A Novel Thermionic-Thermoacoustic Combined Thermoelectric Conversion System

A technology of thermoelectric conversion and thermoion, applied in electrical components, generators/motors, machines/engines, etc., can solve the problems of only 17% thermoelectric conversion efficiency, waste of heat energy, low energy utilization rate, etc., and achieve good one-way transmission Effects of thermal properties, realization of heat loss and heat transfer, and improvement of thermoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

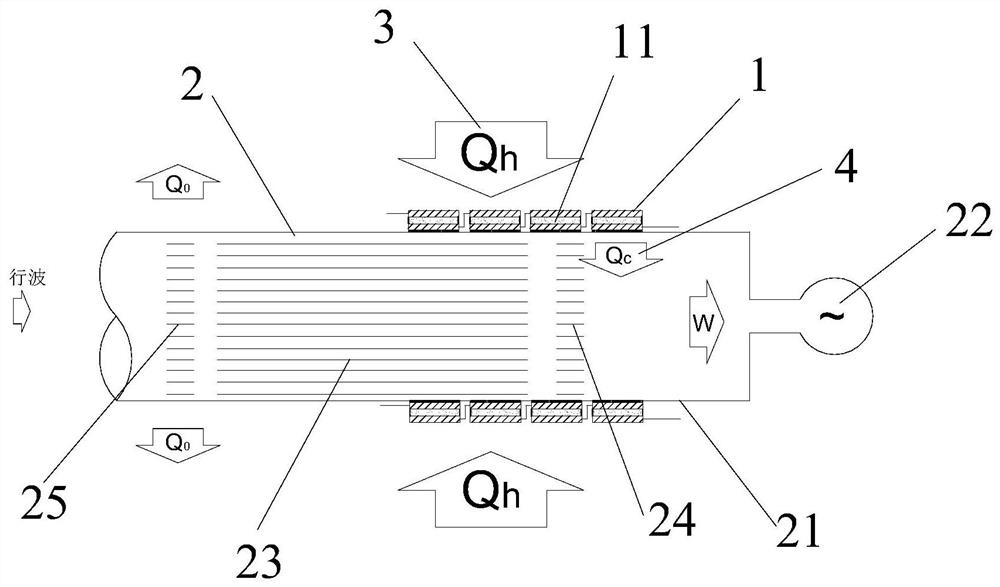

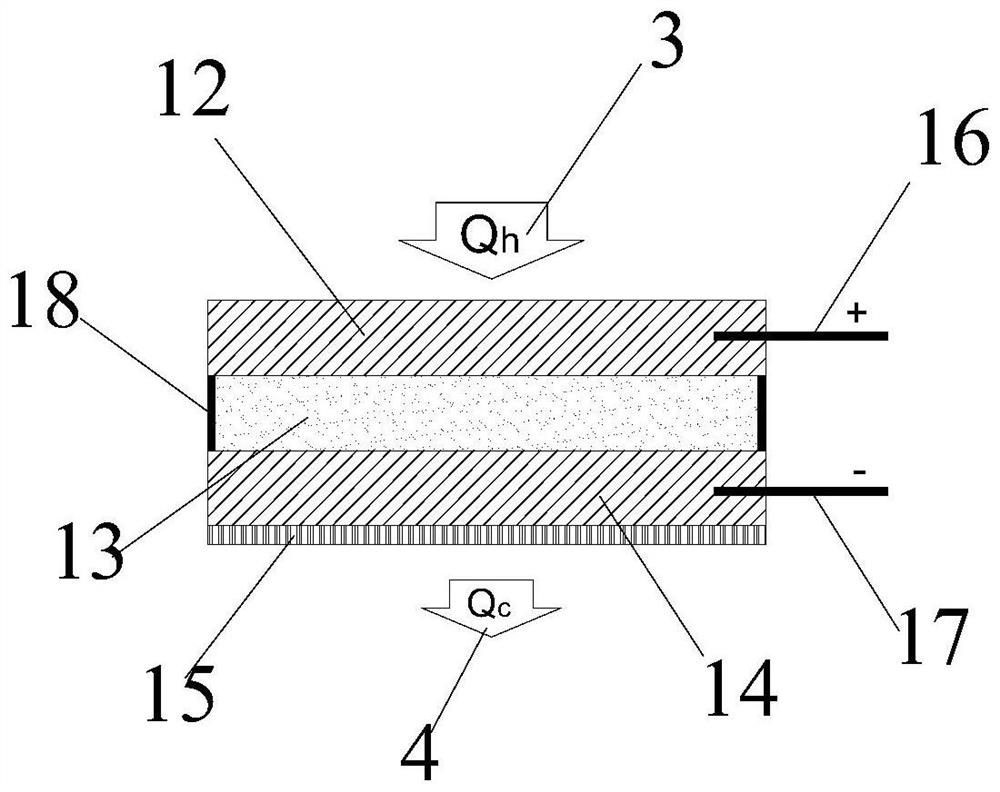

[0032] Such as Figure 1-5 As shown, a new type of hot ion-thermo-sound combination thermoelectric conversion system including a hot ion power generation module 1 and a thermoelectric power generation module 2; wherein one end of the hot ion power generation module 1 receives a high temperature heat source 3 and converted into a current. The other end is released by the carbon nanotube heat transfer layer 15; the thermal sound generating module 2 receives the remaining heat 4 released by the carbon nanotube heat exchange layer 15 and converted to electrical energy.

[0033] See figure 1 with figure 2 The hot ion power generation module 1 includes one or more hot ion converters 11, each of which is divided into an emitter 12, an electrode gap 13, a receiving pole 14 and a carbon nanotube in the transfer direction of the high temperature heat source 3, respectively. The heat exchange layer 15. Among them, the high temperature heat source 3 is a heat source having a temperature of 1...

Embodiment 2

[0043] This example is used to illustrate the final thermoelectric conversion efficiency of the new type 1 described above in Example 1.

[0044] In the solar power system, the light energy is converted to thermal energy, and the heat ion converter 11 emits 12 to 2000K. The related operation parameters of the high-efficiency combined thermoelectric conversion system are: emitter 12 temperature TE = 2000K, the receiving pole 14 temperature Tc = 1000K; the surface work function of the emitter 12 is φe = 2.8eV, the receiving pole 14 surface work function φC = 2.2ev; The actual heat transfer efficiency of the carbon nanotube heat exchange layer 15 is about 85%.

[0045] According to the Richardson-Dusman launch equation, the output current calculation formula of the hot ion power generation module 1 is as follows:

[0046] J = AT 2 Exp (-φ / kt) (1)

[0047] Among them, A is Richardson constant (1.202 × 10 6 A / M 2 K 2 ), K is Bolzman constant (1.38 × 10 -23 J / K -1 ), T is the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com