Rapid preparation method of Ho:Sc2O3 nano-crystal powder

A nanocrystal and sc2o3 technology, applied in the direction of nanotechnology, chemical instruments and methods, rare earth metal compounds, etc., can solve the problems of product quality decline, low synthesis efficiency, etc., and achieve the effect of ensuring quality, improving efficiency, and increasing reaction titration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

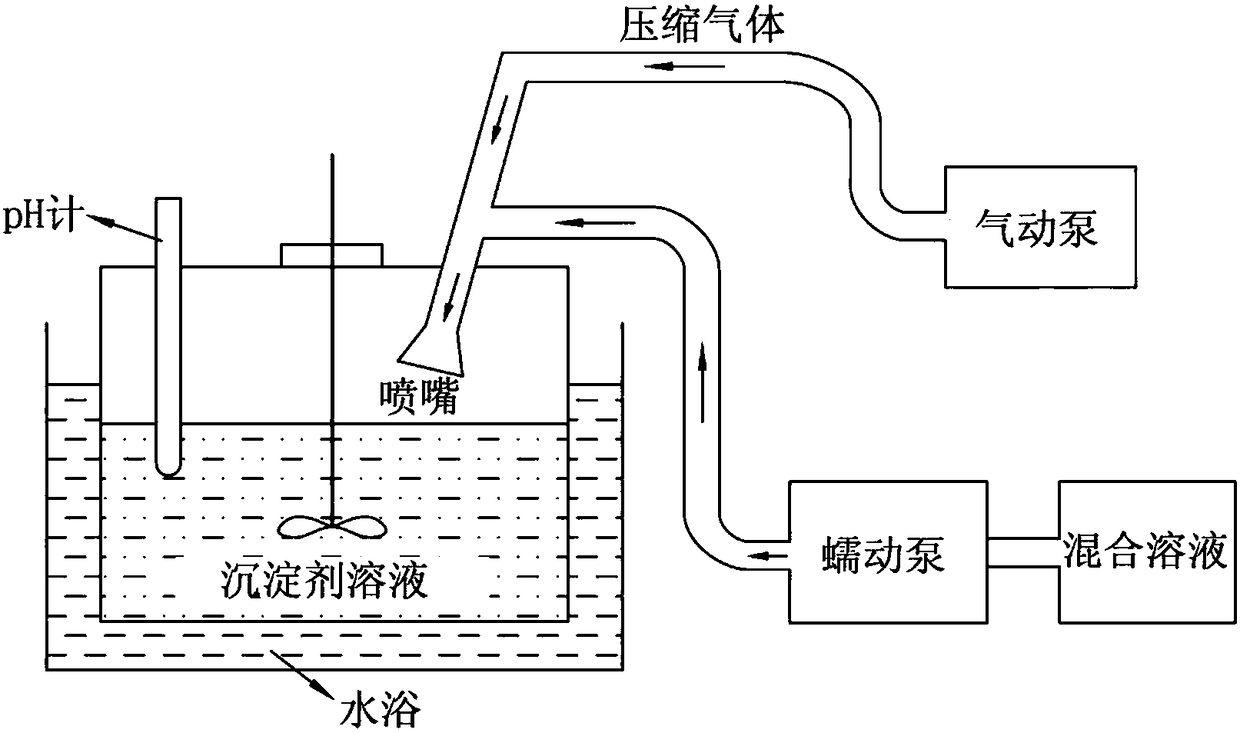

[0039] The embodiment of the invention discloses a Ho:Sc 2 o 3 The rapid preparation method of nanocrystalline powder comprises the following steps:

[0040] Step 1, preparation of cationic salt solution

[0041] Using micron-sized scandium oxide and micron-sized holmium oxide powder as raw materials, add dilute nitric acid to scandium oxide and holmium oxide raw materials respectively until the excess is reached, heat and stir until the raw material powder is completely dissolved, continue heating to make the excess nitric acid volatilize completely, and then add Dilute with deionized water to obtain scandium nitrate solution and holmium nitrate solution, and calibrate Sc in scandium nitrate solution 3+ Concentration and Ho in holmium nitrate solution 3+ Concentration, take scandium nitrate solution and holmium nitrate solution according to the required doping concentration, mix evenly to obtain cation salt solution, dilute the cation salt solution, and keep the total conc...

Embodiment 1

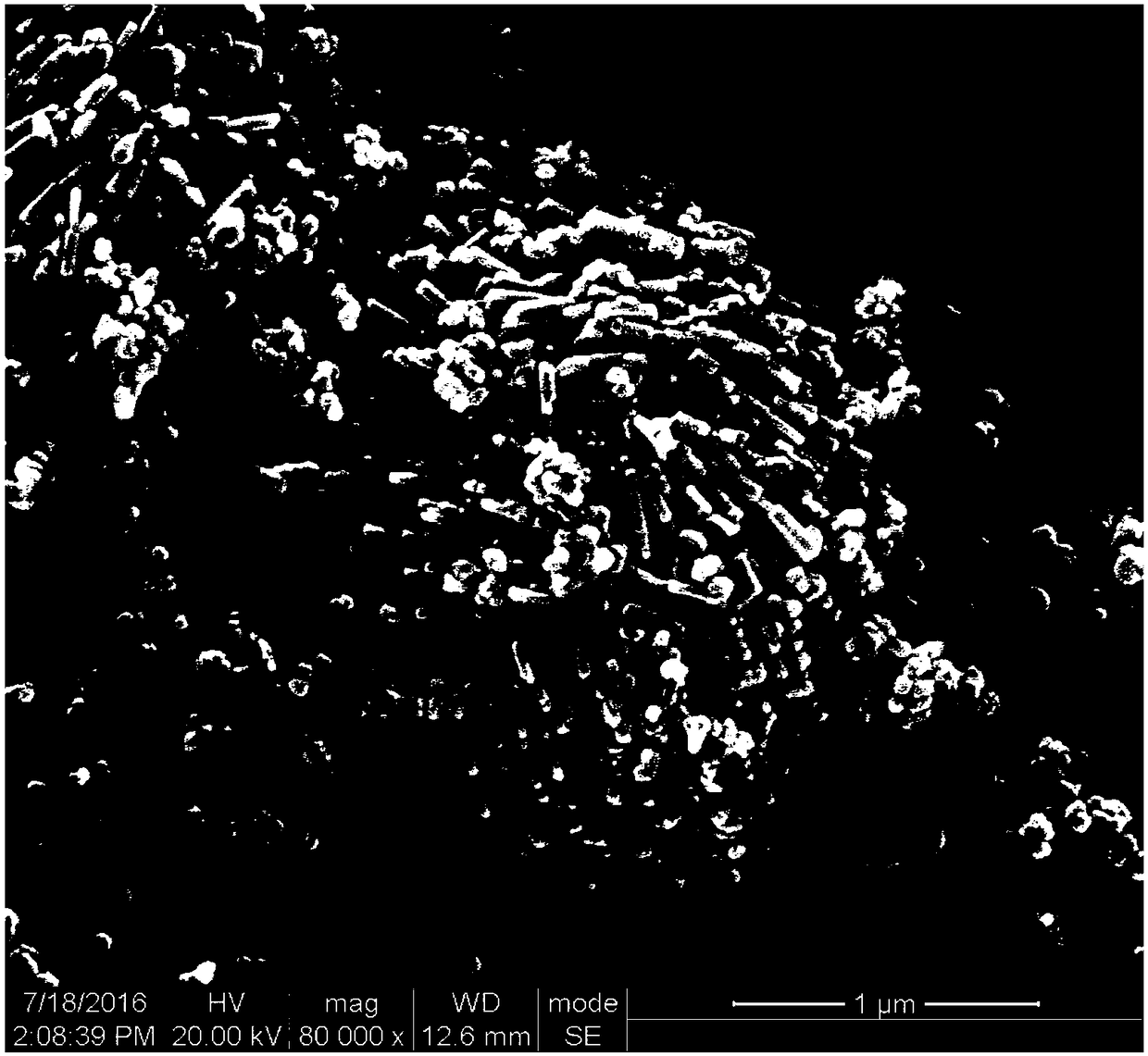

[0061] According to the method of the above-mentioned invention embodiment, the cation concentration of the salt solution is controlled to 0.4mol / liter, and the spray speed is 80ml / min. After the obtained precursor is calcined at 1200°C for two hours, the morphology characteristics of the electron microscope are as shown in the attached figure 2 shown. It can be seen from the SEM morphology that the prepared powder has a large amount of abnormal rod-shaped powder and serious agglomeration.

Embodiment 2

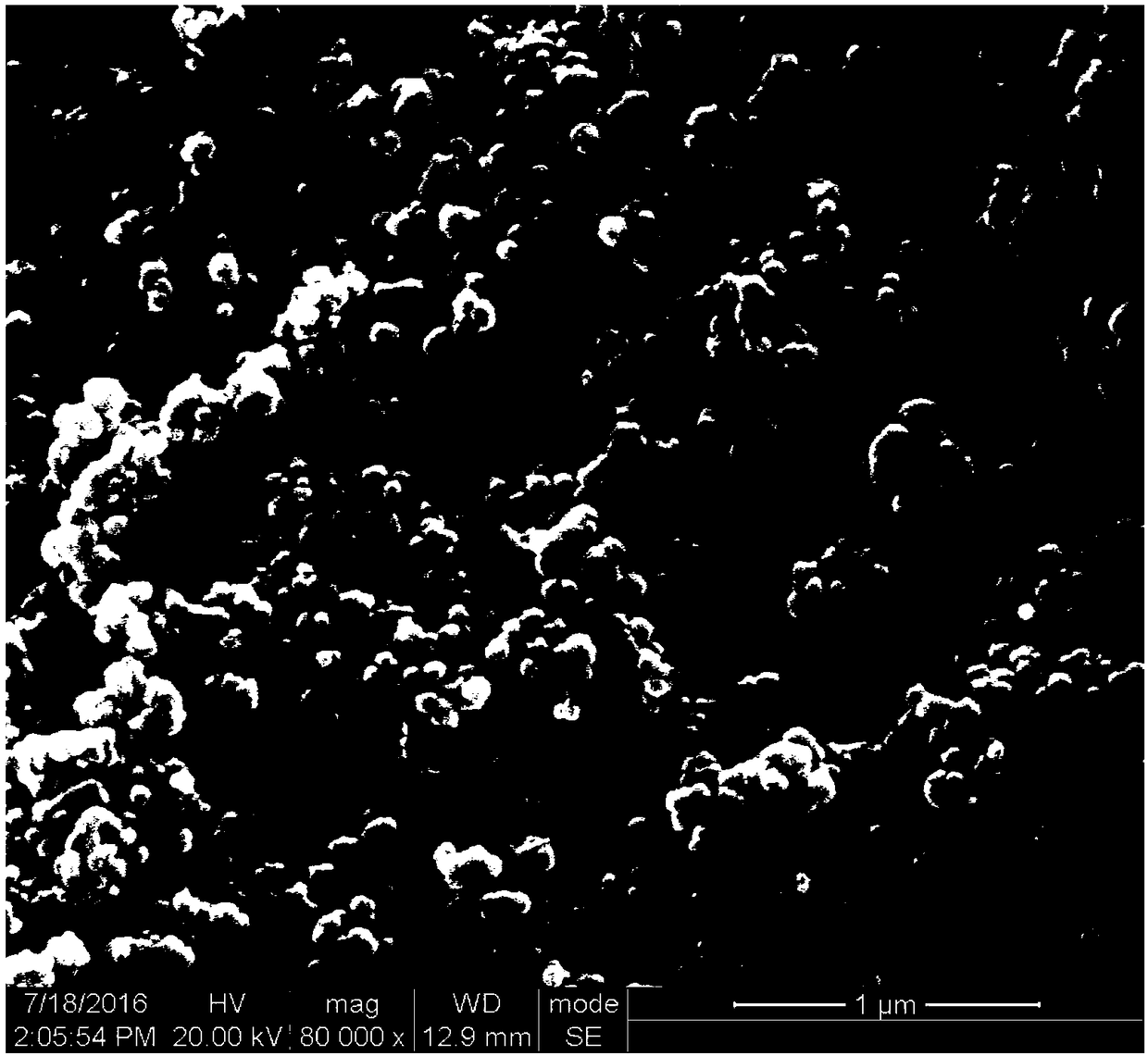

[0063] According to the method of the above-mentioned invention embodiment, the cation concentration of the salt solution is controlled to 0.4 mol / liter, and the spray speed is 20ml / min. After the obtained precursor is calcined at 1200° C. for two hours, the morphology characteristics of the electron microscope are as follows: image 3 As shown, from the SEM morphology characteristics, the obtained nano-powder grains are evenly distributed and well dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com