Preparation method for rod-like Sc2W3O12 negative thermal expansion material

A negative thermal expansion material, sc2w3o12 technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of high reaction temperature, long reaction time, irregular product morphology, etc., to achieve simple procedures, easy operation and effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

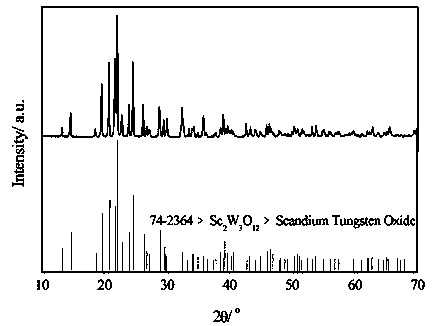

[0016] Rod-shaped Sc was successfully synthesized by hydrothermal method 2 W 3 o 12 Negative thermal expansion material, raw material: Sc(NO 3 ) 3 · wxya 2 O (analytically pure), H 40 N 10 o 41 W 12 · wxya 2 O (chemically pure), first prepare scandium nitrate and ammonium tungstate into 0.5mol / L and 0.1mol / L solutions respectively, and then use the double drop method to mix the two solutions of scandium nitrate and ammonium tungstate by Sc 3+ :W 6+ The molar ratio was 2:3, and nitric acid solution was added to the mixed solution to adjust the pH=5 under constant stirring, and stirred at 70°C for 3 hours; Seal and heat at 180°C for 10 hours. After the reaction is complete, use a centrifuge to dehydrate. After pouring off the supernatant, wash and centrifuge repeatedly for 3 times, and then dry at 100°C to obtain the precursor; put the precursor in the muffle furnace The final product Sc was obtained after heating at 550 °C for 5 h 2 W 3 o 12 ,Depend on figure ...

Embodiment 2

[0018] Rod-shaped Sc was successfully synthesized by hydrothermal method 2 W 3 o 12 Negative thermal expansion material, raw material: Sc(NO 3 ) 3 · wxya 2 O (analytically pure), H 40 N 10 o 41 W 12 · wxya 2 O (chemically pure), HNO 3 (analytical pure), first prepare scandium nitrate and ammonium tungstate into 1mol / L and 0.05mol / L solutions respectively, dissolve them in deionized water respectively, and use the double drop method to mix the two solutions of scandium nitrate and ammonium tungstate by Sc 3+ :W 6+ Mix at a molar ratio of 2:3, add nitric acid solution to the mixed solution to adjust pH=4 under constant stirring, and stir at 60°C for 4 hours; then transfer the mixed solution to a reaction kettle with a polytetrafluoroethylene liner, Seal and heat at 160°C for 15 hours. After the reaction is complete, use a centrifuge to dehydrate, discard the supernatant, wash and centrifuge repeatedly for 3 times, and then dry at 80°C to obtain the precursor; put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com