Method for preparing nano-hydroxyapatite with assistance of segmented pulse ultrasound

A technology of nano-hydroxyapatite and hydroxyapatite, which is applied in the direction of nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of high preparation cost and toxicity of organic solvents, and achieve excellent adsorption performance and large adsorption capacity , the effect of rich pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Existing ultrasonic-assisted method for preparing nano-hydroxyapatite

[0043] A. Dissolve 2.736g of dipotassium hydrogen phosphate and 0.7286g of D-sorbitol in 100ml of SBF solution to form a 0.12mol / L phosphorus source solution; dissolve 2.22g of anhydrous calcium chloride in 100ml of SBF solution Form a 0.20mol / L calcium source solution, then pour the calcium source solution directly into the phosphorus source solution and stir the suspension for 1h. After the suspension was placed in a 40 kHz, 50 W ultrasonic wave for 10-60 min, it was washed twice with water and ethanol to remove excess ions. Finally, the product was heated and dried in an oven to obtain powdered HAP.

[0044] The reaction time of the method exceeds 1 hour, and the prepared nano-hydroxyapatite has a length of 200 nm and a diameter of about 30 nm.

[0045] B. Take 0.5mol / L CaCl respectively 2 solution, 0.5mol / L NH 4 h 2 PO 4 After mixing 30 mL and 50 mL of the solution, adjust the pH...

Embodiment 2

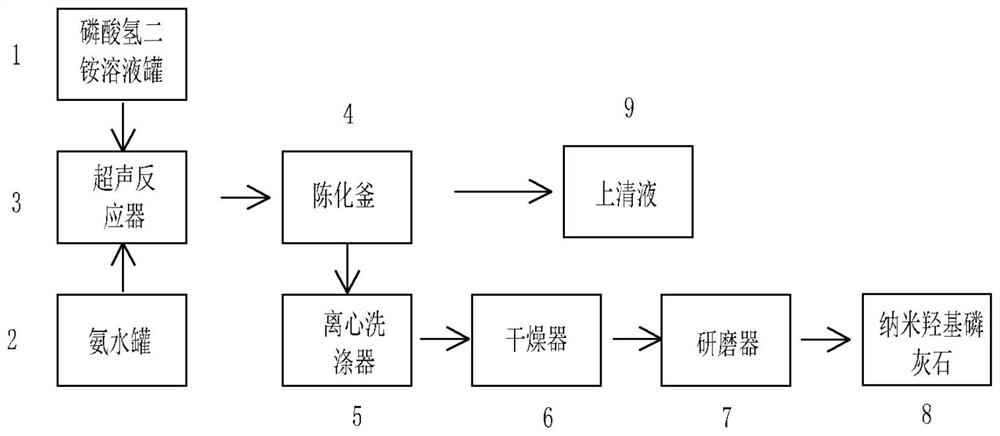

[0050] Example 2 The method for preparing nano-hydroxyapatite assisted by segmental pulse ultrasound under different pulse ultrasound working conditions according to the present invention

[0051] In order to study the modification effect of different pulsed ultrasonic conditions, a total of 10 kinds of material preparation experiments were designed, and the specific pulsed ultrasonic conditions are shown in the table.

[0052]

[0053] * The t1 segment refers to the drug mixing and stirring segment, and the t2 segment refers to the drug reaction segment. The number represents the duration of the ultrasonic wave, and 36s / 18s represents the duration of an ultrasonic pulse.

[0054] Working condition No. 6 (t1-1s / 35s; t2-16s / 2s)

[0055] (1) (preheating cycle) Take calcium nitrate tetrahydrate solid and add ultrapure water to prepare a solution with a concentration of 0.025mol / L, then take 250ml and pour it into an ultrasonic reactor, turn on the magnetic stirring, insert a t...

Embodiment 3

[0068] Example 3 Results Analysis of Segmented Pulse Ultrasound Assisted Preparation of Nano-Hydroxyapatite under Different Pulse Conditions

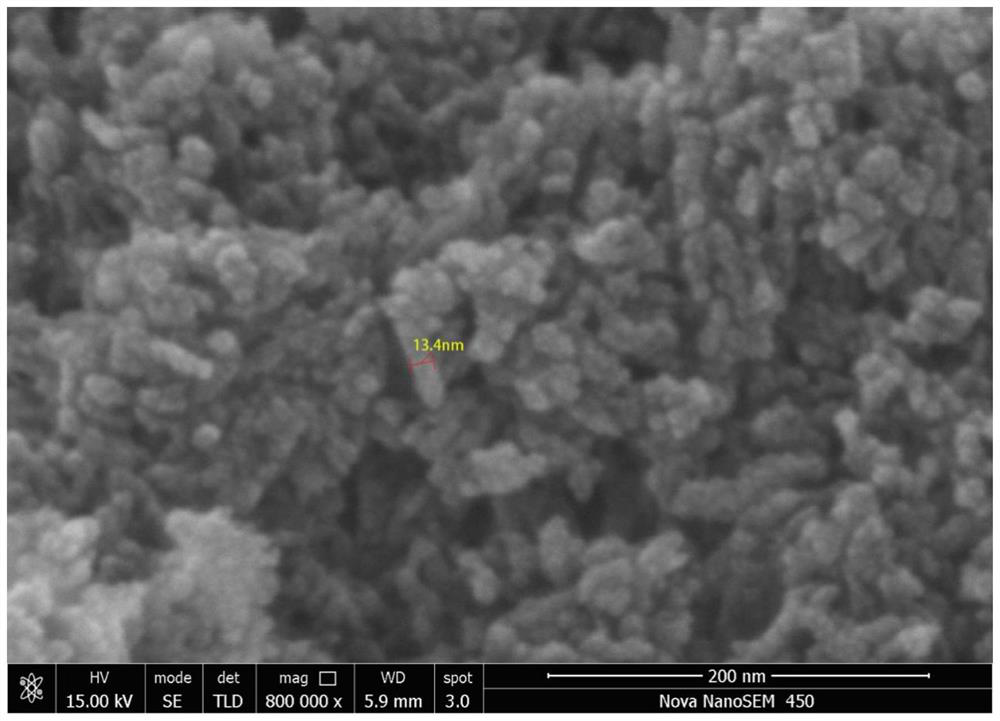

[0069] Nano hydroxyapatite SEM figure prepared by this method (see figure 2 ) shows that the prepared nano-hydroxyapatite nanoparticles are rod-shaped and spherical, with a width of 9nm and a length of 40nm. 2 / g.

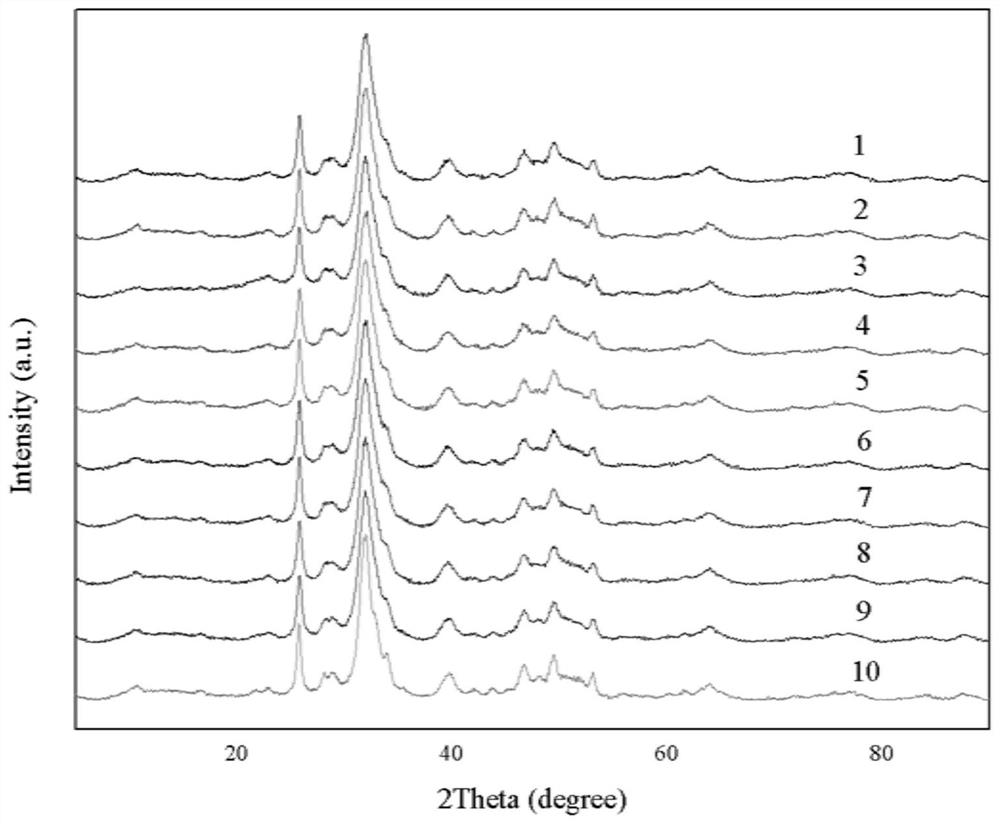

[0070] XRD test (see image 3 ) shows that the phase of the material is mainly Ca 10 (PO 4 ) 6 Oh 2 , while FTIR (see Figure 4 ) shows that the material has PO 4 2- group and OH - . Comparing the XRD and FTIR patterns of 10 materials, it can be found that the crystalline phase of the materials is roughly similar, and does not change with the length of the pulse ultrasound, indicating that ultrasound will not change the material changes during the material preparation process. But at 1100cm -1 Appearing on the left and right represents PO 4 2- The absorption vibration peaks of No. 4 and No. 8 are slightly large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com