Patents

Literature

35results about How to "Welding quality is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

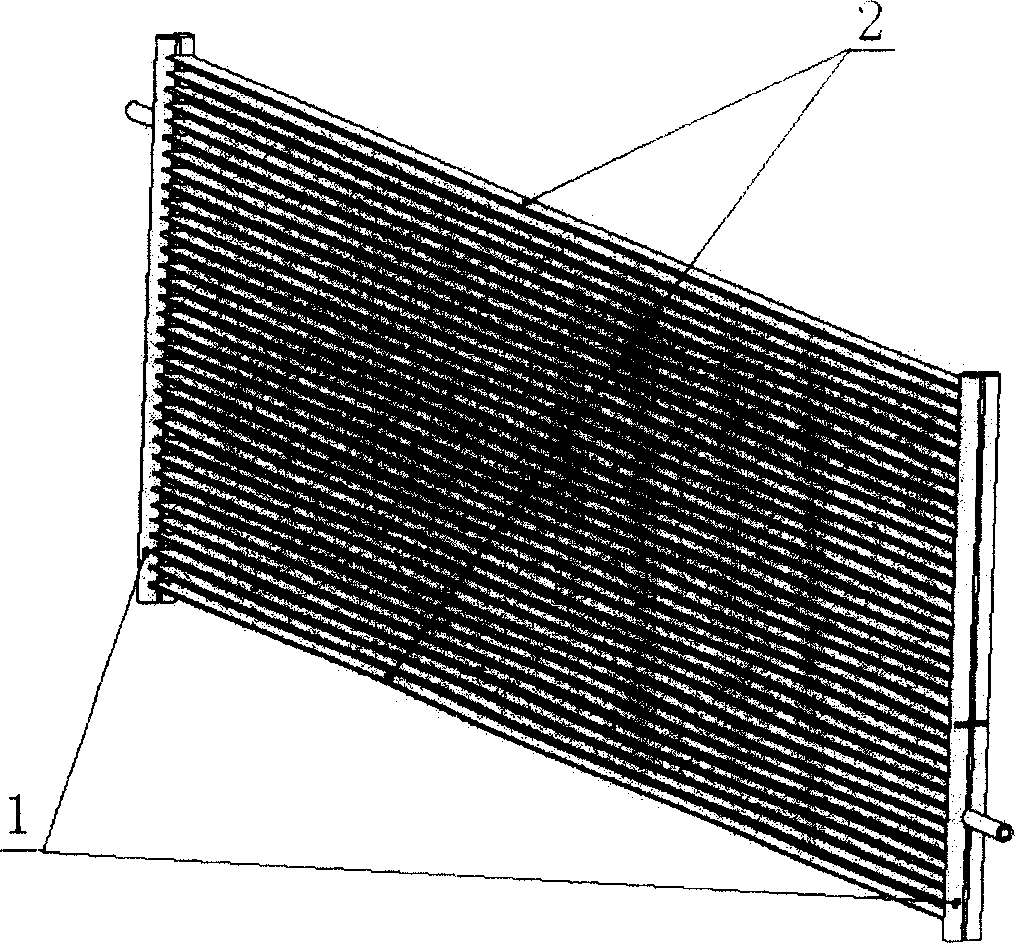

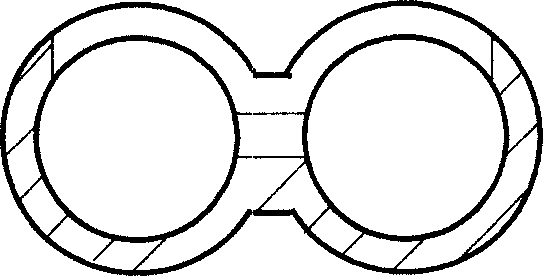

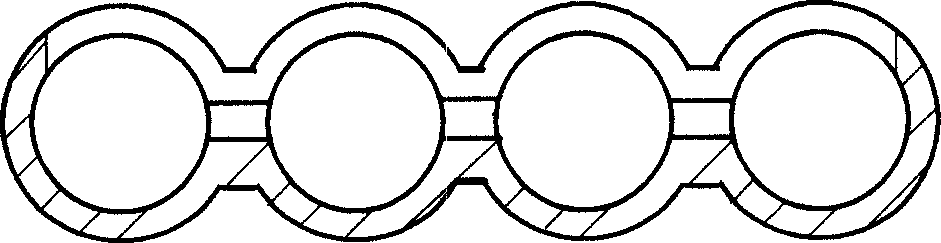

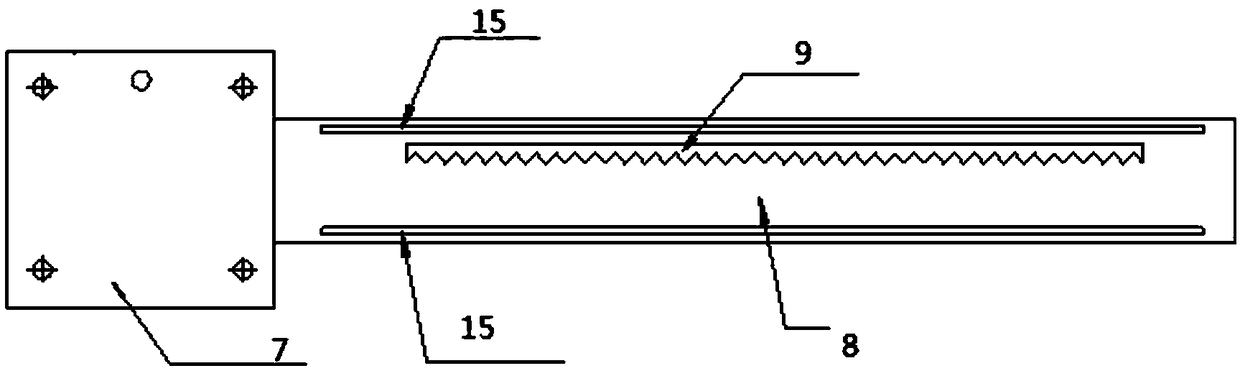

Micro-path parallel current heat-exchanger for transcritical Co2 circulation and mfg. method

ActiveCN1710367ATo counteract the effects of weakening strengthEasy to postStationary conduit assembliesGas coolerEngineering

A method for preparing microchannel and parallel flow exchanger for transcritical CO2 circulation includes extrusion - moulding collector tube in multi-tube structure and heat exchanging flat tube separately to let one side of multi-tube collector tube be planar structure, making parallel slots for heat exchanging flat tubes on planar side of multi-tube collector tube, using weld flux to cover the part of the flat tube to be welded and applying vacuum one - body brass soldering for finishing .

Owner:TSINGHUA UNIV +1

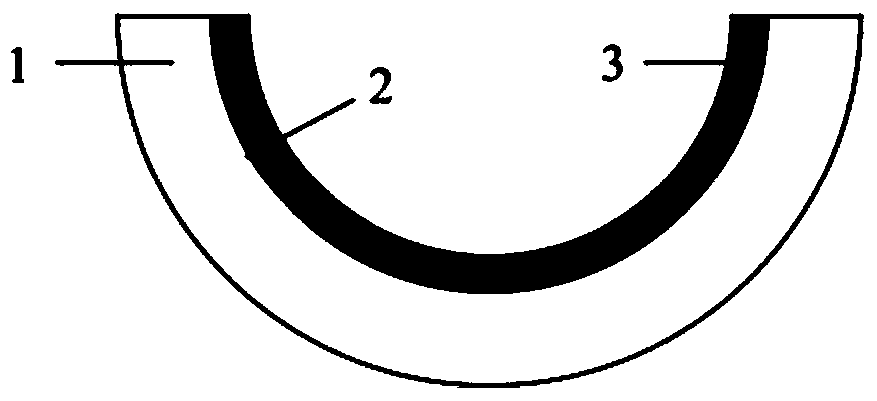

Method for manufacturing copper base alloy bearing bush wear-resisting layer

The invention discloses a method for manufacturing a copper base alloy bearing bush wear-resisting layer and relates to a bead weld method. The method for manufacturing the copper base alloy bearing bush wear-resisting layer aims at solving the problems that an existing bearing bush coating is low in combining strength, poor in coating performance and short in service life. The method includes the first step of polishing, the second step of cleaning, the third step of tin coating, the fourth step of bead weld of babbit metal on the surface of a bearing bush by a CMT welding machine and the fifth step of turning or scraping. The method is used for improving the combining strength of the wear-resisting coating and a copper base bearing bush base body, optimizing a coating organization, prolonging service life, improving the machining precision of the bearing bush and manufacturing the copper base alloy bearing bush wear-resisting layer.

Owner:严格集团股份有限公司

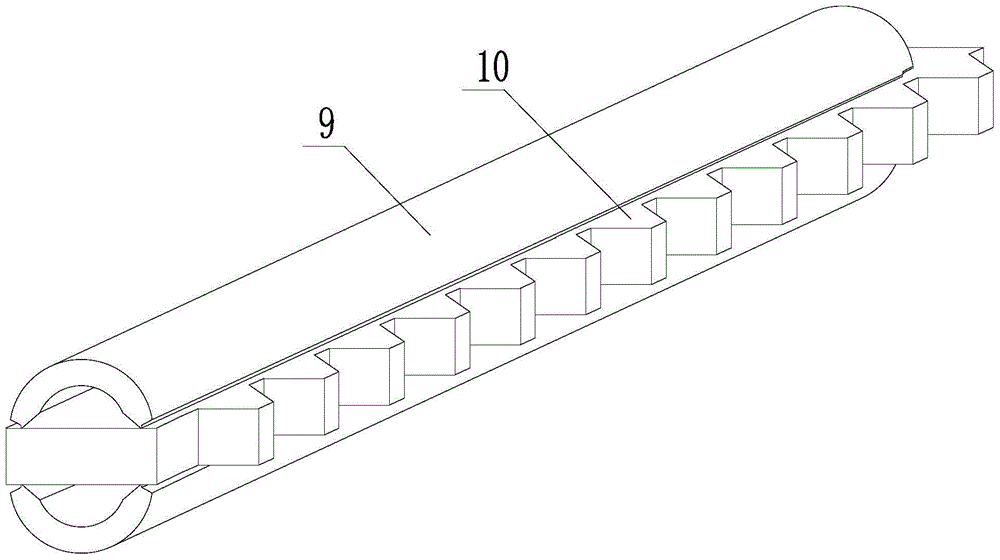

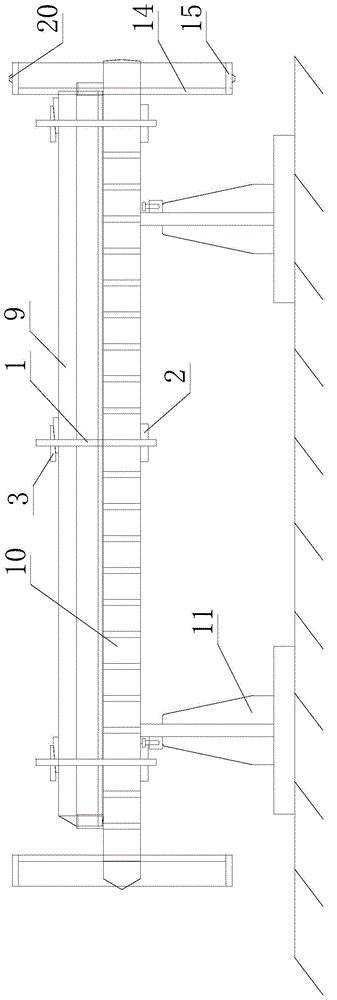

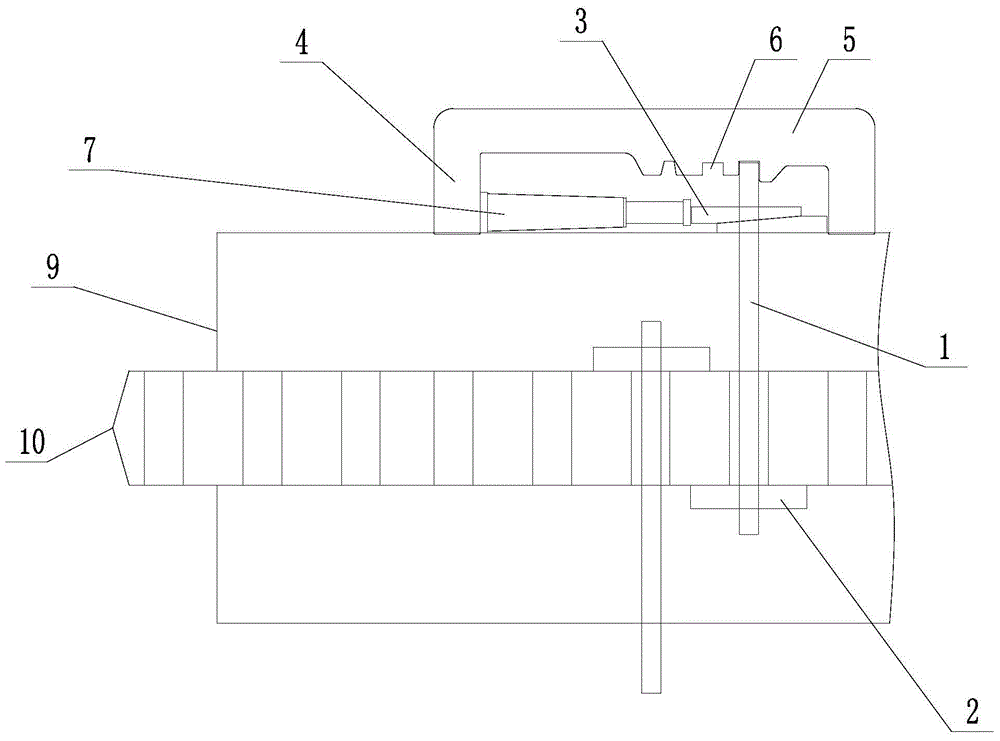

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

Outside-furnace welding device and method for auxiliary electrodes of vacuum arc furnace

ActiveCN106312265ACentering accuracy is easy to controlGuaranteed coaxiality accuracyWelding/cutting auxillary devicesAuxillary welding devicesElectric arc furnaceAuxiliary electrode

The invention provides an outside-furnace welding device and method for auxiliary electrodes of a vacuum arc furnace. The outside-furnace welding device and method are used for welding between the auxiliary electrodes of the vacuum arc furnace and consumable electrodes. A consumable electrode positioning device comprises a first center frame regulation device, a second center frame regulation device and a third center frame regulation device, wherein the first center frame regulation device, the second center frame regulation device and the third center frame regulation device are arranged in a manner of spacing a certain interval and are of the same structure. An auxiliary electrode positioning device comprises a fixed shear type regulation device, a movable shear type regulation device, a guide rail, a sighting device positioning mechanism and a scale mechanism. An electrode lifting and rotating drive device comprises a first lifting type rotation device, a second lifting type rotation device and a third lifting type rotation device. The second lifting type rotation device actively rotates (is provided with a drive mechanism), and the first lifting type rotation device and the third lifting type rotation device passively rotate (are not provided with drive mechanisms except a drive roller). By means of the outside-furnace welding device and method, the cylindrical auxiliary electrodes of different specifications and cylindrical consumable electrodes of different specifications can be welded outside the vacuum arc furnace according to a certain coaxiality requirement so that the original manner for conducting welding inside the vacuum arc furnace can be replaced.

Owner:宝武特种冶金有限公司

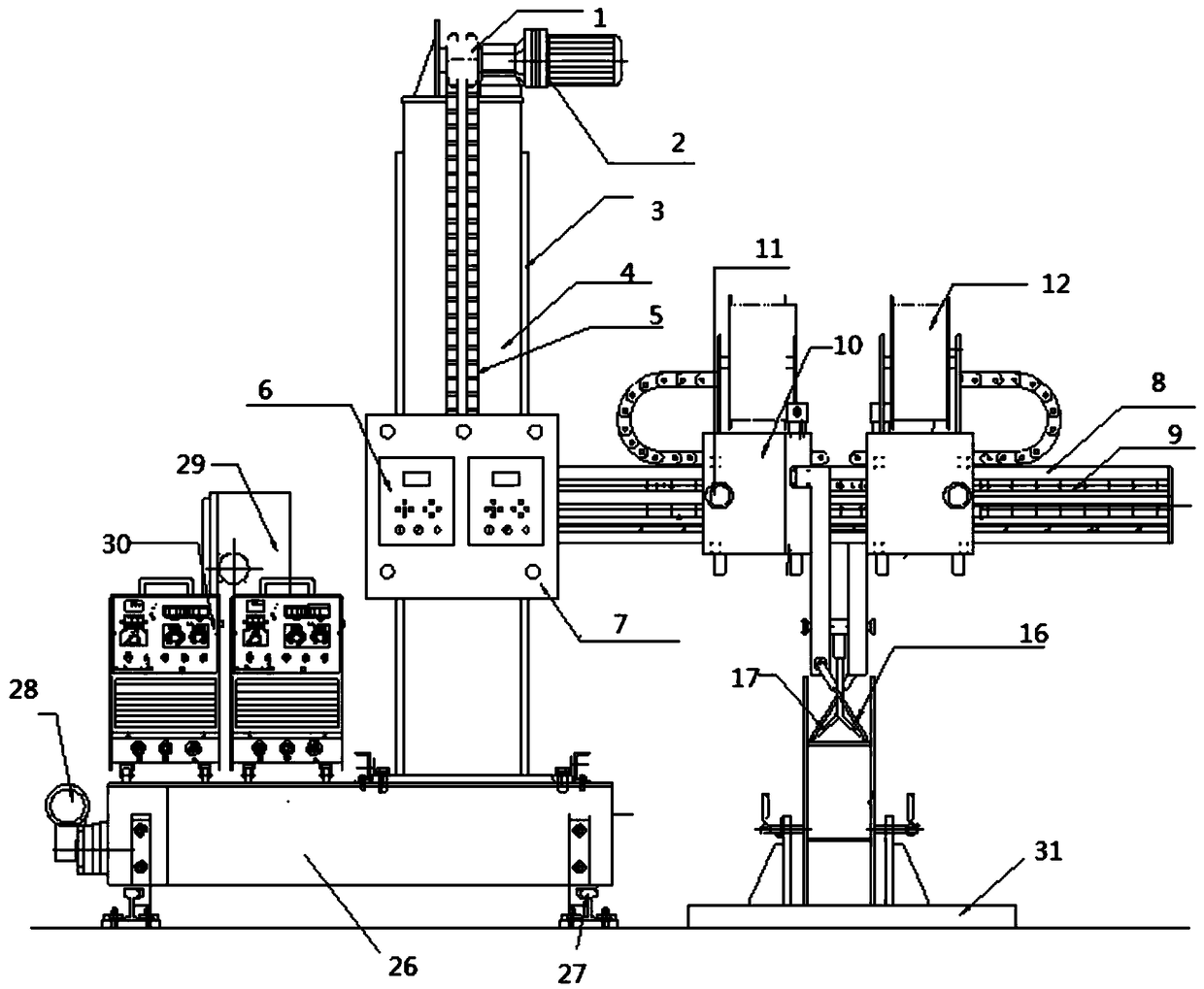

Cantilever welding machine of fillet weld in narrow space

PendingCN109434243AEasy to operateDoes not affect welding qualityElectrode supporting devicesWelding accessoriesFillet weldElectrical control

The invention discloses a cantilever welding machine of fillet weld in a narrow space. The cantilever welding machine comprises a lifting mechanism, a transverse moving mechanism, a welding mechanism,an electric controller and an electric welding machine, wherein the lifting mechanism is vertically arranged, the transverse moving mechanism is arranged on the lifting mechanism, and the lifting mechanism drives the transverse moving mechanism to move up and down; the welding mechanism is arranged on the transverse moving mechanism, the welding mechanism can move on the transverse moving mechanism, the welding mechanism is connected with the electric welding machine, the electric welding machine is connected with the electric controller; and the lifting mechanism and the transverse moving mechanism are both connected to the electric controller, and the electric controller can control the lifting mechanism and the transverse moving mechanism to move. According to the cantilever welding machine, the operation is simple, digital, accurate and controllable.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

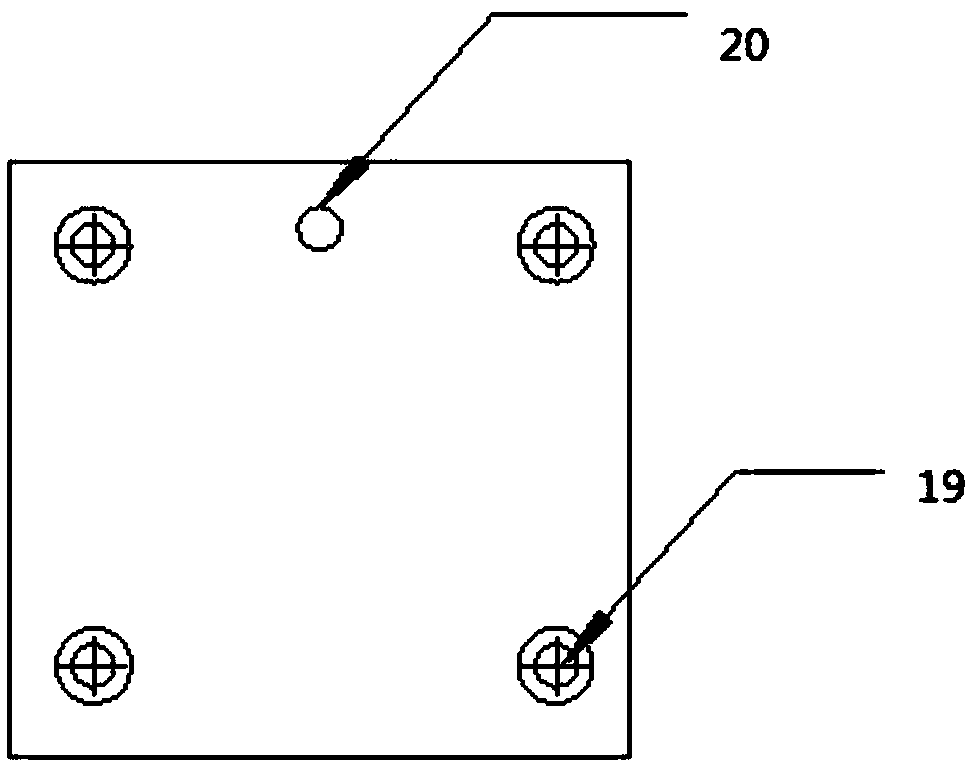

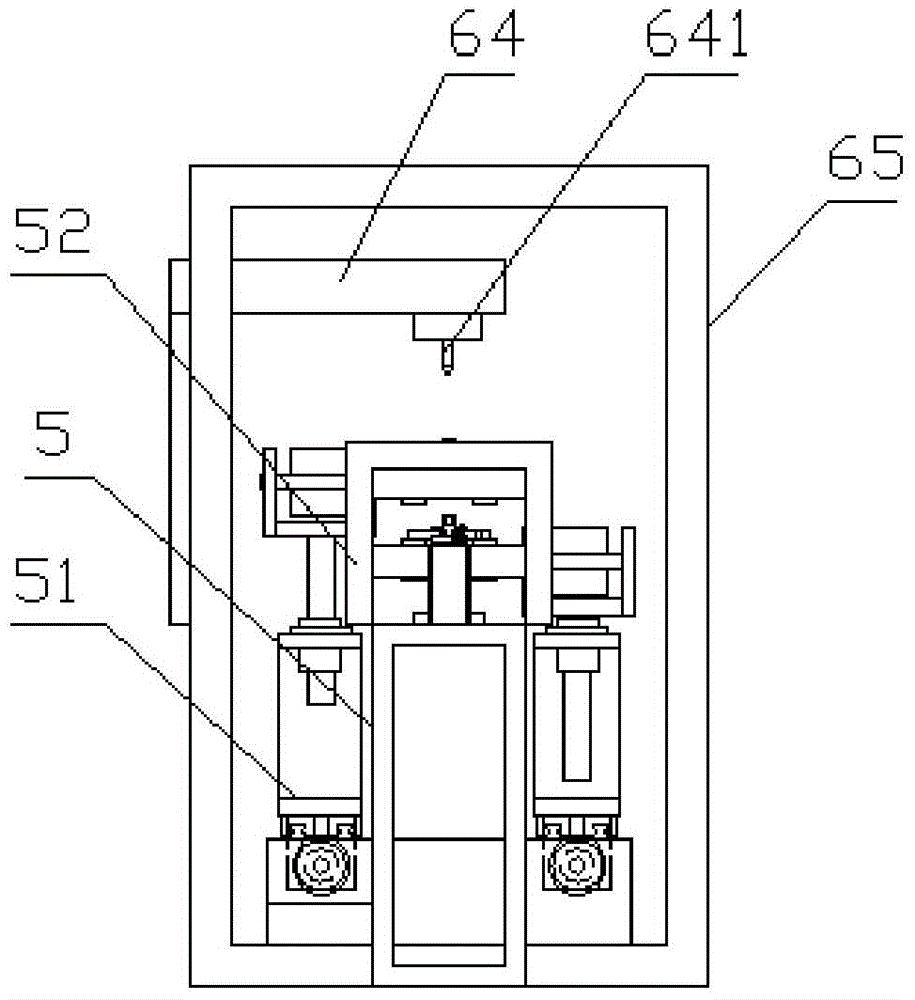

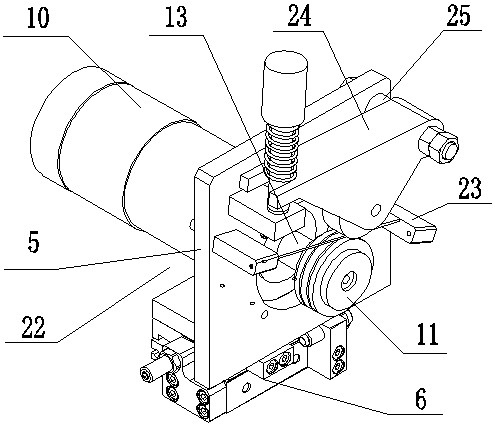

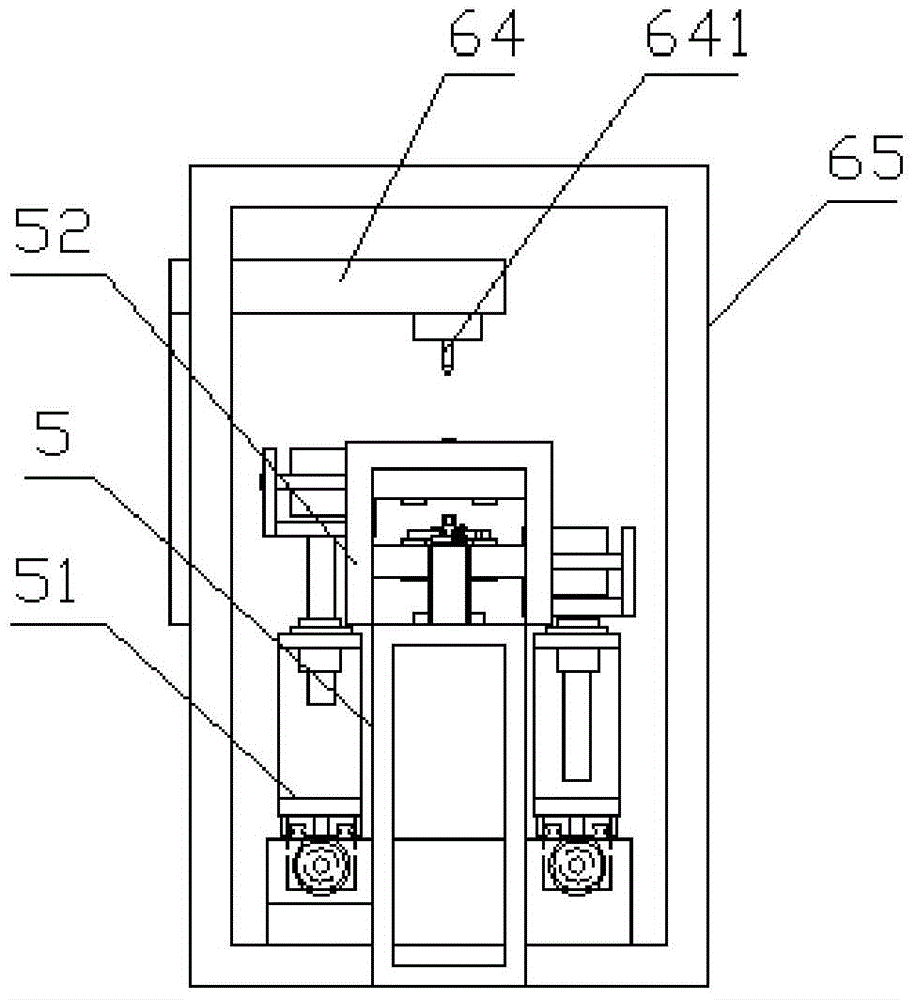

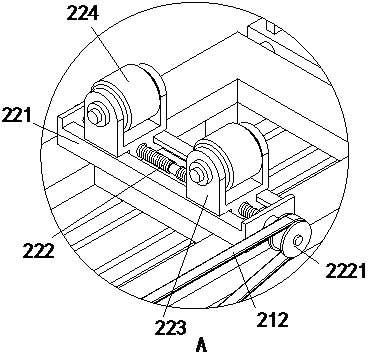

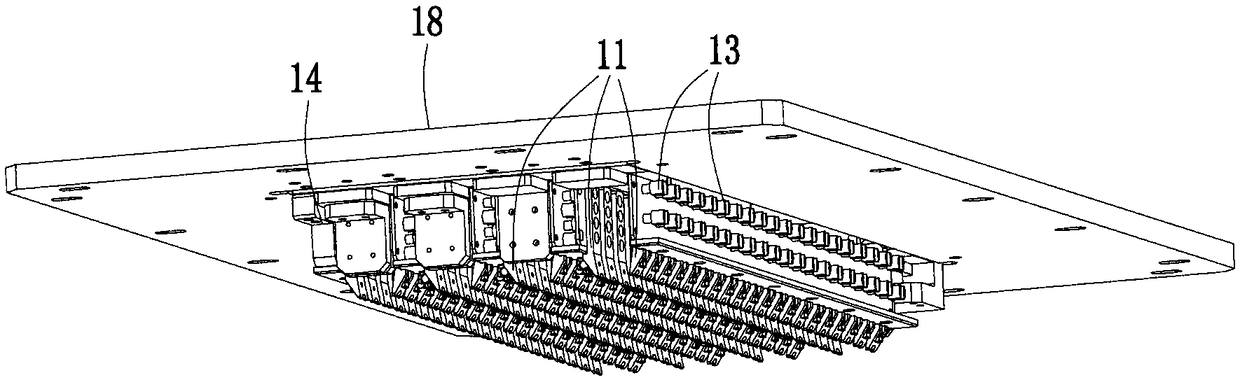

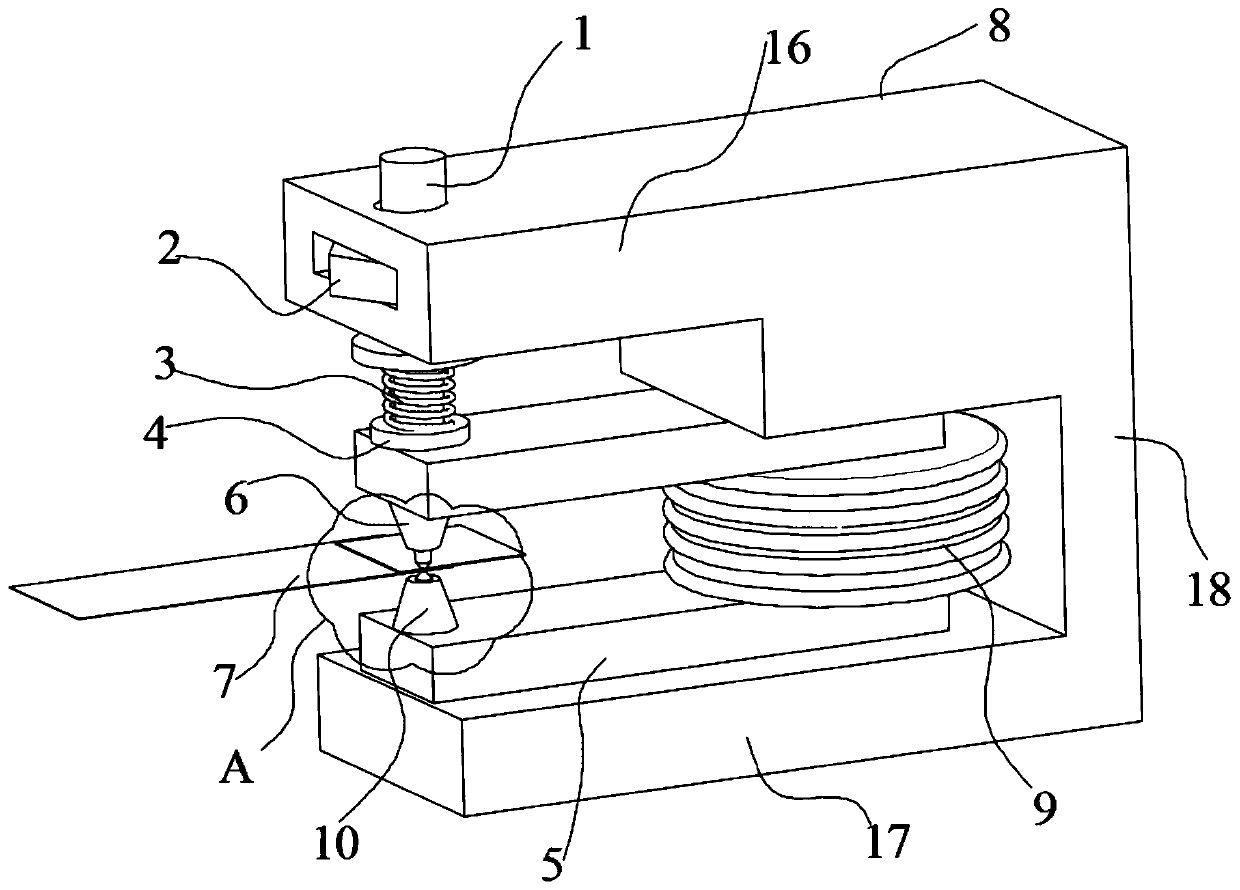

Horizontal positioning drive apparatus for tab positioning

InactiveCN104827159AWelding quality is easy to controlWelding/cutting auxillary devicesAuxillary welding devicesDrive motor

Disclosed in the invention is a horizontal positioning drive apparatus for tab positioning. The horizontal positioning drive apparatus comprises a die shell for placing a plate group; an intermediate positioning plate is arranged in the middle of the upper side of the die shell; and tab positioning plates are arranged at the two sides of the intermediate positioning plate in parallel. In addition, the drive apparatus is also provided with a tab positioning horizontal drive unit including a clamping lead screw; the clamping lead screw is driven by a clamp drive motor; two tab positioning lead screw nuts are arranged at the clamping lead screw and are respectively connected with the tab positioning plates at the two sides. According to the invention, the clamping lead screw is driven by the drive motor to make rotation and the two tab positioning lead screw nuts drive the tab positioning plates to move towards the middle position, thereby clamping the tabs; and thus the welding quality can be controlled easily.

Owner:张涛

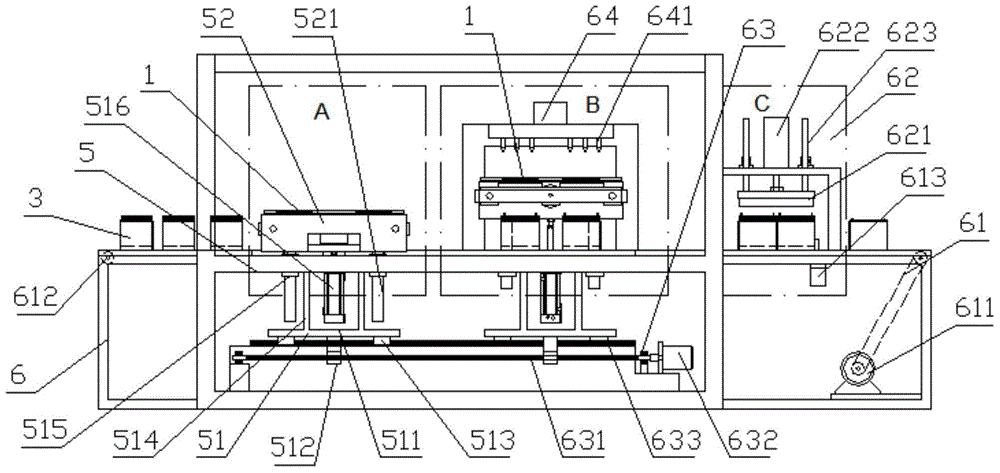

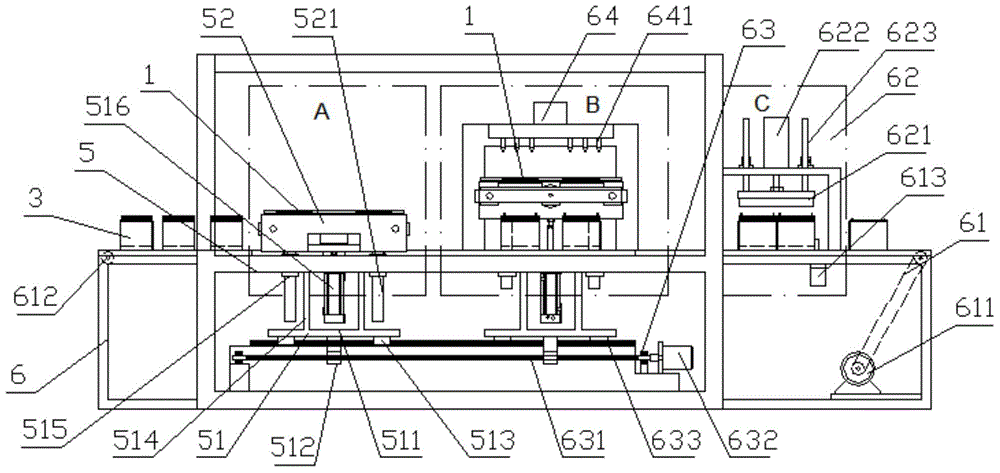

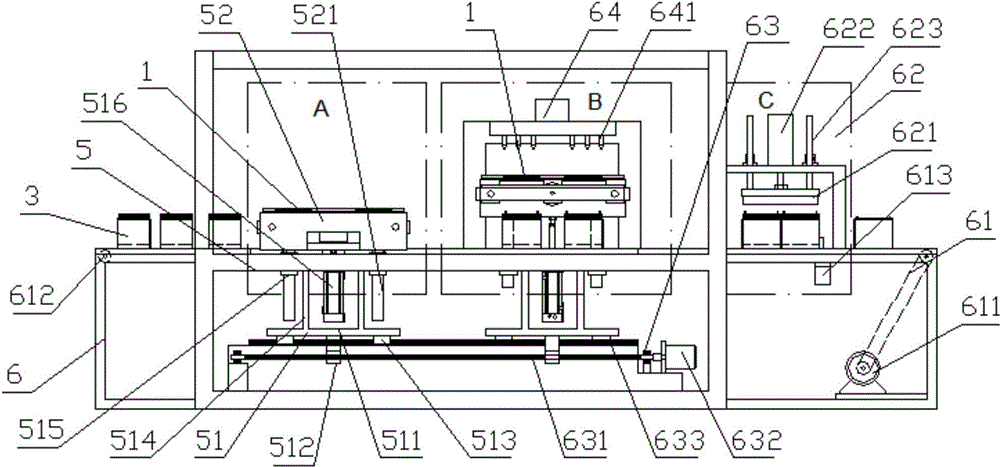

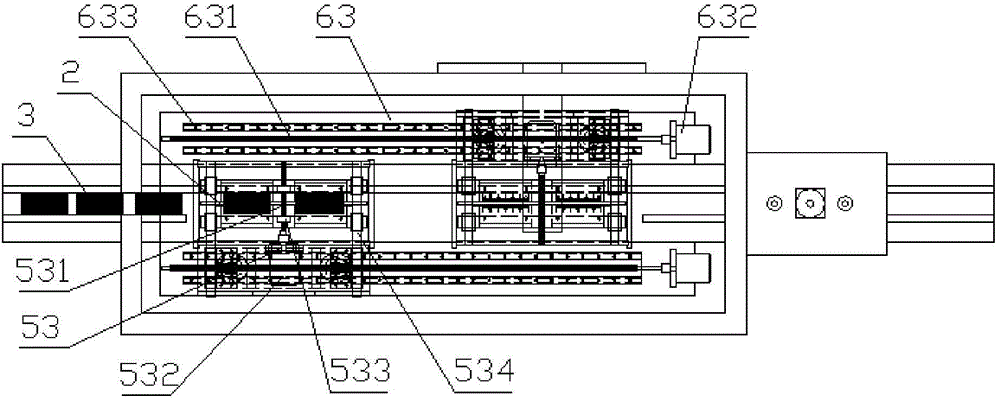

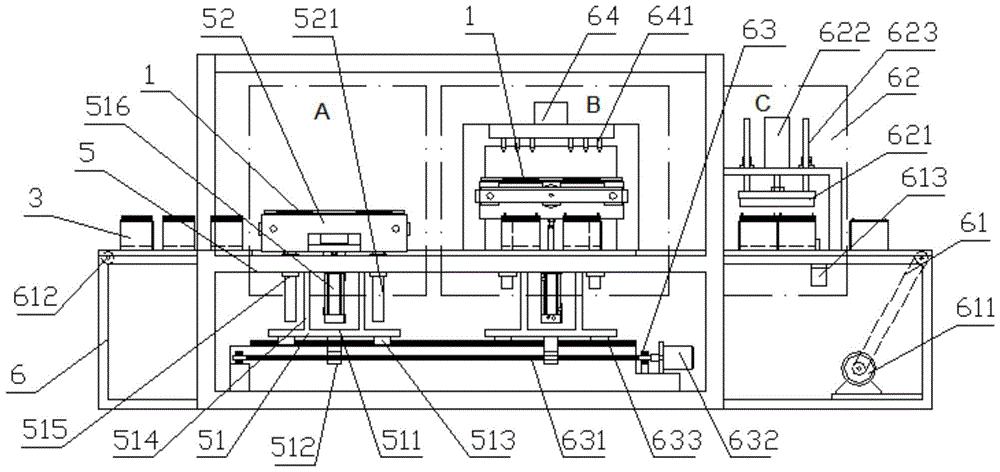

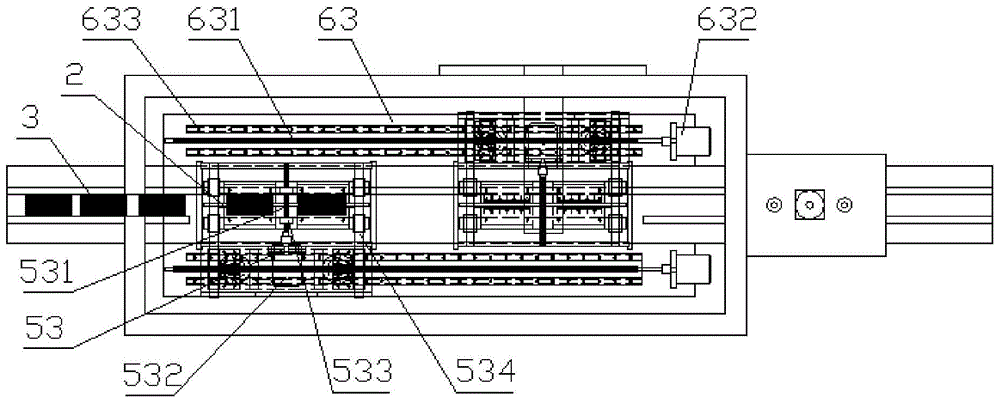

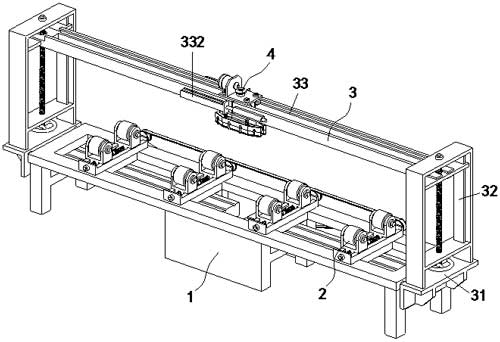

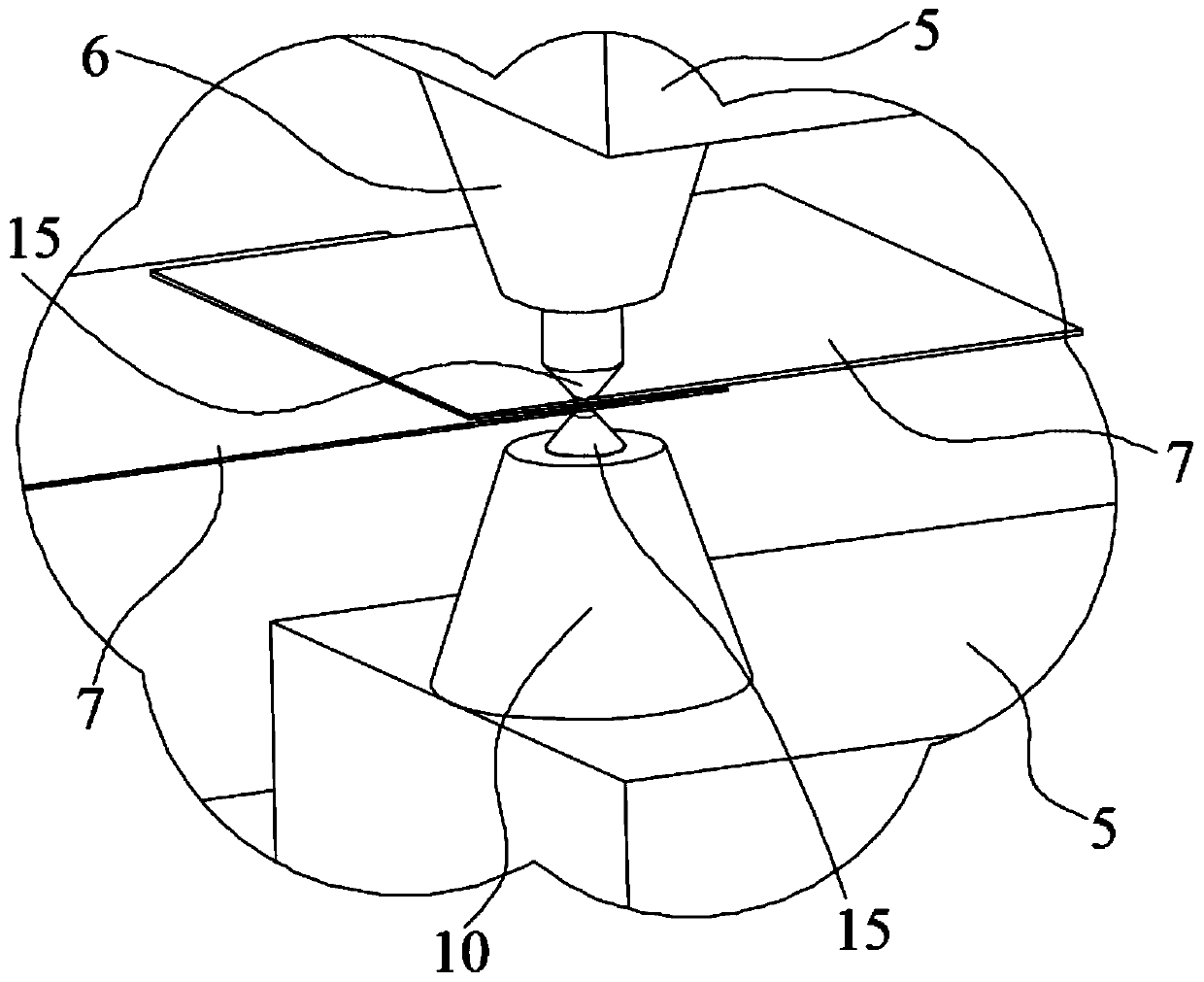

Horizontal conveying apparatus for lead-acid cell plate group welding machine

InactiveCN104827158ASimple welding processReduce welding costsWelding/cutting auxillary devicesAuxillary welding devicesWelding processCell plate

Disclosed in the invention is a horizontal conveying apparatus for a lead-acid cell plate group welding machine. A plate group horizontal conveying apparatus is arranged between the head and the tail of a rack; and a plate group welding device is arranged at the middle part of the rack. The plate group welding device located inside a box body is divided into a plate group arrangement zone A and a plate group welding zone B from the front to back; plate group arrangement is carried out at the plate group arrangement zone A; and plate group welding is carried out at the plate group welding zone B. The plate group horizontal conveying apparatus pushes the welded plate groups at the plate group welding zone B to move backwardly and the plate groups enter a plate group box entrance zone C. A plate group box entrance mechanism for placing the plate groups into a battery box is arranged at the tail of the rack by corresponding to the plate group box entrance zone C. According to the invention, the plate group horizontal conveying apparatus is used for conveying plate groups; during the conveying process, plate group arrangement and plate group welding are carried out; and then the plate groups are put into the battery box at the plate group box entrance zone C by the plate group box entrance mechanism. Therefore, the plate group welding process is simplified; the plate group welding cost is lowered; and the welding quality can be controlled easily.

Owner:黎明

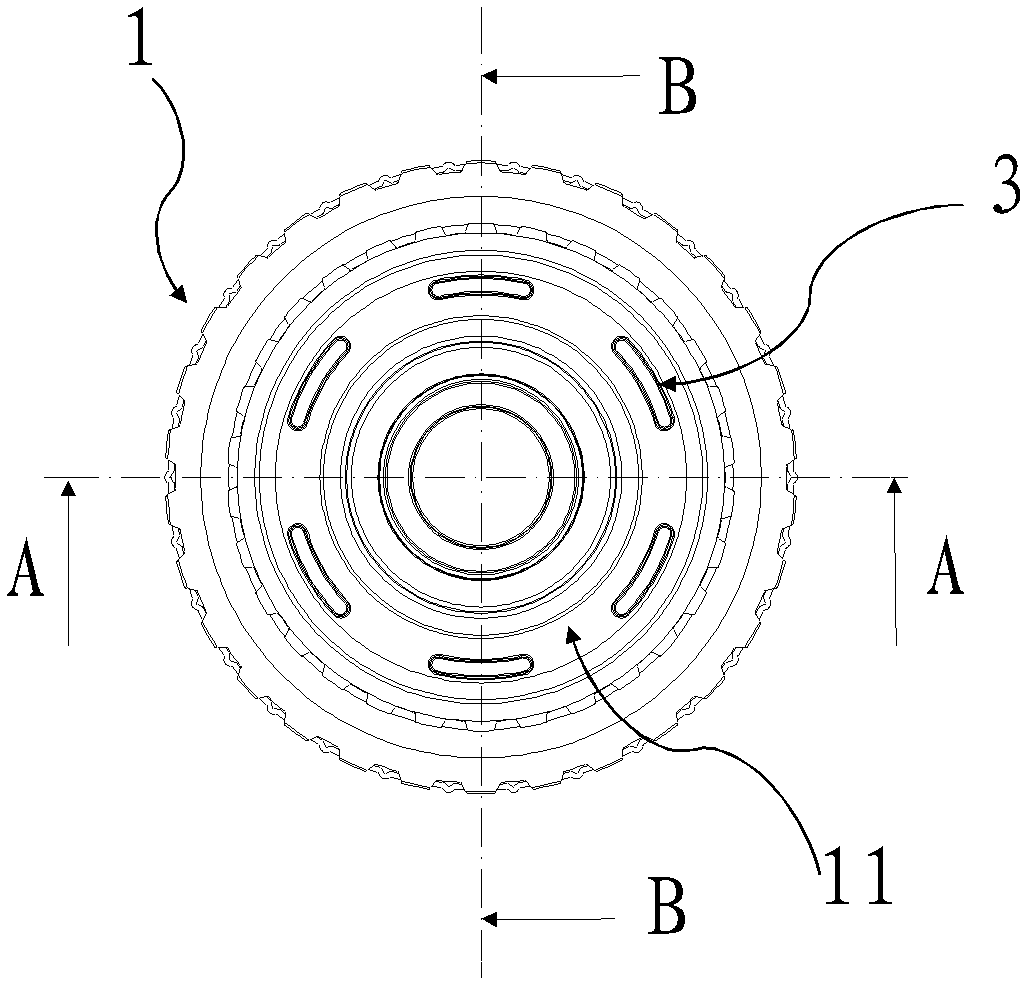

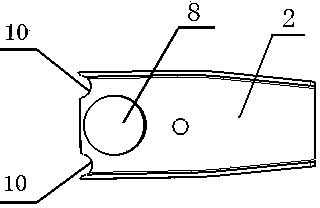

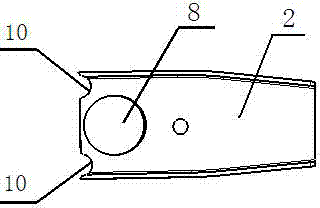

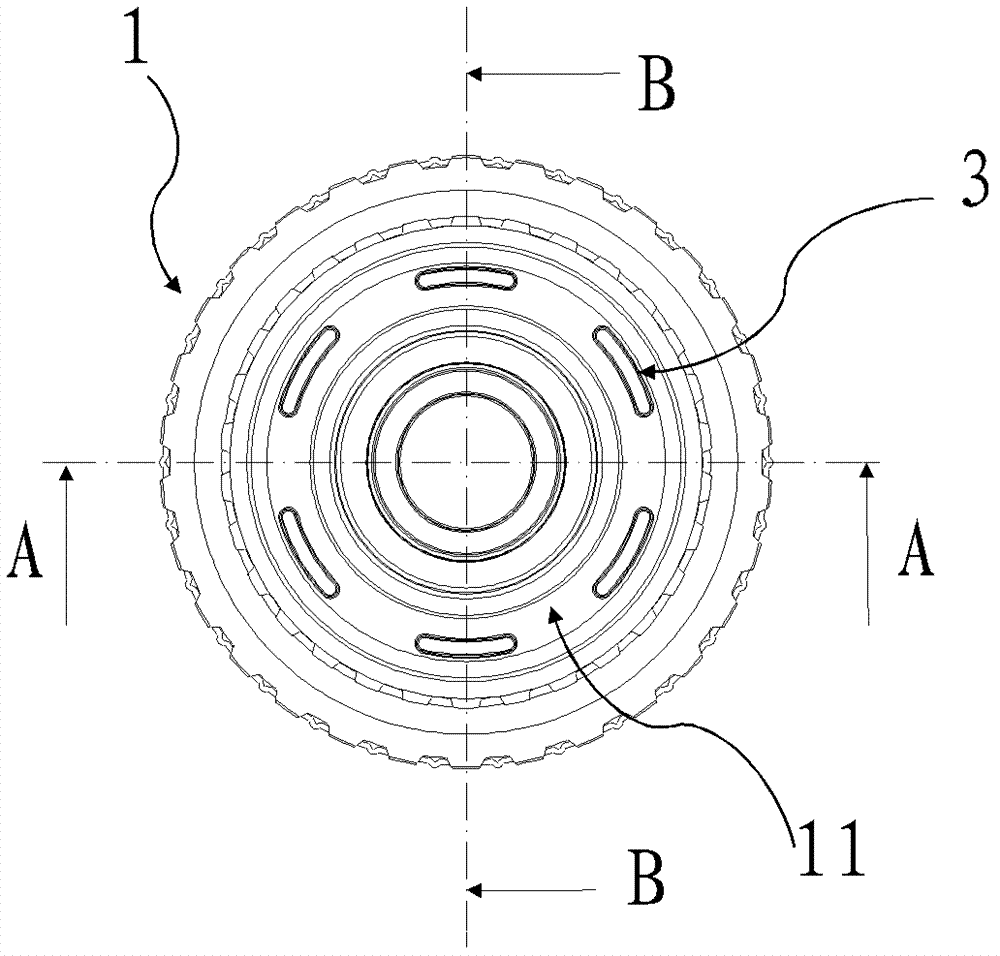

Seam welder electrode wheel for invar boards of liquid cargo tank of LNG ship

InactiveCN103331510ARealize continuous automatic weldingImprove welding efficiencyElectrode featuresWelding with roller electrodesWater channelEngineering

The invention discloses a seam welder electrode wheel for invar boards of a liquid cargo tank of an LNG (Liquefied Natural Gas) ship. The wheel is characterized by comprising a wheel body, wherein a welding working surface of the electrode wheel is arranged on an external circumference surface of the wheel body; annular oblique surfaces are arranged between the two side end surfaces of the wheel body and the welding working surface; a circular groove is formed on one side end surface of the wheel body coaxially; a circular sealing board is arranged on the other side end surface of the wheel body coaxially; a mounting hole set is axially arranged between the circular sealing board and the circular groove in a penetrating way; the wheel body is internally provided with a circulating water channel; and a water inlet hole and a water outlet hole are formed in the center of the circular groove, and are communicated by the circulating water channel. The wheel has the advantages that since the wheel is combined with a seam welder, continuous automatic welding of the invar boards of the liquid cargo tank of the LNG ship can be realized; the welding efficiency is improved greatly; the welding quality is easy to control; and the stability is better.

Owner:ZHEJIANG JINHUA JUNENG ELECTRONICS TECH

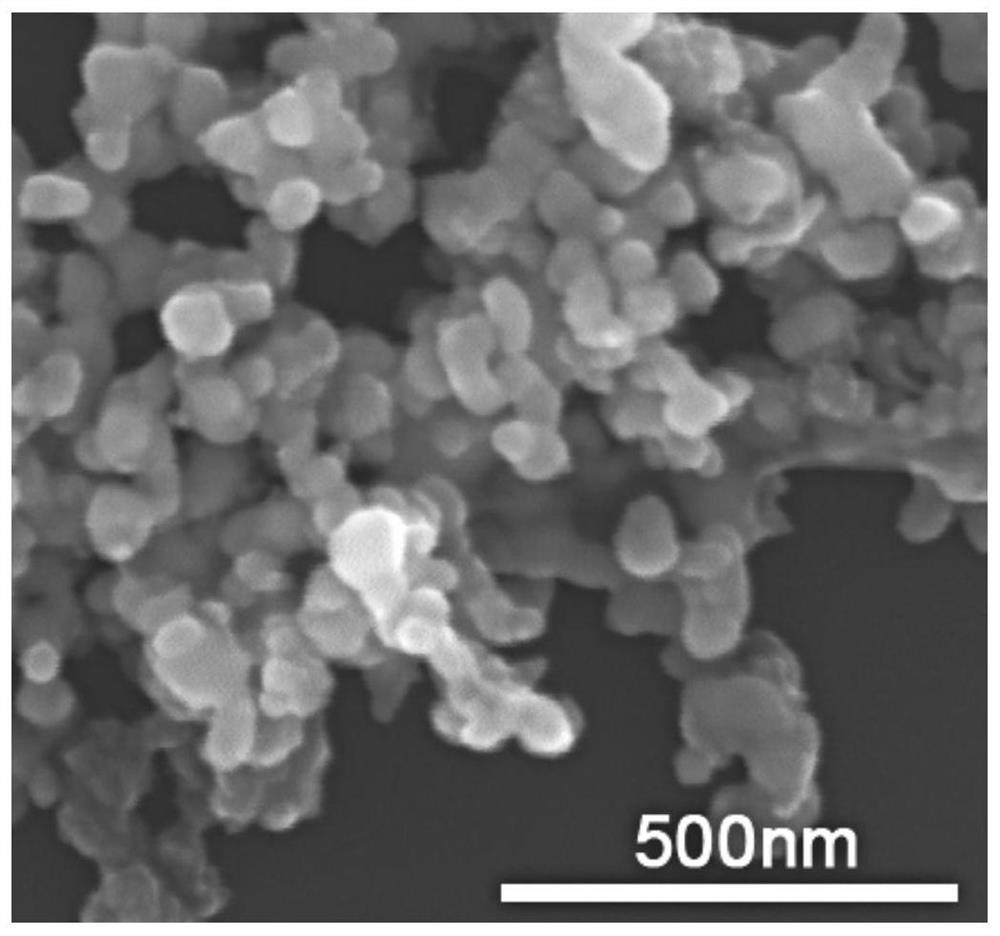

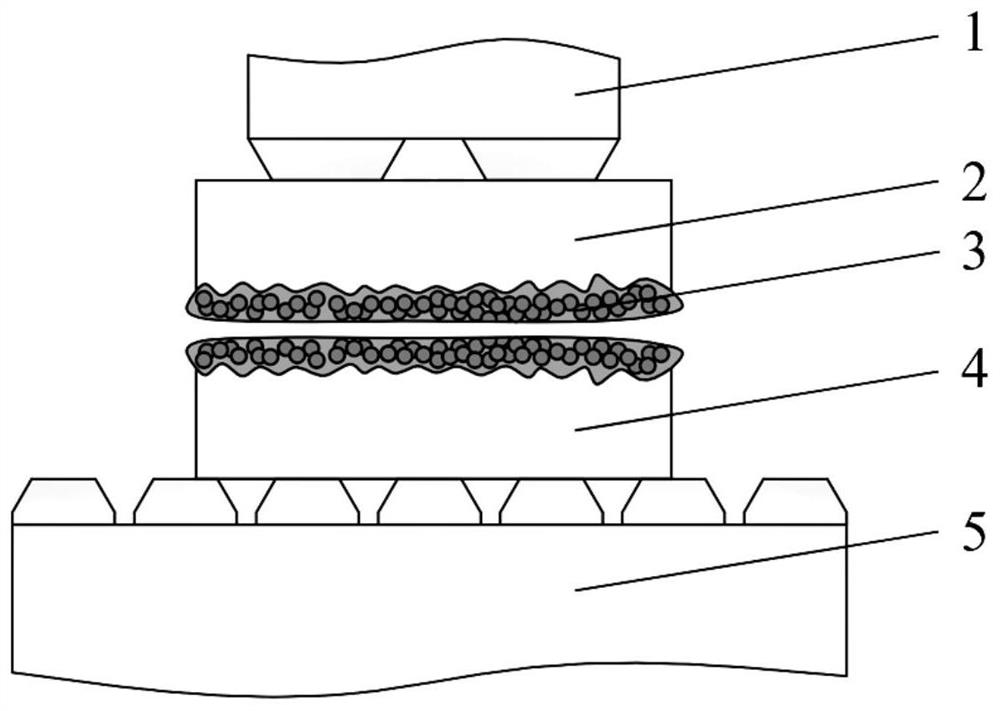

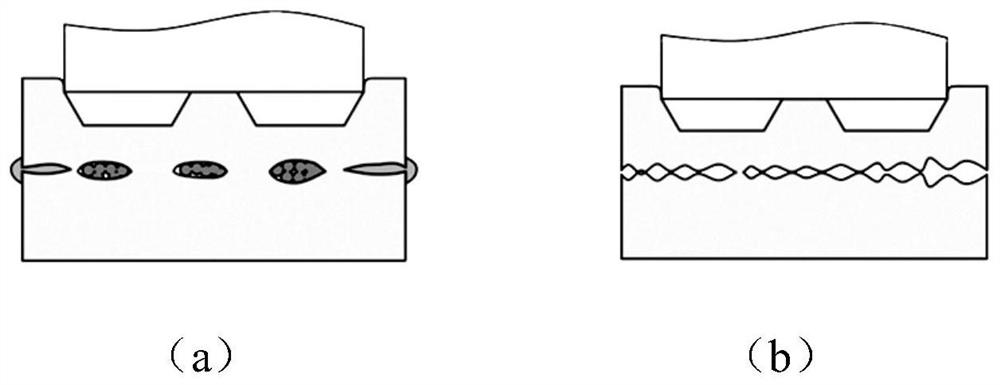

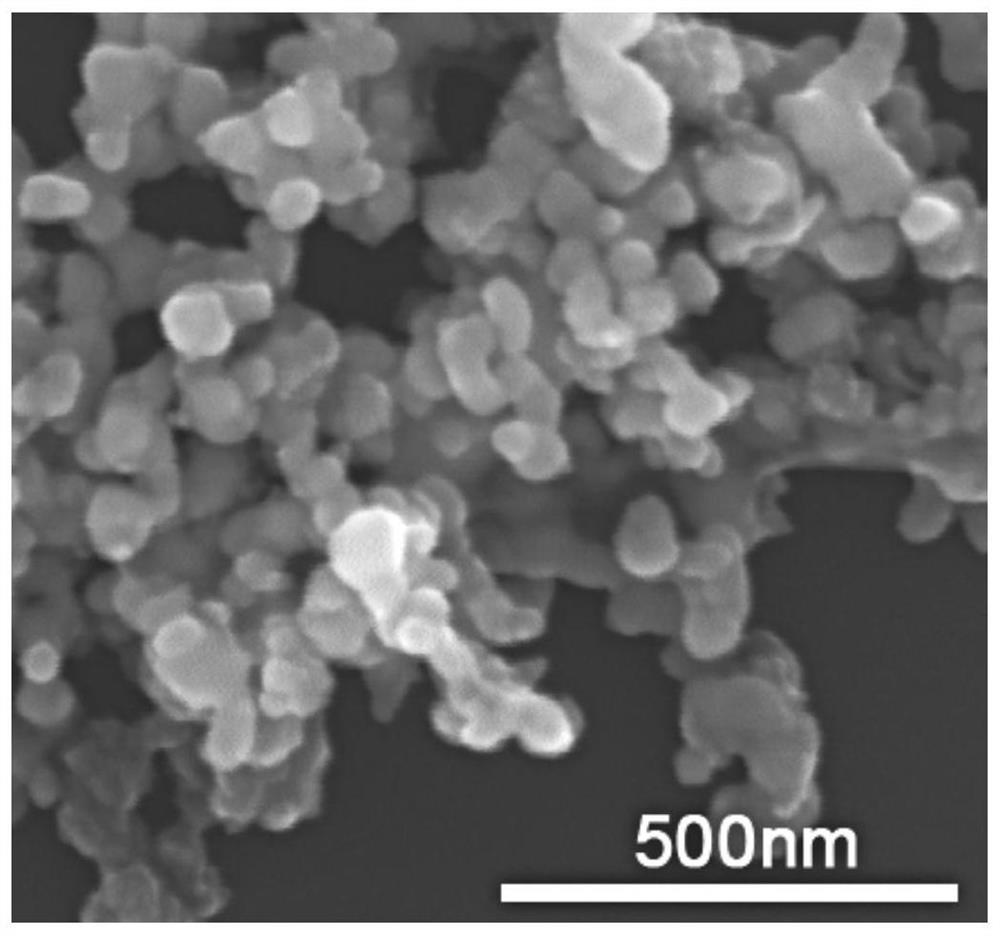

Method of driving low energy ultrasonic metal welding by nanoparticles

ActiveCN111715993AImprove mechanical propertiesImprove thermal conductivityNon-electric welding apparatusRough surfaceUltrasonic welding

The invention provides a method of driving low energy ultrasonic metal welding by nanoparticles. The method comprises the following steps of preparing nanoparticle paste or powder; and coating a to-be-welded surface f upper and lower to-be-welded metals with 1-50 [mu]m thick nanoparticle paste or powder and then carrying out ultrasonic welding at room temperature or in a heating condition. By adopting the technical scheme, conventional solid phase connection at a peak of a coarse surface in the ultrasonic welding process, a size effect of the nanoparticles at gaps, a friction temperature riseeffect and a gap filling effect are integrated to further form a good ultrasonic welding joint with a lower ultrasonic welding input energy, so that the production process is simplified, the influenceto a to-be-welded material is reduced, and performance such as sealing property of a weld joint, mechanical properties of the welding joint, electrical conductivity and heat conductivity are improved.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

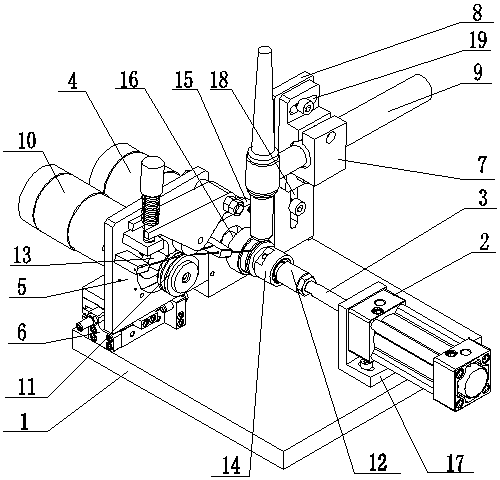

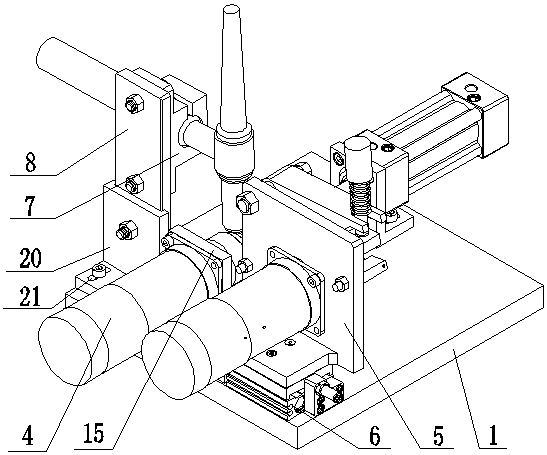

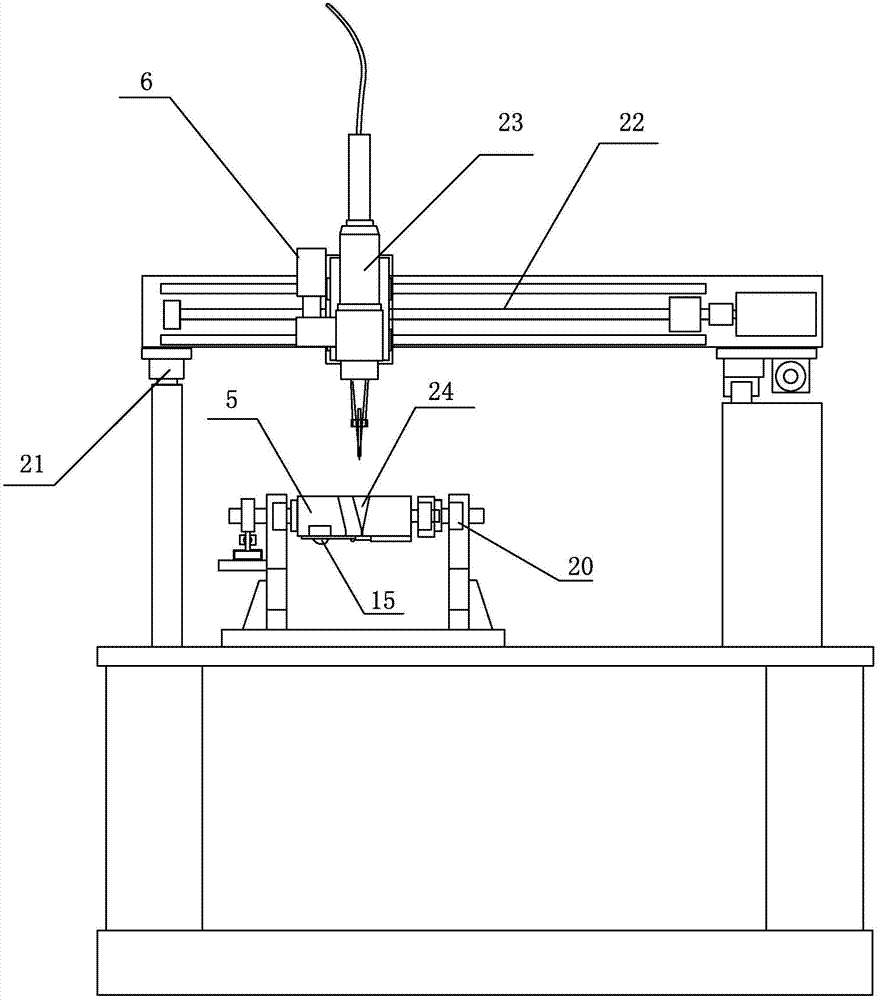

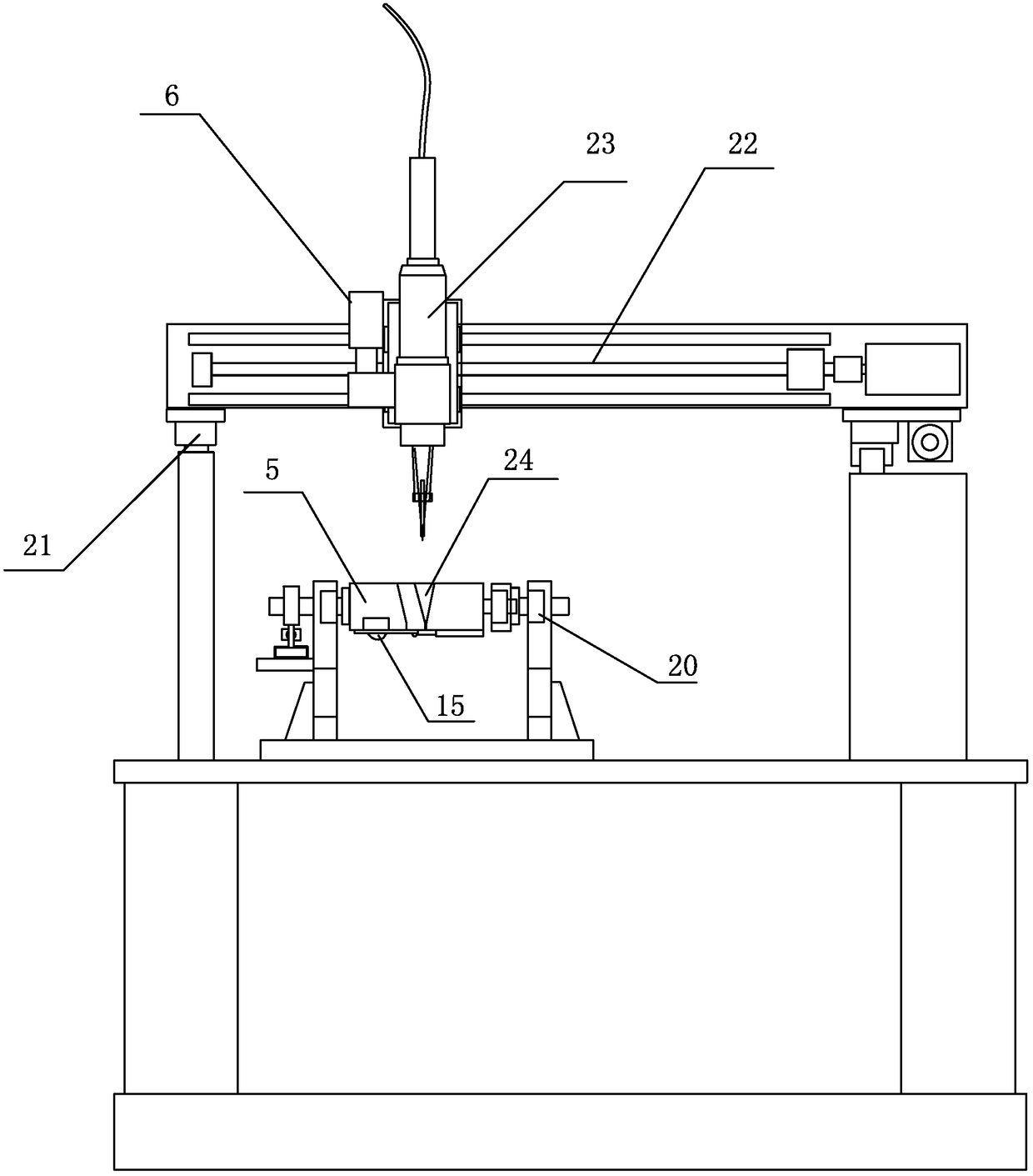

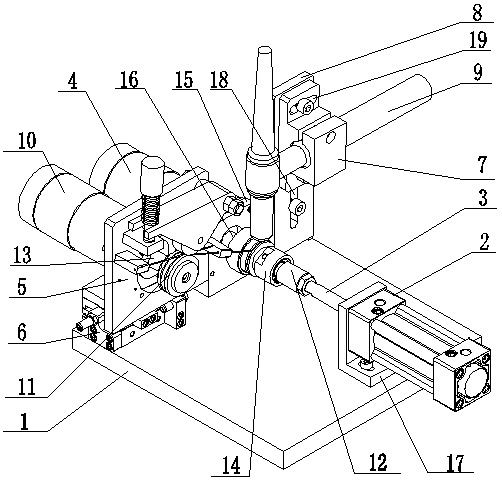

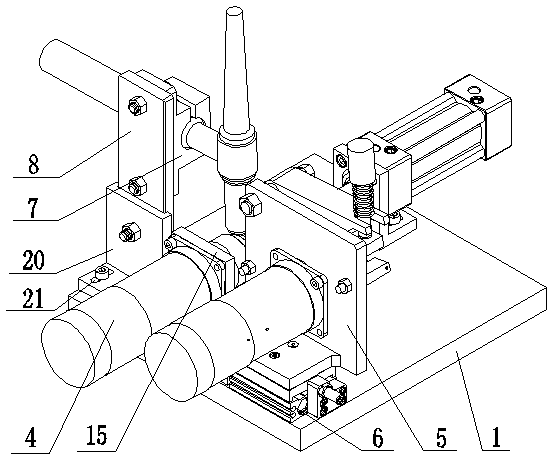

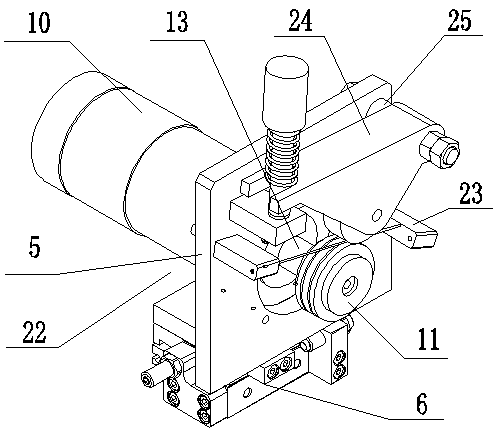

Rotary body part automatic argon arc welding device

ActiveCN108274098AGood welding consistencyEasy to controlWelding accessoriesElectric controlAir cylinder Press

The invention discloses a rotary body part automatic argon arc welding device. The welding device is composed of a mechanical part, an electric control part and a pneumatic control part, and mainly comprises an electrode holder, an electrode holder clamp, a wire feeder, a rotary servo motor, a wire feeding servo motor, a telescopic air cylinder, a sliding table air cylinder and the like. During work, the telescopic air cylinder presses and positions a workpiece needing to be welded, then an argon switch works, the sliding table air cylinder moves forwards to enable a welding wire and the workpiece to be welded, meanwhile, the rotary servo motor and the wire feeding servo motor rotate synchronously, after the rotary servo motor rotates by one circle, the sliding table air cylinder retracts,argon supply is stopped, and welding is completed. The welding device is accurate in control and high in automation degree, and can meet requirements of different welding beads.

Owner:JILIN TEACHERS INST OF ENG & TECH

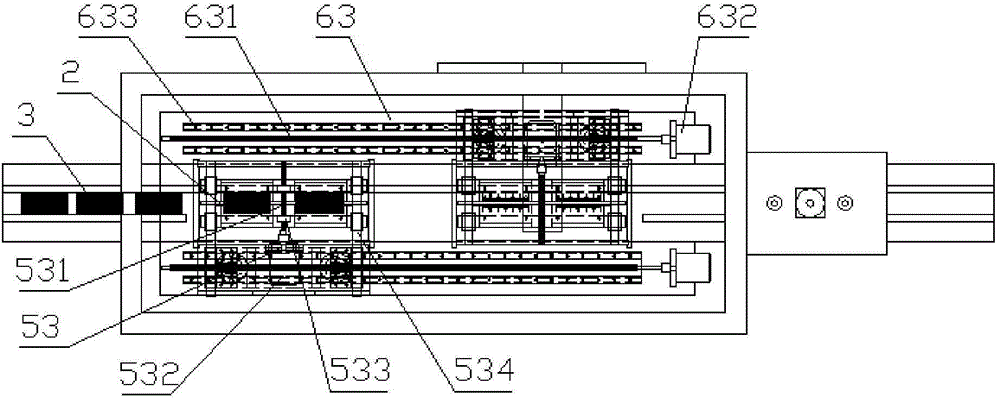

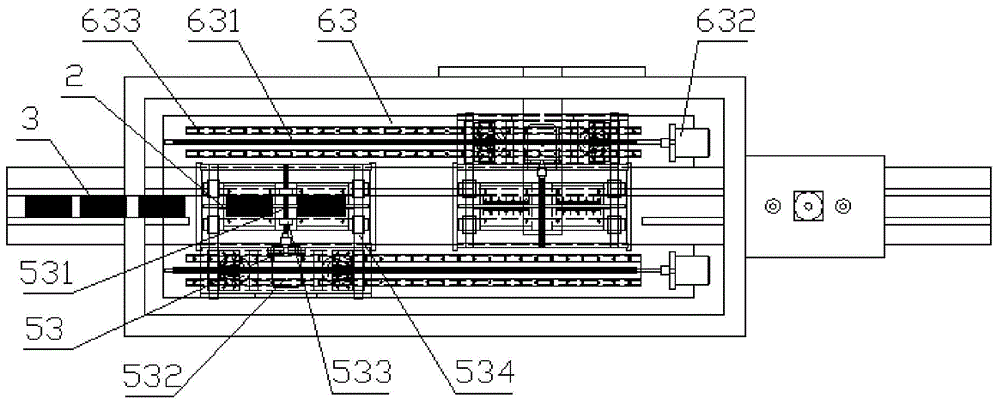

Lead-acid battery pole group welding technology

InactiveCN104625307AReduce manufacturing costIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention discloses a lead-acid battery pole group welding technology. After a pole group is conveyed to a pole group arranging area, a lug positioning structure positions lugs, and posts and lead bridges are placed; a pole group welding module reciprocating driving unit makes a pole group welding module in the pole group arranging area move to a pole group welding area as a whole, meanwhile, another pole group welding module originally located in a pole group welding area is moved to the pole group arranging area under driving of another pole group welding module reciprocating driving unit, and the pole group welding module reaching the pole group arranging area completes pole group arranging work; after the pole group welding module reaches the pole group welding area, a three-axis numerical control mechanism and a fire gun nozzle start to work. At the time, the pole group welding module in the pole group arranging area completes arranging movement, and the two pole group welding modules exchange positions under driving of the pole group welding module reciprocating driving unit. The heating fusion welding principle is adopted, production cost is low, production efficiency is high, and welding quality can be controlled more easily.

Owner:贵州省万航电能科技有限公司

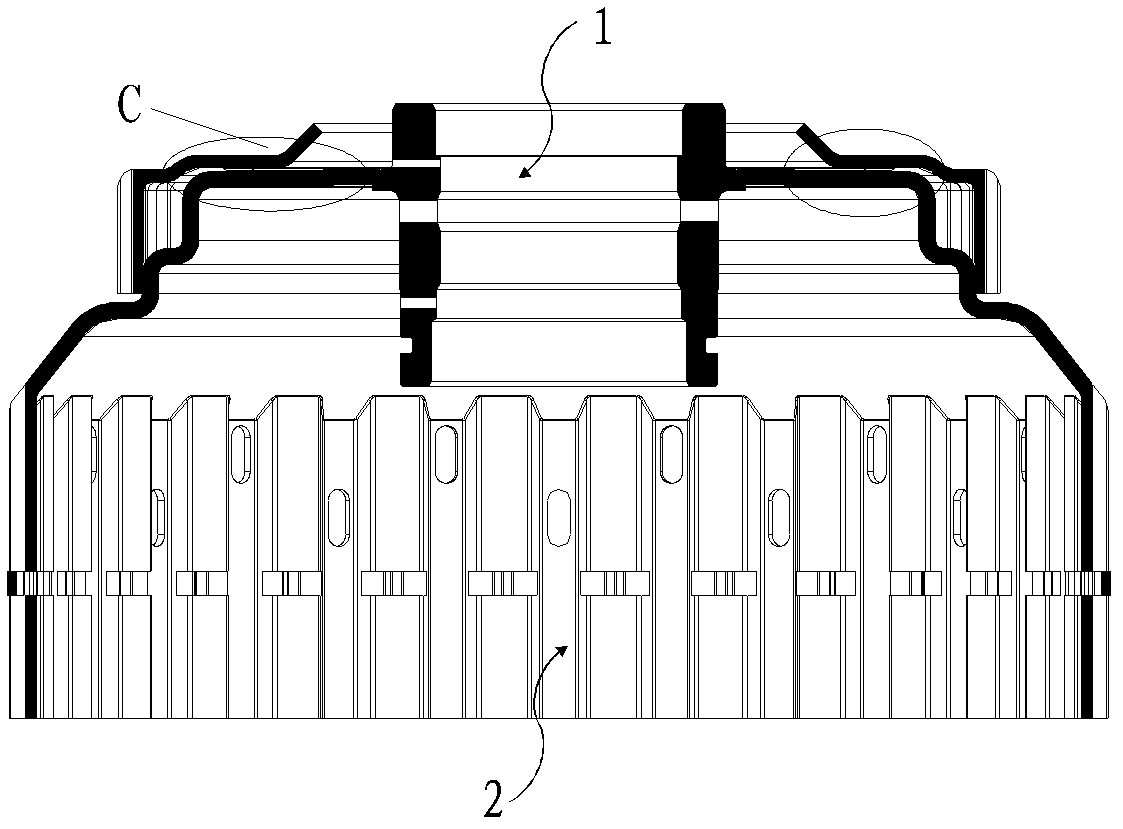

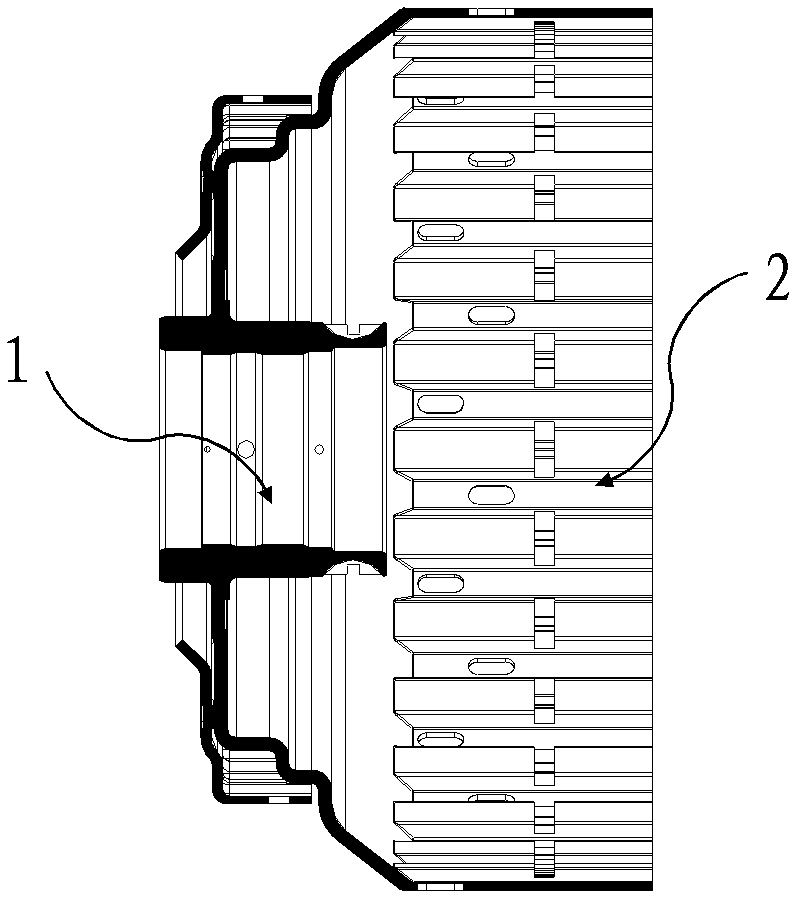

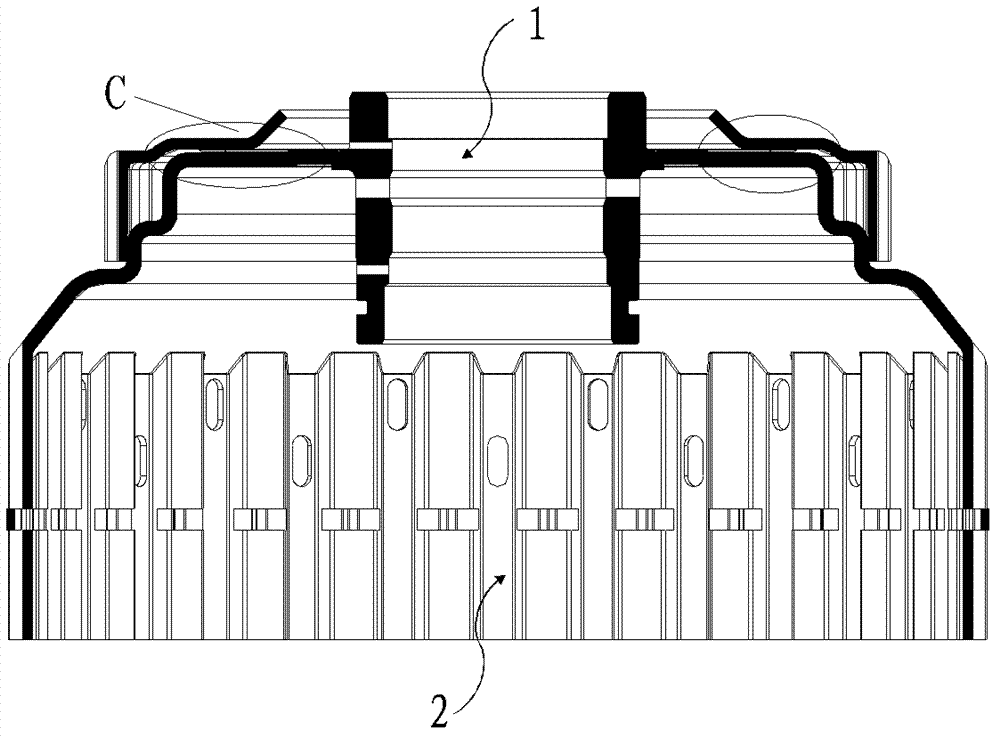

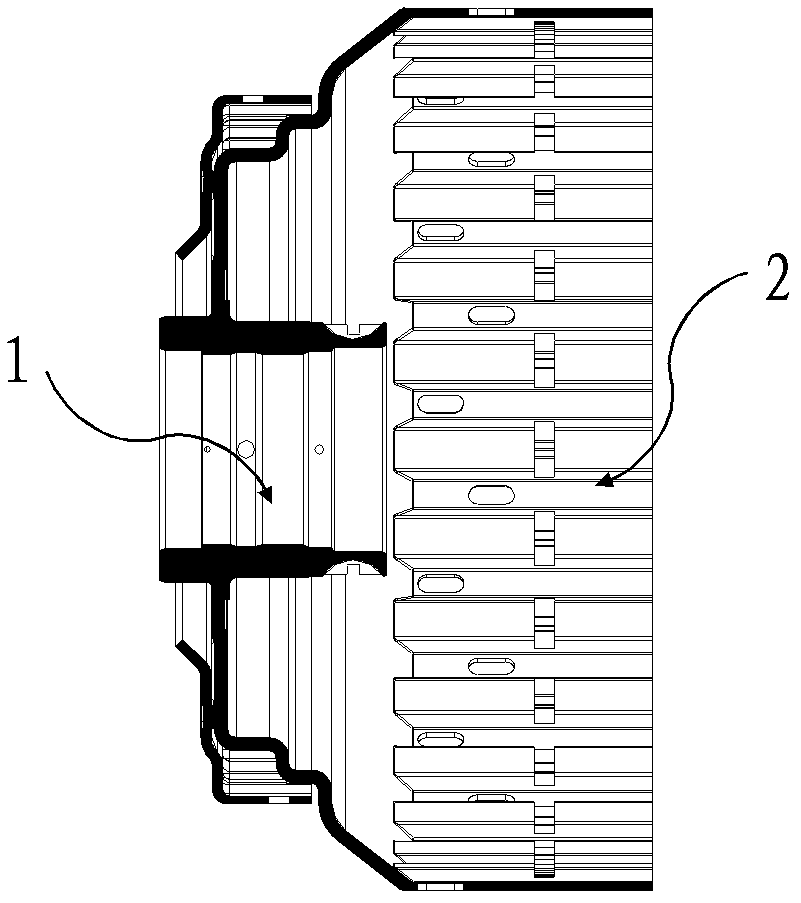

Automatic speed changer shell body and welding method thereof

ActiveCN103104678AWelding quality is easy to controlExtended service lifeGearboxesGear lubrication/coolingAutomatic transmissionEngineering

The invention discloses an automatic speed changer shell body used in the field of automobile spare parts. The automatic speed changer shell body comprises an inner hub and an outer hub, a first ring welding face is arranged at the bottom of the inner hub, a second ring welding face is arranged on the top of the outer hub, a plurality of welding bosses with equal heights are evenly distributed along the first ring welding face, and the faces of the welding bosses are welded with the second ring welding face. The automatic speed changer shell body can effectively enable lubricating oil to flow into the interior of the automatic speed changer shell body, conducts lubricating for a clutch assembly, prolongs service life of the clutch assembly, and simultaneously reduces labor intensity of welding the automatic speed changer shell body, and welding quality of the automatic speed changer shell body is easy to control.

Owner:SHANGHAI JIAOYUN AUTOMOTIVE POWER SYST

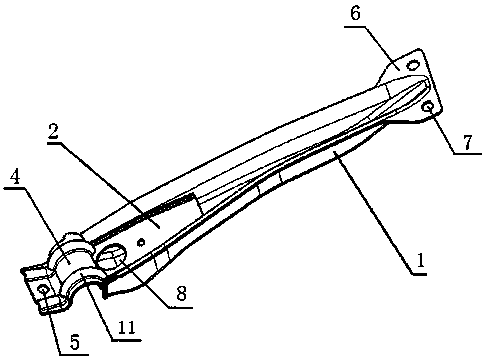

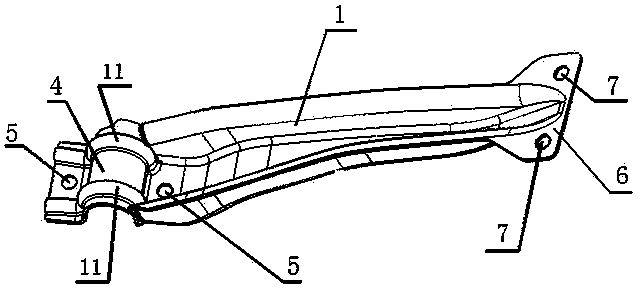

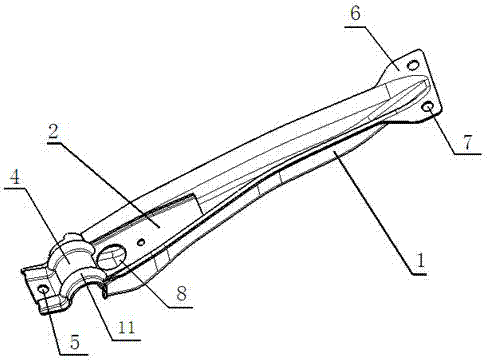

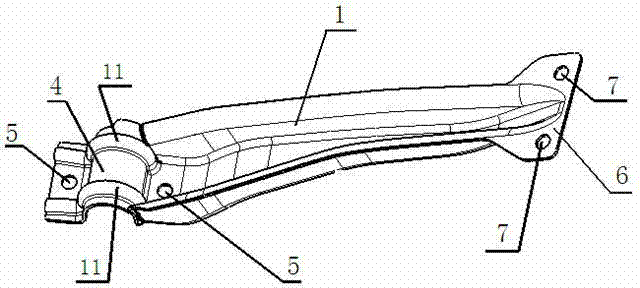

Longitudinal supporting frame of automobile transverse stabilizing bar

ActiveCN103434360AAvoid stitchingAvoid crackingInterconnection systemsOmegaUltimate tensile strength

The invention discloses a longitudinal supporting frame of an automobile transverse stabilizing bar. The longitudinal supporting frame comprises a longitudinal supporting frame body with the U-shaped cross section, an omega-shaped clamping hoop is connected to the front end of the longitudinal supporting frame body, the clamping hoop is formed in the mode that the bottom face of the longitudinal supporting frame body forwards extends, and an outward turning edge is arranged at the back end of the longitudinal supporting frame body. A strengthening piece provided with the U-shaped cross section and formed by sheet metal parts in a whole stamping mode is arranged in the longitudinal supporting frame body, the front end of the strengthening piece is welded with the arc face of the clamping hoop, and the two sides of the strengthening piece are welded with the two sides of the longitudinal supporting frame body. The longitudinal supporting frame is high in strength and good in bearing capacity, and can solve the problems of deformation and weld failures in the using process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

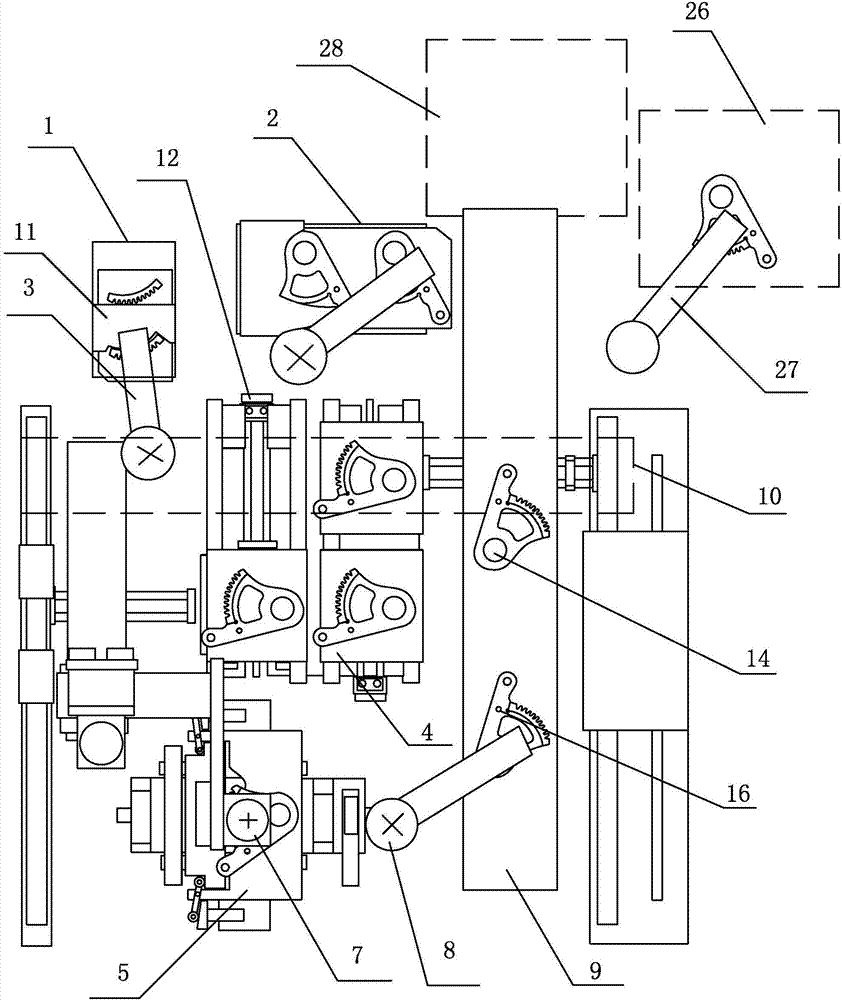

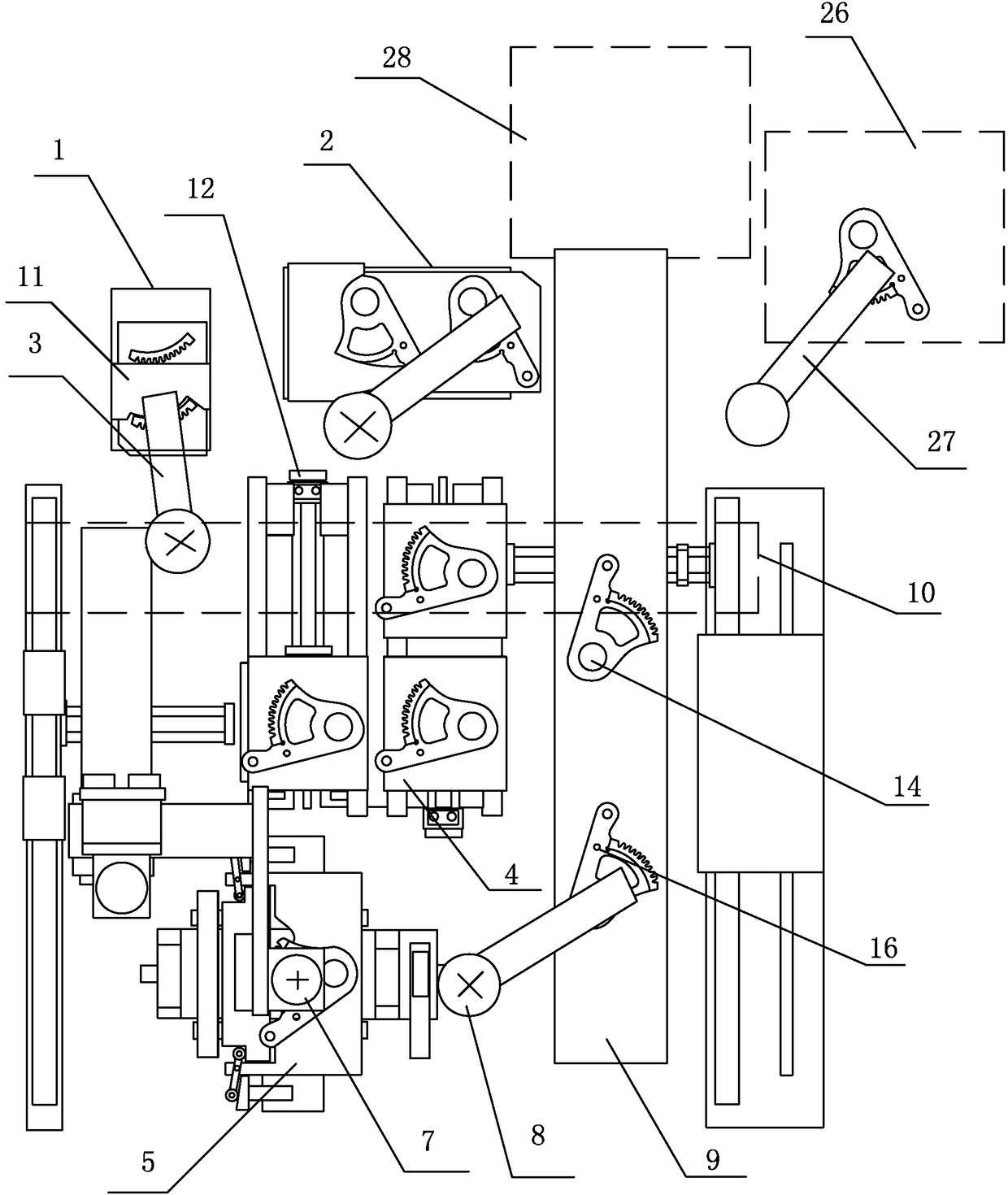

Automatic system for producing toothed plate structures in automobile seats

InactiveCN106862765AImprove yield rateNo human intervention requiredLaser beam welding apparatusCentre of rotationEngineering

The invention discloses an automatic system for producing toothed plate structures in automobile seats. The automatic system is characterized by comprising a charging mechanism, a re-positioning mechanism, a welding mechanism, a discharging mechanism and a visual detection mechanism, wherein the charging mechanism comprises a rack charging station and a connection plate charging station; the pre-positioning mechanism comprises at least one positioning table; a connection plate positioning pin which is matched with a toothed plate rotary central hole is arranged on the positioning table; the welding mechanism comprises a welding platform, a laser welding device and a magnetic clamping component; the discharging mechanism comprises a discharging mechanical arm and a conveyer belt; the visual detection mechanism judges whether the toothed plates are qualified or not through an image comparison device; unqualified products are removed; and qualified products are output by the conveyer belt. By adopting the automatic system, automatic production of the toothed plate structures is realized through charging, positioning, welding, discharging and detecting; and production yield and production efficiency are improved.

Owner:上海唐立工业科技有限公司

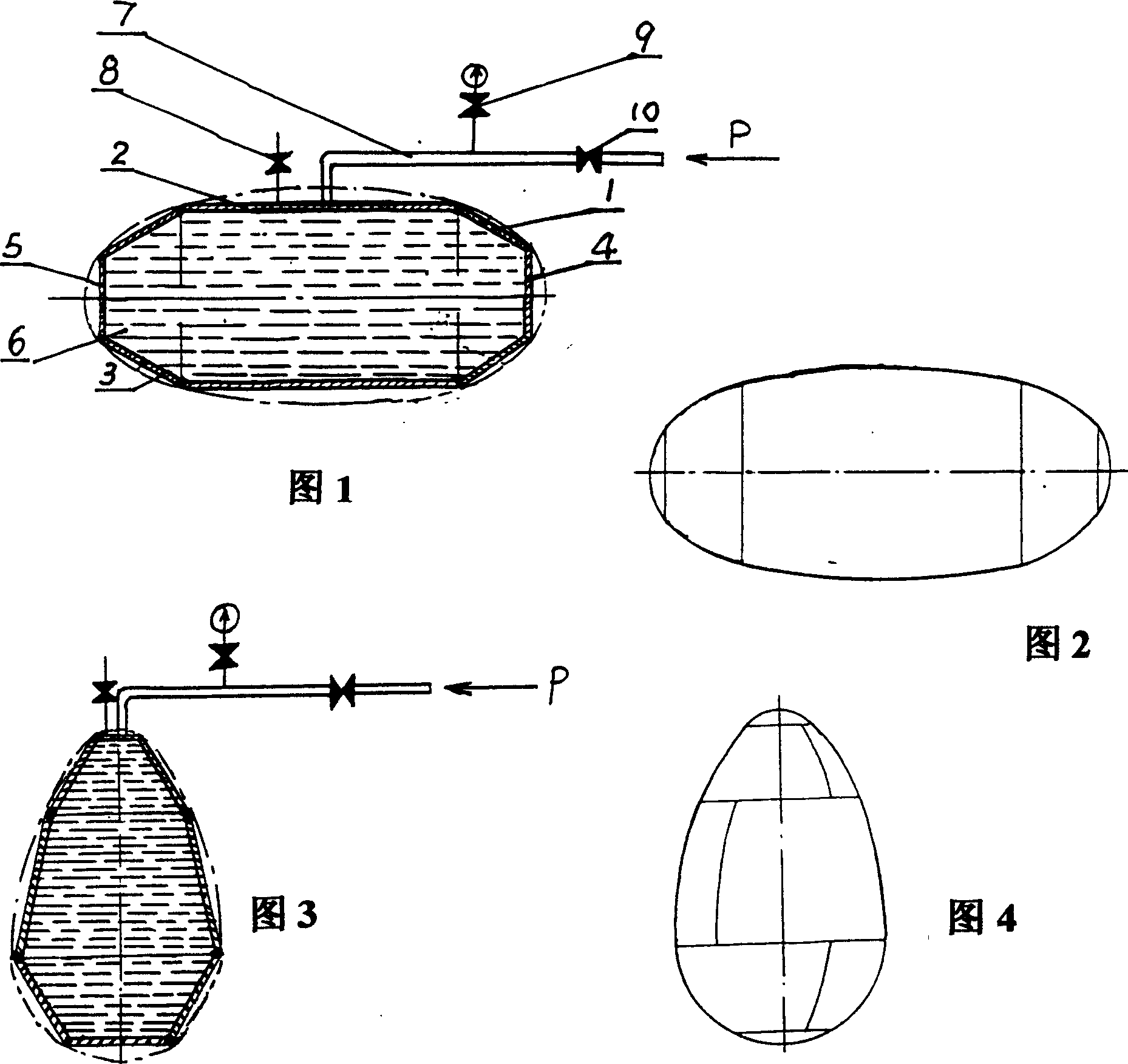

Non-die hydraulic integrally forming ultra-thin spherical shell technology

InactiveCN1231312CReduce residual stressNo deformationHollow articlesManufacturing technologyEngineering

The ultra-thin spherical shell is highly valued by users for its good force characteristics, beautiful appearance and material saving. However, the traditional complex manufacturing technology prevents it from being widely used. The moldless overall hydroforming ultra-thin spherical shell technology simplifies various special-shaped spherical shells such as metal standard oval balls, eggshell balls, and raindrop balls, and various metal special-shaped spherical shells made of different materials. body manufacturing process. The production cost is only 1 / 20 of the traditional technology to manufacture the same shell, and the production cycle is 1 / 50. This technology is ideal for the production of ultra-thin metal spherical shells and ultra-thin spherical shells made of different materials. Economical and practical manufacturing technology.

Owner:王南海

Lead-acid battery electrode group welding process

InactiveCN104625307BReduce manufacturing costIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention discloses a lead-acid battery pole group welding technology. After a pole group is conveyed to a pole group arranging area, a lug positioning structure positions lugs, and posts and lead bridges are placed; a pole group welding module reciprocating driving unit makes a pole group welding module in the pole group arranging area move to a pole group welding area as a whole, meanwhile, another pole group welding module originally located in a pole group welding area is moved to the pole group arranging area under driving of another pole group welding module reciprocating driving unit, and the pole group welding module reaching the pole group arranging area completes pole group arranging work; after the pole group welding module reaches the pole group welding area, a three-axis numerical control mechanism and a fire gun nozzle start to work. At the time, the pole group welding module in the pole group arranging area completes arranging movement, and the two pole group welding modules exchange positions under driving of the pole group welding module reciprocating driving unit. The heating fusion welding principle is adopted, production cost is low, production efficiency is high, and welding quality can be controlled more easily.

Owner:贵州省万航电能科技有限公司

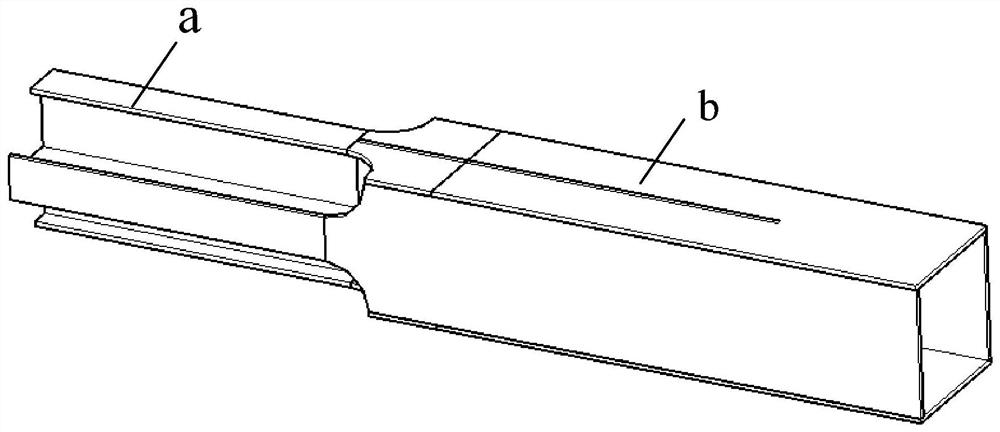

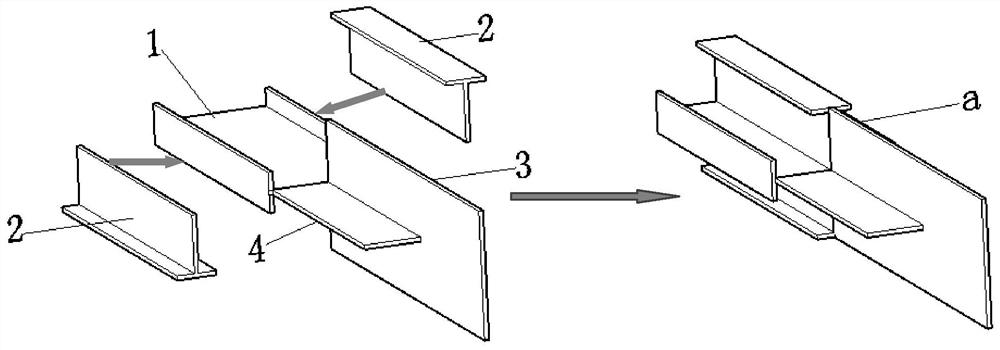

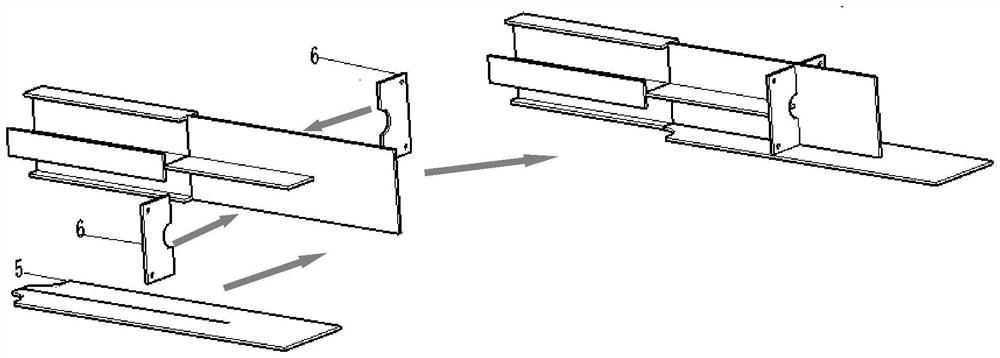

A method for making a cross transformer box-shaped node

ActiveCN110711961BOptimize assembly processControl deformationBuilding constructionsWelding apparatusStress concentrationButt welding

The invention discloses a method for manufacturing a cross-shaped box-shaped node, including the assembly and splicing of the cross-shaped column and the box-shaped column; step 1, the assembly and splicing of the cross-shaped column; the cross-shaped column is composed of one H-shaped steel and two T-shaped steels; the steps 2. Assembly and splicing of box-shaped columns, including box-shaped column bottom plate and internal assembly, box-shaped column U-shaped structure assembly, correction of deformed parts according to process requirements, and box-shaped column cover plate assembly; step 3, transitional inlay Repair segment group welding. The present invention preferably avoids the problem of stress concentration by first welding the welding seam of the box-shaped column top partition, then welding the connecting weld seam between the cross column and the box-shaped column, and finally welding the butt weld seam between the wing plate of the cross column and the cover plate of the box-shaped column , and the connecting weld between the cross column and the box column adopts slotted external plug welding, which avoids opening welding holes at the end of the cross column or outside the box column and affecting the appearance of the component, and realizes the cross column and box column The welding quality is controllable, and the cross box section welding process is optimized.

Owner:YCIH STEEL STRUCTURE CO LTD

An eddy current resistance welding device and welding method for foil miniature parts

InactiveCN110405333BPrevent unfused phenomenonReduce areaHigh frequency current welding apparatusResistance welding apparatusElectrical resistance and conductanceEngineering

Owner:WUHAN UNIV

A Nanoparticle-Driven Method for Low-Energy Ultrasonic Metal Welding

ActiveCN111715993BImprove mechanical propertiesImprove thermal conductivityNon-electric welding apparatusRough surfaceUltrasonic welding

The invention provides a method for nanoparticle-driven low-energy ultrasonic metal welding, which includes: preparing nanoparticle paste or powder; coating the surface to be welded with 1-50 μm thick nanoparticle paste or powder on the upper and lower layers of the metal to be welded, Ultrasonic welding is then performed at room temperature or under heating. Adopting the technical scheme of the present invention, the traditional solid-phase connection at the peak of the rough surface in the ultrasonic welding process, as well as the size effect, frictional heating effect and gap filling effect of the nano-particles in the gap are integrated, thereby realizing lower ultrasonic welding input energy Form a good ultrasonic welded joint, simplify the production process, reduce the impact of the material to be welded, and improve the sealing performance of the weld seam, the mechanical properties of the welded joint, and the electrical and thermal conductivity.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Longitudinal supporting frame of automobile transverse stabilizing bar

ActiveCN103434360BEasy to passImprove torsion resistanceInterconnection systemsOmegaUltimate tensile strength

The invention discloses a longitudinal supporting frame of an automobile transverse stabilizing bar. The longitudinal supporting frame comprises a longitudinal supporting frame body with the U-shaped cross section, an omega-shaped clamping hoop is connected to the front end of the longitudinal supporting frame body, the clamping hoop is formed in the mode that the bottom face of the longitudinal supporting frame body forwards extends, and an outward turning edge is arranged at the back end of the longitudinal supporting frame body. A strengthening piece provided with the U-shaped cross section and formed by sheet metal parts in a whole stamping mode is arranged in the longitudinal supporting frame body, the front end of the strengthening piece is welded with the arc face of the clamping hoop, and the two sides of the strengthening piece are welded with the two sides of the longitudinal supporting frame body. The longitudinal supporting frame is high in strength and good in bearing capacity, and can solve the problems of deformation and weld failures in the using process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

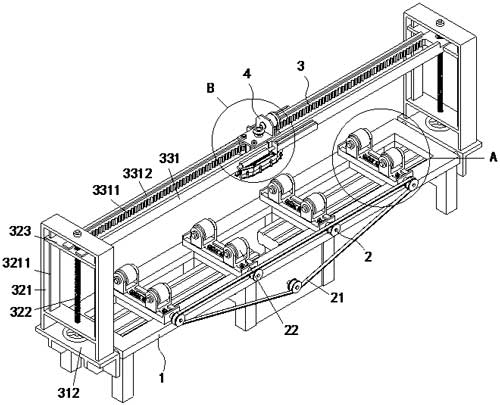

A seam guide device for longitudinally welded pipe production

ActiveCN114378497BAchieving Parallel PositioningRealize automatic guided weldingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSeam welding

The invention relates to the technical field of welded pipe welding processing, and specifically proposes a weld guide device for straight seam welded pipe production, including a support frame, an adjustable idler group mechanism assembled on the support frame, and a welding guide mechanism assembled on the support frame And the welding walking device assembled on the welding guide mechanism; the adjustable roller group mechanism can support the welded pipe horizontally to realize the parallel positioning of the weld seam, and the welding walking device is assembled on the welding guide mechanism, and the submerged arc welding Part of the welding walking device can be used as a supporting carrier, and the long frame-shaped guide rail cooperates with the welding walking device for walking guidance, thereby replacing the manual automatic guiding welding of the welding position of the welded pipe. The welding quality is controllable and is not affected by human factors. In addition , There are two coaming plate assemblies arranged on the welding walking device, so the flux can be collected and reused in a centralized manner during the whole welding process, which improves the utilization rate of the flux and avoids waste.

Owner:河北华洋钢管有限公司

Automatic speed changer shell body and welding method thereof

ActiveCN103104678BWelding quality is easy to controlExtended service lifeGearboxesGear lubrication/coolingAutomatic transmissionUltimate tensile strength

Owner:SHANGHAI JIAOYUN AUTOMOTIVE POWER SYST

An automated system for producing toothed plate structures in car seats

InactiveCN106862765BImprove yield rateNo human intervention requiredLaser beam welding apparatusCharging stationLaser

Owner:上海唐立工业科技有限公司

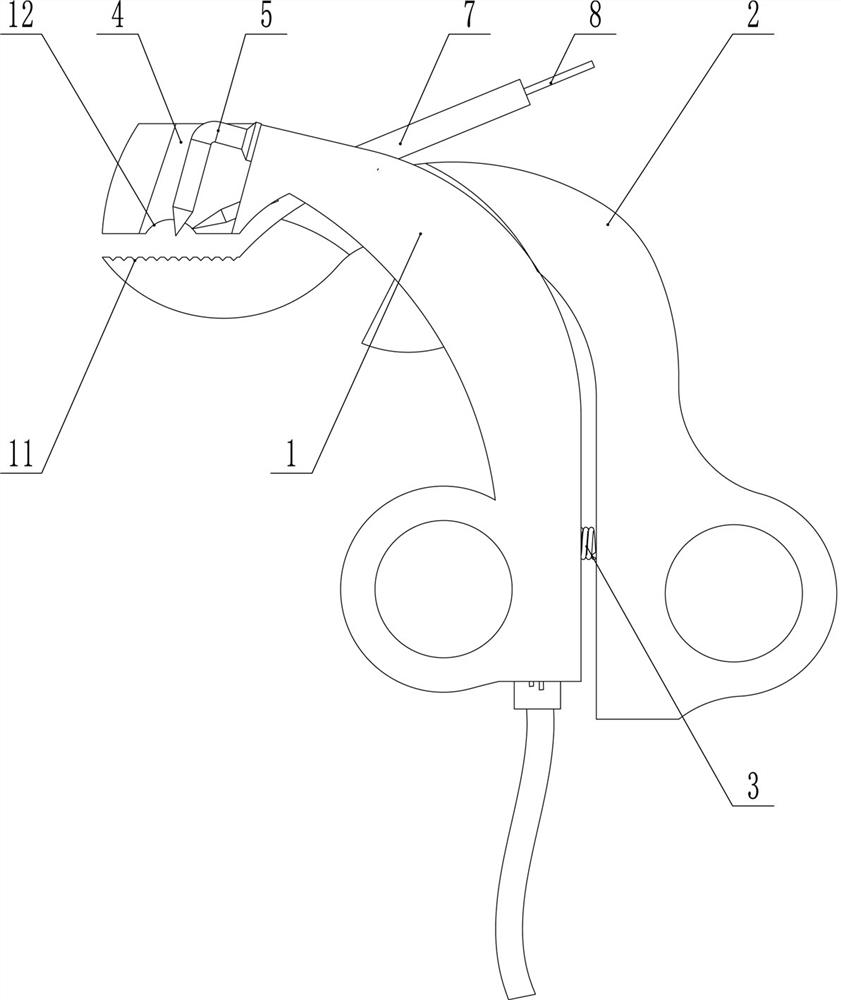

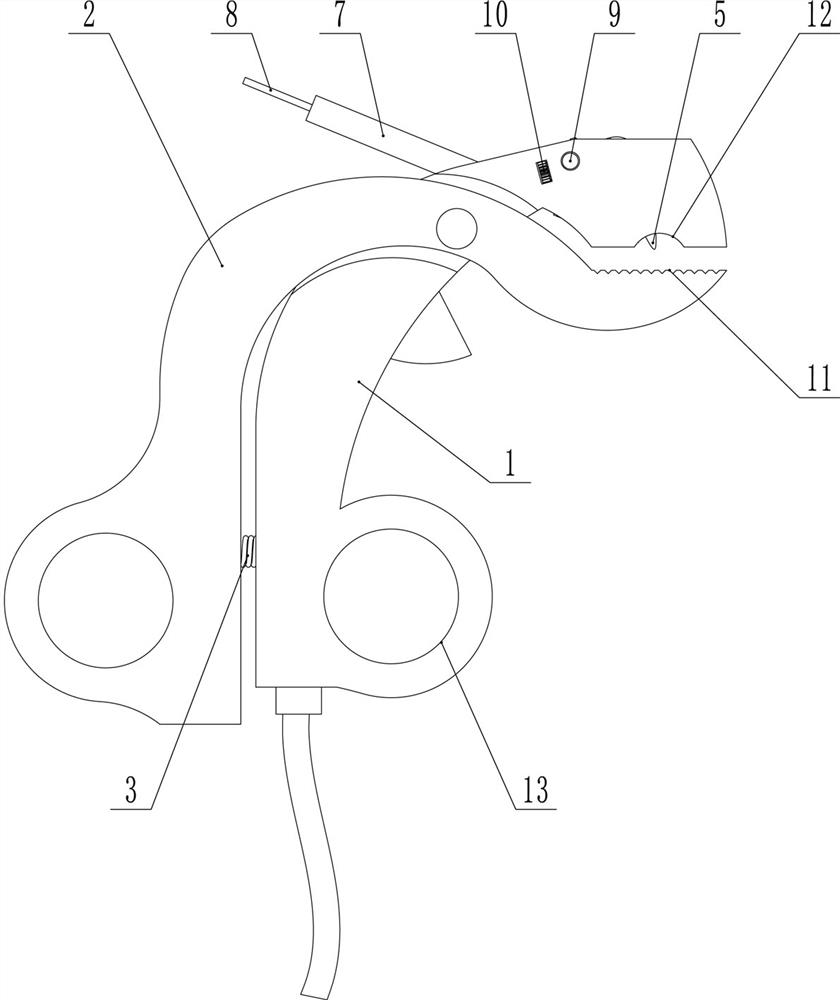

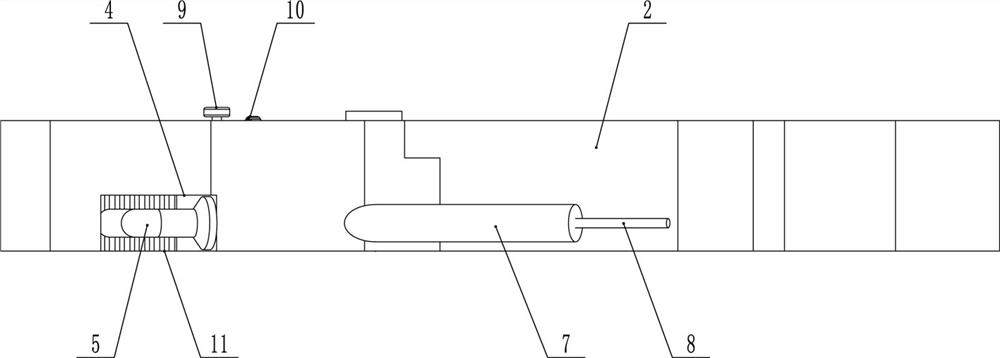

Scissor type integrated tin welding gun

PendingCN114523171AAchieve natural clampingImplement dippingSoldering ironSolder feeding devicesMechanical engineeringMaterials science

The invention provides a scissor type integrated tin welding gun which comprises a scissor type clamping mechanism, an electric iron complexing mechanism and a tin feeding cavity channel, the scissor type clamping mechanism comprises a first hinge piece and a second hinge piece, and the head of the first hinge piece and the head of the second hinge piece are provided with wire clamping mechanisms matched with each other. A tension spring is connected between the tail of the first hinge piece and the tail of the second hinge piece, the first hinge piece is provided with an installation cavity channel and a head welding groove, the head welding groove and the wire clamping mechanism are arranged side by side, and the side face of the head welding groove is open; the electric iron winding mechanism comprises an iron winding head, a power line, a driving mechanism and a jacking switch, the rear end of the iron winding head is rotatably installed at the front end of the installation cavity channel, the iron winding head is contained in the head welding groove, the tin inlet cavity channel penetrates through the head of the first hinge piece, and the outlet end of the tin inlet cavity channel extends to the position close to the wire clamping mechanism. The scissor type integrated tin welding gun has the advantages of being scientific in design, capable of being operated by one person, easy in welding quality control and high in practicability.

Owner:ZHENGZHOU UNIV +1

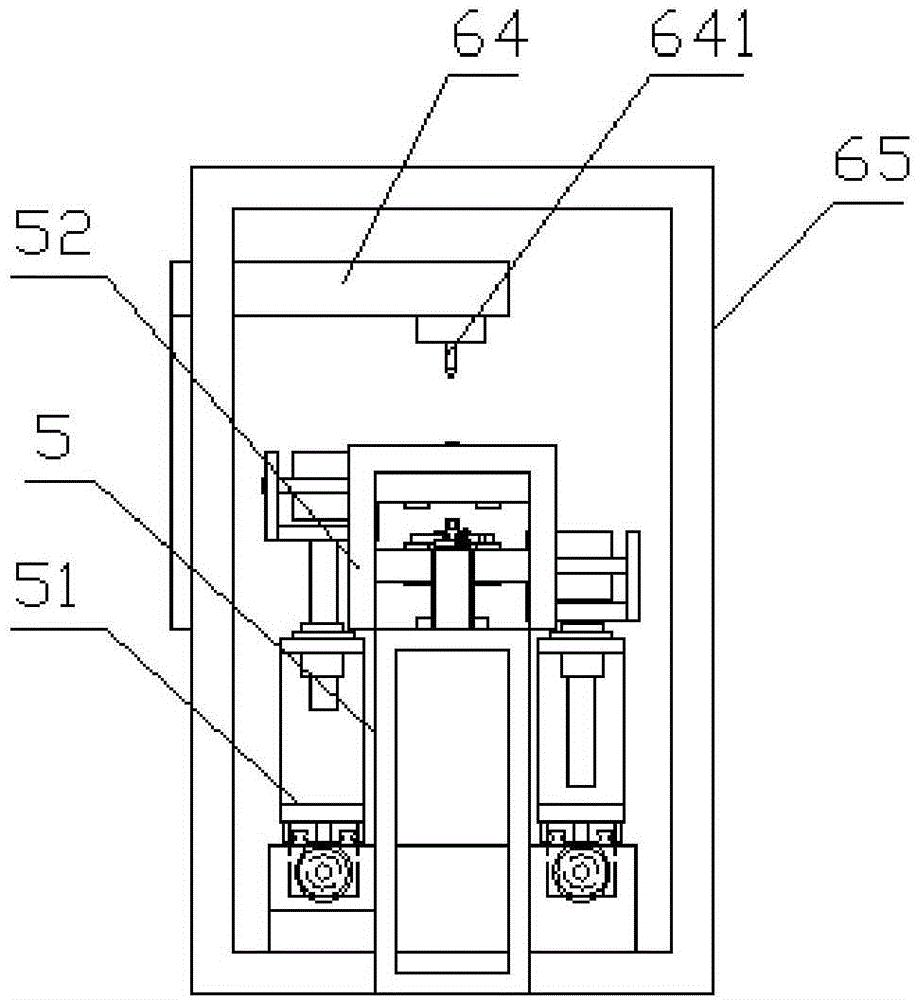

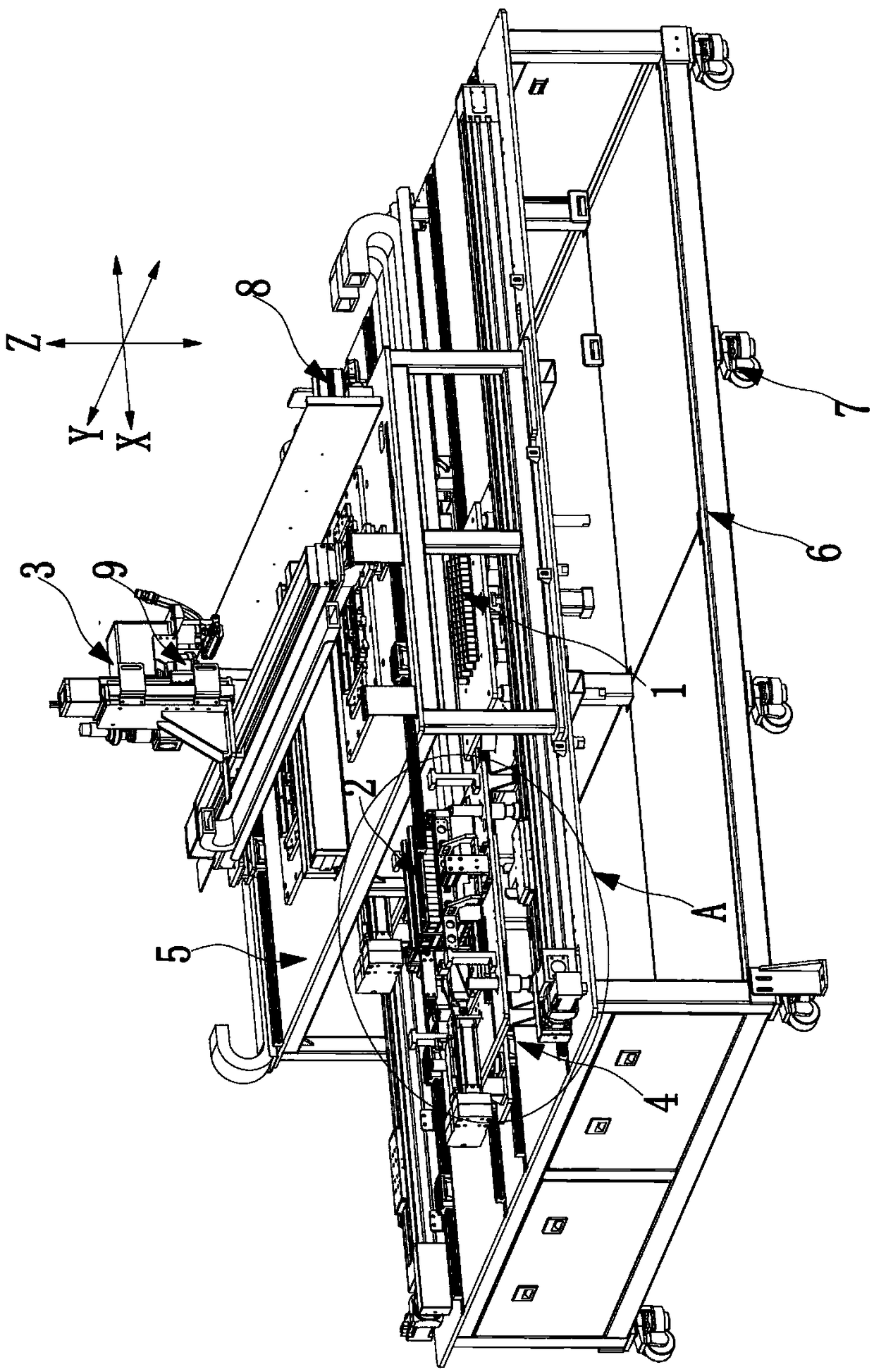

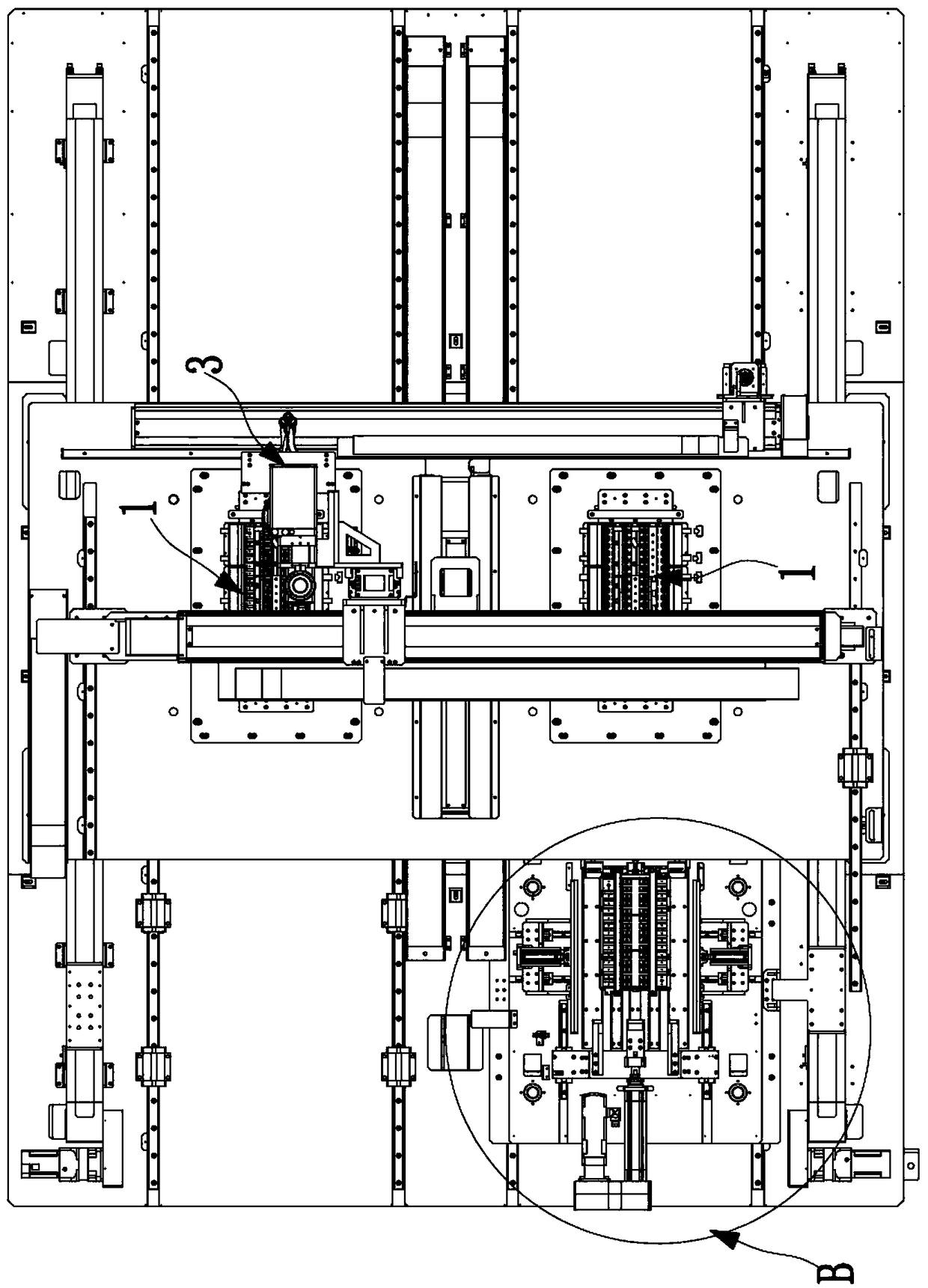

Cell module BUSBAR welding robot and machining method thereof

PendingCN108772638AExquisite designSimple structureWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionBusbar

The invention discloses a cell module BUSBAR welding robot and a machining method thereof. The welding robot comprises at least one false welding prevention device and a welding device, wherein the false welding prevention devices limit cell modules with BUSBARs in a welding position, and enable at least electrode part of each cell in the cell module to tightly bond with the BUSBARs in a self-adaption manner; and the welding device at least can perform a reciprocating motion in a first direction and a second direction, and adopts non-contact welding to realize connection between the cell modules and the BUSBARs. The welding robot can perform self-adaption adjustment according to the fitness between the electrodes of each cell and the BUSBARs through a set of extension columns, so that theelectrodes of each cell are tightly bonded with the BUSBARs, the false welding condition during welding can be effectively prevented, and the welding quality is fully guaranteed; and meanwhile, the non-contact welding mode is adopted without considering adverse effect on the welding quality from the factors of welding voltage, welding pressure, welding needles and the like, so that the welding process is easy to control, the automation degree is high, the welding quality is stable, and the efficiency is high.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

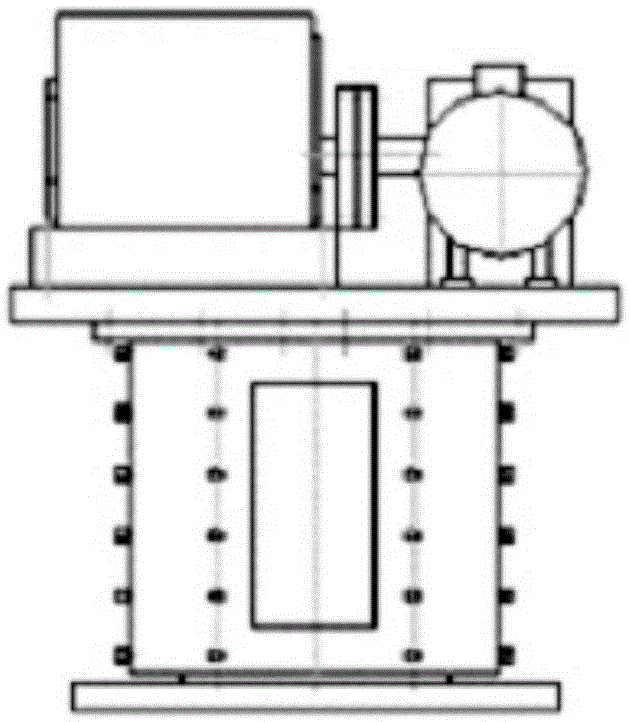

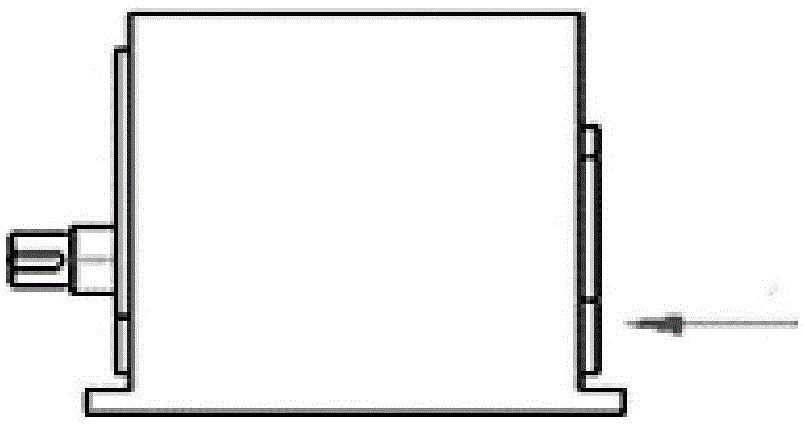

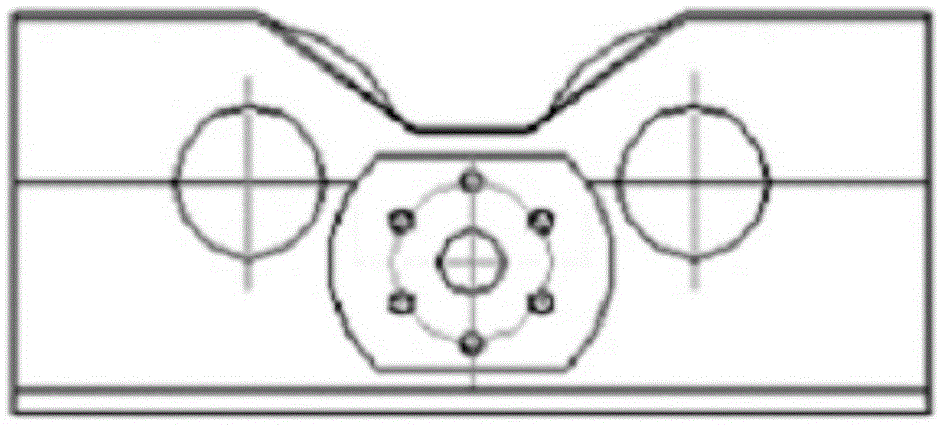

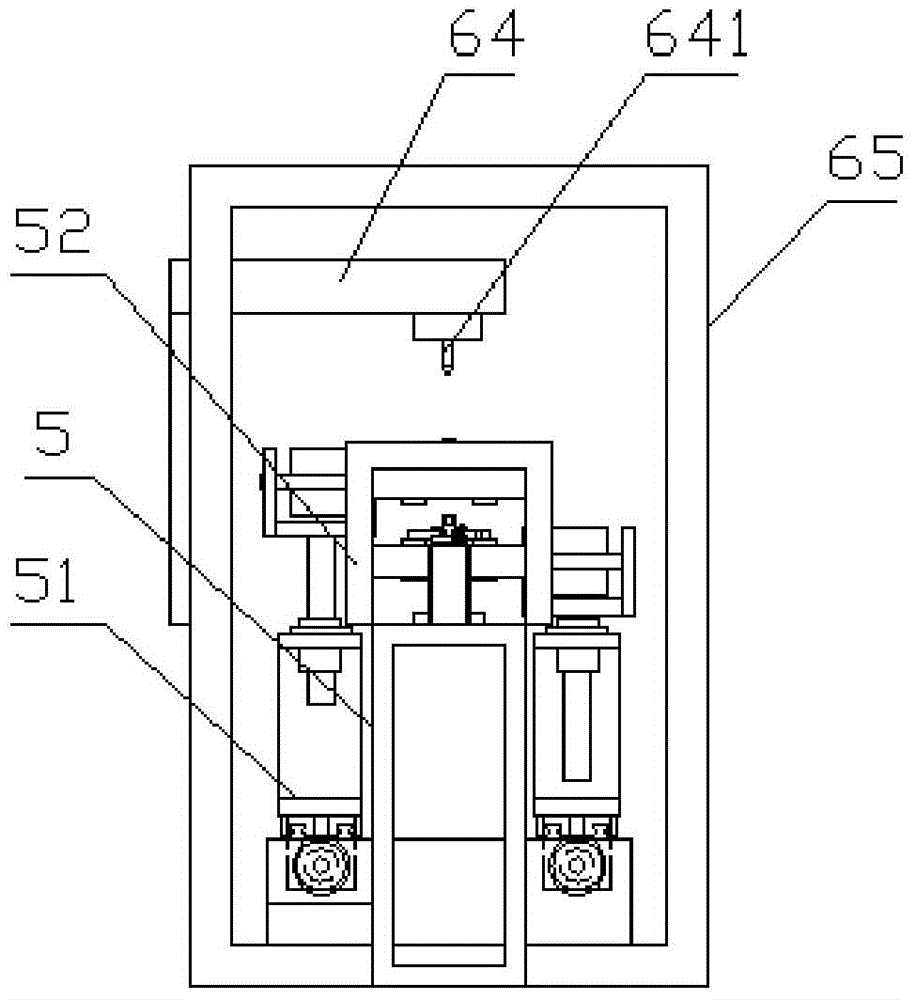

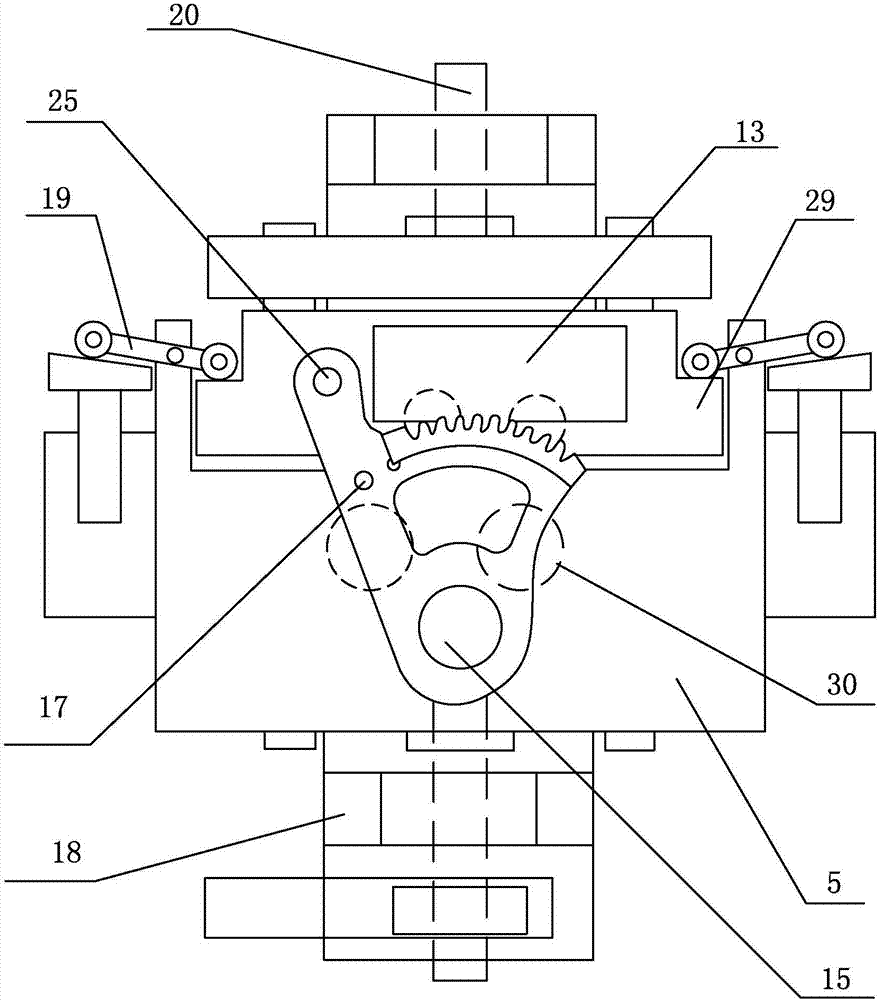

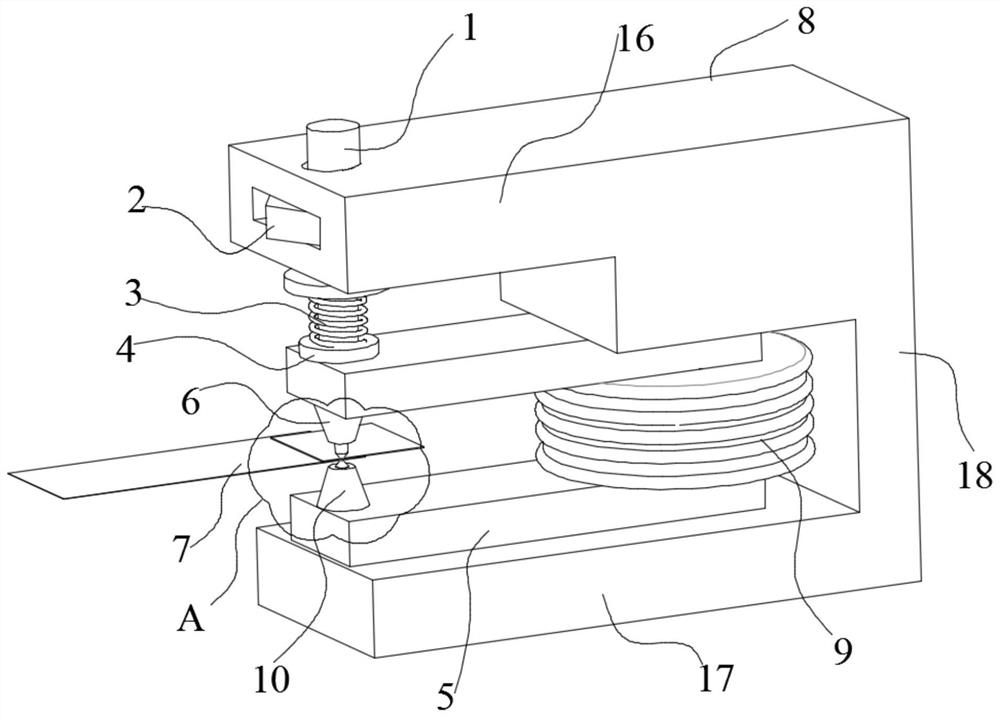

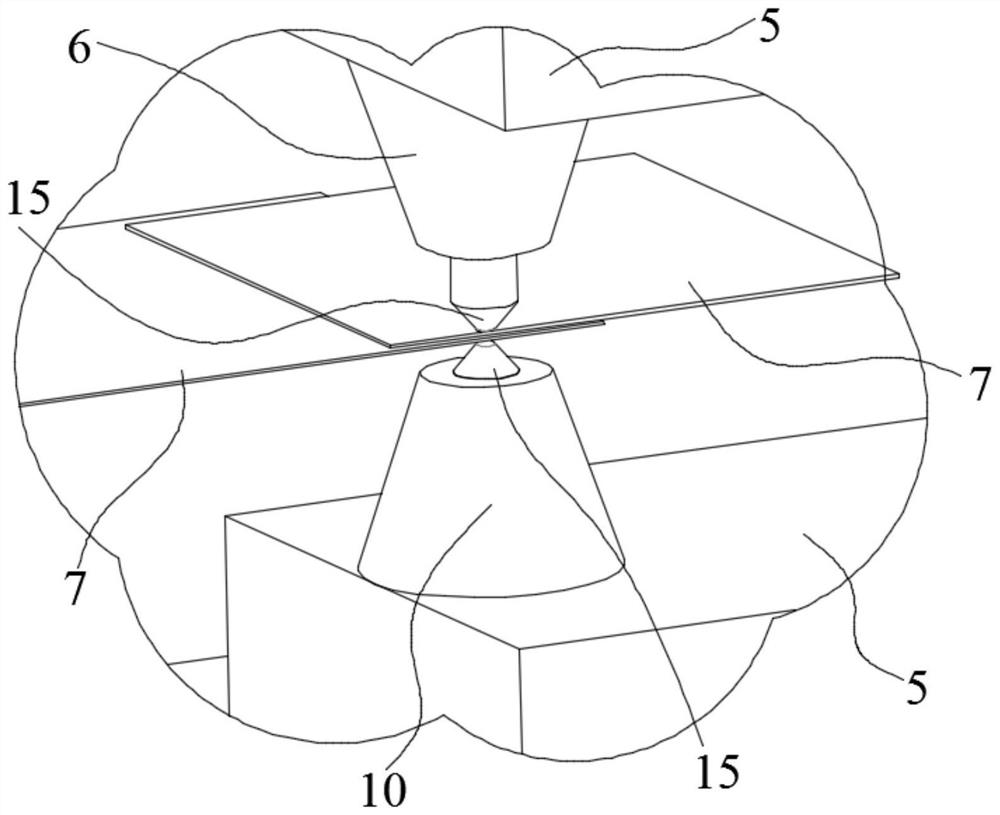

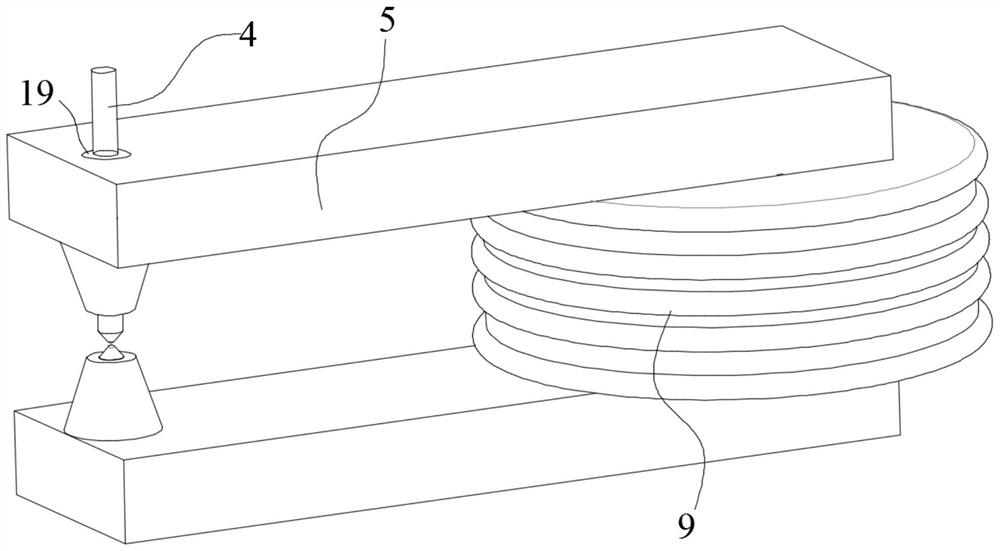

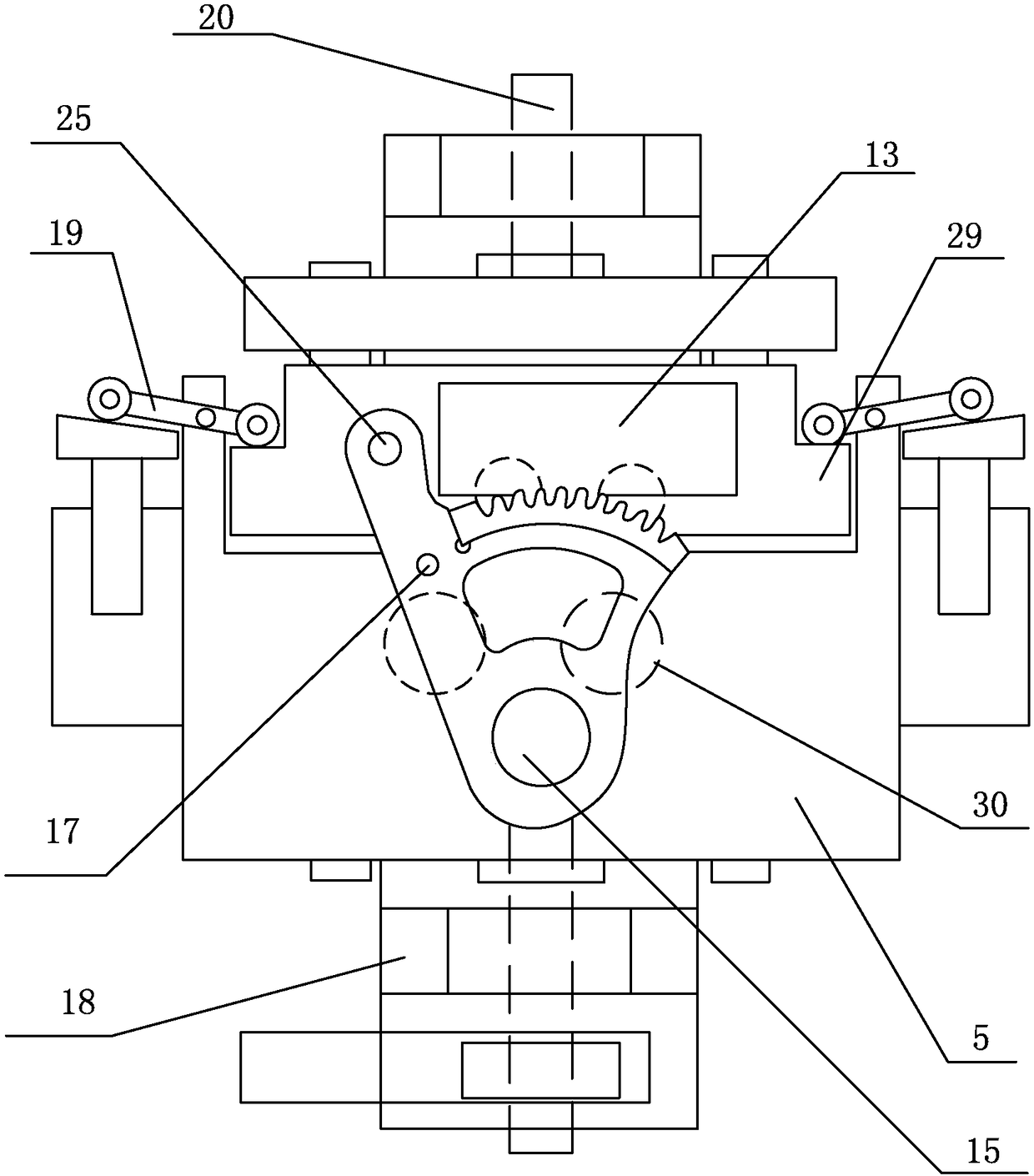

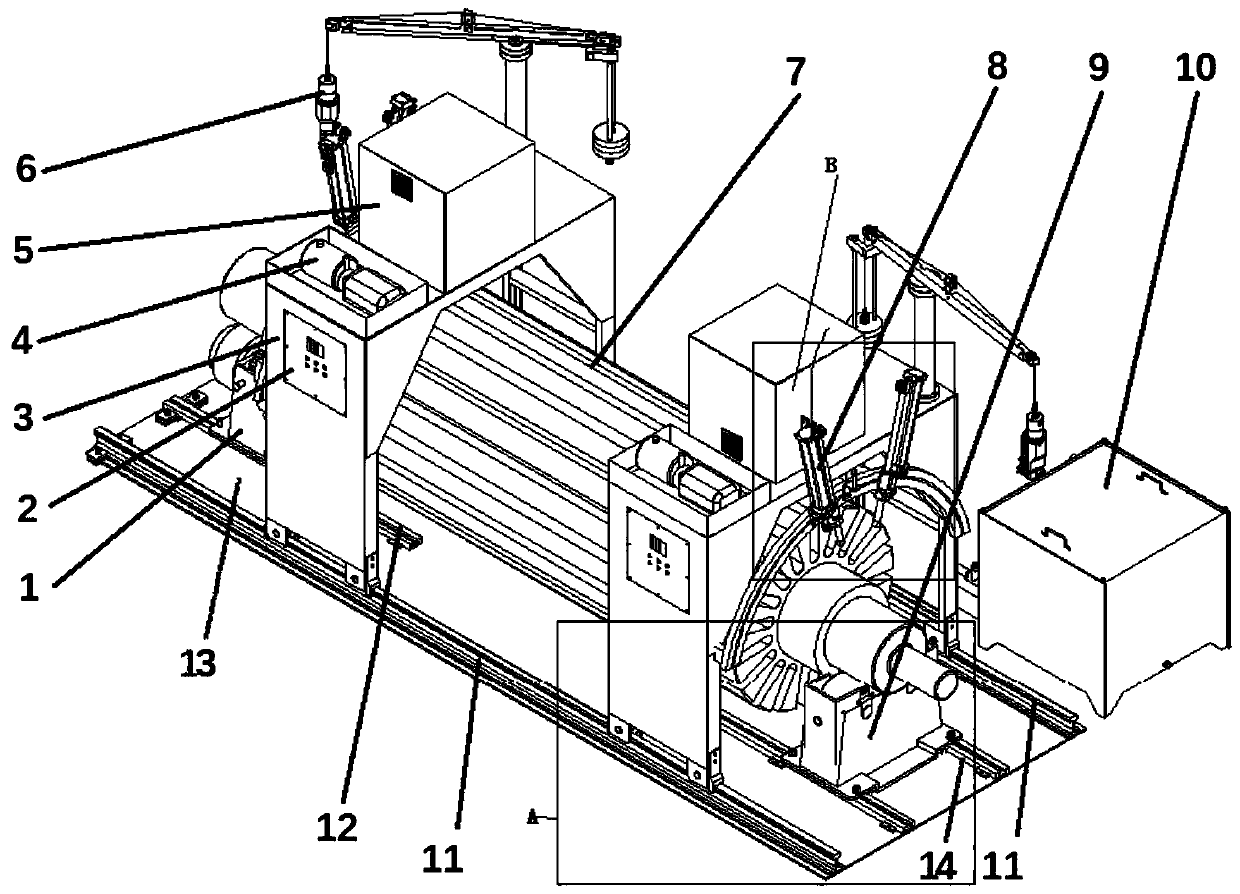

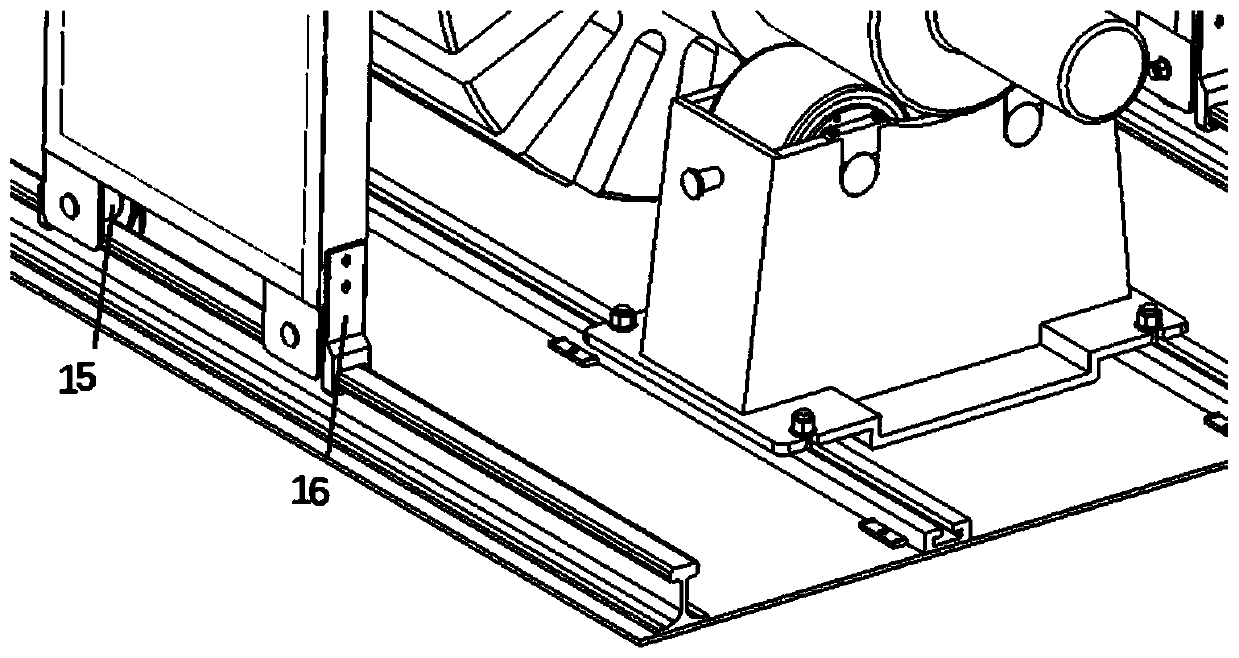

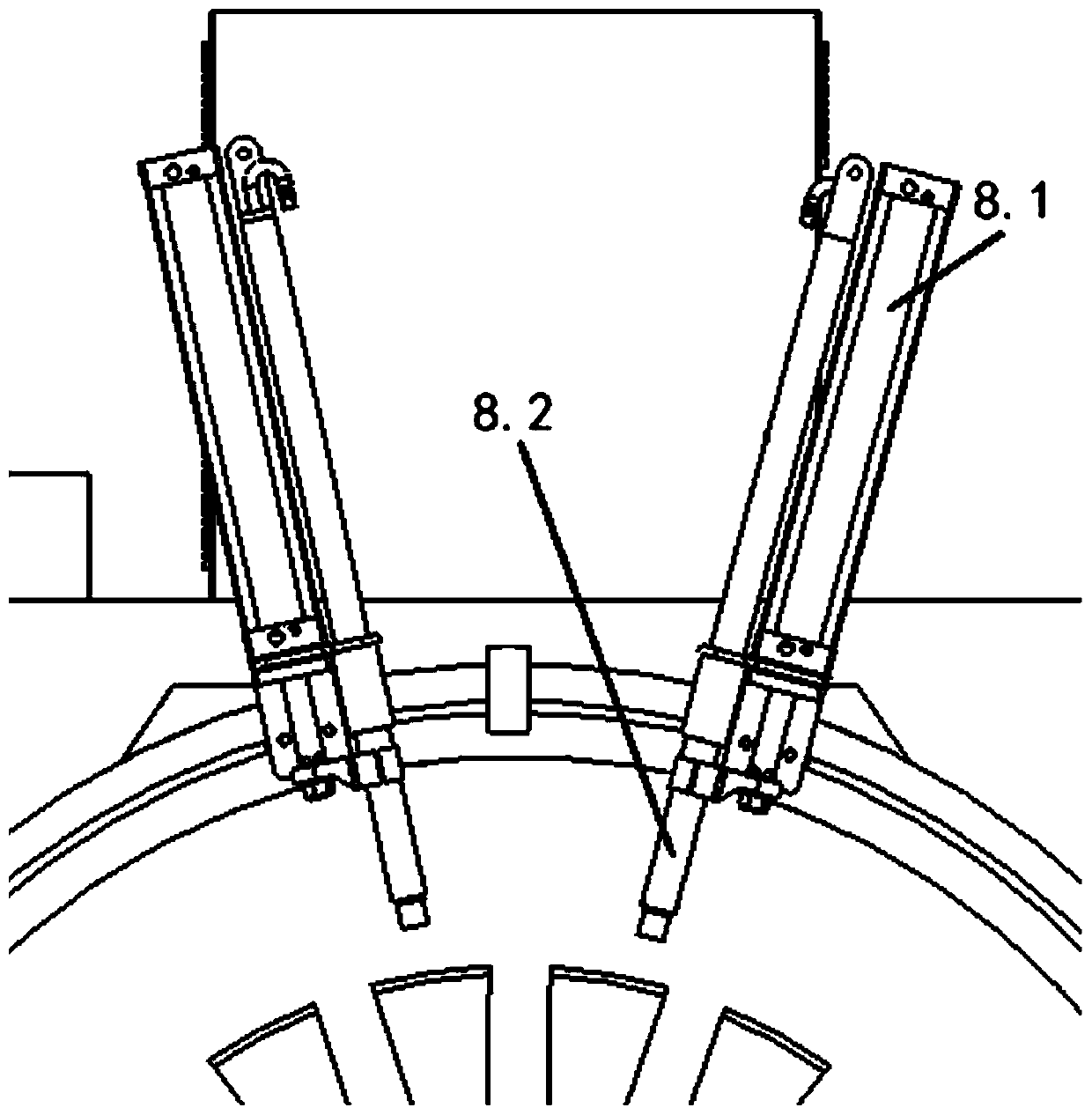

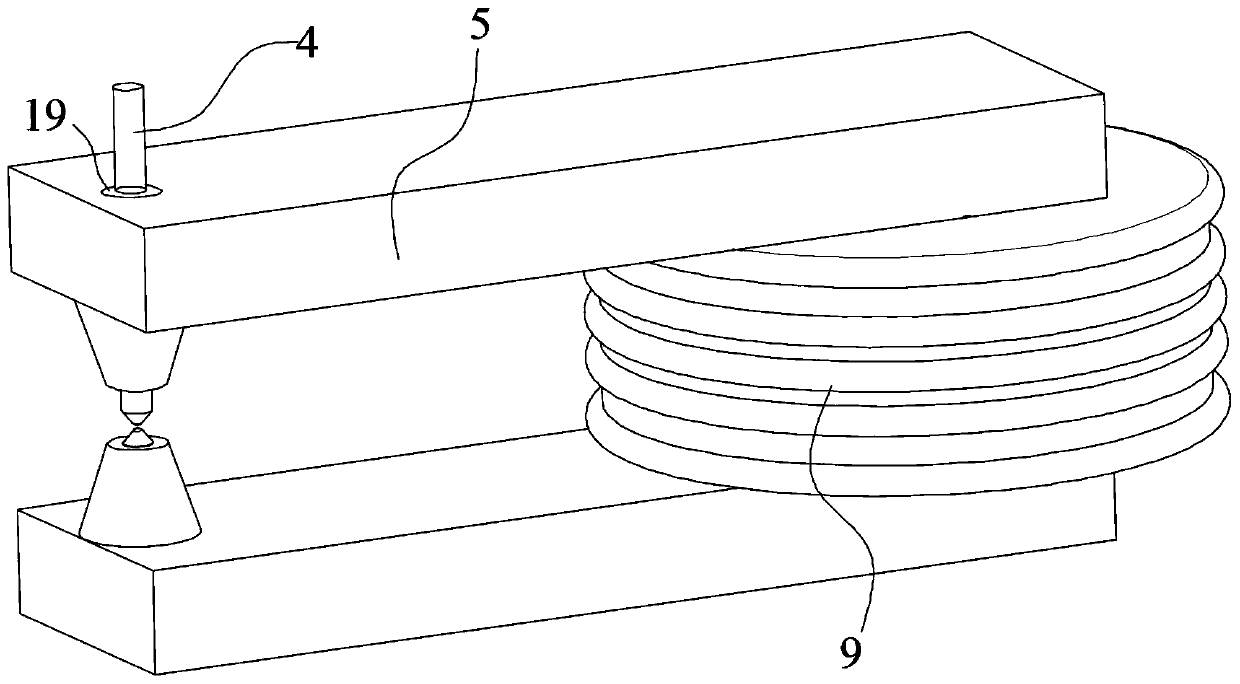

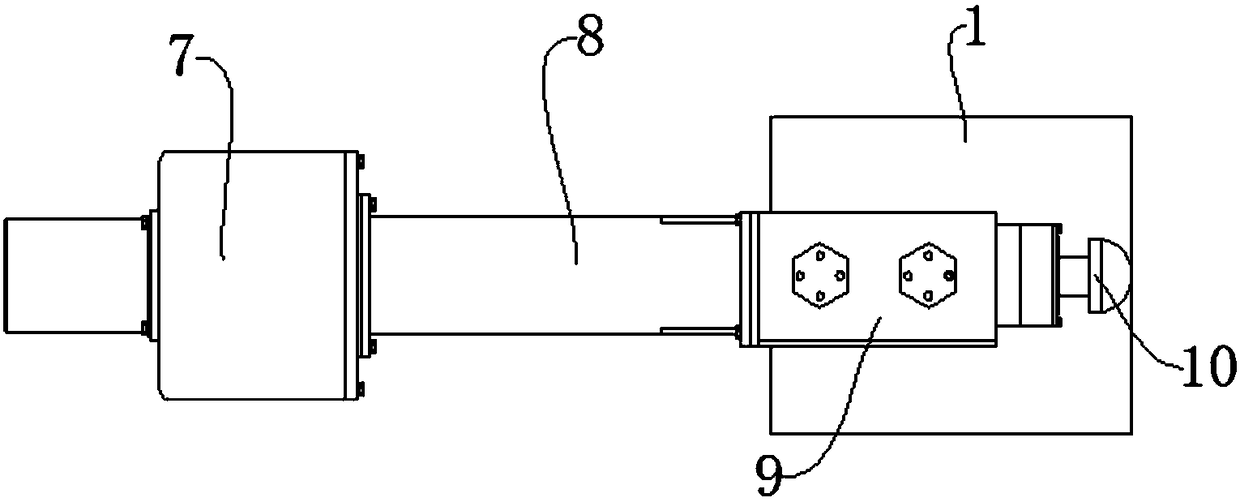

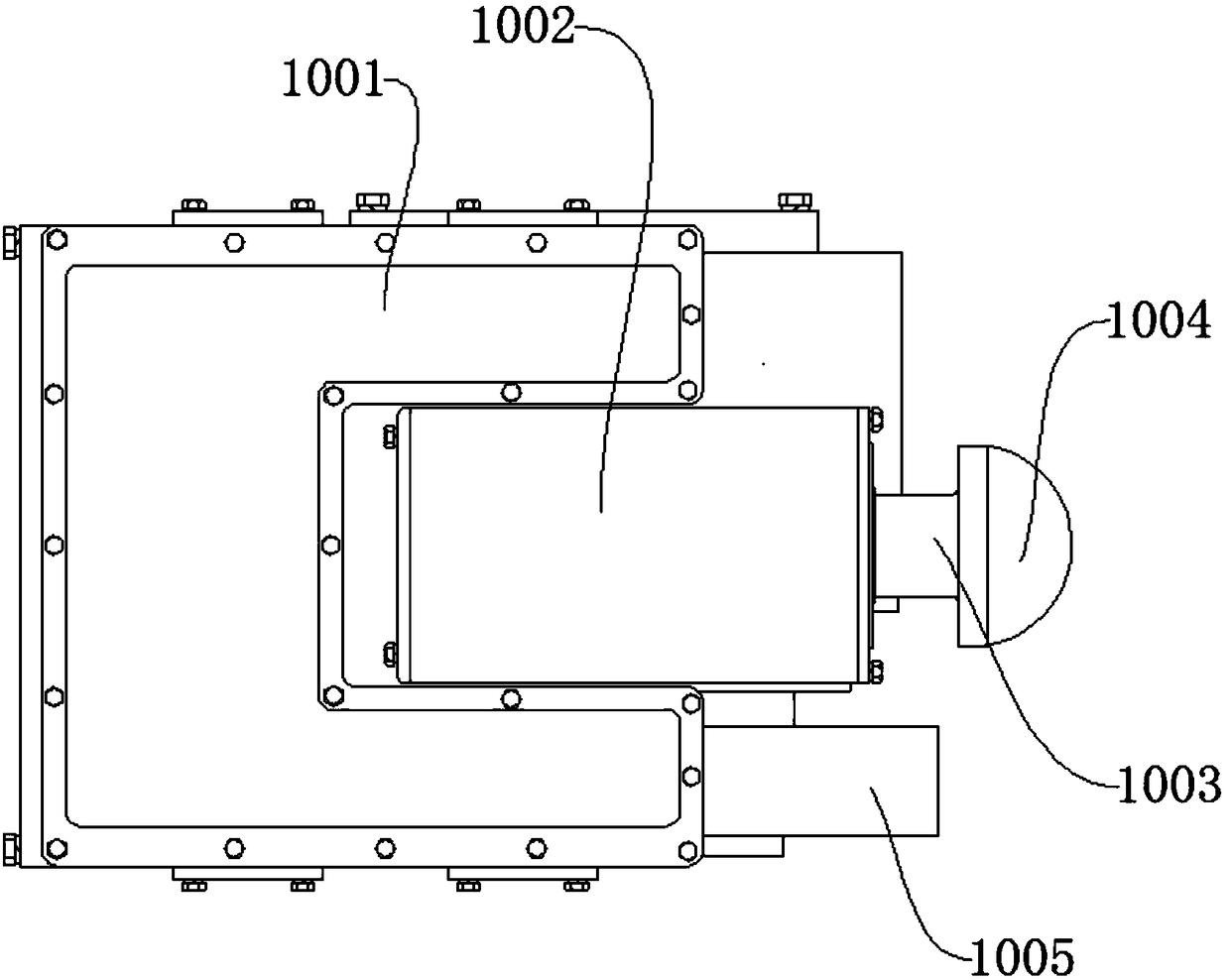

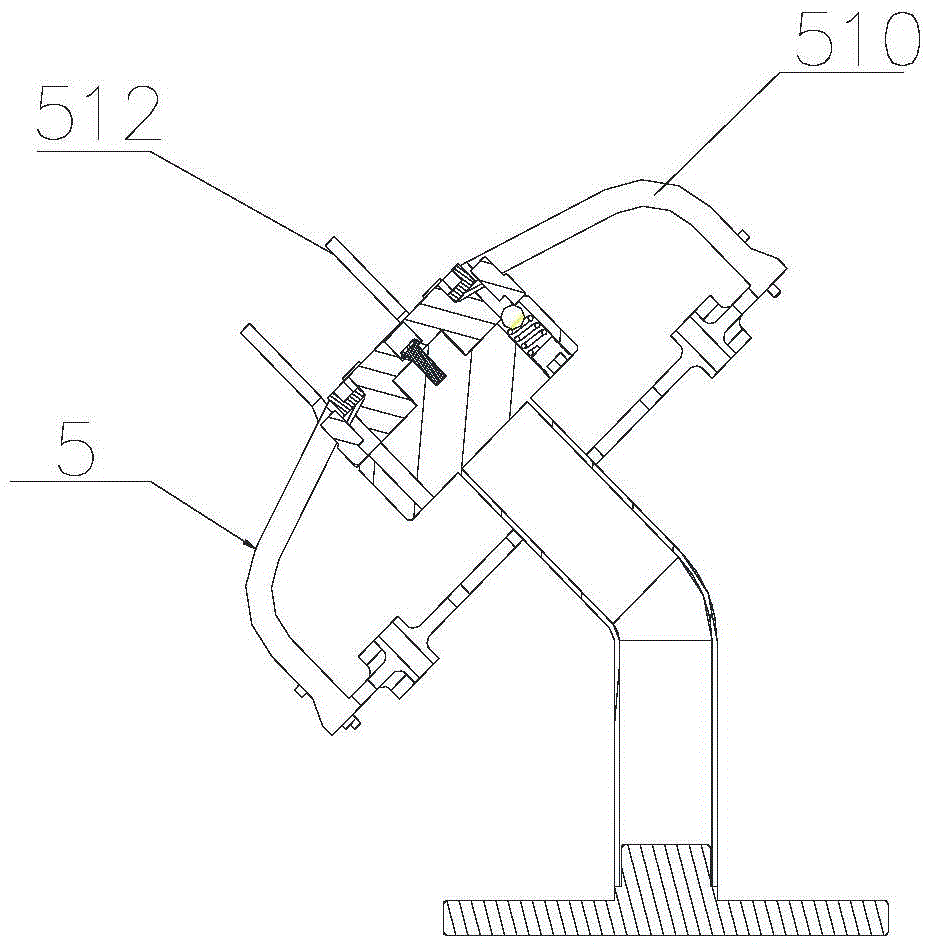

Resistance butt welding machine for welding rotor coils of steam turbine generator set

PendingCN110153540AWelding quality is easy to controlHigh resistance welding qualityCoils manufactureResistance welding apparatusElectrical resistance and conductanceButt welding

The invention relates to a resistance butt welding machine for welding rotor coils of a steam turbine generator set. The resistance butt welding machine for welding the rotor coils of the steam turbine generator set comprises a fixed platform. A first pair of guide rail mechanisms are arranged on the fixed platform. A second pair of guide rail mechanisms and a third pair of guide rail mechanisms are arranged between the first pair of guide rail mechanisms. The axes of the first pair of guide rail mechanisms, the second pair of guide rail mechanisms and the third pair of guide rail mechanisms are overlapping. A number of welding table systems are arranged on the first pair of guide rail mechanisms through sliding grooves. Each welding table system comprises an inverted-arranged U-shaped welding support. Each welding support is provided with a hydraulic pump, a heating transformer and a shaping hydraulic shear. A controller is arranged on one side of each welding support. The resistancebutt welding machine for welding the rotor coils of the steam turbine generator set has the beneficial effects that the rotor welding quality of the generator set is easy to control, and the resistance welding quality is high; it is easy for the operating staff to master the welding method, and the assembling technology of a large-scale generator set is simplified; both sides work simultaneously,and efficiency is high; and overturning is assisted by rolling racks, and working efficiency and safety are improved.

Owner:河北力特工程机械有限公司

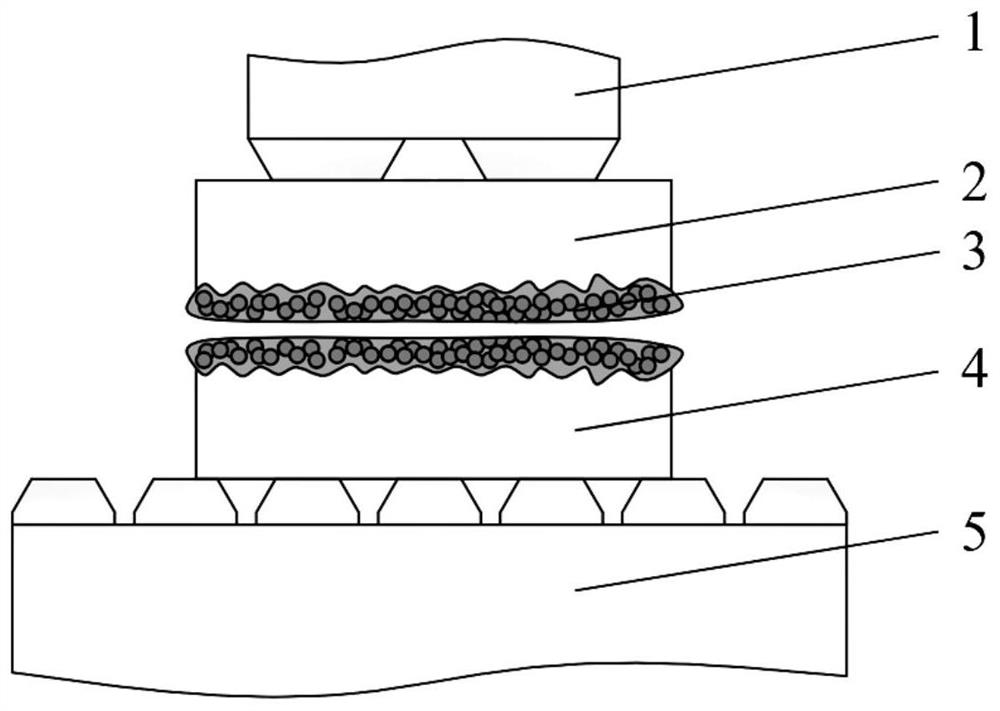

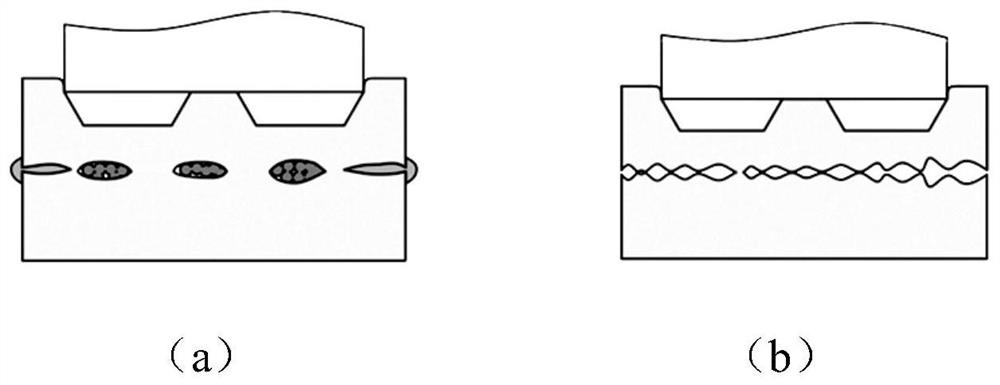

Vortex electric resistance welding device for foil micro-pieces and welding method thereof

InactiveCN110405333APrevent unfused phenomenonReduce areaHigh frequency current welding apparatusResistance welding apparatusElectrical resistance and conductanceHigh intensity

The invention discloses a vortex electric resistance welding device for foil micro-pieces and a welding method thereof. The vortex electric resistance welding device comprises a U-shaped magnetic core, an alternating magnetic field generating device, an upper electrode and a lower electrode, wherein the alternating magnetic field generating device is arranged on the rear portion of the U-shaped magnetic core and is used for providing alternating magnetic fields for the U-shaped magnetic core, the upper electrode and the lower electrode are oppositely arranged on the inner sides of the front ends of two limbs of the U-shaped magnetic core and are used for clamping to-be-welded foil micro-pieces, the upper electrode and the lower electrode are made of insulating magnetizers, and the U-shapedmagnetic core is used for conducting the alternating magnetic fields into the upper electrode and the lower electrode. According to the device, after the surfaces of the to-be-welded foil micro-pieces are cleaned up, the to-be-welded foil micro-pieces overlap each other in an up and down mode and are laid between the upper electrode and the lower electrode; a high-frequency oscillating circuit isstarted, the alternating magnetic fields are generated by the high-frequency oscillating circuit and are intensively gathered at the electrodes; and high-intensity vortexes are generated on the foilsin areas which are covered by the electrodes to heat work pieces, so that welding is completed under the electrode pressure. The device is suitable for ultra-thin work pieces, low in welding cost, easy to operate, easy to implement and high in production efficiency.

Owner:WUHAN UNIV

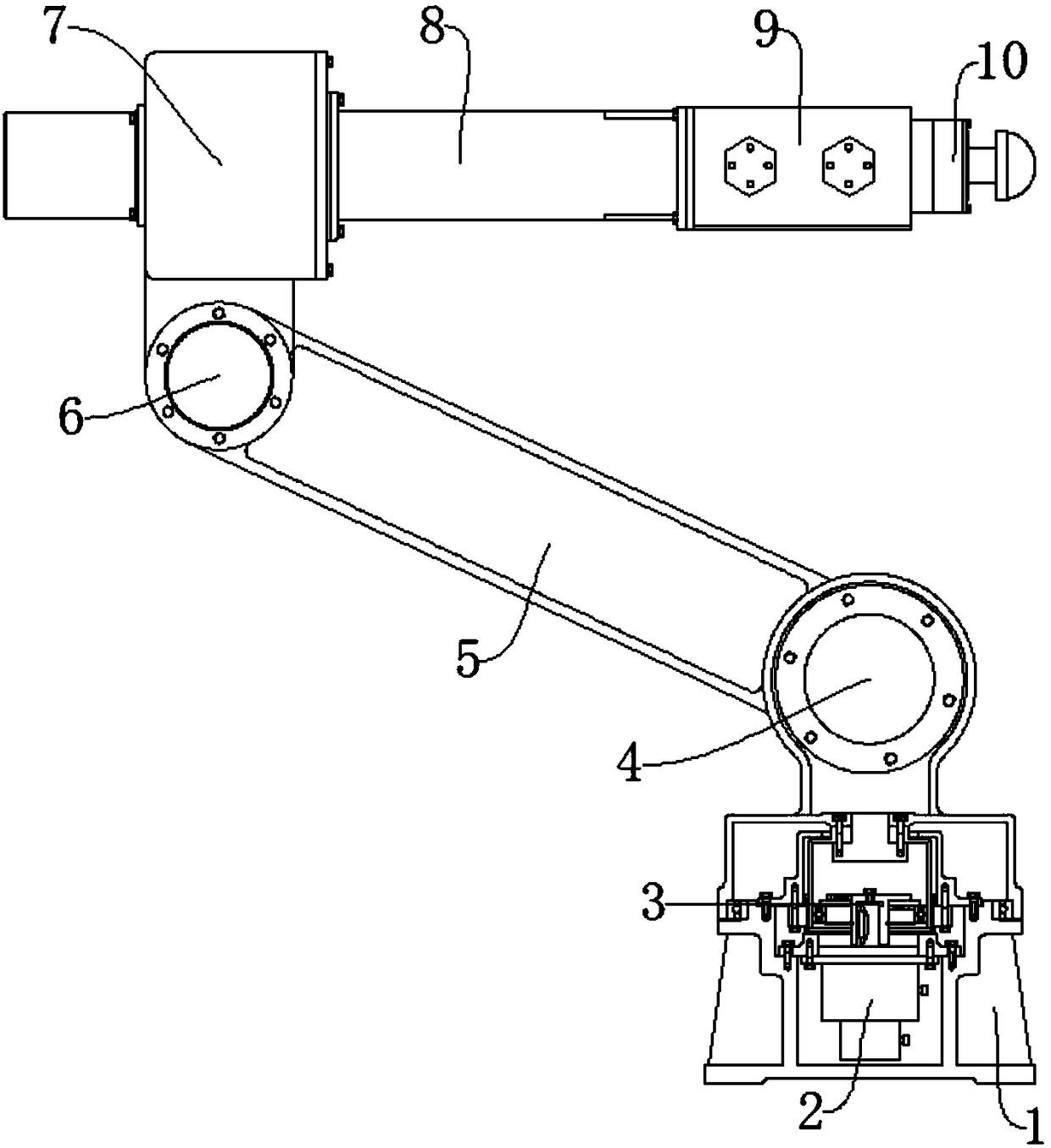

Welding robot

InactiveCN108406789AHigh degree of automationWelding quality is easy to controlManipulatorNon-electric welding apparatusFriction weldingAutomatic control

The invention discloses a welding robot and belongs to the field of welding equipment. The welding robot comprises a base, a second motor and a friction welder. A first motor is arranged inside the base, the first motor is connected with a rotating shaft at the bottom through a transmission box, the rotating shaft at the bottom is connected with a rotating shaft on the top through a large arm, therotating shaft on the top is arranged below the second motor, the second motor is connected with an automatic controller through a small arm, the automatic controller is connected with the friction welder, the friction welder is composed of a clamping sleeve, a friction welding machine, a buckle type joint pin, a friction head and a positioning device, the friction welding machine is arranged inside the clamping sleeve, and the friction welding machine and the friction head are connected through the buckle type joint pin. The welding direction and angle can be automatically controlled and adjusted, a to-be-welded portion is subjected to positioning and friction welding treatment through automatic positioning, and the welding robot has the advantages of being high in automation degree, controllable in welding quality and low in cost.

Owner:WUHU HAILIAN MACHINERY INSTALLATION

An automatic argon arc welding device for rotary parts

ActiveCN108274098BGood welding consistencyEasy to controlWelding accessoriesElectric controlAir cylinder Press

The invention discloses a rotary body part automatic argon arc welding device. The welding device is composed of a mechanical part, an electric control part and a pneumatic control part, and mainly comprises an electrode holder, an electrode holder clamp, a wire feeder, a rotary servo motor, a wire feeding servo motor, a telescopic air cylinder, a sliding table air cylinder and the like. During work, the telescopic air cylinder presses and positions a workpiece needing to be welded, then an argon switch works, the sliding table air cylinder moves forwards to enable a welding wire and the workpiece to be welded, meanwhile, the rotary servo motor and the wire feeding servo motor rotate synchronously, after the rotary servo motor rotates by one circle, the sliding table air cylinder retracts,argon supply is stopped, and welding is completed. The welding device is accurate in control and high in automation degree, and can meet requirements of different welding beads.

Owner:JILIN TEACHERS INST OF ENG & TECH

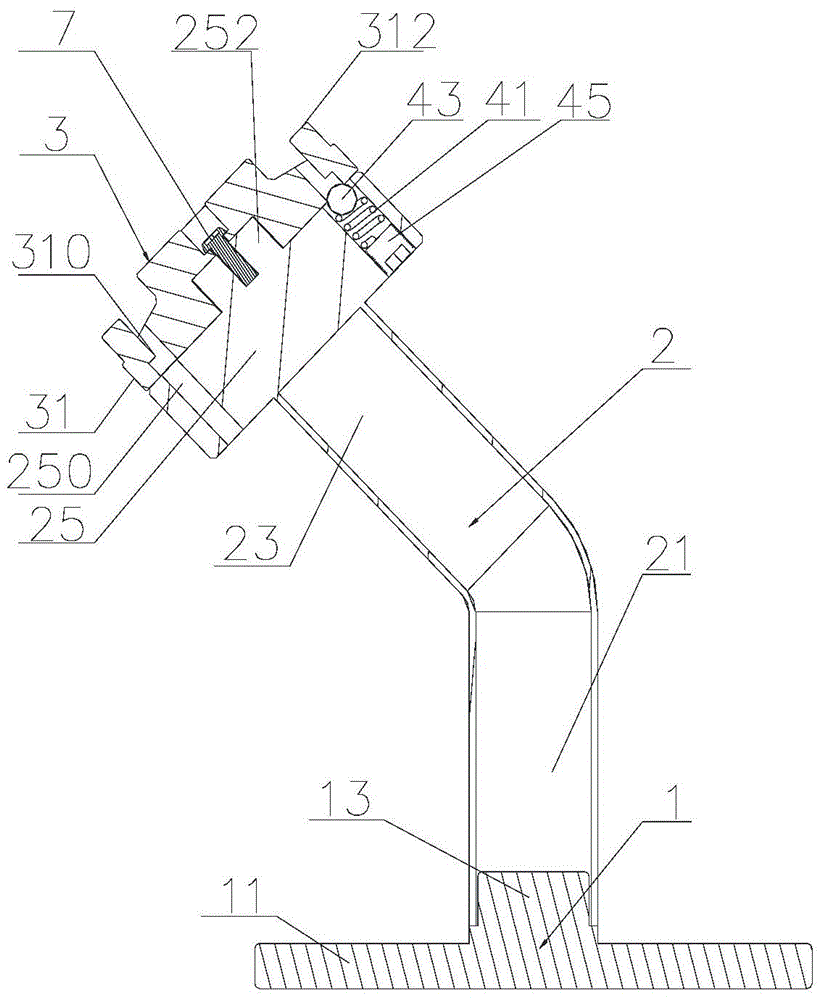

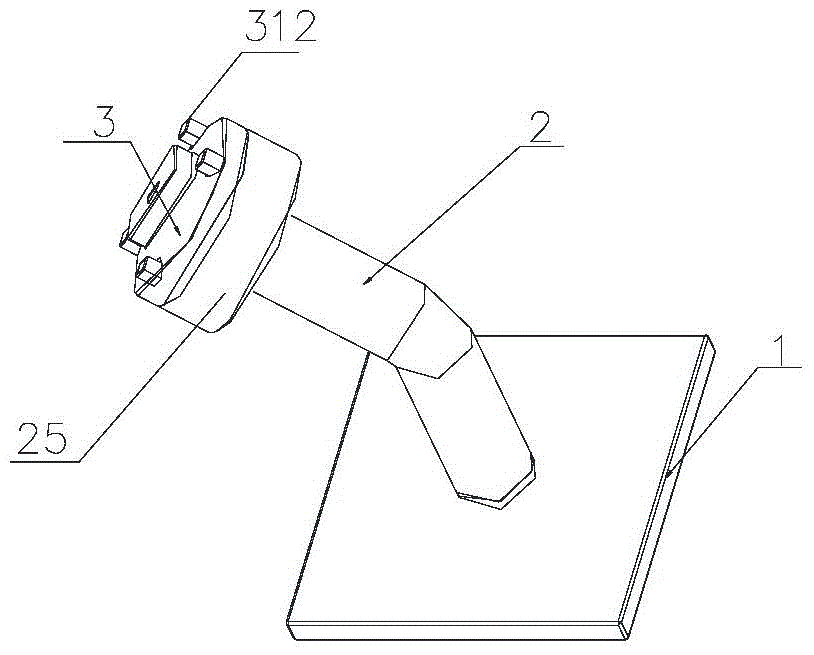

Vibrator feeder welding tooling

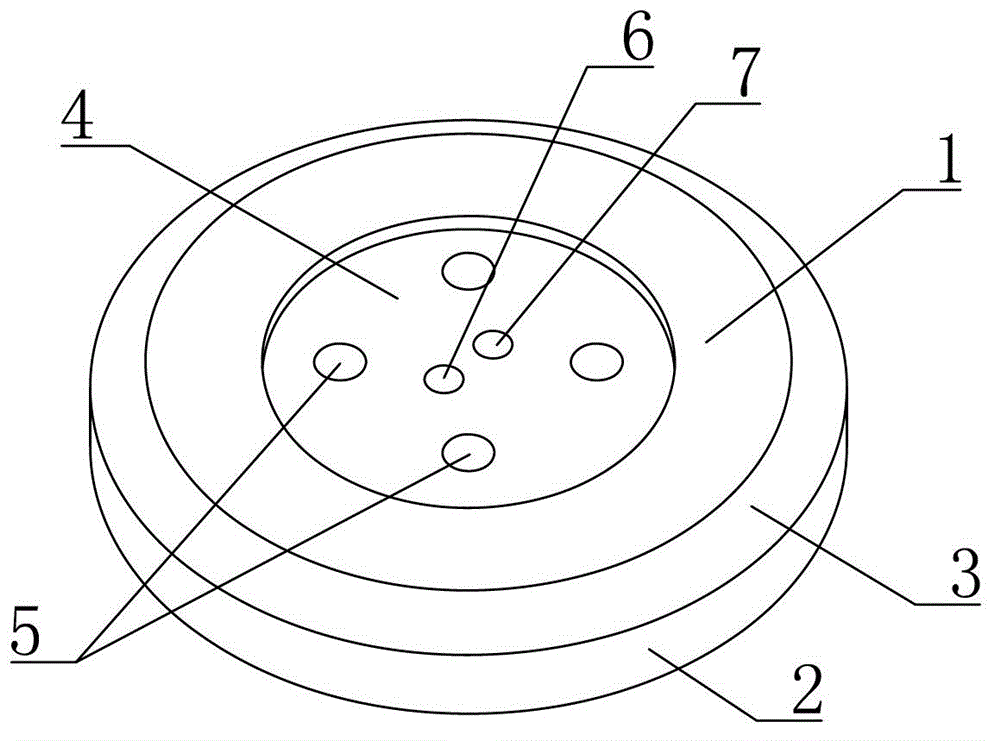

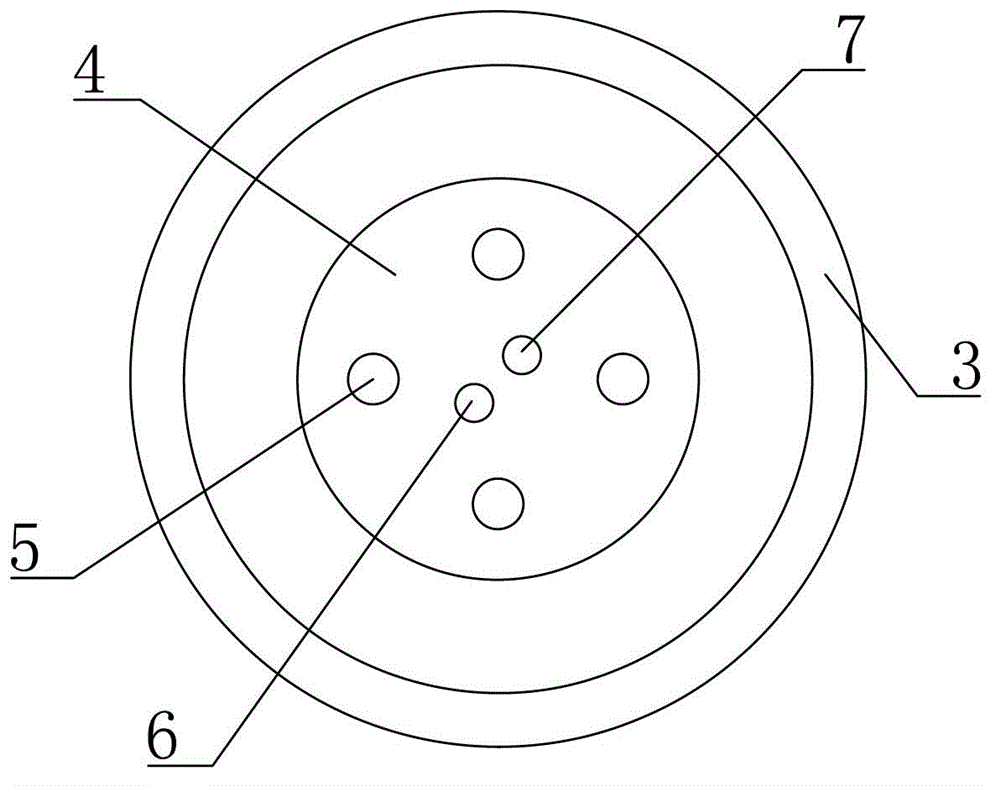

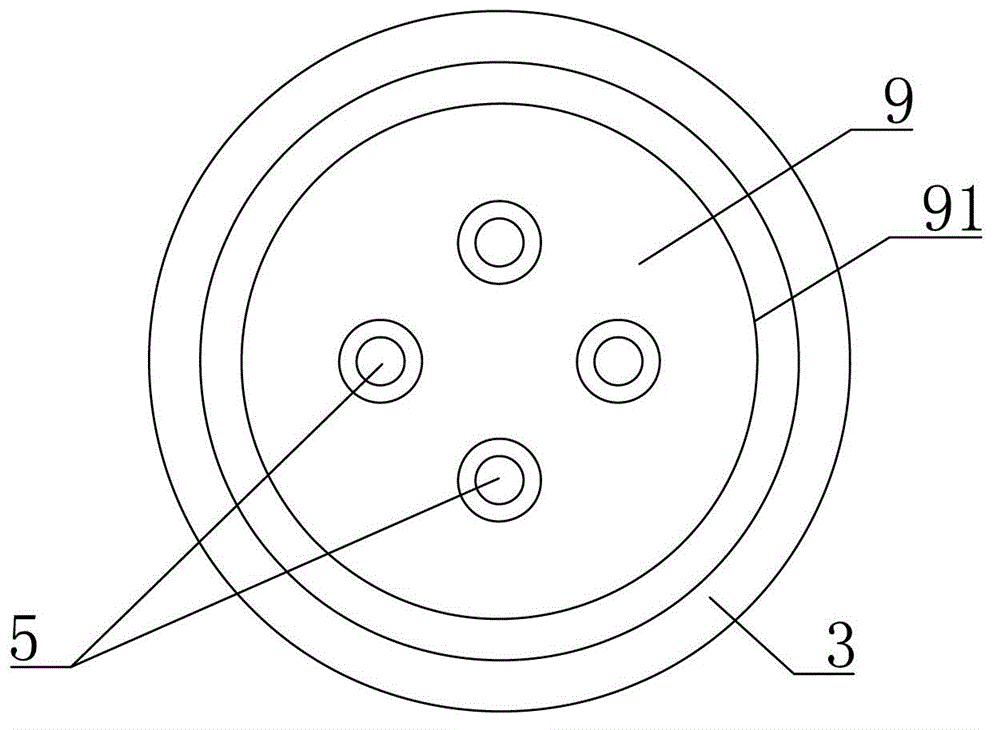

ActiveCN104588829BPrecise positioningImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to an oscillator feeder line welding tool. The oscillator feeder line welding tool comprises a support body (2), a fixing piece (3) for mounting an oscillator, and a connecting piece (7); the fixing piece (3) is detachably connected to the support body (2) through the connecting piece (7); an elastic positioning piece (4) for limiting the relative position of the support body (2) and the fixing piece (3) is also arranged between the support body (2) and the fixing piece (3); the fixing piece (3) also comprises a positioning hole (310) which is matched with the elastic positioning piece (4); the support body (2) comprises a support plate (25) which is used for supporting the fixing piece (3); the support plate (25) comprises accommodating holes (250); the elastic positioning piece (4) comprises an elastic piece (41) and a positioning piece (43) which are sequentially accommodated in the accommodating holes (250); the positioning piece (43) is matched with the positioning hole (310) of the fixing piece (3); the elastic piece (41) provides an elastic force directed to the positioning hole (310) for the positioning piece (43). The oscillator feeder line welding tool disclosed by the invention can be conveniently and rapidly operated, so that the welding process is stable and the welding quality is easily controlled; the welding efficiency is improved; the manpower is reduced; the production cost is reduced.

Owner:SHENZHEN EPLU SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com