Preparation method and application of ultrafine tungsten-rhenium composite powder containing scandium and strontium

The technology of composite powder and mixed powder is applied in the field of preparation of ultrafine tungsten-rhenium composite powder containing scandium and strontium. The effect of low performance and equipment requirements and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

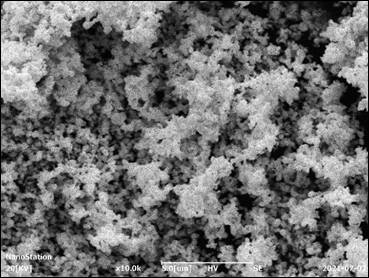

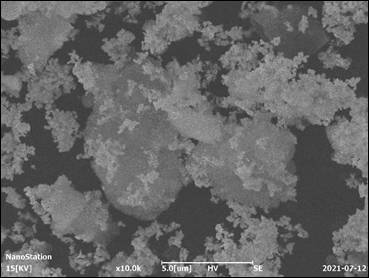

Image

Examples

Embodiment 1

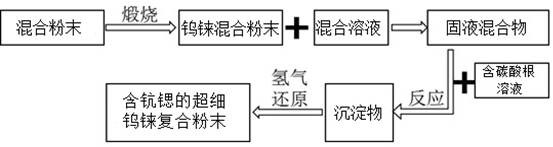

[0044] Such as figure 1 As shown, this embodiment includes the following steps:

[0045]Step 1: Ball mill 88.5g of tungsten oxide powder, 4.3g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain Tungsten-rhenium mixed powder;

[0046] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.02mol / L, the concentration of strontium nitrate is 0.02mol / L, the concentration of aluminum nitrate nonahydrate is 0.08mol / L, the concentration of barium nitrate is 0.12 mol / L, the concentration of calcium nitrate tetrahydrate is 0.02mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0047] Step 3, preparation 1000mL concentration is the solution that contains carbonate group of 2mol / L, then joins the solution that contains car...

Embodiment 2

[0054] Such as figure 1 As shown, this embodiment includes the following steps:

[0055] Step 1. Ball mill 61.3g of tungsten oxide powder, 20g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain tungsten Rhenium mixed powder;

[0056] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.03mol / L, the concentration of strontium nitrate is 0.03mol / L, the concentration of aluminum nitrate nonahydrate is 0.1mol / L, the concentration of barium nitrate is 0.14 mol / L, the concentration of calcium nitrate tetrahydrate is 0.03mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0057] Step 3, preparation of 1000mL concentration of 3mol / L solution containing carbonate, then the solution containing carbonate is added to the ...

Embodiment 3

[0060] Such as figure 1 As shown, this embodiment includes the following steps:

[0061] Step 1. Ball mill 55.34g of tungsten oxide powder, 37.46g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain Tungsten-rhenium mixed powder;

[0062] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.04mol / L, the concentration of strontium nitrate is 0.04mol / L, the concentration of aluminum nitrate nonahydrate is 0.12mol / L, the concentration of barium nitrate is 0.16 mol / L, the concentration of calcium nitrate tetrahydrate is 0.04mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0063] Step 3, preparing 1000mL concentration of 4mol / L solution containing carbonate, then adding the solution containing carbonate to the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com