Preparation method and application of superfine tungsten-rhenium composite powder containing scandium and strontium

A composite powder and mixed powder technology, which is applied in the field of preparation of ultrafine tungsten-rhenium composite powder containing scandium and strontium, can solve the problems of uniform distribution affecting the cathode electron emission performance, low product qualification rate, and low impregnation efficiency, so as to improve The effect of electron emission performance, low equipment requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

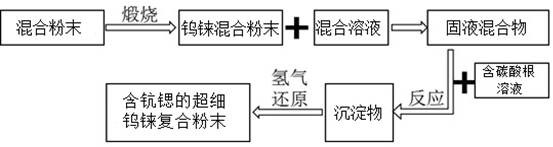

[0044] Such as figure 1 As shown, this embodiment includes the following steps:

[0045]Step 1: Ball mill 88.5g of tungsten oxide powder, 4.3g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain Tungsten-rhenium mixed powder;

[0046] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.02mol / L, the concentration of strontium nitrate is 0.02mol / L, the concentration of aluminum nitrate nonahydrate is 0.08mol / L, the concentration of barium nitrate is 0.12 mol / L, the concentration of calcium nitrate tetrahydrate is 0.02mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0047] Step 3, preparation 1000mL concentration is the solution that contains carbonate group of 2mol / L, then joins the solution that contains car...

Embodiment 2

[0054] Such as figure 1 As shown, this embodiment includes the following steps:

[0055] Step 1. Ball mill 61.3g of tungsten oxide powder, 20g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain tungsten Rhenium mixed powder;

[0056] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.03mol / L, the concentration of strontium nitrate is 0.03mol / L, the concentration of aluminum nitrate nonahydrate is 0.1mol / L, the concentration of barium nitrate is 0.14 mol / L, the concentration of calcium nitrate tetrahydrate is 0.03mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0057] Step 3, preparation of 1000mL concentration of 3mol / L solution containing carbonate, then the solution containing carbonate is added to the ...

Embodiment 3

[0060] Such as figure 1 As shown, this embodiment includes the following steps:

[0061] Step 1. Ball mill 55.34g of tungsten oxide powder, 37.46g of ammonium perrhenate powder and 7.2g of carbon black to obtain a mixed powder, and then heat it to 1000°C at a heating rate of 5°C / min for 4 hours under an argon atmosphere to obtain Tungsten-rhenium mixed powder;

[0062] Step 2, prepare the mixed solution of 1000mL, wherein the concentration of scandium nitrate hexahydrate is 0.04mol / L, the concentration of strontium nitrate is 0.04mol / L, the concentration of aluminum nitrate nonahydrate is 0.12mol / L, the concentration of barium nitrate is 0.16 mol / L, the concentration of calcium nitrate tetrahydrate is 0.04mol / L, then the tungsten-rhenium mixed powder obtained in step 1 is added in the mixed solution to obtain a solid-liquid mixture;

[0063] Step 3, preparing 1000mL concentration of 4mol / L solution containing carbonate, then adding the solution containing carbonate to the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com