Scandium doping zinc oxide-bismuth vanadium oxide composite photodegradation material and preparation method thereof

A technology for degrading materials, bismuth vanadate, is applied in the field of photodegradable materials, which can solve the problems of easy compounding, increasing the size of ZnO grains, and short absorption of visible light waves, so as to improve the degradation efficiency, shorten the diffusion time, and increase the absorption. Band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In order to achieve the above object, the present invention provides the following technical solutions: a scandium-doped zinc oxide-bismuth vanadate composite photodegradable material and its preparation method, comprising the following raw materials in parts by weight: 42-58 parts of zinc hydroxide, 4-8 parts of citric acid, 0.5-1 part of scandium nitrate hexahydrate, 15-20 parts of bismuth trichloride, 22-27 parts of sodium vanadate, 0.5-2 parts of sodium hydroxide, Zn(OH) in zinc hydroxide 2 The content is 92.5-95.8%, the mass fraction of citric acid is 94.8-96.3%, and Sc(NO 3 ) 3 ·6H 2 O content is 95.5-97.2%, BiCl in bismuth trichloride 3 The content is 93.6-96.7%, Na in sodium vanadate 3 VO 4 The content is 92.4-94.8%, the NaOH content in sodium hydroxide is 95.2-98.4%, a scandium-doped zinc oxide-bismuth vanadate composite photodegradable material, and the preparation method includes the following steps:

[0024](1) Preparation of Mn-doped ZnO: Add 600mL dis...

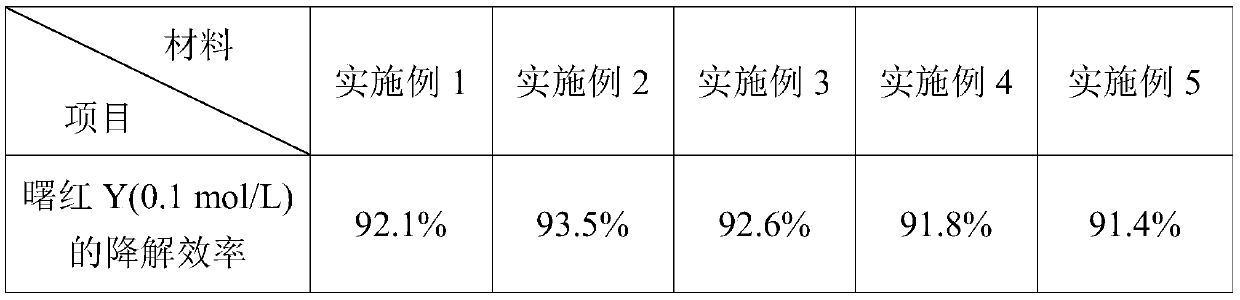

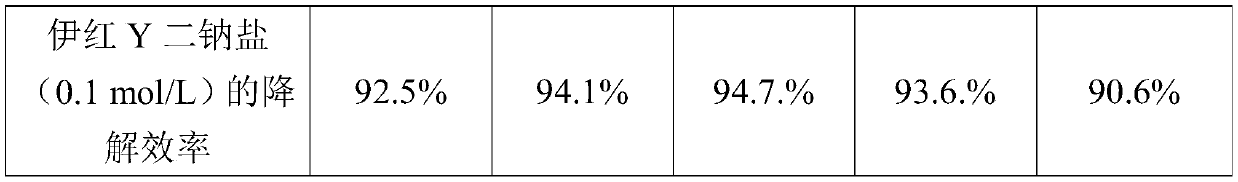

Embodiment 1

[0028] (1) Preparation of Mn-doped ZnO: Add 600mL of distilled water to a 1000mL beaker, then weigh 58 parts of zinc hydroxide, 0.5 parts of scandium nitrate hexahydrate and 4 parts of citric acid into the beaker and stir them evenly, then put the beaker Put it in an ultrasonic processor with an ultrasonic frequency of 25KHz and an ultrasonic power of 1500W. Ultrasonic disperse for 2-3 hours to form a sol. Then place the beaker in an oven to heat up to 70-75°C and heat for 15-18 hours until the material is anhydrous. Gel-like, then heat up to 120-125°C, heat for 30-35h for dehydration and puffing, to obtain a brown solid mixture Mn-doped ZnO precursor, and then put the precursor into a high-energy planetary ball mill for 6-8h, the speed is 100-120rpm, then put the ground material in a tube-type resistance furnace at a heating rate of 5°C / min, heat to 650-660°C for 3-4h, and obtain an off-white solid. Use 500-700mL with a concentration of 11.5-12.5 % dilute hydrochloric acid to...

Embodiment 2

[0032] (1) Preparation of Mn-doped ZnO: Add 600mL of distilled water to a 1000mL beaker, then weigh 54 parts of zinc hydroxide, 0.6 parts of scandium nitrate hexahydrate and 5 parts of citric acid into the beaker and stir evenly, then put the beaker Put it in an ultrasonic processor with an ultrasonic frequency of 25KHz and an ultrasonic power of 1500W. Ultrasonic disperse for 2-3 hours to form a sol. Then place the beaker in an oven to heat up to 70-75°C and heat for 15-18 hours until the material is anhydrous. Gel-like, then heat up to 120-125°C, heat for 30-35h for dehydration and puffing, to obtain a brown solid mixture Mn-doped ZnO precursor, and then put the precursor into a high-energy planetary ball mill for 6-8h, the speed is 100-120rpm, then put the ground material in a tube-type resistance furnace at a heating rate of 5°C / min, heat to 650-660°C for 3-4h, and obtain an off-white solid. Use 500-700mL with a concentration of 11.5-12.5 % dilute hydrochloric acid to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com