A kind of polishing method of 1 inch germanium processing sheet

A technology for processing wafers and polishing liquids. It is applied to metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc. It can solve the problems of high speed of large disks and ceramic disks, poor surface flatness, and high consumption of liquid medicine. , to reduce the cost of polishing liquid, reduce liquid consumption, and improve polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Processing customer 1 inch order, 1008 pieces 1 inch germanium:

[0030] Preparation of the polishing fluid is: After mixing the silica polishing fluid, sodium bicarbonate and pure water, the sodium chlorite to the polishing liquid is 5.9 g / L, and finally the pH of sodium hydroxide to the polishing fluid is 10.1. Where each 1 ml of silica polishing is required to 0.75 g sodium carbonate and 50 ml of water.

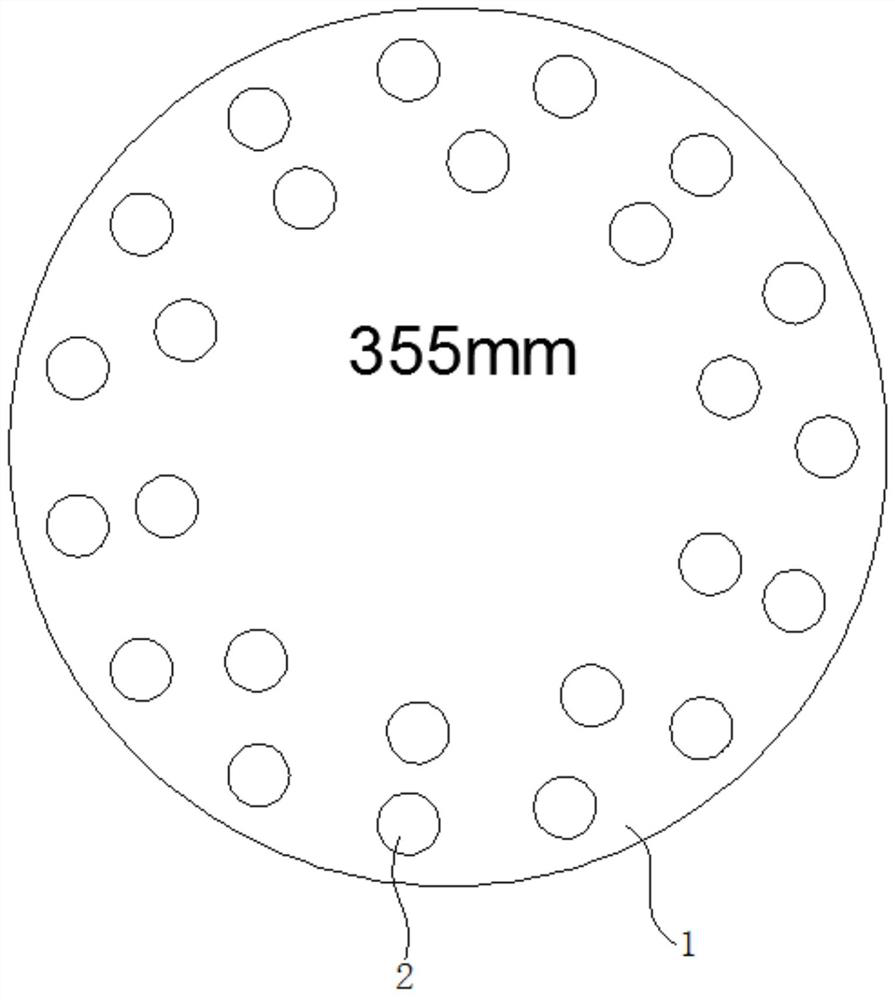

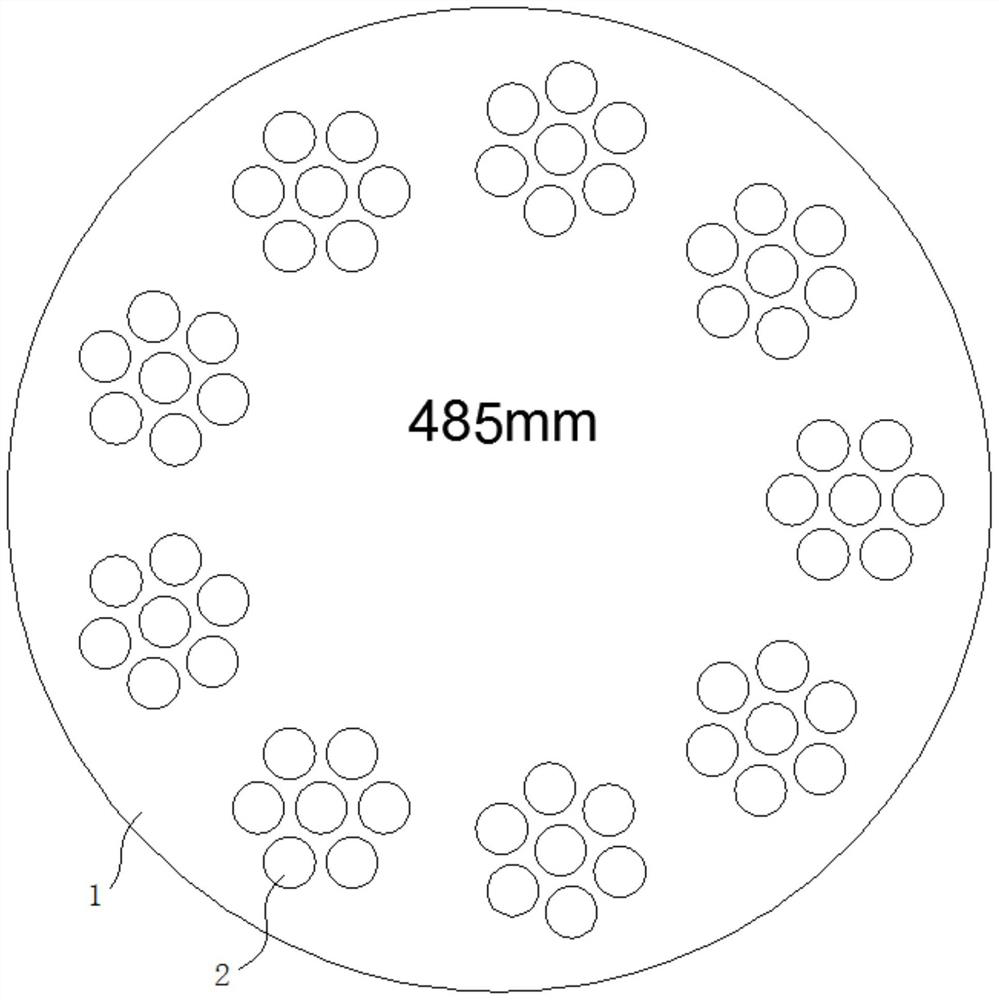

[0031] The equipment used is created 50B, the large disk diameter is 1300mm, the ceramic disk diameter is 485mm; the arrangement of 1 inch germanium processing on the ceramic dish is like figure 2 As shown, a ceramic disc is arranged in a 63-inch germanium processing sheet along the periphery, and the lower surface of each ceramic plate is posted with a 1 inch germanium processing sheet. There are 7 1 inch germanium processing tablets per group. 1 inch germanium per group. The arrangement is arranged in the middle, and the remaining six in the middle of the 6-inch ger...

Embodiment 2

[0042] Processing customer 1 inch order, 1008 pieces 1 inch germanium:

[0043] As in Example 1, the difference is: when the preparation of the polishing fluid, the sodium chlorite to the polishing liquid is 5.95 g / L, and finally the pH of sodium hydroxide to the polishing fluid is 10.15; after all processing is completed According to statistics, the finished product rate is 96.9%, the drop rate is about 1.2 um / s, and 10 pieces of surface is 5 o'clock in 1-2 um, and the polishing liquid is consumed 260L, and 0.258L / piece is equipped with 0.258L / piece, and there is no running piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com