Electrolyte corrosion inhibitor, aluminum-air battery electrolyte and preparation method thereof

An aluminum-air battery and electrolyte technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of single function, reduce the activity of aluminum anodes, and reduce the corrosion inhibition effect, and achieve a dense deposition layer , good corrosion inhibition effect, and improved deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

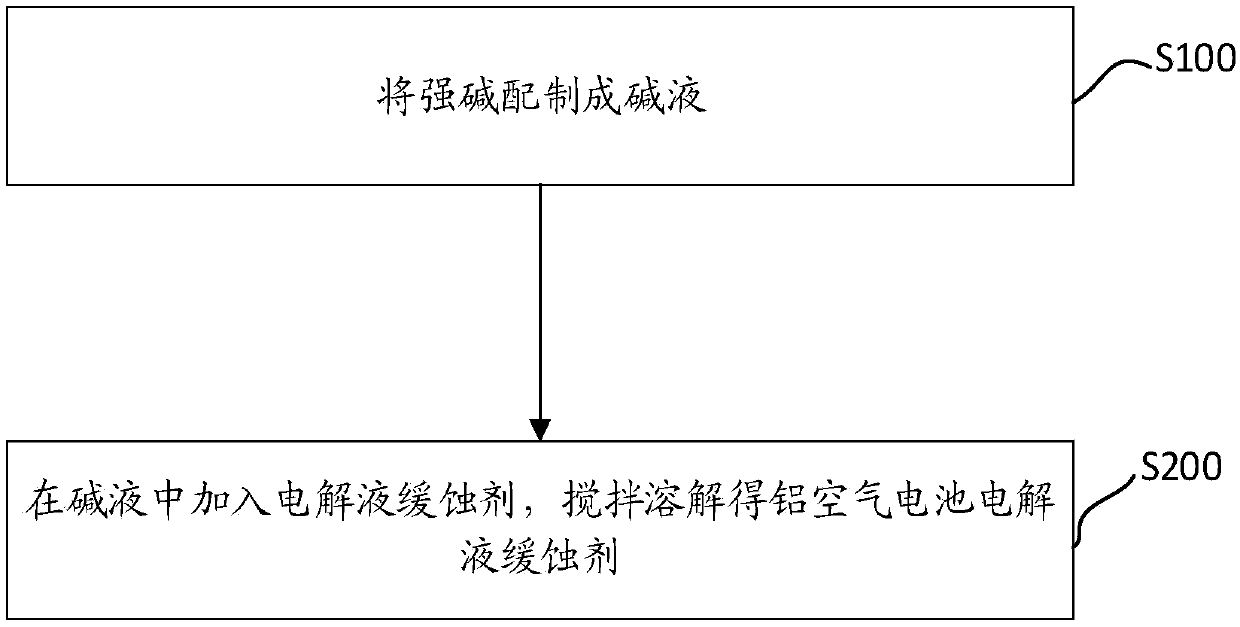

[0039] Such as figure 1 As shown, this embodiment also provides a method for preparing an aluminum-air battery electrolyte, including the following steps:

[0040] Step S100: providing or preparing a strong alkali solution.

[0041] Wherein, the strong alkali solution can be potassium hydroxide solution or sodium hydroxide solution, with a concentration of 1 to 8 mol / L, preferably 3.5 to 5.5 mol / L;

[0042] Step S200: Add an electrolyte corrosion inhibitor into the strong alkali solution, and mix well to obtain an aluminum-air battery electrolyte.

[0043] As a preferred solution, step S100 can adopt the following specific steps:

[0044] Step S110: preparing sodium hydroxide into a sodium hydroxide solution.

[0045] The concentration of the sodium hydroxide solution is prepared to be 1-8 mol / L, preferably 3.5-5.5 mol / L.

[0046] Step S120: adding powdered aluminum hydroxide to the sodium hydroxide solution, stirring under the condition of heating in a constant temperatur...

Embodiment 1

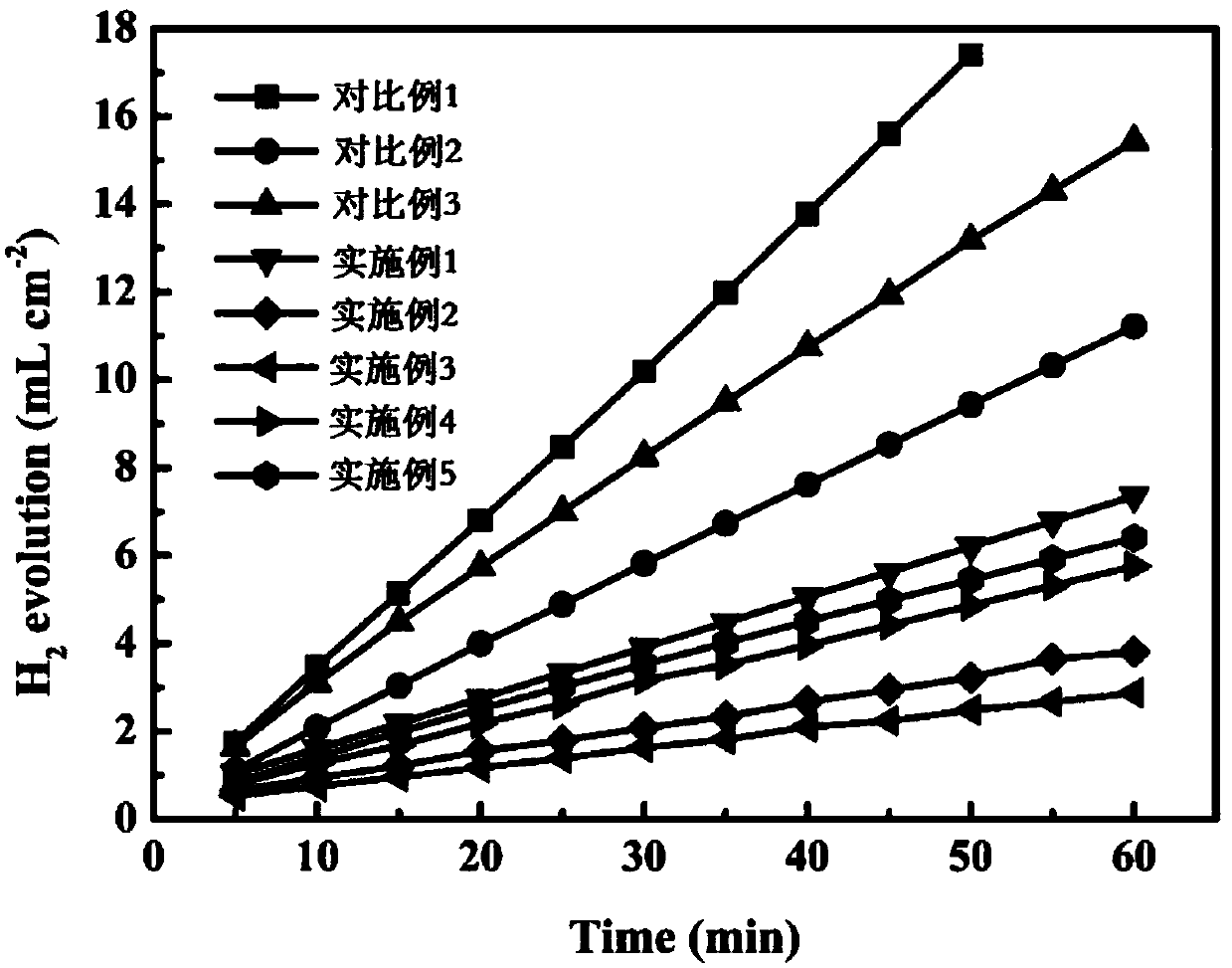

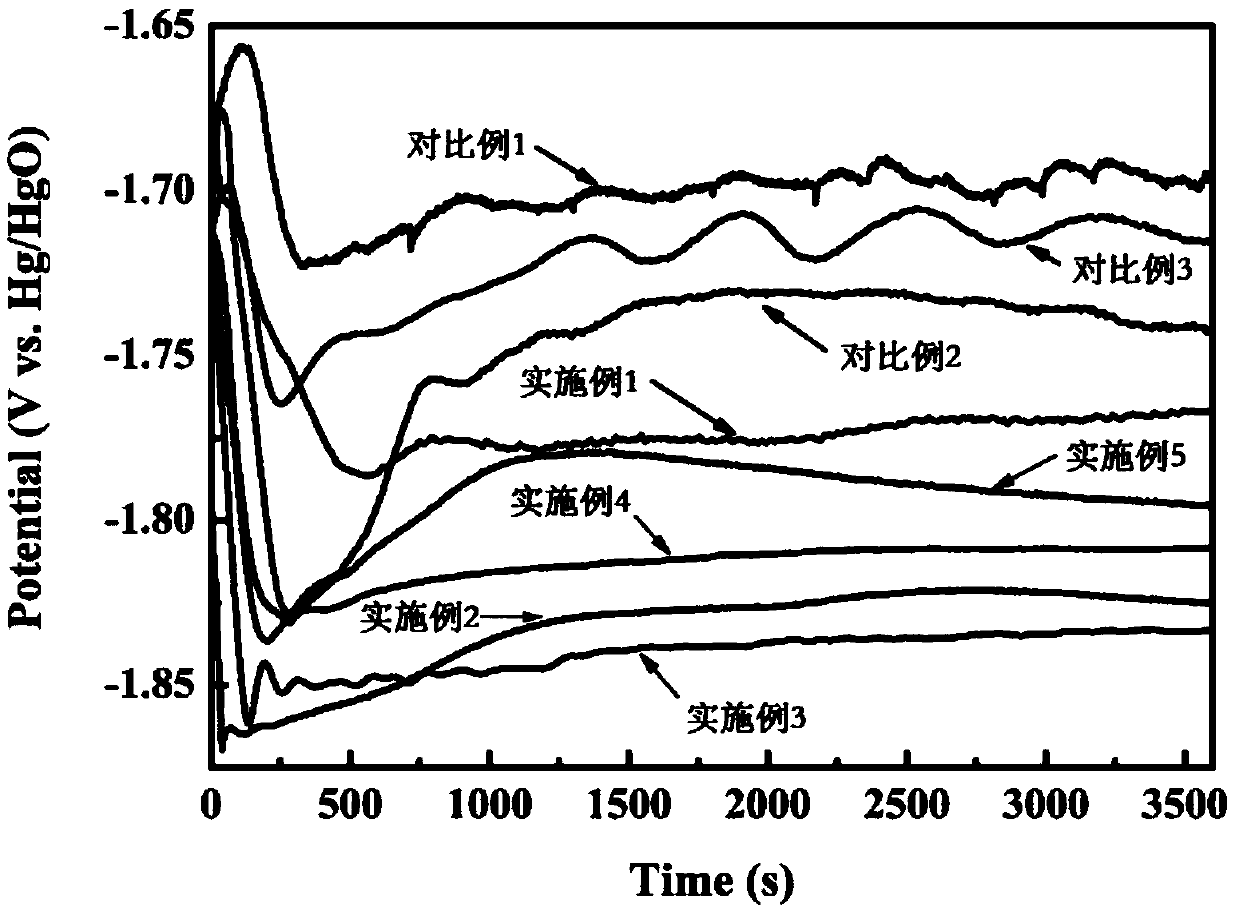

[0060] Electrolyte corrosion inhibitors include inorganic phase-forming corrosion inhibitors and organic adsorption corrosion inhibitors. Alkyl dimethyl benzyl ammonium bromide 0.0008mol. Prepare 1L of sodium hydroxide solution with a concentration of 4mol / L, add 40g of aluminum hydroxide powder to the sodium hydroxide solution as a seed crystal, and stir evenly under the condition of heating in a constant temperature water bath at 60°C to obtain lye. Add the ground and mixed electrolyte corrosion inhibitor into the lye, add it in 5 times, and wait for the electrolyte corrosion inhibitor to dissolve under the condition of heating in a constant temperature water bath at 60°C to obtain an aluminum-air battery electrolyte.

Embodiment 2

[0062] Electrolyte corrosion inhibitors include inorganic phase-forming corrosion inhibitors and organic adsorption corrosion inhibitors. Triazole 0.005mol, aspartic acid 0.02mol, cetyltrimethylammonium chloride 0.0005mol. Prepare 1 L of sodium hydroxide solution with a concentration of 4 mol / L, add 40 g of aluminum hydroxide powder as a seed crystal into the sodium hydroxide solution, and stir evenly to obtain lye. Add the ground and mixed inorganic phase-forming corrosion inhibitor into the lye, and add it in 5 times. After the inorganic phase-forming corrosion inhibitor dissolves, add the fully ground and mixed organic adsorption-type corrosion inhibitor, and stir to dissolve. Aluminum-air battery electrolyte. The stirring process in the above preparation process is all completed under the condition of heating in a constant temperature water bath at 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com