Electron-accepting structures that can reduce surface oxidation of Aln cold cathodes

A surface oxidation and receiving structure technology, applied in the direction of circuits, electrical components, discharge tube main electrodes, etc., can solve the problems of affecting electron emission performance and aggravating the surface oxidation of AlN cold cathode materials, so as to improve electron emission performance and reduce hindrance , The effect of speeding up the development process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

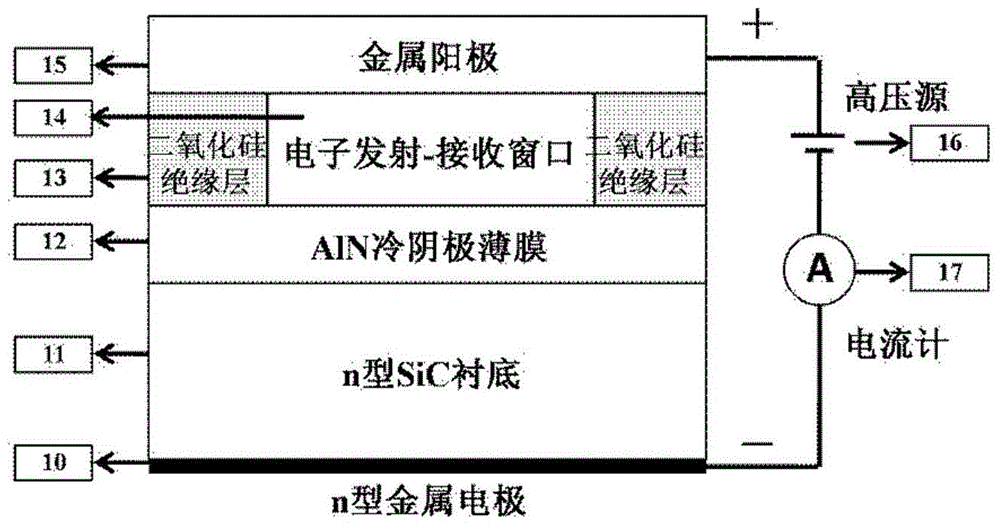

[0021] refer to figure 1 As shown, the present invention provides a kind of electron accepting structure that can reduce AlN cold cathode surface oxidation, comprises:

[0022] An n-type SiC substrate 11, the resistivity of the n-type SiC substrate 11 is 0.02-0.2Ω·cm, and the thickness is 200-500μm;

[0023] An n-type metal electrode 10, which is made on the lower surface of the n-type SiC substrate 11, the material of the n-type metal electrode 10 is Ni or Ni / Au, and the thickness of the Ni layer in the Ni or Ni / Au is 50- 200nm, the thickness of Au layer is 50-200nm; Ni or Ni / Au film is annealed to form ohmic contact, the annealing atmosphere is nitrogen or argon, the annealing temperature is 950°C, and the annealing time is 1-5min;

[0024] An AlN cold cathode 12, which is epitaxially grown on an n-type SiC substrate 11, the thickness of the AlN cold cathode 12 is 10-500nm, and the Si doping concentration is 1×1018-1×1020cm-3;

[0025] A metal anode 15, the metal anode 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com