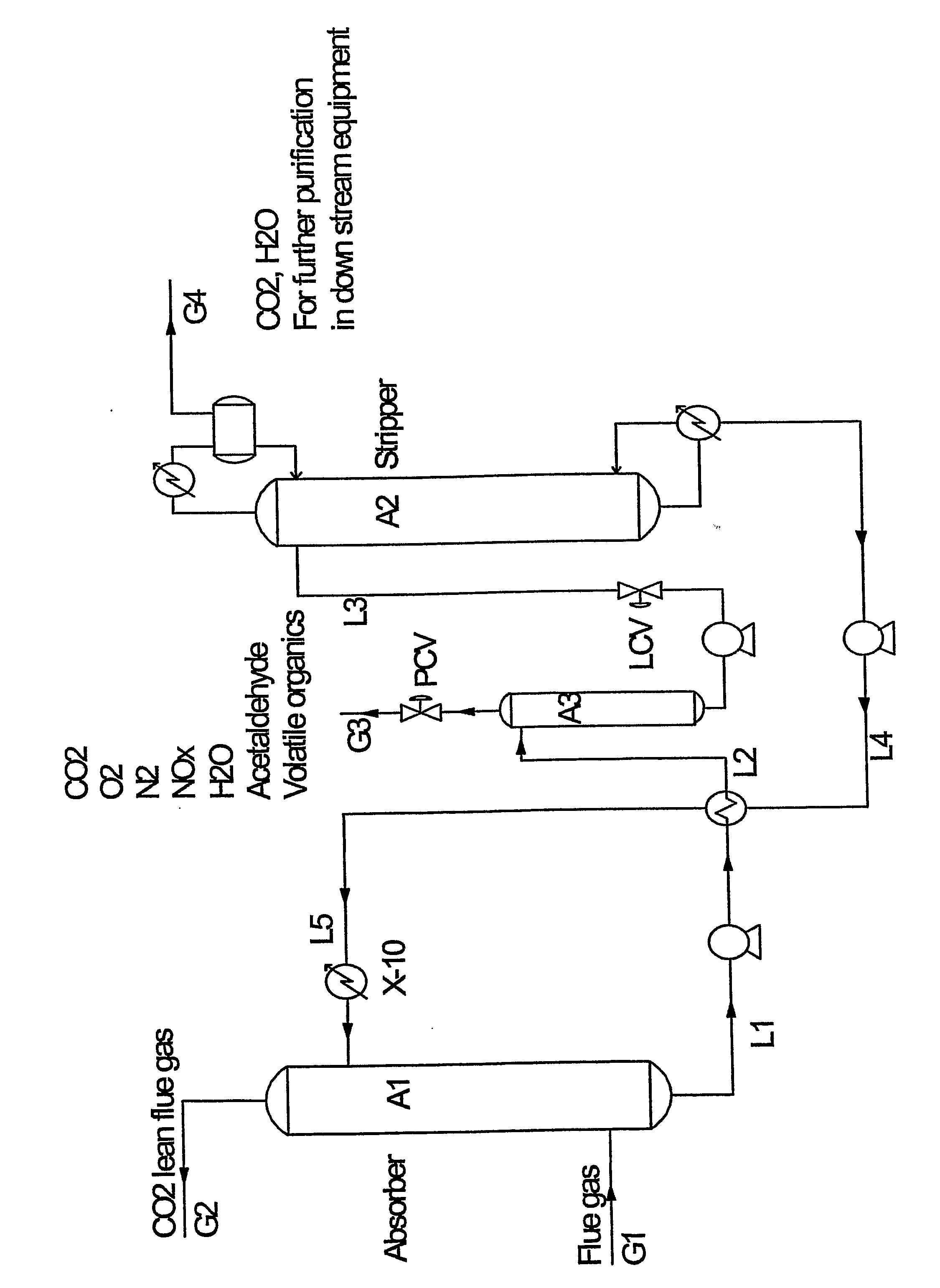

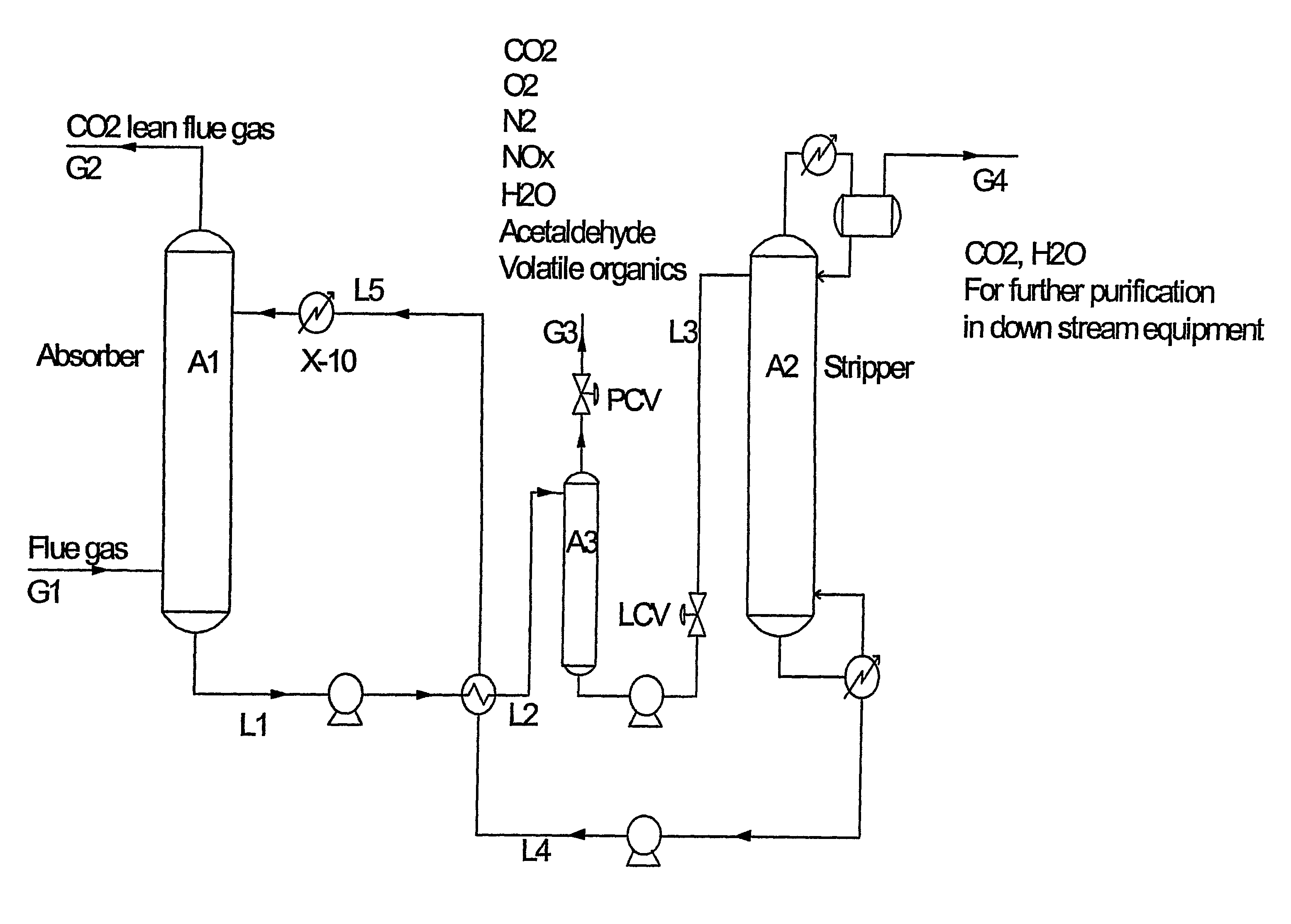

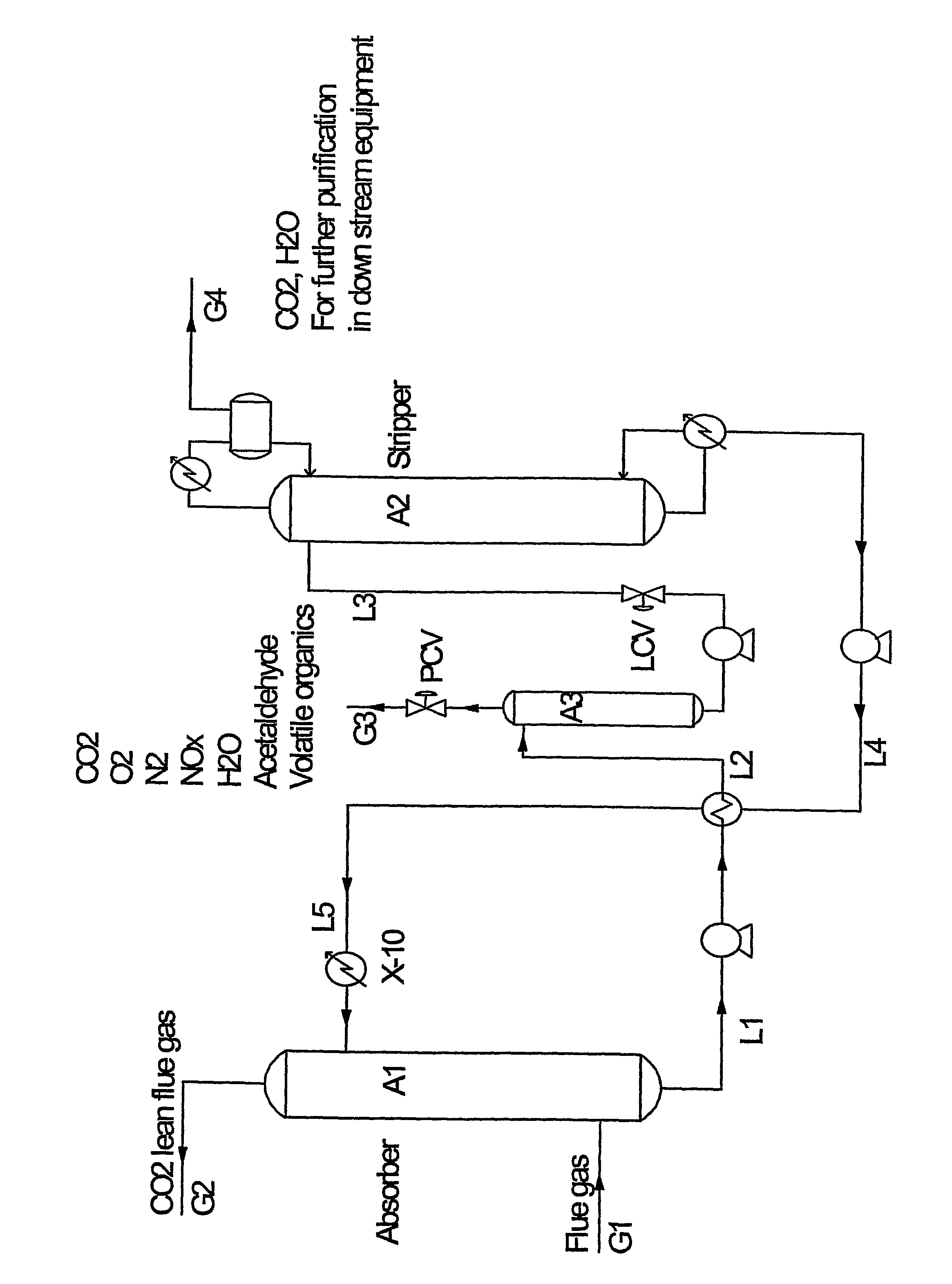

Method for Recovery of High Purity Carbon Dioxide From a Gaseous Source Comprising Nitrogen Compounds

The present invention describes a method for recovery of high purity carbon dioxide, which is substantially free of nitrogen oxides. The present invention also discloses a plant for recovery of said high purity carbon dioxide comprising an absorption column, a flash column, a stripper column, and a purification unit.

Owner:UNION ENG

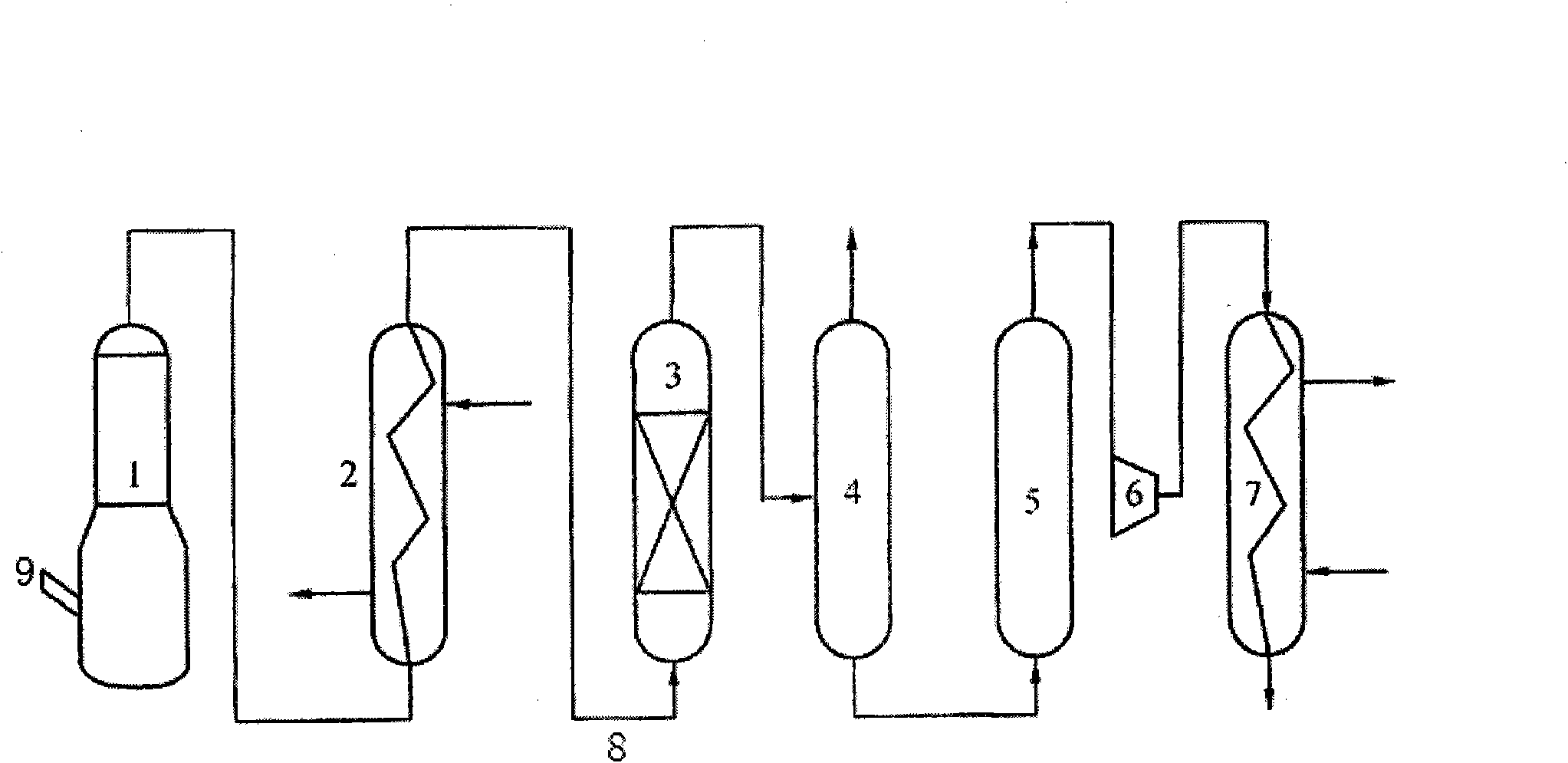

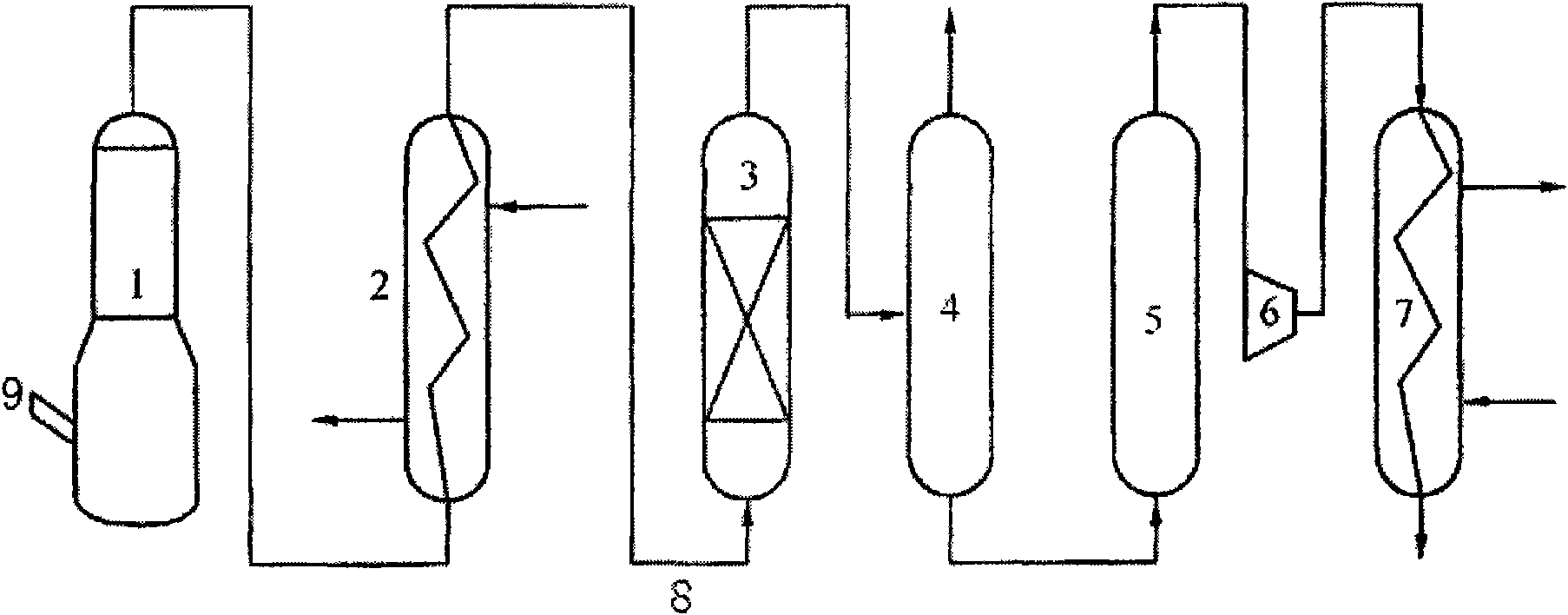

Technique for preparing nitrous oxide by decomposing ammonium nitrate

The invention discloses a technique for preparing nitrous oxide by decomposing ammonium nitrate. A reactor with a charging hole, a cooling tower, a drier, a rectifying tower, a buffer tank, a compressor, and a condenser are assembled into a whole through a connecting pipeline according to system functions thereof. The technique has the advantages of reasonable design and convenient use, and is ideal nitrous oxide preparation technology.

Owner:TIANJIN TAIYUAN INDAL GAS

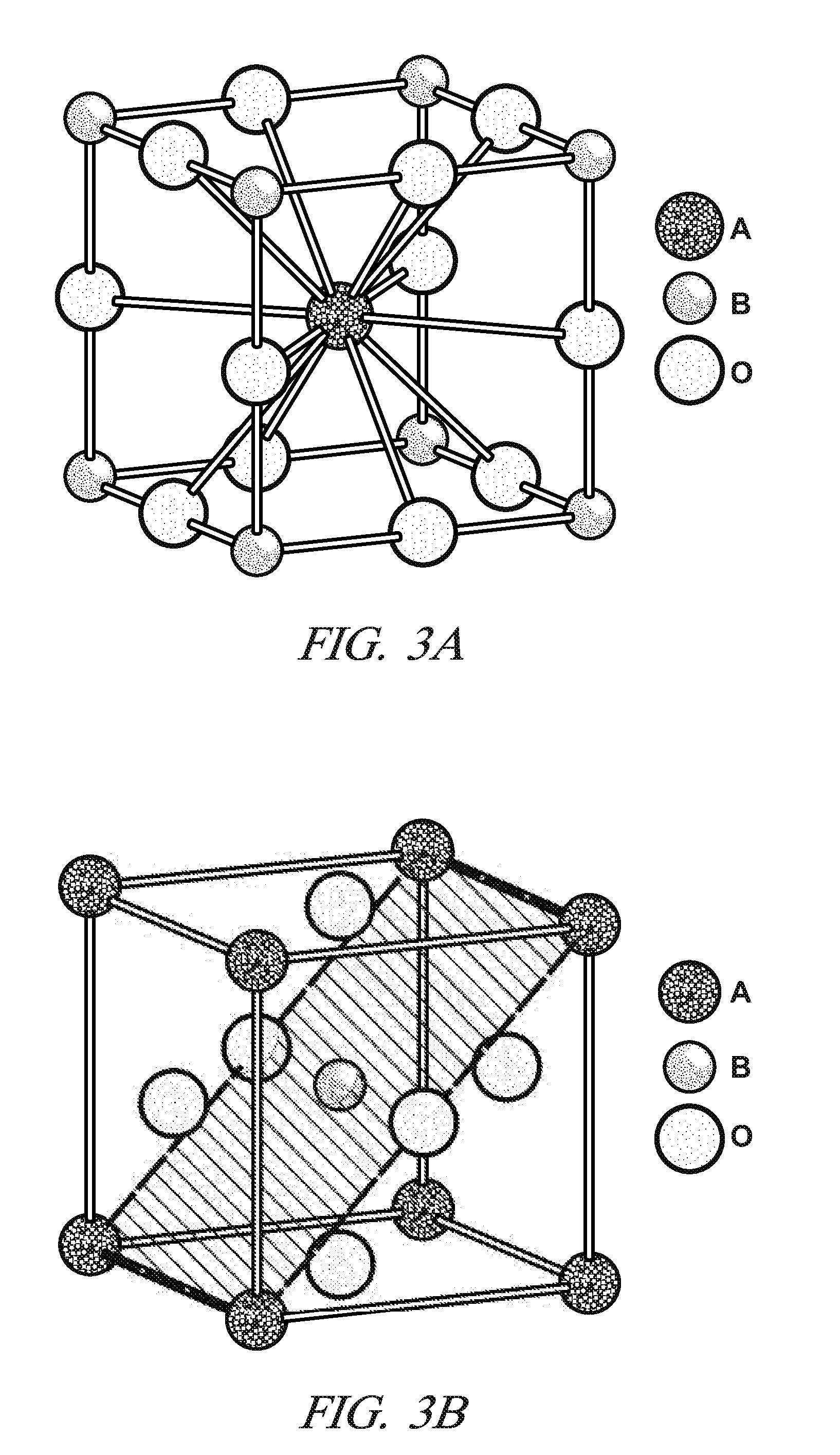

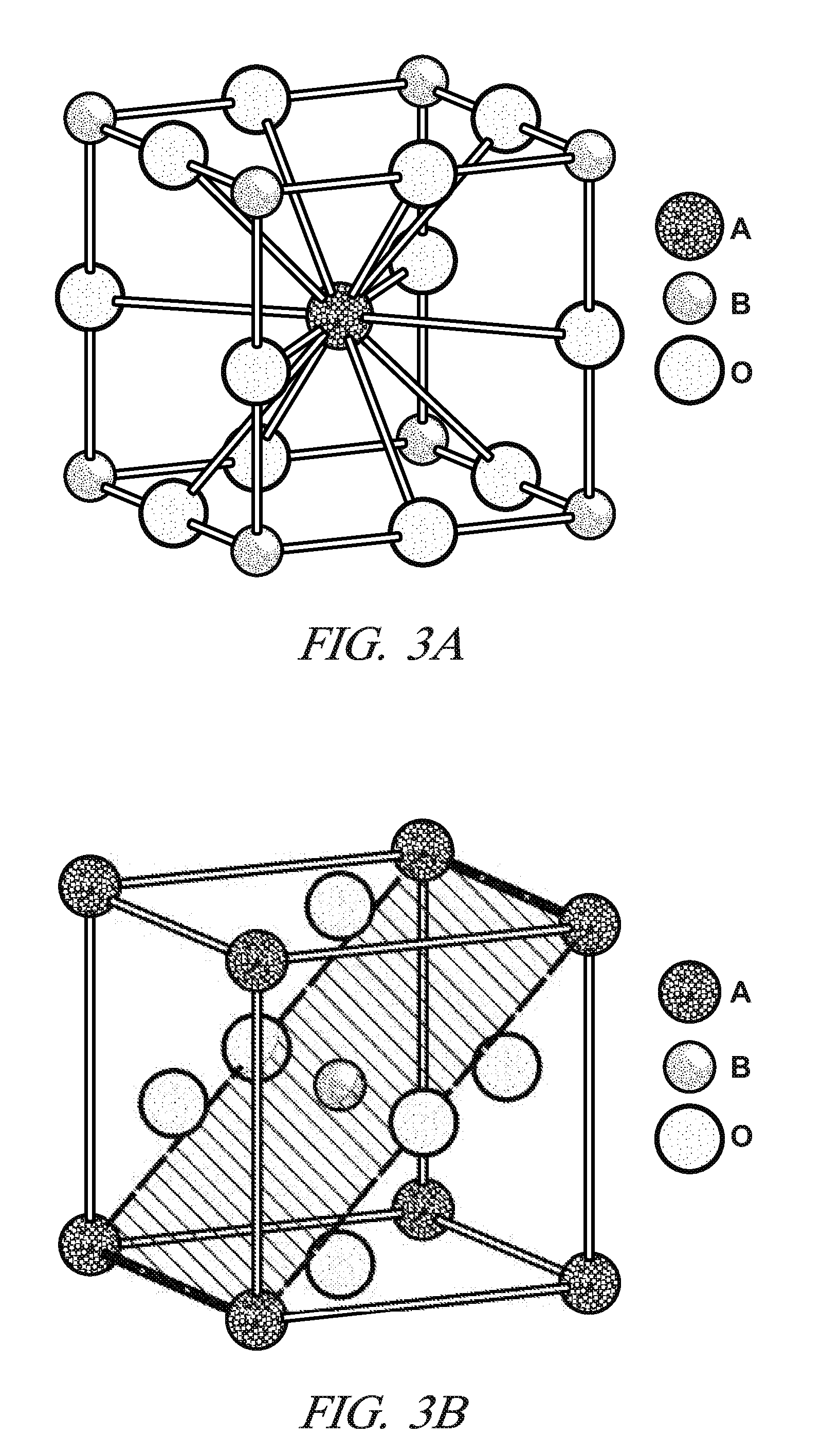

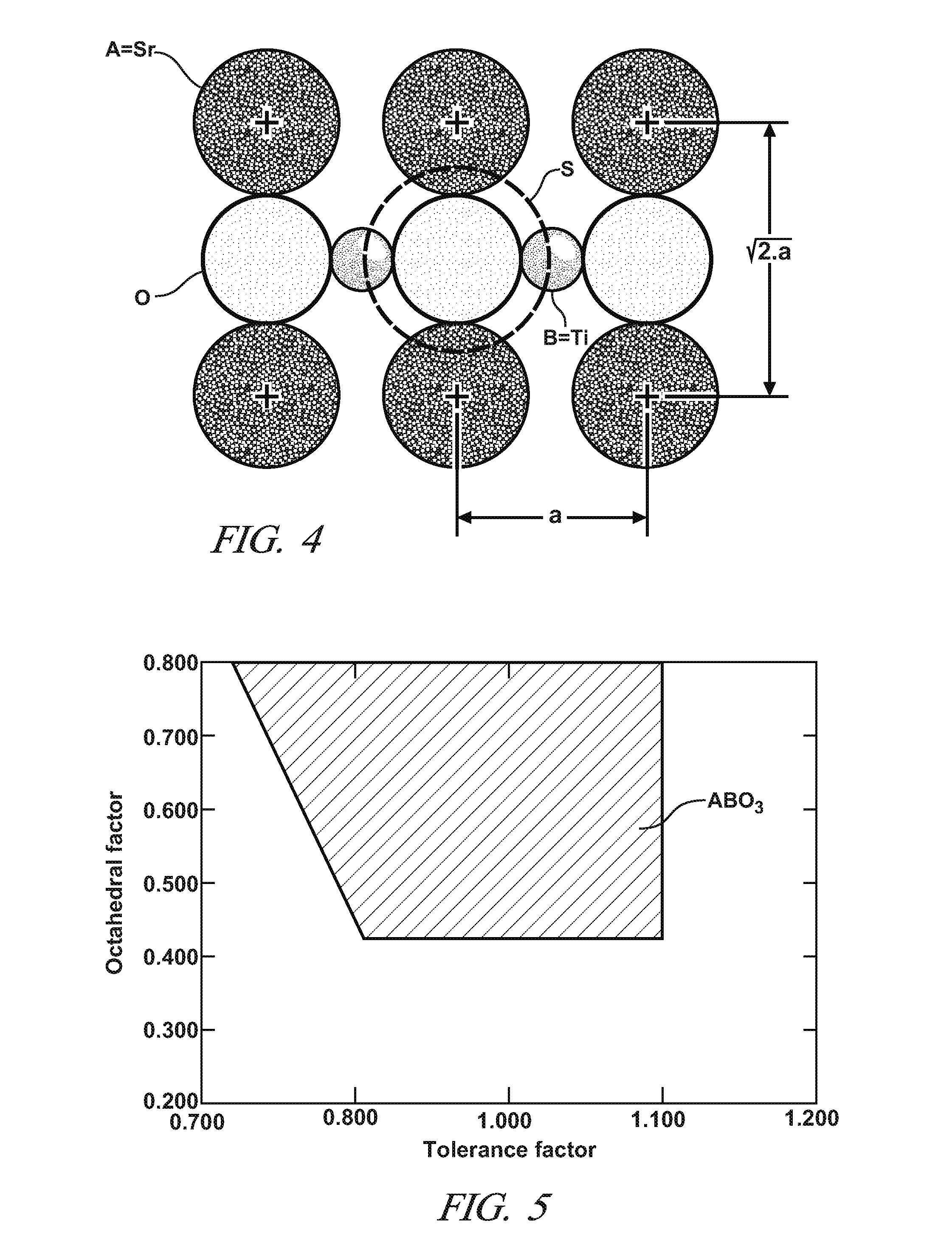

SULFUR-TOLERANT PEROVSKITE NOx OXIDATION CATALYSTS

A method for catalytic oxidation of NO to NO2 in the sulfur-containing exhaust gases of lean-burn engines, such as diesel engines is disclosed. The catalysts are oxide perovskites with a credible likelihood of being sulfur-tolerant.

Owner:GM GLOBAL TECH OPERATIONS LLC

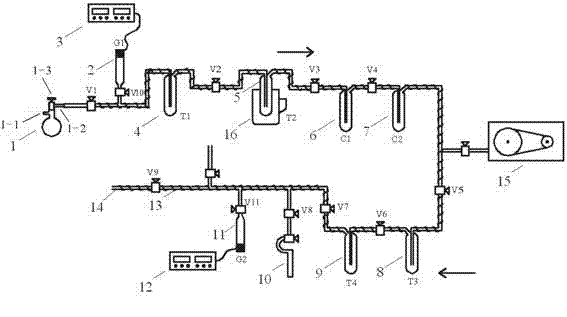

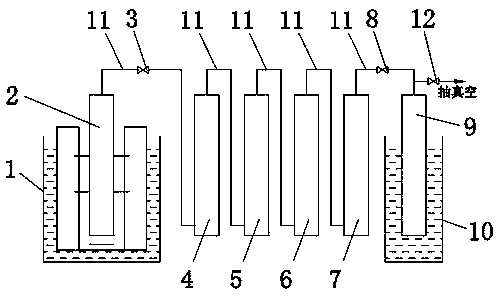

Device for converting nitrite into nitrous oxide for purification and method thereof

The invention relates to a device for converting nitrite into nitrous oxide for purification and a method thereof. The device comprises a sample reactor, a first cold trap, a second cold trap, a first chemical trap, a second chemical trap, a third cold trap, a fourth cold trap, a N2O sample collection pipe and a vacuumizing system, wherein a discharge port end of the sample reactor is connected with the first cold trap through a conduit; the first cold trap, the second cold trap, the first chemical trap, the second chemical trap, the third cold trap and the fourth cold trap are connected end to end through a conduit to form a main pipeline; a branch is arranged on the main pipeline behind the fourth cold trap; and the N2O sample collection pipe is arranged on the branch. The device can extract and purify nitrite or a sample containing nitrite such as natural water to obtain N2O which can be directly delivered to a gas mass spectrometer for testing the N and O isotopes; and moreover, the influence of air or other impurities can be effectively avoided in N2O conversion and purification processes, and the operation is convenient.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

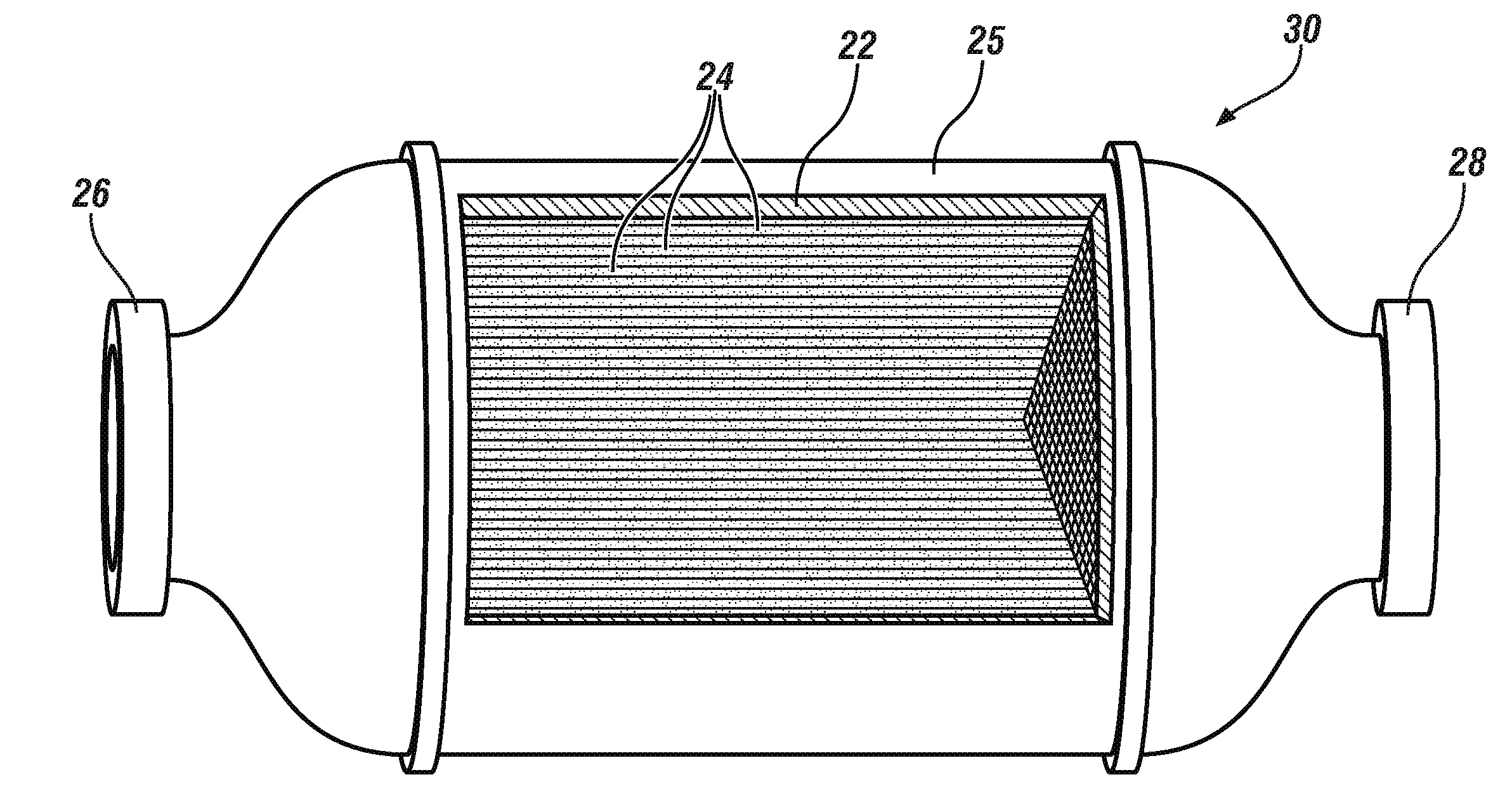

Indirectly heated temperature controlled adsorber for sorbate recovery

InactiveUS20100150812A1Quantity minimizationOther chemical processesCarbon compoundsTemperature controlChemistry

Systems and processes are provided that relate to the recovery of sorbates in processes utilizing temperature controlled adsorption. Sorbate recovery can include providing a temperature controlled adsorber that is undergoing a regeneration cycle after undergoing an adsorption cycle. The temperature controlled adsorber can have one or more adsorption flow passages and one or more heat transfer flow passages. The one or more adsorption flow passages can contain an adsorptive material coating with a sorbate adsorbed thereto. A heating fluid can be provided to the one or more heat transfer flow passages of the temperature controlled adsorber. A regeneration stream can be provided to the one or more adsorption flow passages of the temperature controlled adsorber. The adsorptive material coating can be regenerated by removing the sorbate from the temperature controlled adsorber to produce a regeneration effluent stream.

Owner:UOP LLC

High Concentration NO2 Generating System and Method for Generating High Concentration NO2 Using the Generating System

ActiveUS20110286908A1Efficient processMaterial nanotechnologyInorganic active ingredientsHigh concentrationPlasma generator

A high concentration NO2 gas generating system including a circulating path configured by connecting a chamber, a plasma generator, and a circulating means, wherein NO2 is generated by circulating a gas mixture including nitrogen and oxygen in the circulating path is provided. The high concentration NO2 gas generating system provides a high concentration NO2 generating system and the high concentration NO2 generating method using the generating system by which NO2 of high concentration (approximately 500 ppm or above) required for a high level of sterilization process in such as sterilization of medical instruments can be simply and selectively obtained. In addition, since indoor air is used as an ingredient, the management of ingredients is simple and highly safe, and the high concentration of NO2 can be simply and selectively prepared on demand.

Owner:NOXILIZER

Synthesis and use of nanocrystalline zeolites

InactiveUS7585490B2High yieldGrow longer andNitrous oxide captureMaterial nanotechnologySolventHydrolysis

Embodiments of the present invention relate to a method for synthesizing nanocrystalline zeolites, the method comprising contacting starting products that comprise a solvent, a silicon source, a cation base, an organic template, and an aluminum source, or any combination thereof sufficient to produce a zeolite gel by hydrolysis, heating the zeolite gel sufficient to produce a first batch of zeolite crystals and a first clear solution, separating the first batch of zeolite crystals from the first clear solution, heating the first clear solution sufficient to produce a second batch of zeolite crystals and second clear solution and separating the second batch of zeolite crystals from the second clear solution. In addition, embodiments relate to a method of using nanocrystalline zeolites, the method comprising contacting a nanocrystalline zeolite with a reductant sufficient to produce a nanocrystalline zeolite with adsorbed reductant and exposing the nanocrystalline zeolite with adsorbed reductant to reactant gases sufficient to obtain reaction products and the nanocrystalline zeolite.

Owner:UNIV OF IOWA RES FOUND

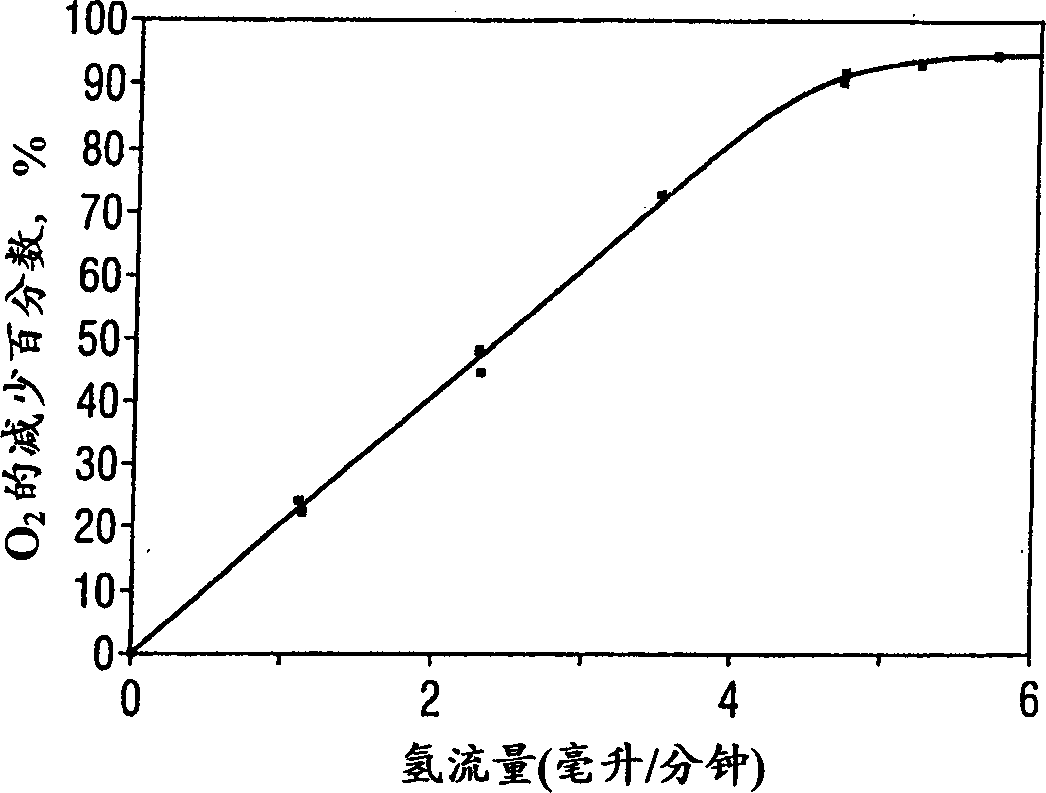

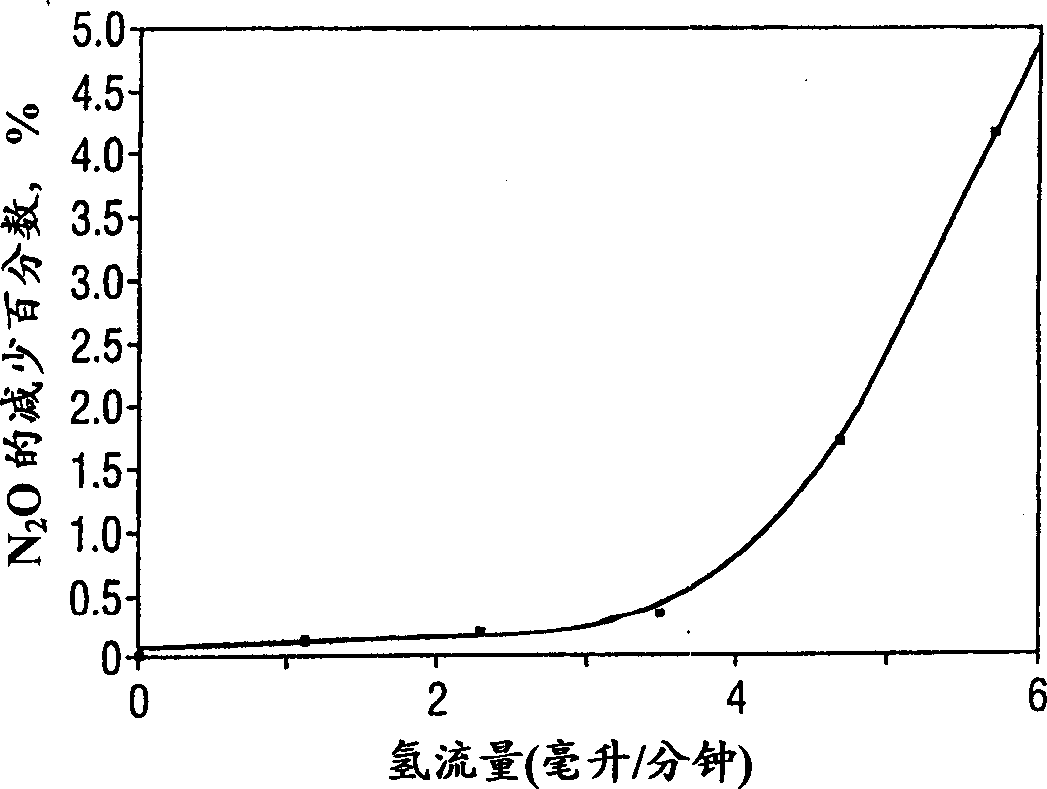

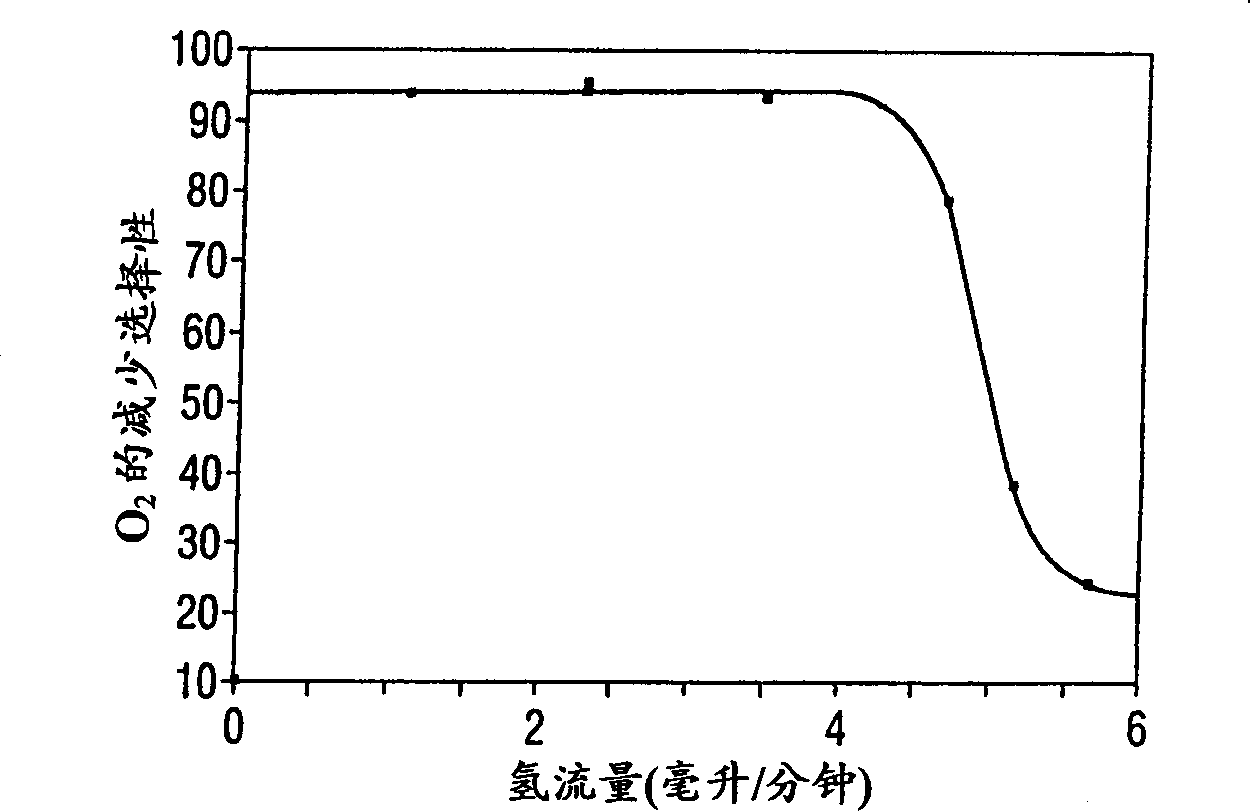

Process for nitrous oxide purification

A method for purification of a nitrous oxide gas by feeding the nitrous oxide gas and a reducing agent into a de-oxidation reactor, performing de-oxidation by reacting the reducing agent with oxygen using a catalyst in order to deplete the oxygen in the nitrous oxide gas, while limiting the amount of nitrous oxide removed from the nitrous oxide gas.

Owner:阿申德高新材料有限责任公司

Sulfur-tolerant perovskite NOx oxidation catalysts

Owner:GM GLOBAL TECH OPERATIONS LLC

Process for separation of NOx from N2O in a mixture

The present invention is a reactive adsorption process for separating NOx (NO and NO2 / N2O4) from N2O in a mixture. The process comprises (A) selectively converting NO to NO2 / N2O4 in a mixture with an oxidant and (B) selectively adsorbing NO2 / N2O4 from the mixture by an adsorbent and (C) recovering a stream of N2O having a substantially reduced NOx concentration. The adsorbed NOx can be recovered from the adsorbent by elevated temperature, reduced pressure, inert gas purge, water wash or any combination thereof.

Owner:CALGON CARBON

Mn, Ce and Zr mixed oxides oxidation catalyst

ActiveUS8404201B2Great proportionImprove performanceOrganic chemistryMachines/enginesMixed oxideSulfur

The oxidation of nitrogen oxide (NO) in an oxygen-containing exhaust gas flow from a diesel or other lean-burn engine may be catalyzed using particles of co-precipitated and calcined manganese (Mn), cerium (Ce) and zirconium (Zr) mixed oxides. In preferred embodiments, the molar ratios of Mn, Ce and Zr to the total amount of base metals in the ternary mixed oxide catalyst are in the range of 0.25-0.35, 0.40-0.50 and 0.20-0.25, respectively. Further, this ternary mixed oxide catalyst is less susceptible to sulfur poisoning than previously-disclosed binary mixed oxide catalysts. The ternary mixed oxide catalyst may also be regenerated—and the inhibiting effect of SO2 reversed—by briefly exposing the catalyst to a reducing exhaust gas environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

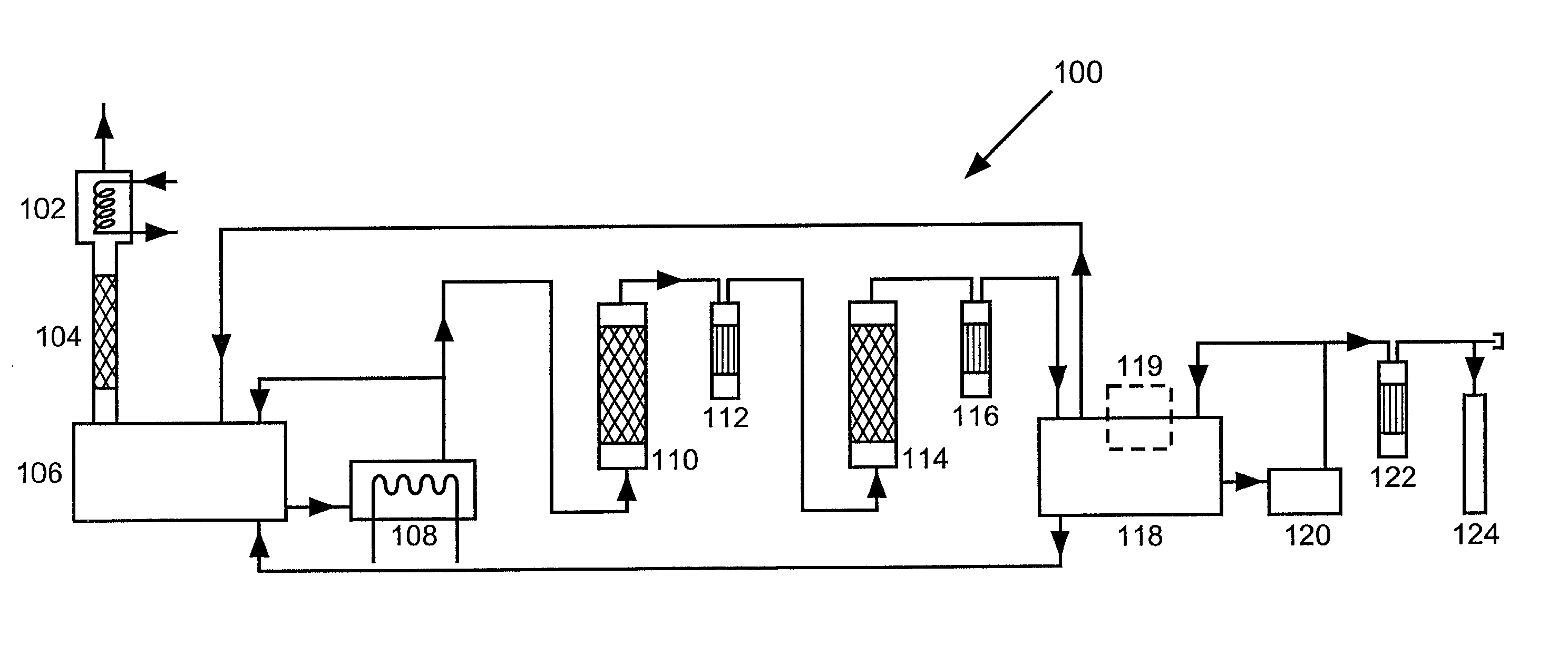

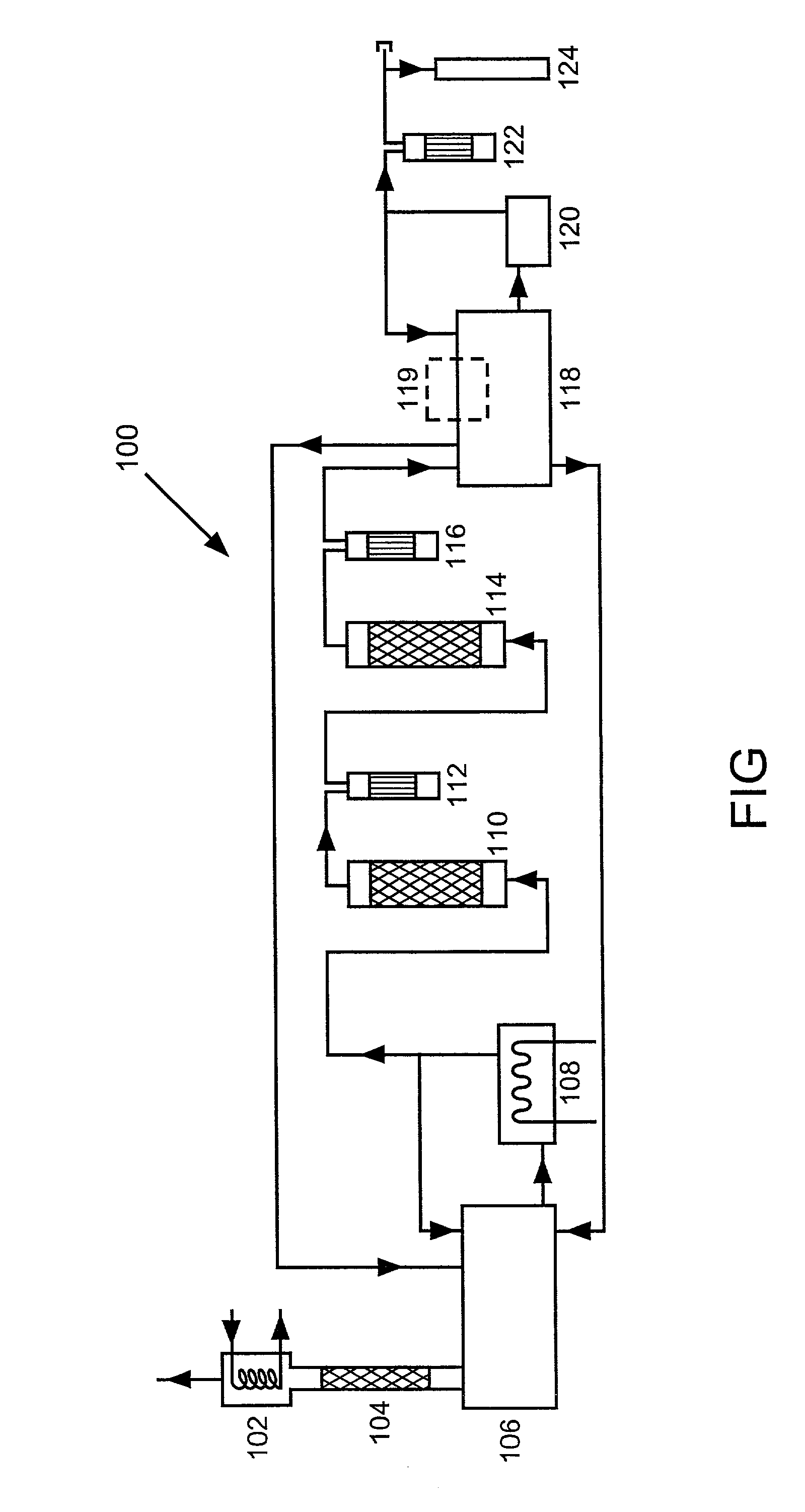

Nitrous oxide purification system and process

InactiveUS20020056289A1Quantity minimizationEasy accessSolidificationLiquefactionFractionating columnProduct gas

Provided are a system and method for nitrous oxide purification, wherein the nitrous oxide product for use in semiconductor manufacturing. The system and process involve a first sub-system having a purification tank for holding a liquefied nitrous oxide, therein; a vaporizer in communication with the purification tank to receive, vaporize and convey a nitrous oxide vapor back to the purification tank; a distillation column disposed on a distal end of the purification tank to receive a nitrous oxide vapor; a condenser disposed on the distillation column, wherein light impurities are removed and wherein a nitrous oxide devoid of light impurities is conveyed and converted into vapor in said vaporizer. A second sub-system having a first dry bed vessel is disposed downstream of the vaporizer to receive the vapor and reacting the acid gas therein; a second dry bed vessel downstream of the said first dry bed vessel for removing water and ammonia in the vapor. A third sub-system having a product tank wherein the purified nitrous oxide vapor is recondensed; a transferring manifold including a liquid pump, liquid filter and a bypass for distributing the purified nitrous oxide to holding vessels.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Method for recovery of high purity carbon dioxide from a gaseous source comprising nitrogen compounds

ActiveUS7829049B2Improve pressure resistanceIncrease temperatureProductsReagentsAbsorption columnNitrogen

The present invention describes a method for recovery of high purity carbon dioxide, which is substantially free of nitrogen oxides. The present invention also discloses a plant for recovery of said high purity carbon dioxide comprising an absorption column, a flash column, a stripper column, and a purification unit.

Owner:UNION ENG

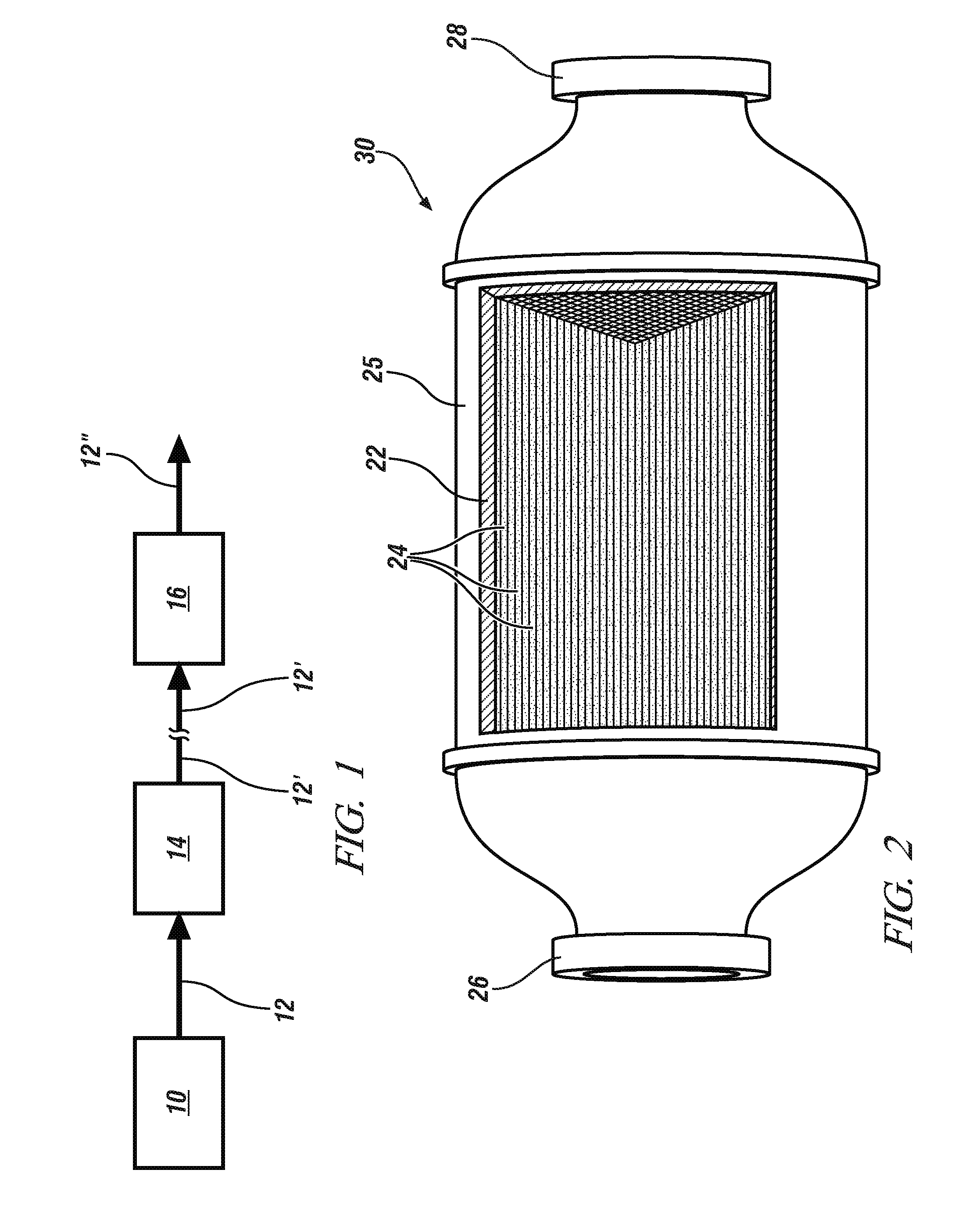

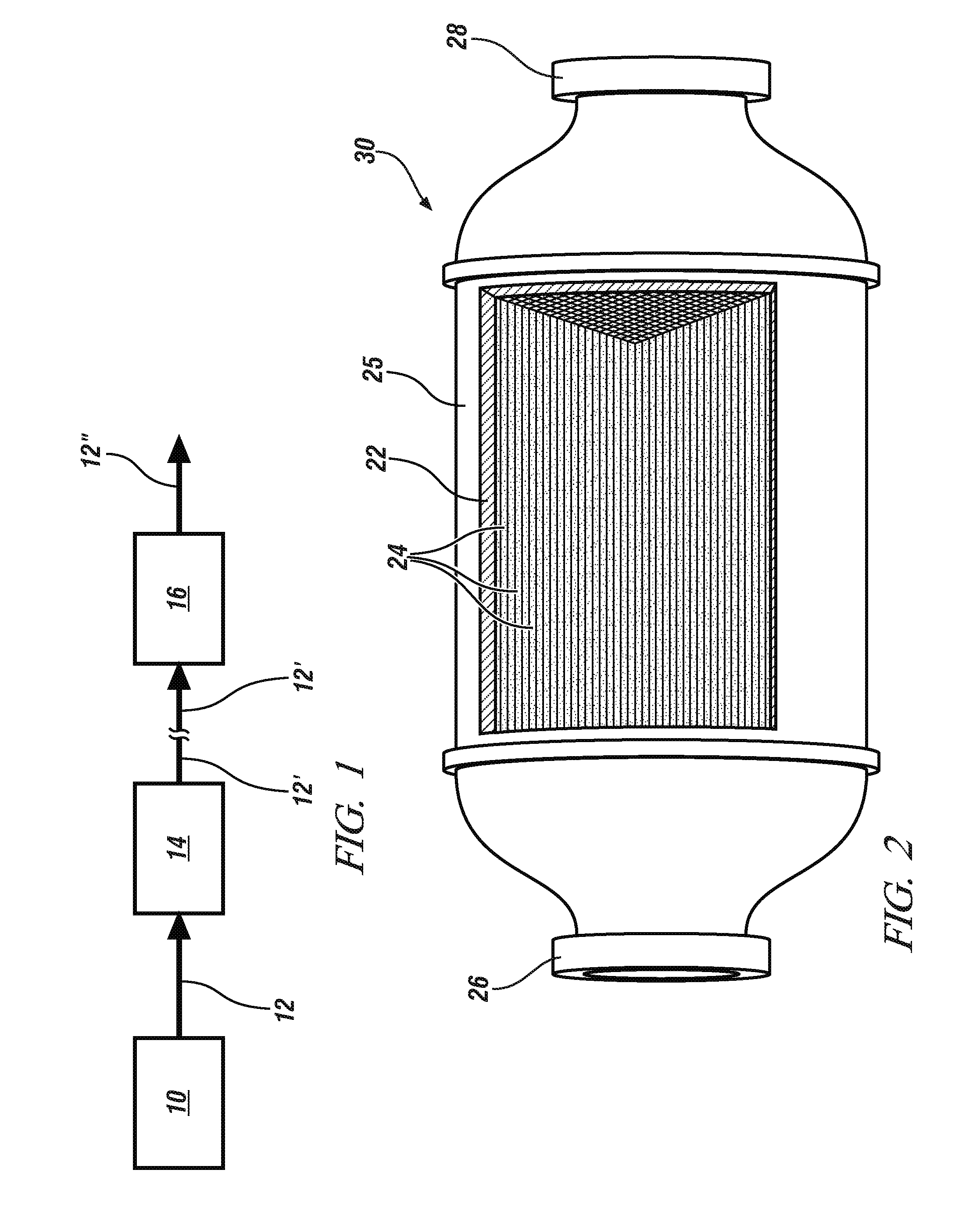

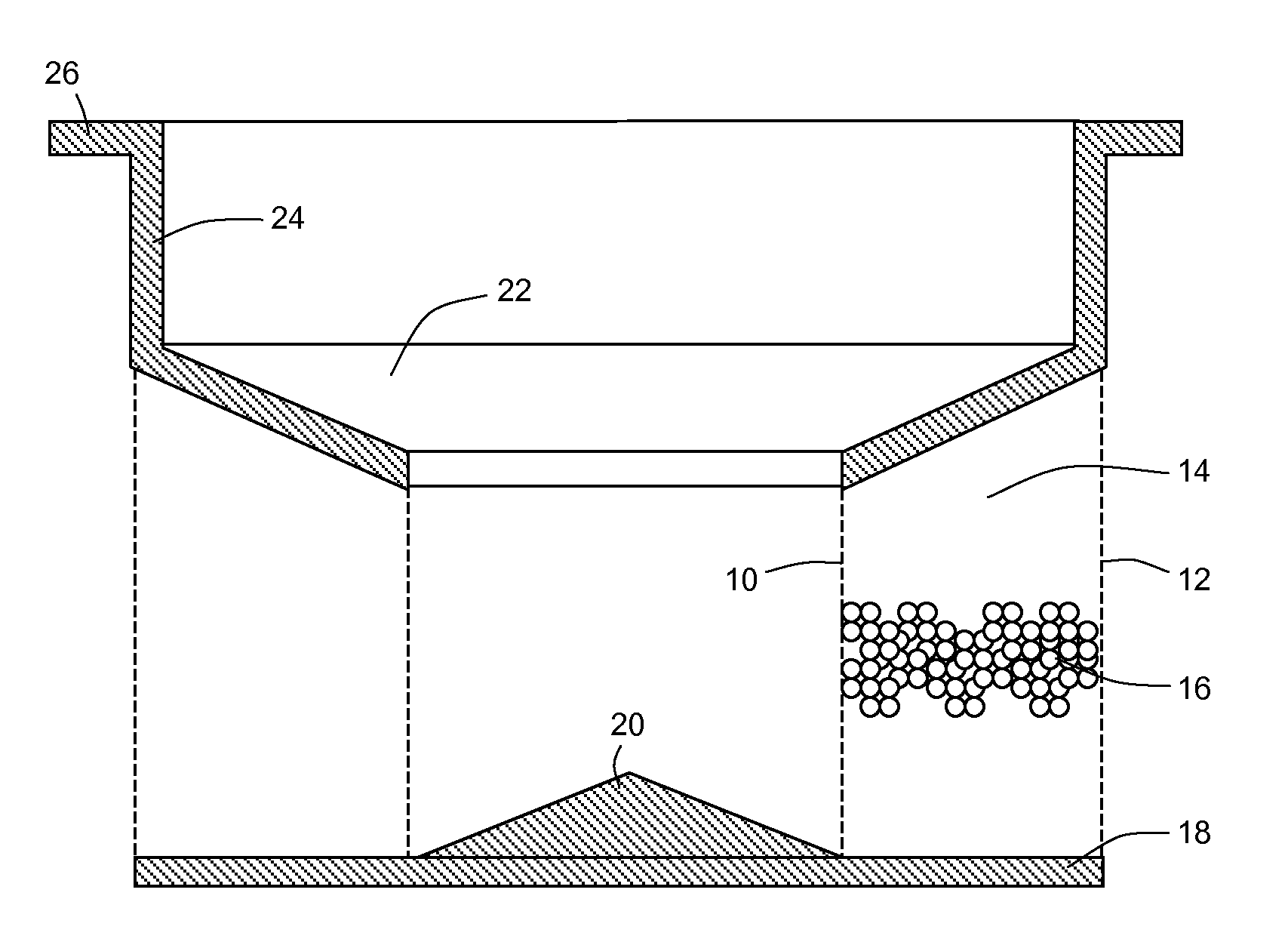

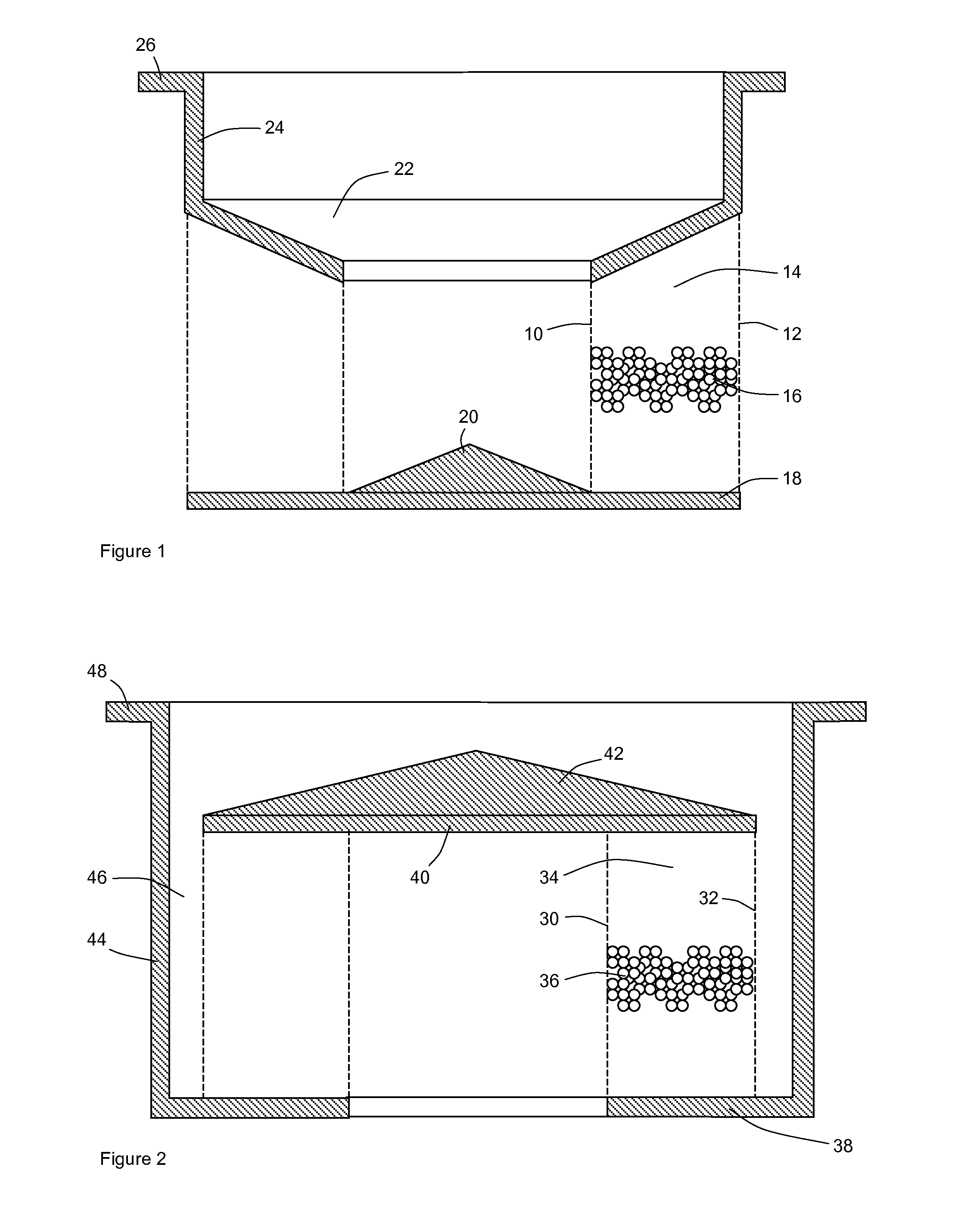

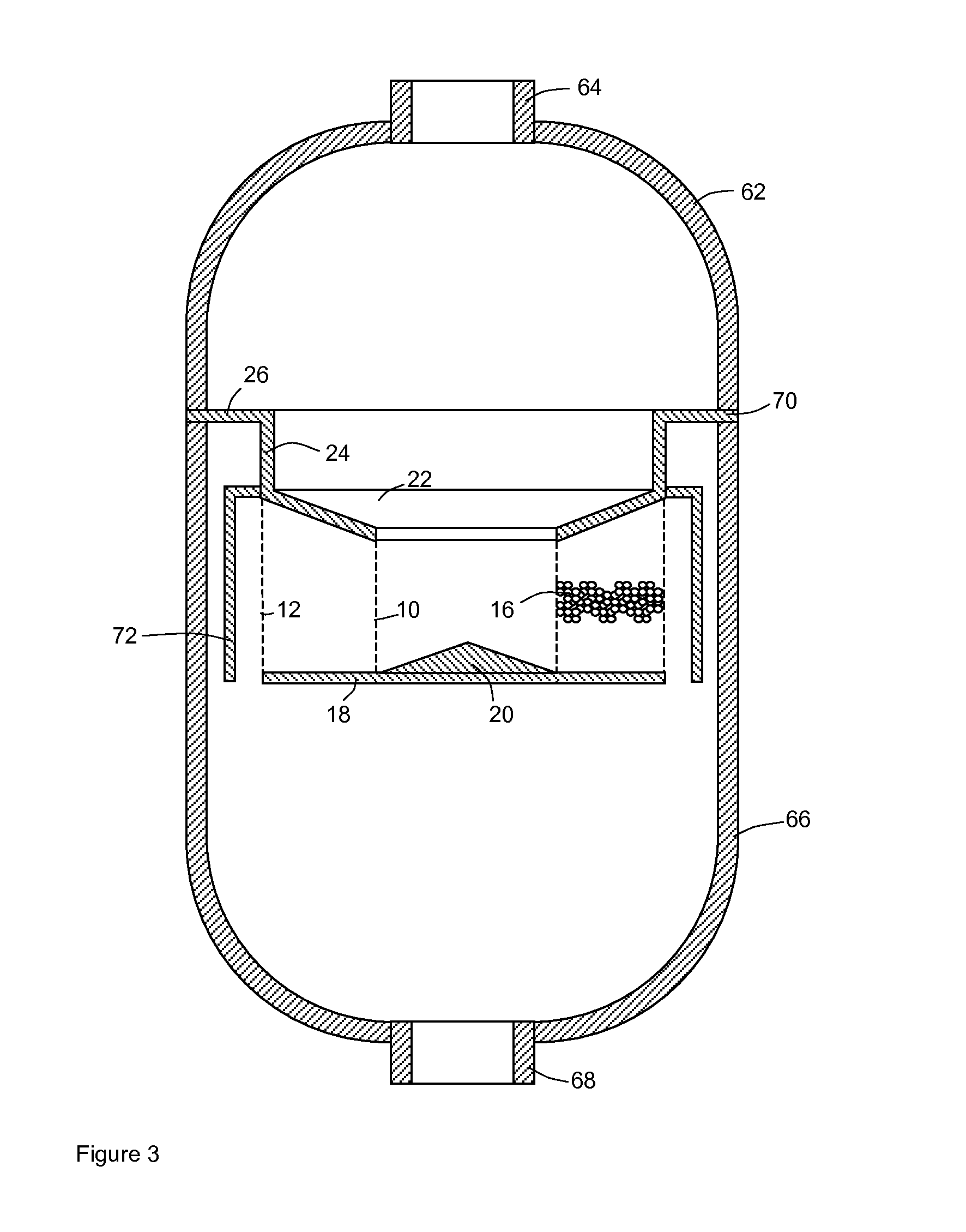

Catalyst containment unit

InactiveUS20110200515A1Lower overall pressure dropImprove operational flexibilityNitrous oxide captureCyanogen compoundsParticulatesProduct gas

A catalyst containment unit includes two concentric perforate members defining an annular space in which a particulate catalyst may be placed, and process fluid-impermeable end members mounted on the ends of the perforate members, wherein one end member extends across the unit to provide a closed end and the other end member closes the annular space thereby providing an open end through which gases may enter or exit the unit, and suspending means attached to one or both end members for securing the unit within an ammonia oxidation vessel. The unit may be suspended, for example, below a precious metal ammonia oxidation gauze pack and may contain a particulate ammonia oxidation catalyst or nitrous oxide abatement catalyst. A catalyst combination includes a precious metal ammonia oxidation catalyst gauze on a supporting framework and a particulate catalyst disposed in a catalyst containment unit.

Owner:JOHNSON MATTHEY PLC

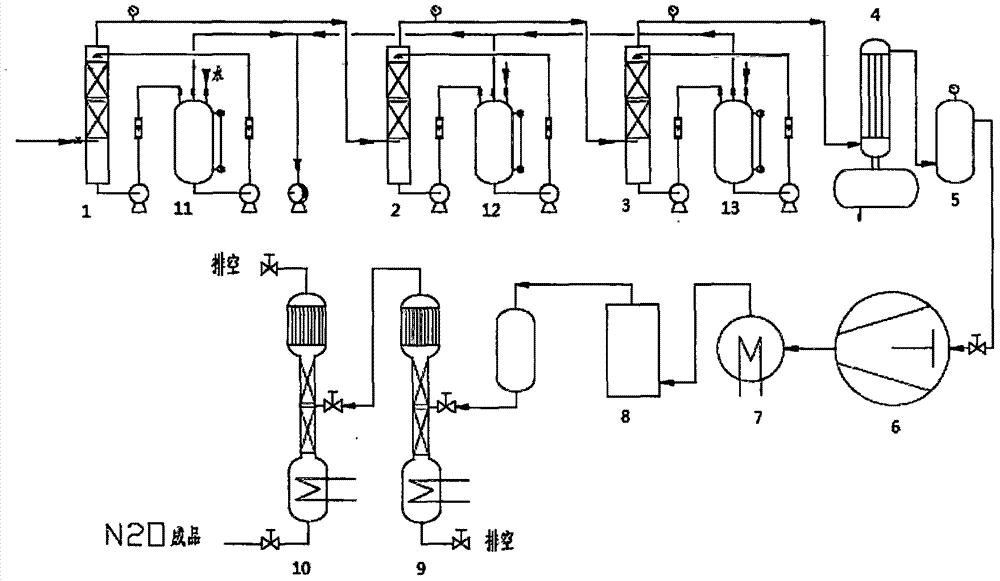

Method for recovering ultra-high purity nitrous oxide

InactiveCN107512708AReduce pollutionHigh degree of automationNitrous oxidesOrganic solventNitrous oxide gas

The invention discloses a method for recovering ultra-high purity nitrous oxide. The method comprises S1, carrying out three-step washing treatment on exhaust gas containing nitrous oxide orderly through a one-step water washing device and a two-step organic solvent washing device, S2, cooling the exhaust gas through a heat exchanger, S3, carrying out two-step adsorption treatment on the exhaust gas through a pressure swing adsorption device and a temperature swing adsorption device, and S4, carrying out two-step rectification treatment on the exhaust gas orderly through a one-step rectification tower and a two-step rectification tower. Through cooperation of the above processes, nitrous oxide in the exhaust gas can be completely separated and ultra-high purity nitrous oxide gas having purity greater than or equal to 99.99999% is obtained. The method meets the requirements on industrial and laboratory ultra-high purity nitrous oxide, greatly reduces environmental pollution caused by the emission of nitrous oxide, realizes recovery and use of nitrous oxide, prevents wastes and saves resources.

Owner:绿菱电子材料(天津)有限公司

Device and method for deep removing water and carbon dioxide in nitrous oxide

ActiveCN104140085AAdd depthImprove adsorption speedNitrous oxide captureProductsChemical industryChemical reaction

The invention discloses a device and method for deep removing water and carbon dioxide in nitrous oxide, and belongs to the technical field of chemical industry production. The device comprises a raw material bottle, a collecting bottle and adsorbing devices. The adsorbing devices include the 13X molecular sieve adsorbing device, the 5A molecular sieve adsorbing device, the modified molecular sieve adsorbing device and the 3A molecular sieve adsorbing device, wherein the 13X molecular sieve adsorbing device, the 5A molecular sieve adsorbing device, the modified molecular sieve adsorbing device and the 3A molecular sieve adsorbing device are sequentially connected. The raw material bottle is heated by a heating device on the outer side of the raw material bottle, a first pressure reducing device is opened when the pressure of raw gas in the raw material bottle reaches 2.0 MPa to 4.0 MPa, and the raw gas sequentially enters the molecular sieve adsorbing devices. When the pressure of the gas in the adsorbing devices reaches 2.0 MPa to 4.0 MPa, a second pressure reducing device is opened, and the gas with impurities removed through the adsorbing devices is collected into the collecting bottle, wherein a refrigerating device is arranged on the outer side of the collecting bottle. By means of the method, the adsorbing depth and the adsorbing speed of adsorbents are increased through high-pressure adsorption, the physical adsorbing function and the chemical reaction function are achieved by conducting chemical modification on molecular sieves, the adsorbing performance of the adsorbents is improved, the water impurity and the carbon dioxide impurity in the nitrous oxide are deep removed, and a high-purity nitrous oxide product is obtained.

Owner:中昊光明化工研究设计院有限公司

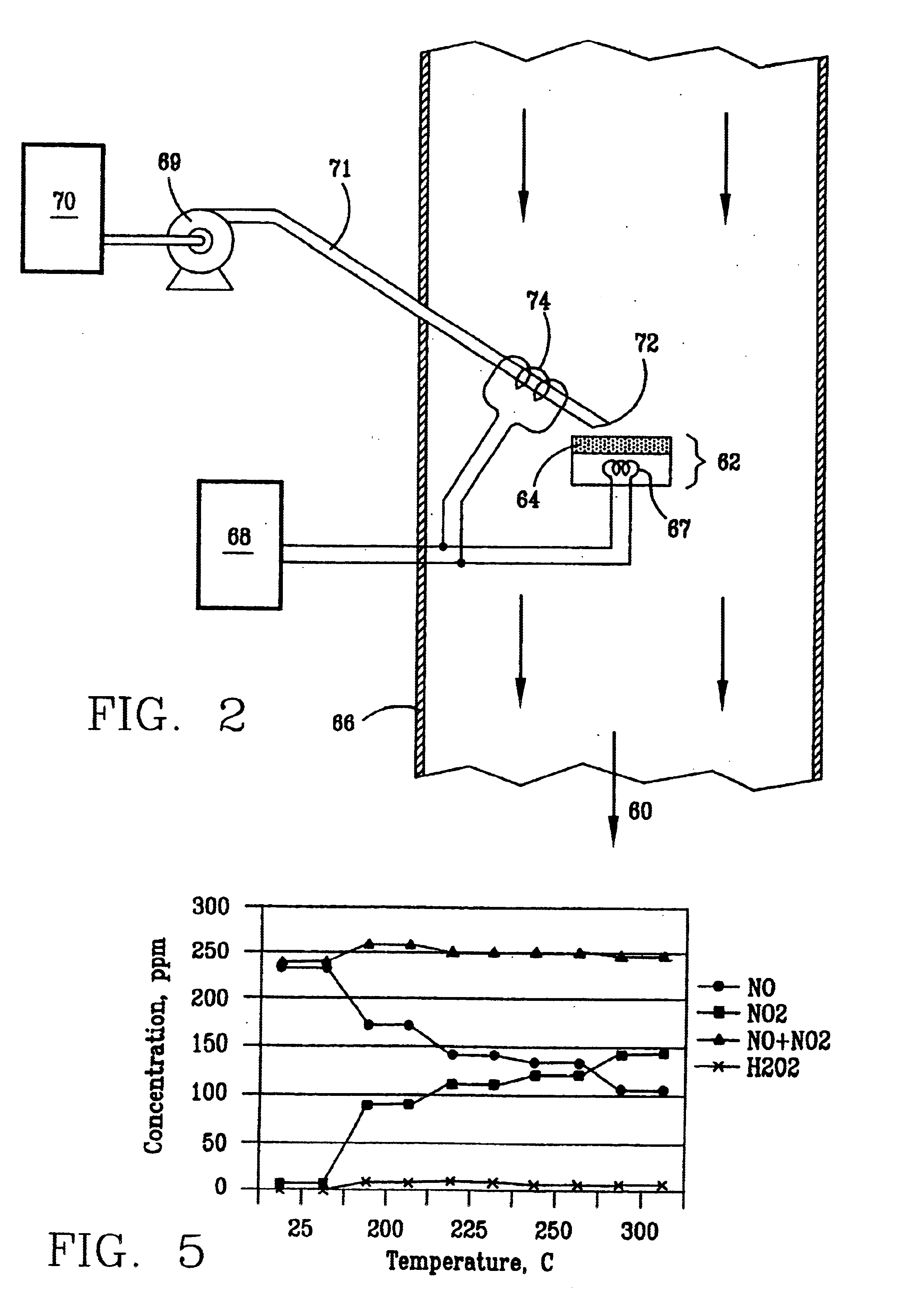

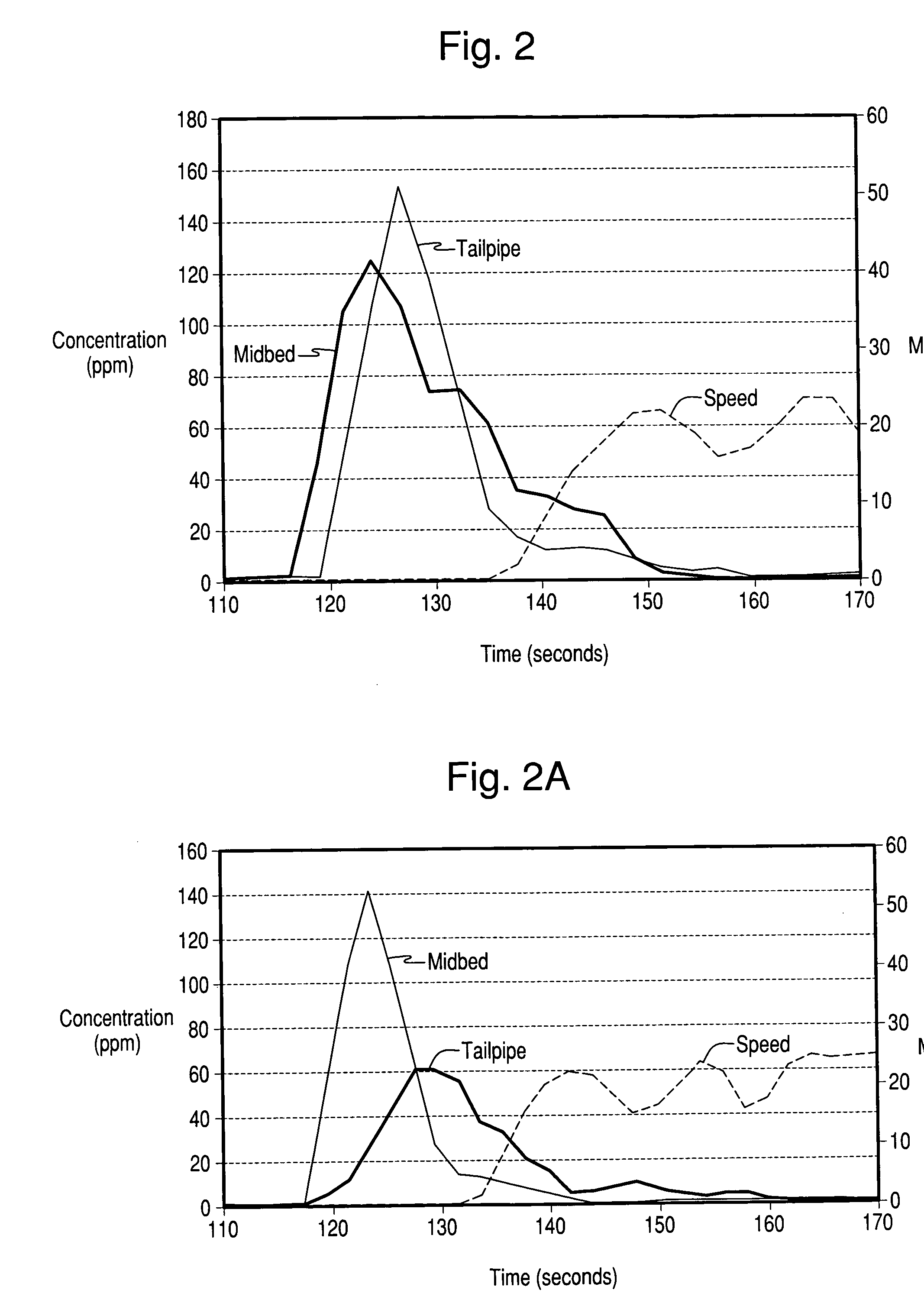

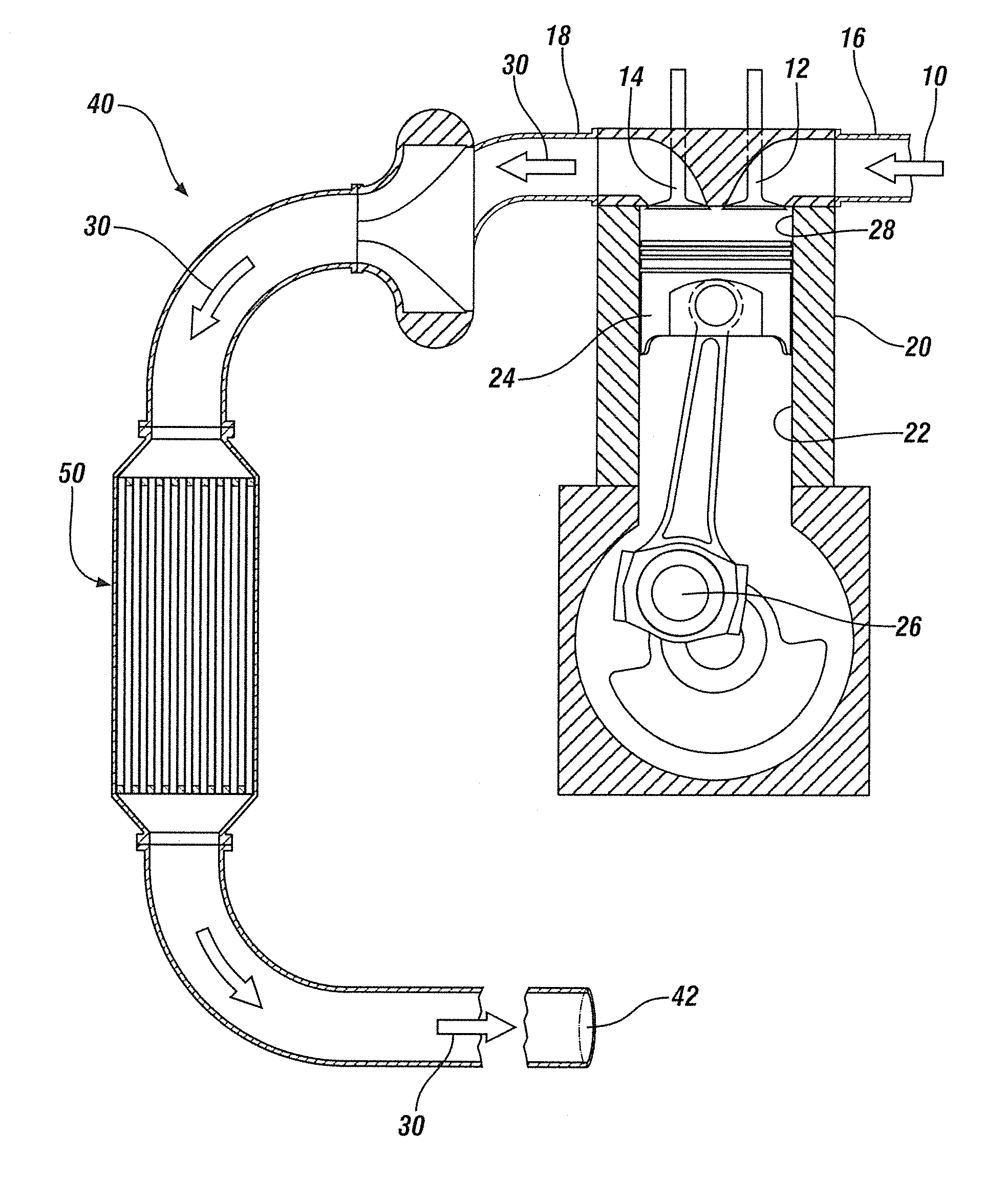

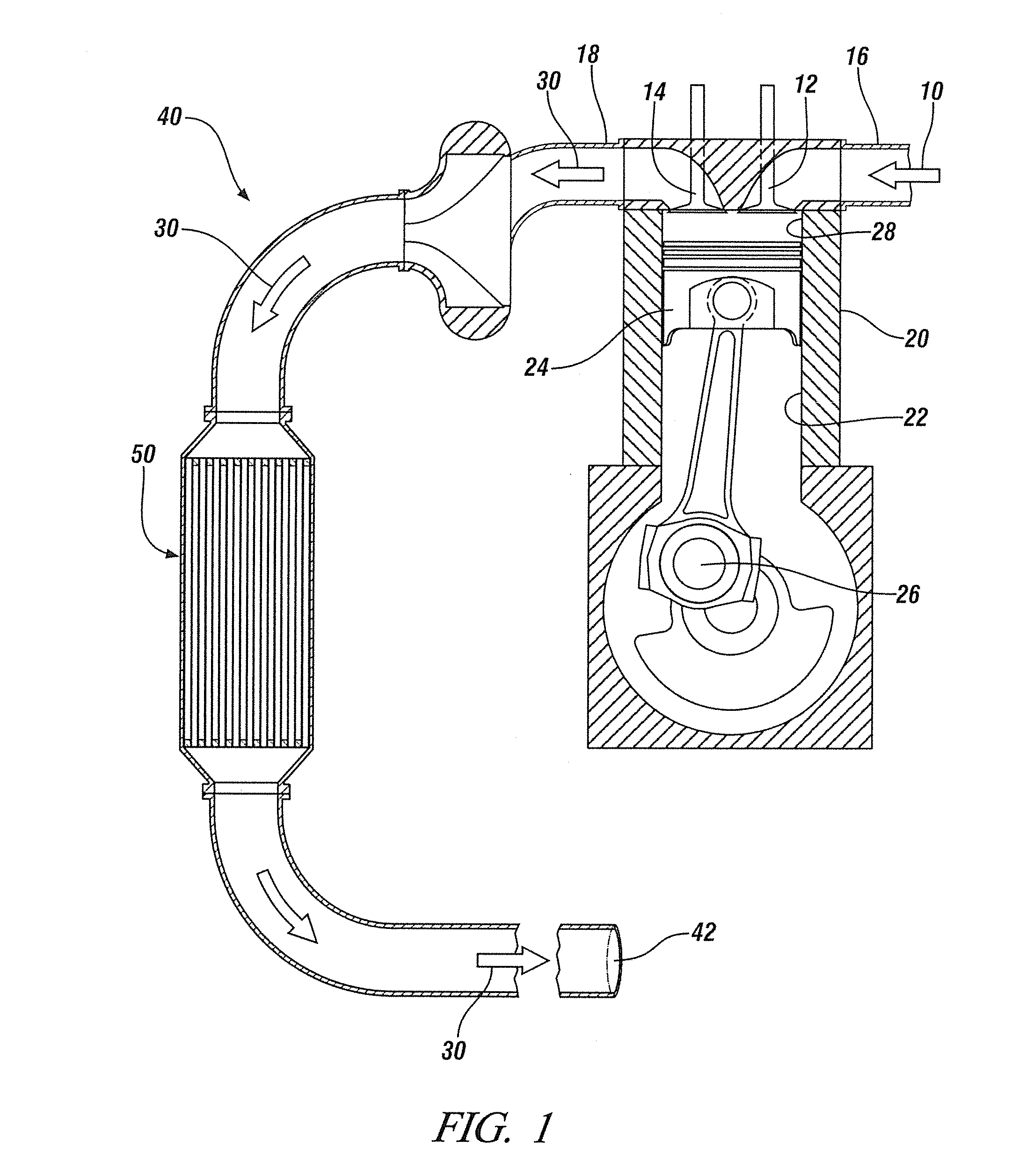

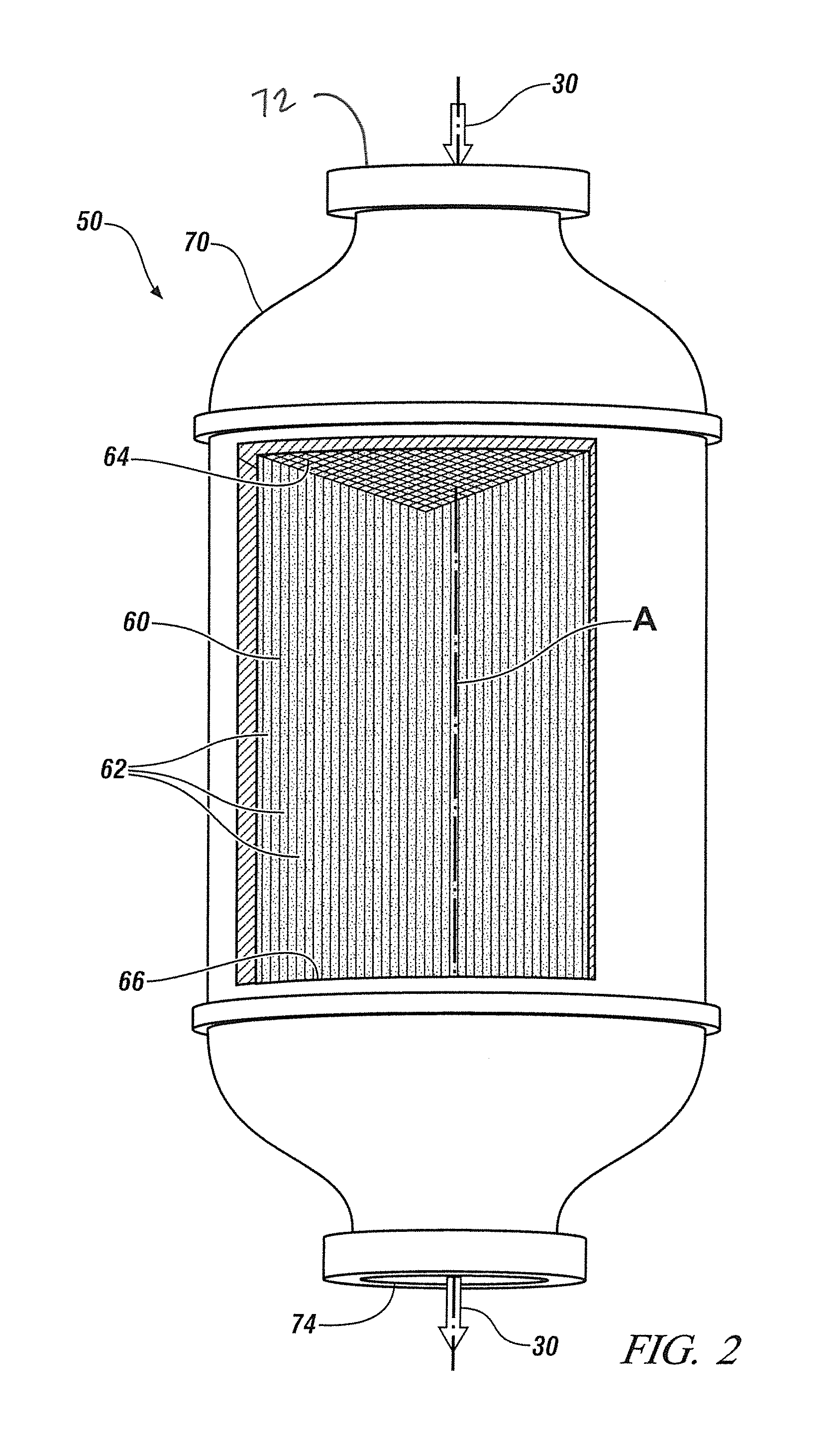

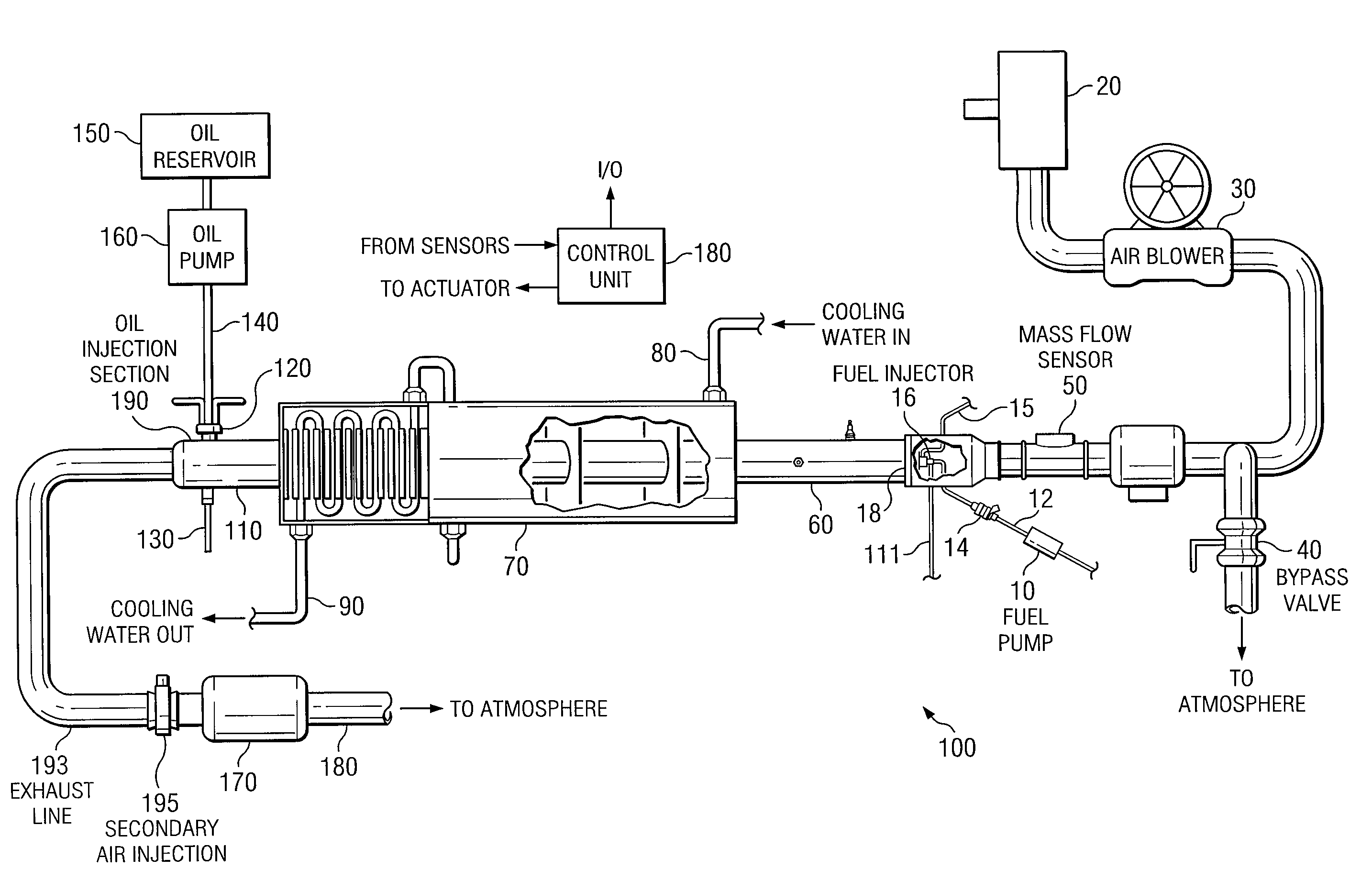

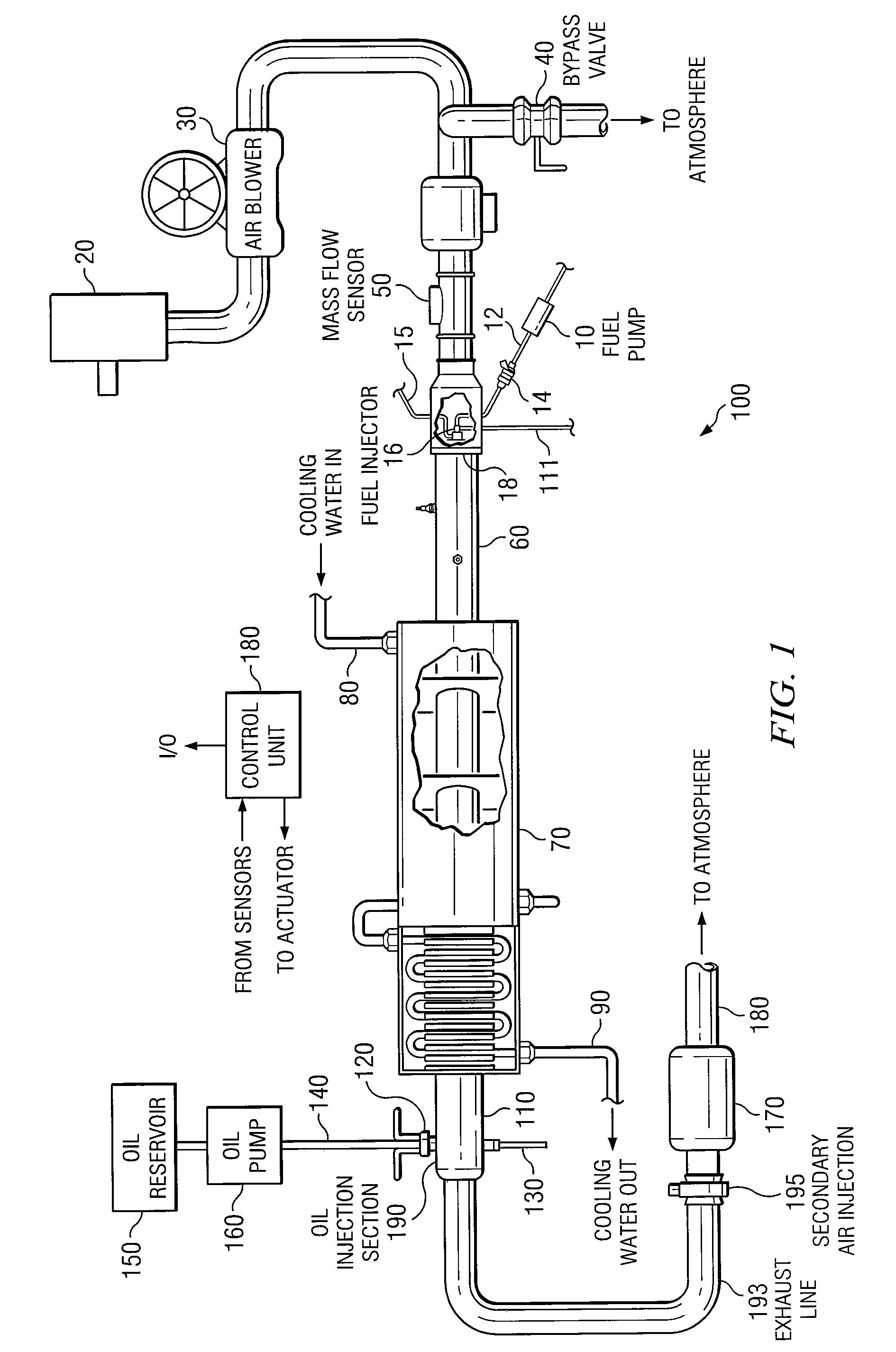

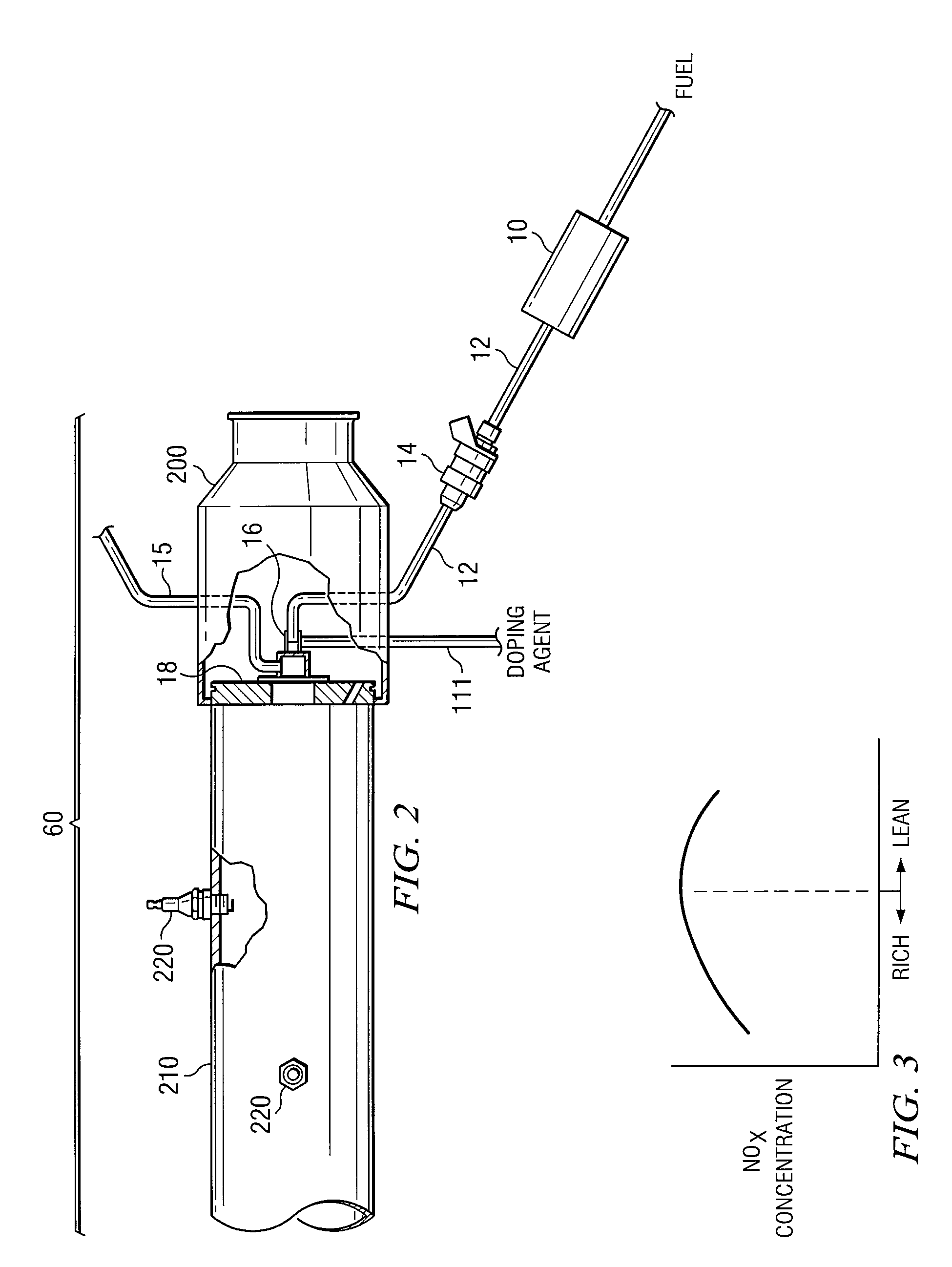

NOx augmentation in exhaust gas simulation system

Various methods and systems for augmenting the amount of NOX in the exhaust of an exhaust flow simulation system. These methods and system can be “combustion” or “post combustion”. A combustion embodiment injects a nitrogen-containing compound (doping agent) into the burner, so that it mixed and combusted with the fuel.

Owner:SOUTHWEST RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com