Technique for preparing nitrous oxide by decomposing ammonium nitrate

A technology of nitrous oxide and ammonium nitrate, which is applied in the direction of nitrous oxide, nitrogen oxides/oxyacids, etc., can solve the problems of complex production technology, poor product quality, and high cost, and achieve convenient use and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

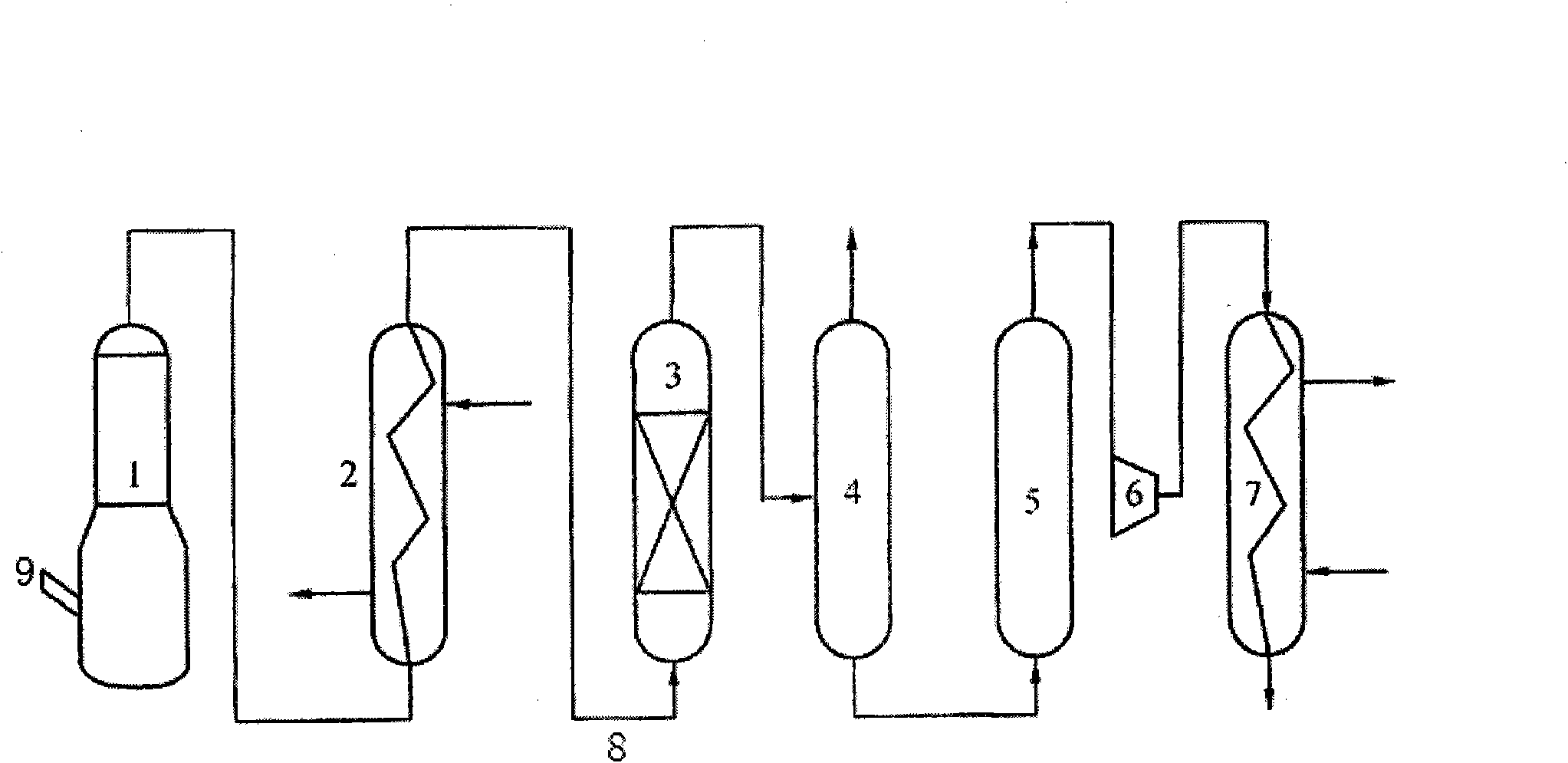

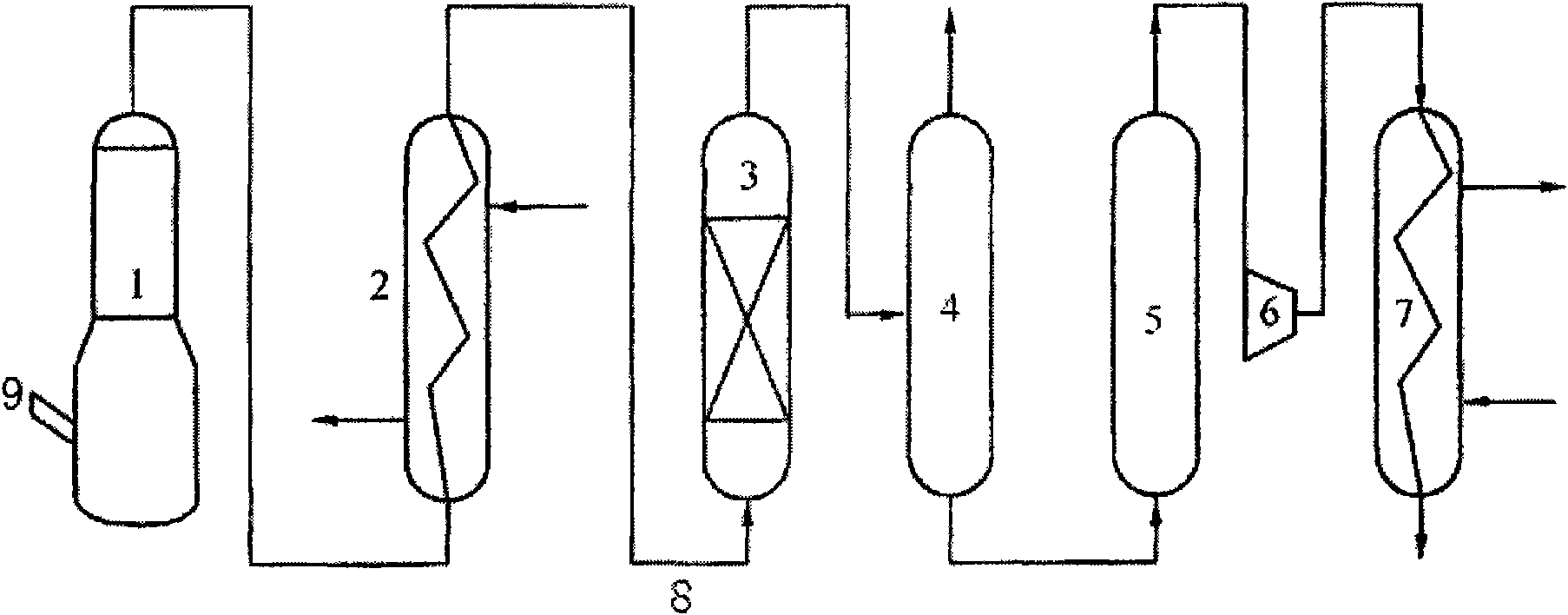

[0011] refer to figure 1 , design reactor (1), cooling tower (2), drier (3), rectification tower (4), surge tank (5), compressor (6), condenser (7) with feeding port (9) ) is formed by assembling a connecting pipeline (7) according to its system function.

[0012] The present invention all adopts stainless steel material to make and assemble. Operation process: Pour granular ammonium nitrate into the feeding tank of the melting pot, add a small amount of water and catalyst (diammonium hydrogen phosphate) to heat to melt; the melted ammonium nitrate is injected into the reaction kettle (1) by the injection pump. The products decomposed in the reaction kettle (1) enter the cooling tower (2), and the water vapor in the reactants in the cooling tower (2) is condensed into water, which is discharged together with the spray cooling water. Water-soluble impurities and mechanical impurities in the reactants are also washed away.

[0013] The gas from which a significant amount of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com