Resistance butt welding machine for welding rotor coils of steam turbine generator set

A turbogenerator set and rotor coil technology, applied in resistance welding equipment, coil manufacturing, welding equipment, etc., can solve complex problems, achieve high work efficiency, easy welding quality, and welding quality control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

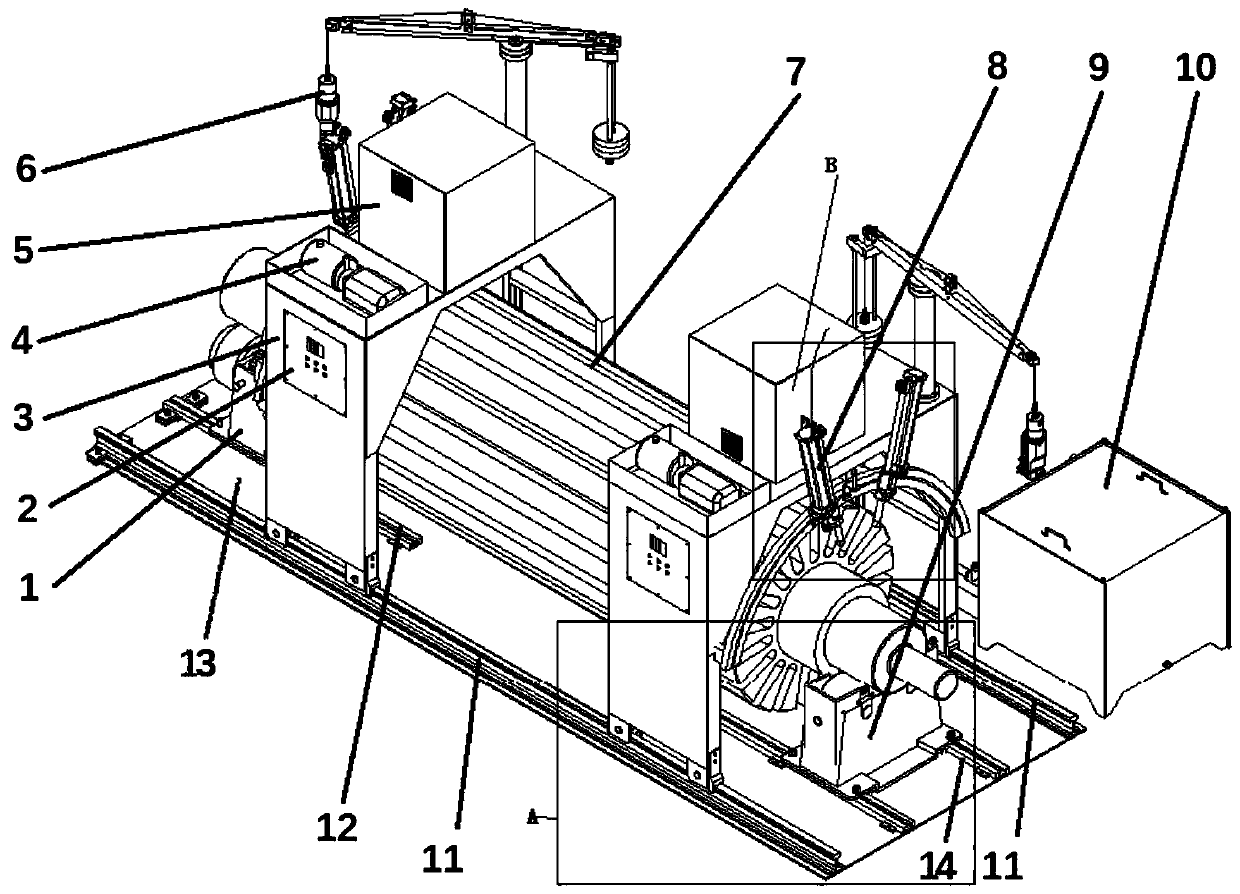

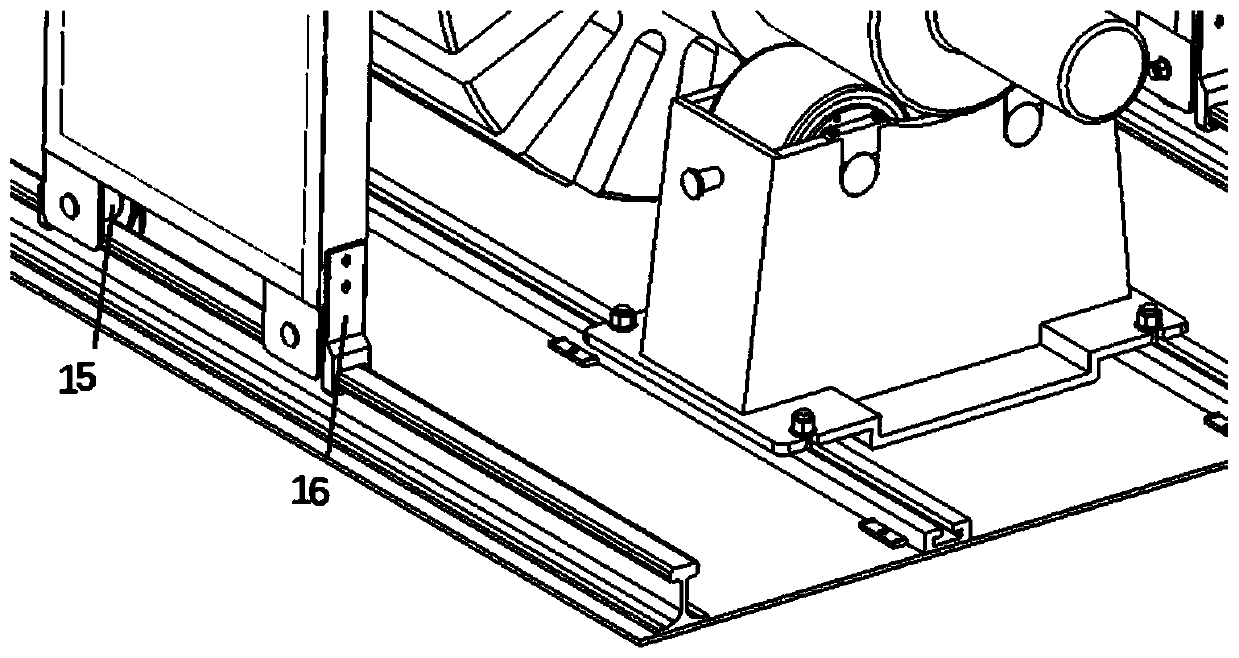

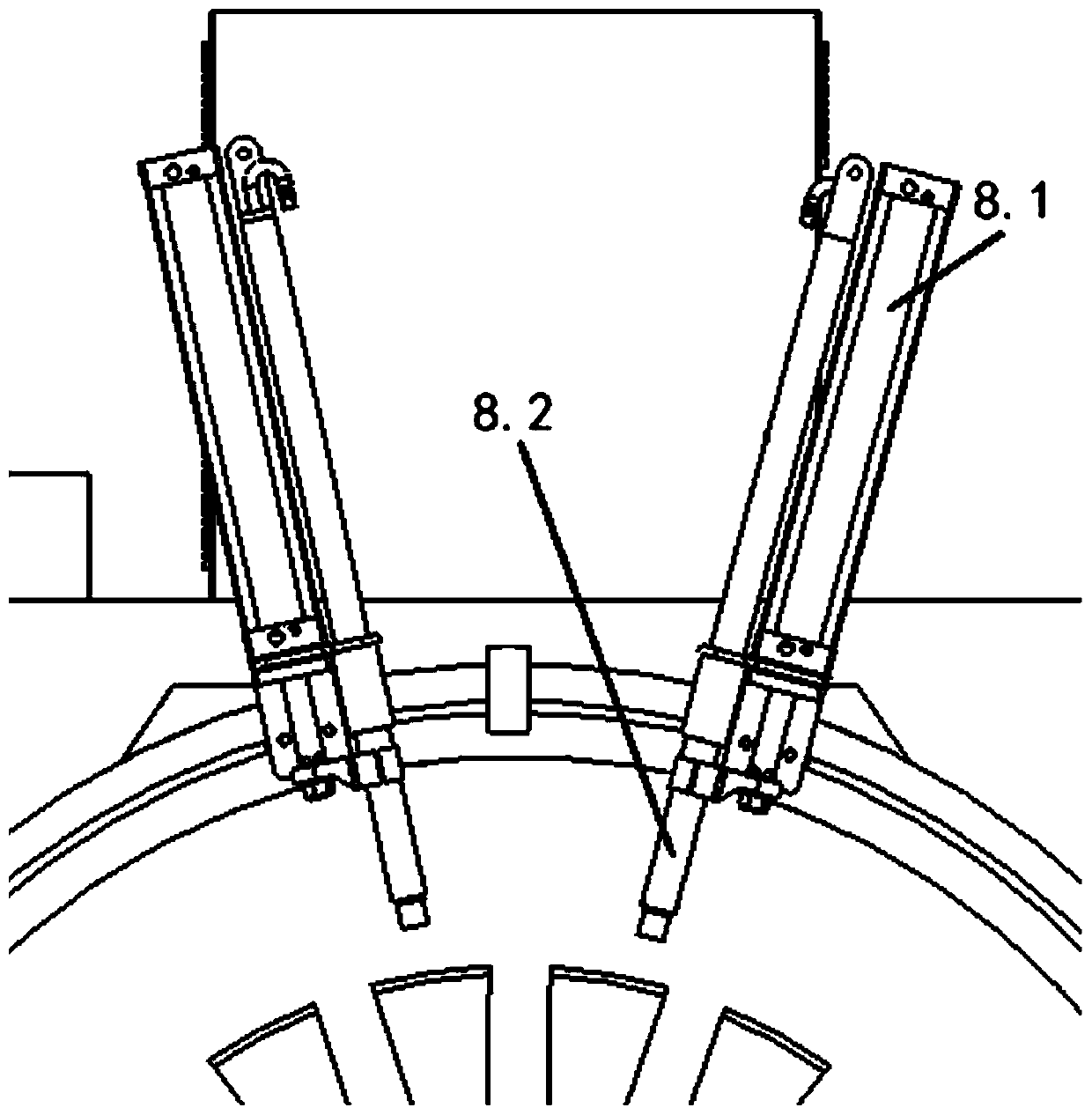

[0026] Such as Figure 1-7 As shown, a resistance butt welding machine for welding the rotor coil of a turbogenerator set according to an embodiment of the present invention includes a fixed platform 13 on which a first pair of guide rail mechanisms 11 is arranged. A second pair of guide rail mechanisms 12 and a third pair of guide rail mechanisms 14 are arranged in the middle of the guide rail mechanism 11. The axes of the first pair of guide rail mechanisms 11, the second pair of guide rail mechanisms 12 and the third pair of guide rail mechanisms 14 coincide, so The first pair of guide rail mechanisms 11 are provided with several welding station systems through chutes, and the welding station system includes an inverted U-shaped welding support 3, and the welding support 3 is provided with a hydraulic pump 4, a heating transformer 5 and a shaping machine. Hydraulic scissors 6, a controller 2 is provided on one side of the welding support 3, the hydraulic pump 4 and the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com