Device and method for deep removing water and carbon dioxide in nitrous oxide

A technology of nitrous oxide and carbon dioxide, which is applied in the field of chemical production, can solve the problems of unable to meet the purity requirements and improve the adsorption performance of the adsorbent, and achieve the effect of improving the adsorption performance, increasing the adsorption speed, and increasing the adsorption depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

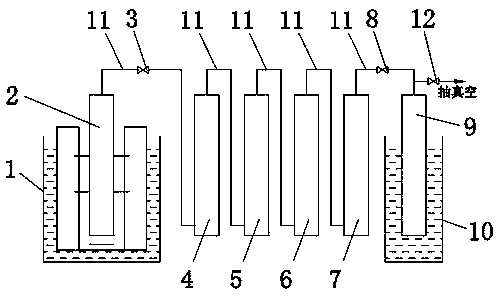

Embodiment 1

[0021] Put the raw material bottle 2 containing 25Kg nitrous oxide into the heater 1, heat the heater 1 to a temperature of 25°C, and when the pressure of the raw material bottle 2 reaches 2.0 MPa, open the first pressure reducing valve 3 to make the raw material gas flow along the gas pipeline (11) Enter the 13X molecular sieve adsorber (4), 5A molecular sieve adsorber (5), modified molecular sieve adsorber (6) and 3A molecular sieve adsorber (7) in sequence for adsorption and removal of impurities. When the pressure in the adsorber reaches 2.0MPa, open the second decompression valve 8, control the adsorber pressure to be 2.0MPa all the time, collect the product bottle temperature at -100--140°C, and collect 5Kg of product. The impurity contents of water and carbon dioxide in the collected nitrous oxide products are H 2 O2 <1PPm.

Embodiment 2

[0023]Put the raw material bottle 2 containing 25Kg of nitrous oxide into the heater 1, heat the heater 1 to a temperature of 25°C, and when the pressure of the raw material bottle 2 reaches 3.0 MPa, open the first pressure reducing valve 3 to make the raw material gas flow along the gas pipeline (11) Enter the 13X molecular sieve adsorber (4), 5A molecular sieve adsorber (5), modified molecular sieve adsorber (6) and 3A molecular sieve adsorber (7) in sequence for adsorption and removal of impurities. When the pressure in the adsorber reaches 3.0MPa, the second pressure reducing valve 8 is opened to control the pressure of the adsorber to be 3.0MPa all the time. The temperature of the collected product bottle is -100--140°C, and 5Kg of product is collected. The impurity contents of water and carbon dioxide in the collected nitrous oxide products are H 2 O2 <1PPm.

Embodiment 3

[0025] Put the raw material bottle 2 containing 25Kg of nitrous oxide into the heater 1, heat the heater 1 to a temperature of 25°C, and when the pressure of the raw material bottle 2 reaches 4.0MPa, open the first pressure reducing valve 3 to make the raw material gas flow along the gas pipeline (11) Enter the 13X molecular sieve adsorber (4), 5A molecular sieve adsorber (5), modified molecular sieve adsorber (6) and 3A molecular sieve adsorber (7) in sequence for adsorption and removal of impurities. When the pressure in the adsorber reaches 4.0MPa, the second pressure reducing valve 8 is opened to control the pressure of the adsorber to be 4.0MPa all the time. The temperature of the collected product bottle is -100--140°C, and 5Kg of product is collected. The impurity contents of water and carbon dioxide in the collected nitrous oxide products are H 2 O2 <1PPm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com