Scandium-strontium-containing active material for thermal cathode material

A technology of active material and hot cathode, which is applied in the field of environmental functional material preparation, can solve the problems of cathode emission current density and low hot cathode emission current density, and achieve the effects of safe production, high promotion and application value, and improvement of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

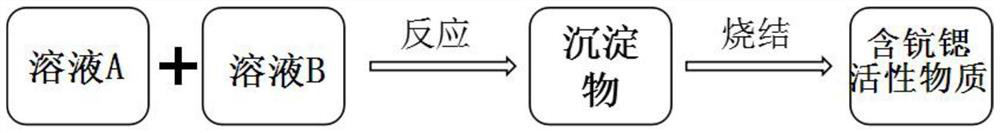

[0035] The preparation process of the scandium-strontium-containing active material used in the hot cathode material in this embodiment includes the following steps:

[0036] Step 1, dissolving ammonium carbonate powder in water and heating to 40°C to prepare 500mL solution A with a concentration of 1mol / L;

[0037] Step 2, dissolving scandium nitrate hexahydrate, strontium nitrate, aluminum nitrate nonahydrate, barium nitrate and calcium nitrate tetrahydrate powder in water and heating to 40°C to prepare 500mL solution B; the amount of scandium nitrate hexahydrate in the solution B The concentration is 0.01mol / L, the concentration of strontium nitrate is 0.01mol / L, the concentration of aluminum nitrate nonahydrate is 0.04mol / L, the concentration of barium nitrate is 0.06mol / L, and the concentration of calcium nitrate tetrahydrate is 0.01mol / L ;

[0038] Step 3: Add solution A obtained in step 1 to solution B at 40°C at 0.1 mL / s, keep stirring and react for 1 hour, then let i...

Embodiment 2

[0044] The preparation process of the scandium-strontium-containing active material used in the hot cathode material in this embodiment includes the following steps:

[0045] Step 1. Dissolve ammonium bicarbonate powder in water and heat to 60°C to prepare 500 mL of solution A with a concentration of 2 mol / L;

[0046] Step 2, dissolving scandium nitrate hexahydrate, strontium nitrate, aluminum nitrate nonahydrate, barium nitrate and calcium nitrate tetrahydrate powder in water and heating to 60°C to prepare solution B; the concentration of scandium nitrate hexahydrate in solution B is 0.02mol / L, the concentration of strontium nitrate is 0.02mol / L, the concentration of aluminum nitrate nonahydrate is 0.06mol / L, the concentration of barium nitrate is 0.08mol / L, and the concentration of calcium nitrate tetrahydrate is 0.02mol / L;

[0047] Step 3. Add solution A obtained in step 1 to solution B at 50°C at 0.5mL / s and keep stirring for 3 hours, then let it stand for precipitation to...

Embodiment 3

[0050] The preparation process of the scandium-strontium-containing active material used in the hot cathode material in this embodiment includes the following steps:

[0051] Step 1, mix ammonium carbonate and ammonium bicarbonate powder according to the molar ratio of 1:1, dissolve in water and heat to 50° C. to prepare 500 mL of solution A with a total solute concentration of 1.5 mol / L;

[0052] Step 2, dissolving scandium nitrate hexahydrate, strontium nitrate, aluminum nitrate nonahydrate, barium nitrate and calcium nitrate tetrahydrate powder in water and heating to 50°C to prepare 500mL solution B; the amount of scandium nitrate hexahydrate in the solution B The concentration is 0.015mol / L, the concentration of strontium nitrate is 0.015mol / L, the concentration of aluminum nitrate nonahydrate is 0.05mol / L, the concentration of barium nitrate is 0.07mol / L, and the concentration of calcium nitrate tetrahydrate is 0.015mol / L ;

[0053] Step 3. Add solution A obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com