Carbon nanomaterial functionalized needle tip modified by low work function material and preparation method of carbon nanomaterial functionalized needle tip

A carbon nanomaterial, low work function technology, which is applied in the field of carbon nanomaterial functionalized needle tips modified by low work function materials and its preparation, can solve the problem that the carbon nanocone functionalized needle tip has not been reported yet, and the functionalized needle tip has not been reported yet, etc. problem, to achieve the effect of improving the electron emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

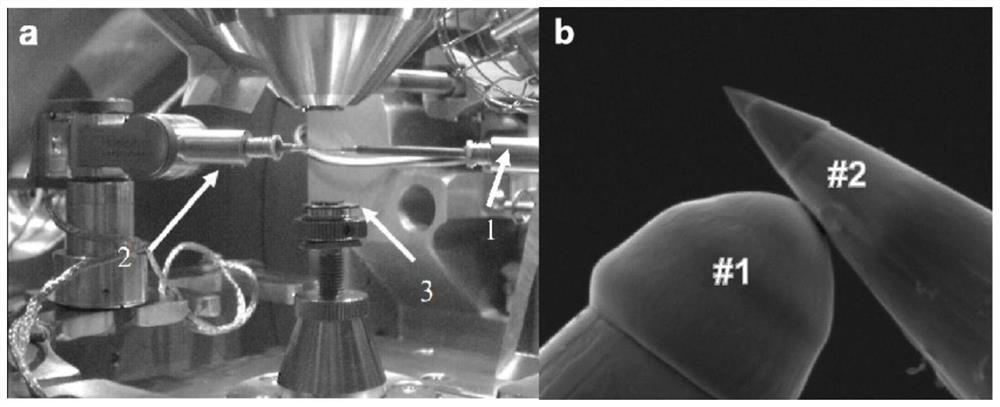

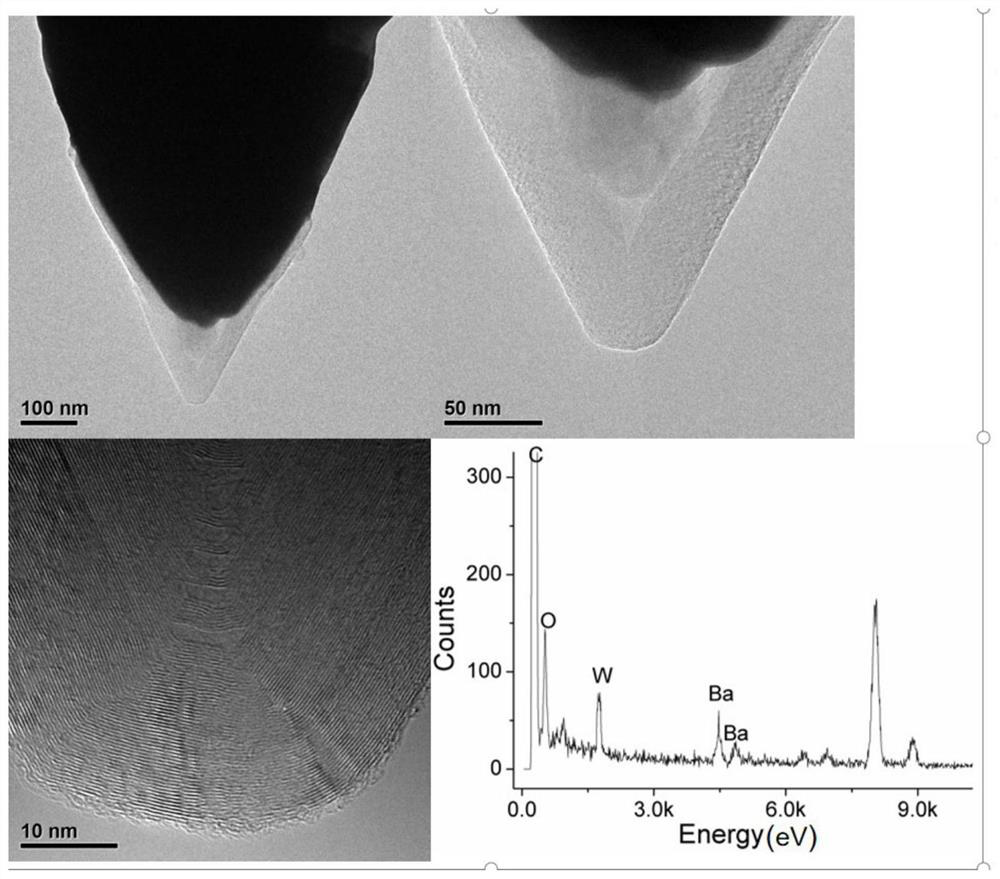

[0079] In this embodiment, the metal W needle tip is plated with a 5 nm thick Ba film (Ba target purity: 99.99%) on the surface by electron beam evaporation coating method, number #2. The carbon nanocone material is ultrasonically dispersed in o-dichlorobenzene solvent, and the obtained dispersion is deposited on the silicon wafer substrate by using a film flinger, and then the silicon wafer substrate is installed on the sample stage 3 of the scanning electron microscope, and the tungsten tip #1 and #2 are respectively installed in figure 1 On the needle tube at the front end of the No. 1 and No. 2 micro-manipulator arms, the tungsten needle tip can be moved in three-dimensional space in the scanning electron microscope sample chamber by controlling the micro-manipulator arm.

[0080] Move tungsten tip #1 so that the tip lightly touches 50 μm from the tip of tungsten probe #2 to form a path. By applying a bias voltage of 50 V, the tip of #1 tungsten probe is immediately melted...

Embodiment 2

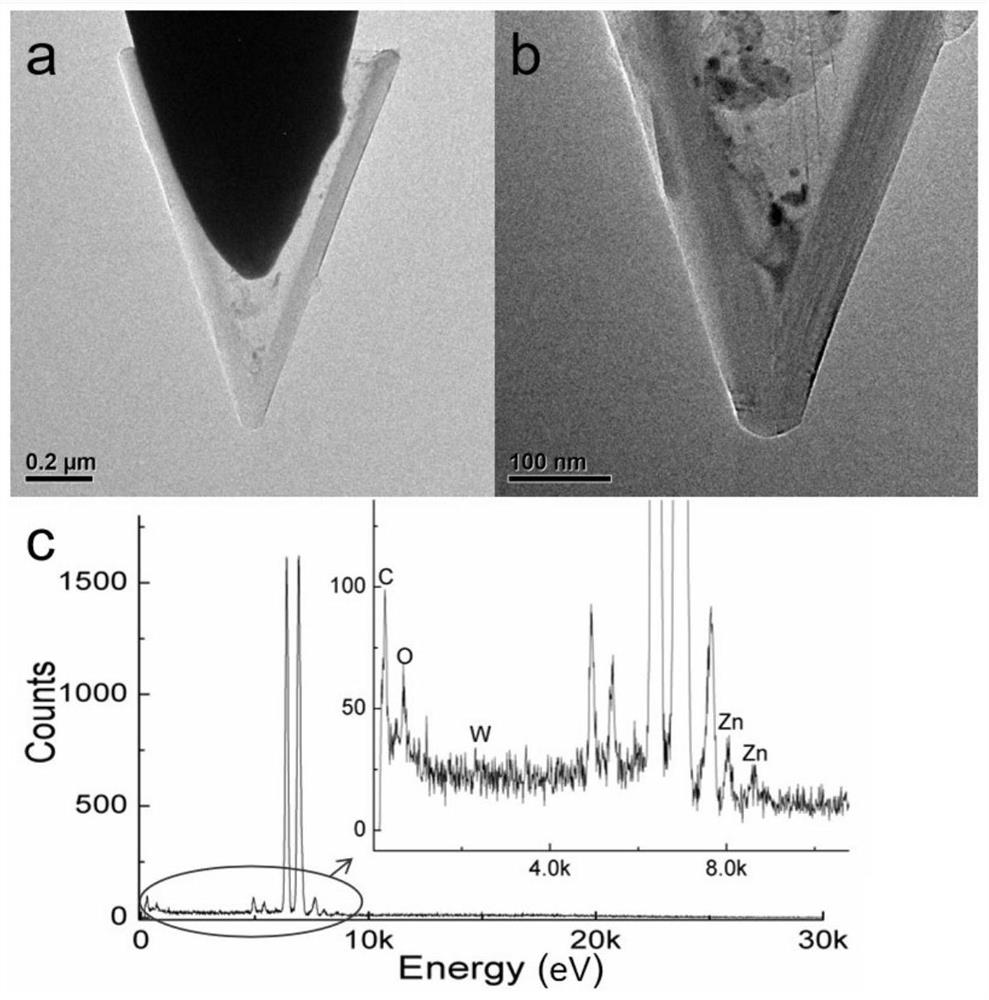

[0083] In this embodiment, the metal W needle tip is coated with a 5nm thick ZnO film (purity of the ZnO target by magnetron sputtering: 99.99%) on the surface by magnetron sputtering coating method, number #2. The carbon nanocone material is ultrasonically dispersed in o-dichlorobenzene solvent, and the obtained dispersion is deposited on the silicon wafer substrate by using a film flinger, and then the silicon wafer substrate is installed on the sample stage 3 of the scanning electron microscope, and the tungsten tip #1 and #2 are respectively installed in figure 1 On the needle tube at the front end of the No. 1 and No. 2 micro-manipulator arms, the tungsten needle tip can be moved in three-dimensional space in the scanning electron microscope sample chamber by controlling the micro-manipulator arm.

[0084] Move tungsten tip #1 so that the tip lightly touches 50 μm from the tip of tungsten probe #2 to form a path. By applying a bias voltage of 50 V, the tip of #1 tungsten ...

Embodiment 3

[0087] In this embodiment, the metal W needle tip is coated with a 5nm thick LaB6 film (LaB6 target purity: 99.99%) on the surface by electron beam evaporation coating method, number #2. The carbon nanocone material is ultrasonically dispersed in o-dichlorobenzene solvent, and the obtained dispersion is deposited on the silicon wafer substrate by using a film flinger, and then the silicon wafer substrate is installed on the sample stage 3 of the scanning electron microscope, and the tungsten tip #1 and #2 are respectively installed in figure 1 On the needle tube at the front end of the No. 1 and No. 2 micro-manipulator arms, the tungsten needle tip can be moved in three-dimensional space in the scanning electron microscope sample chamber by controlling the micro-manipulator arm.

[0088] Move tungsten tip #1 so that the tip lightly touches 50 μm from the tip of tungsten probe #2 to form a path. By applying a bias voltage of 50 V, the tip of #1 tungsten probe is immediately mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com