Patents

Literature

124 results about "Air cylinder Press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

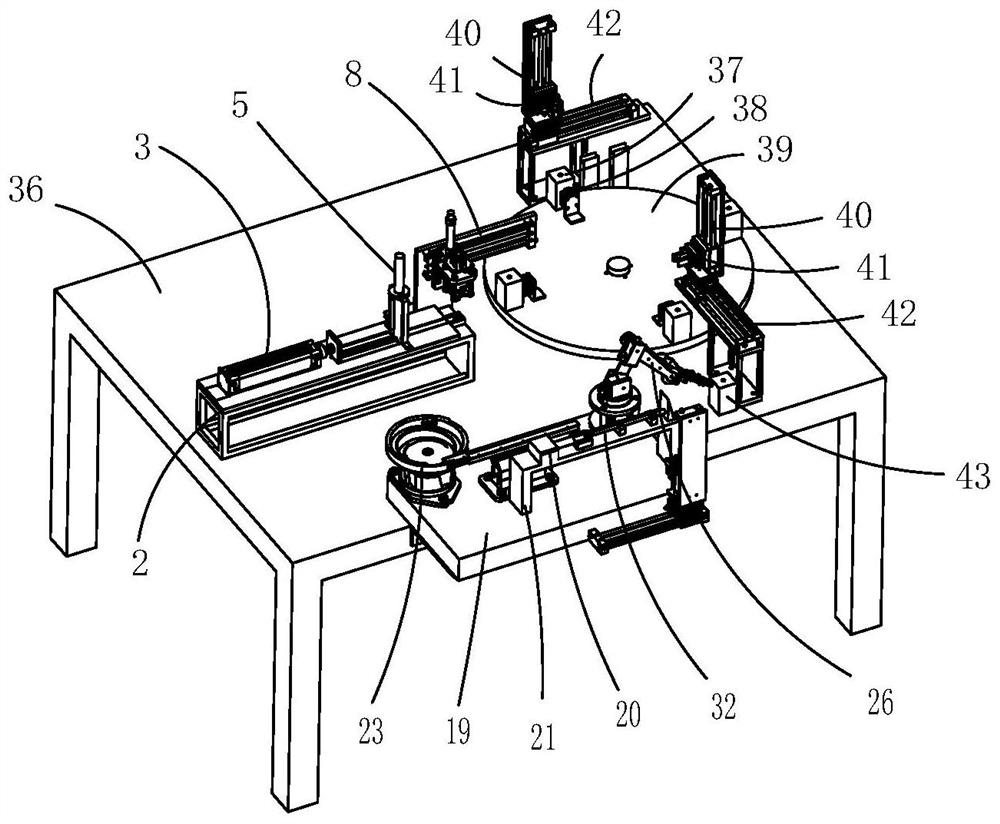

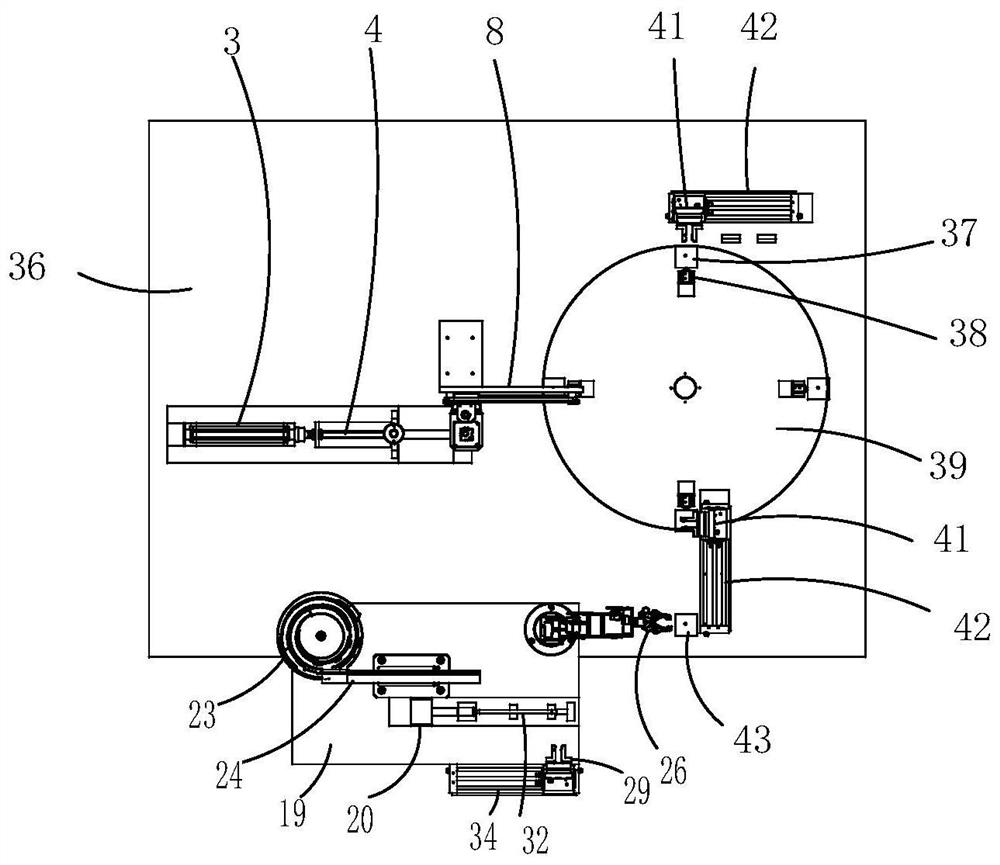

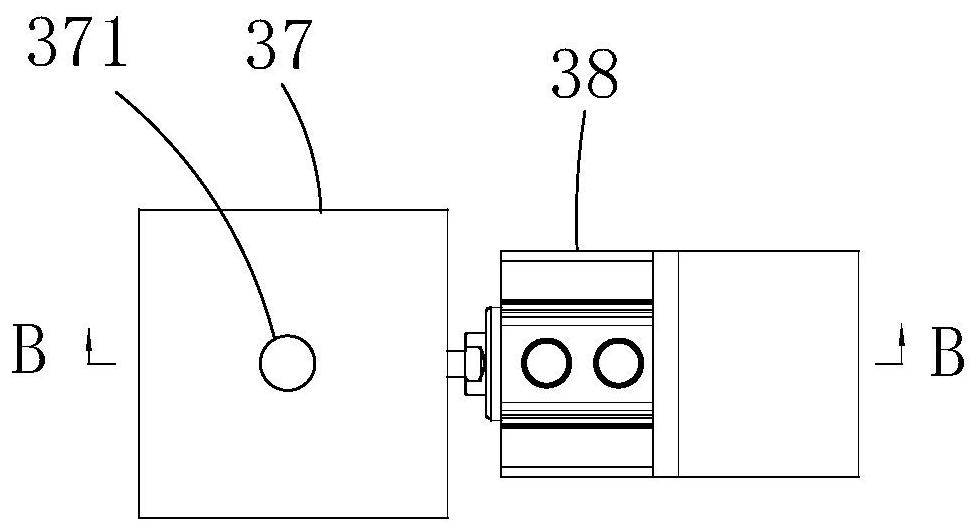

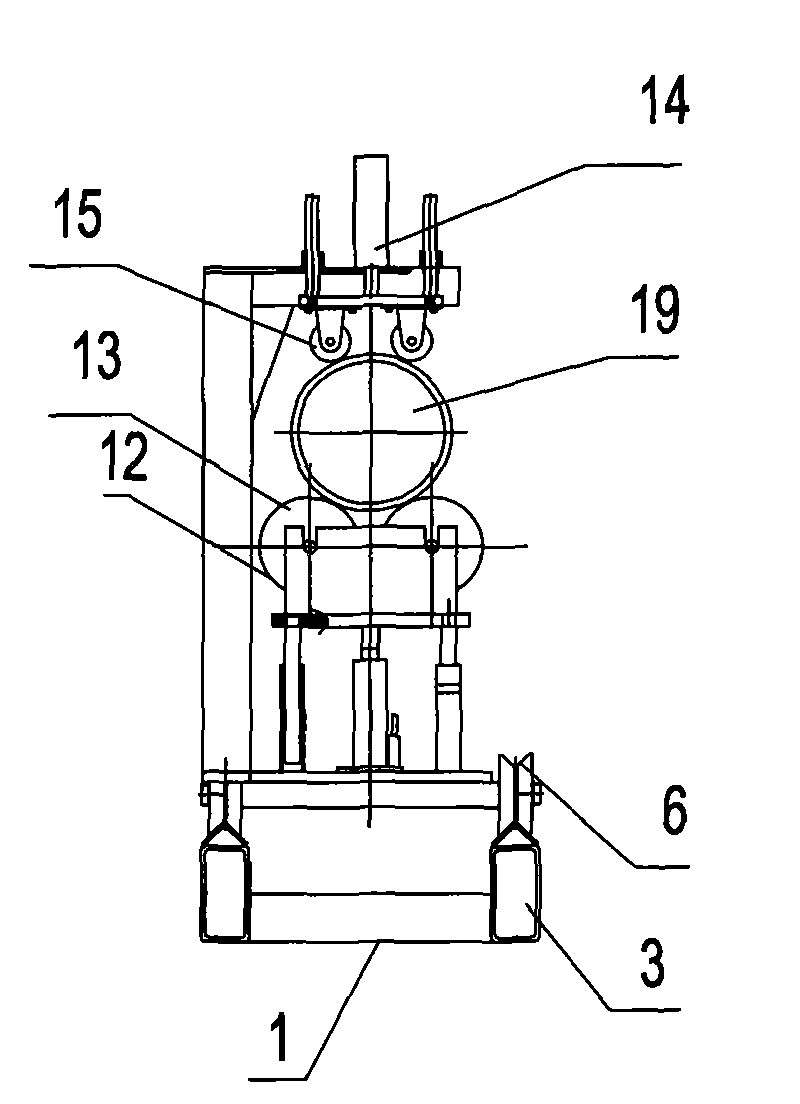

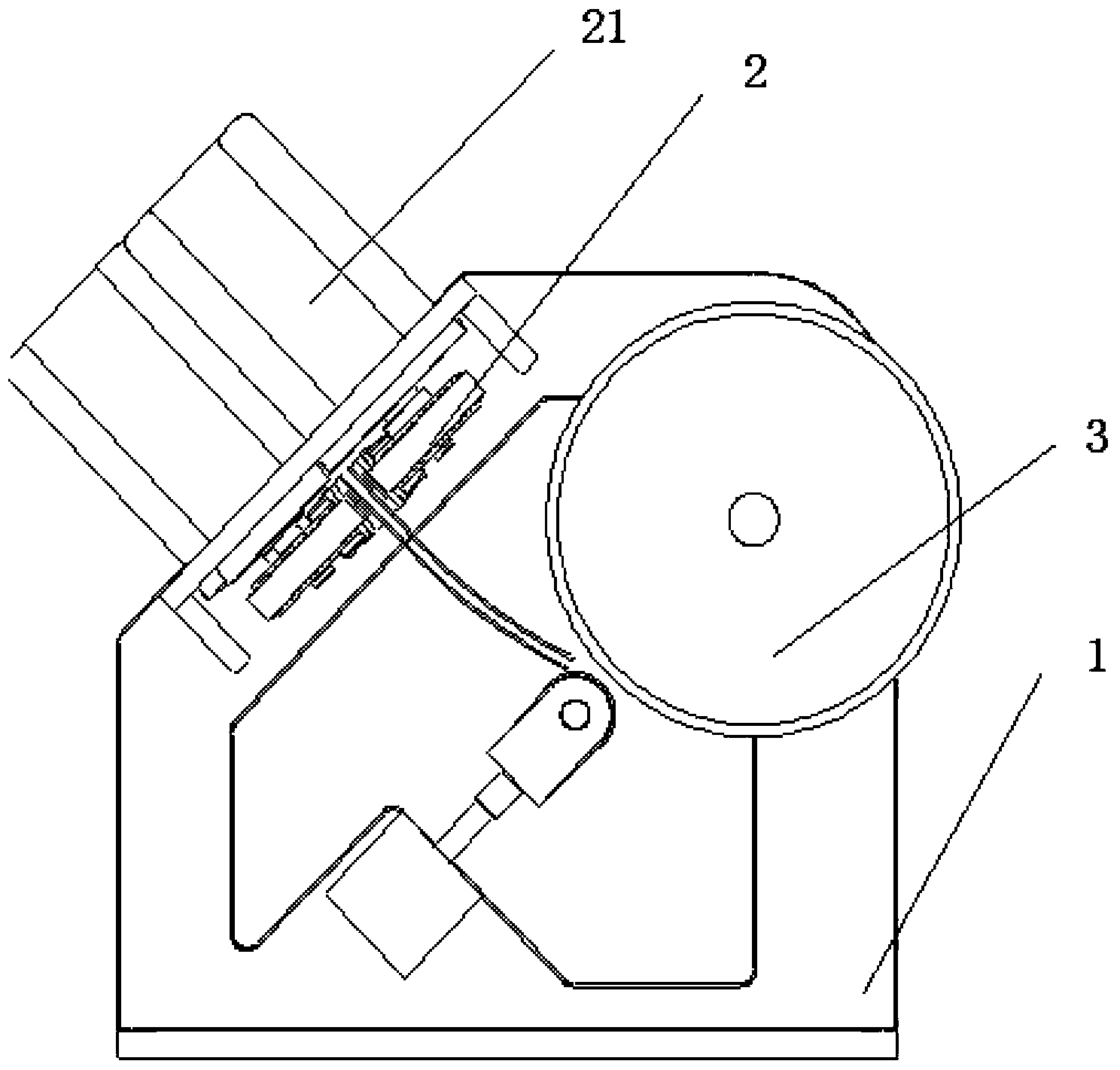

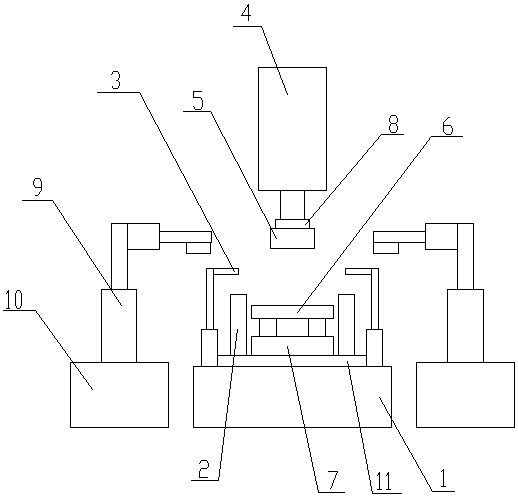

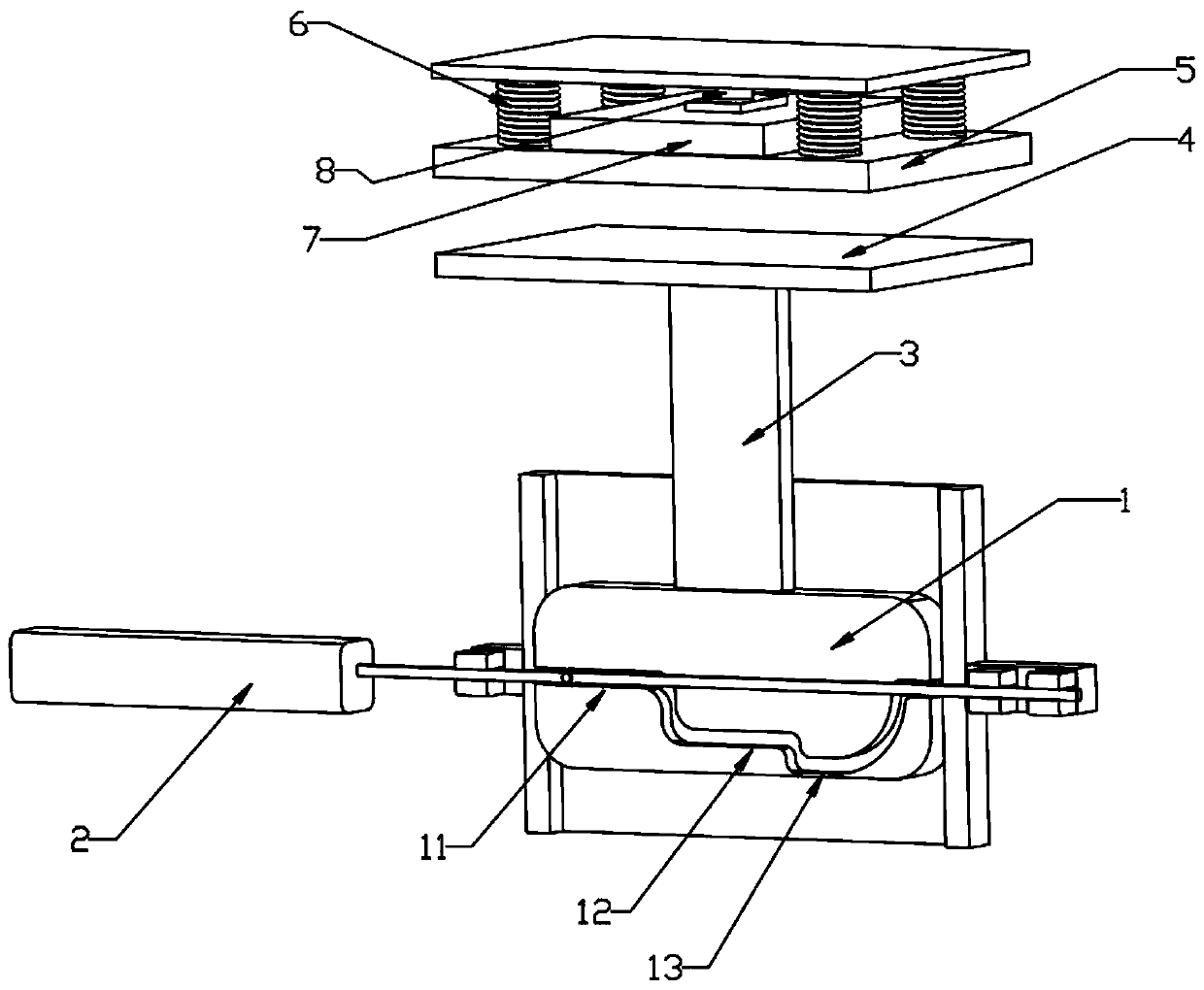

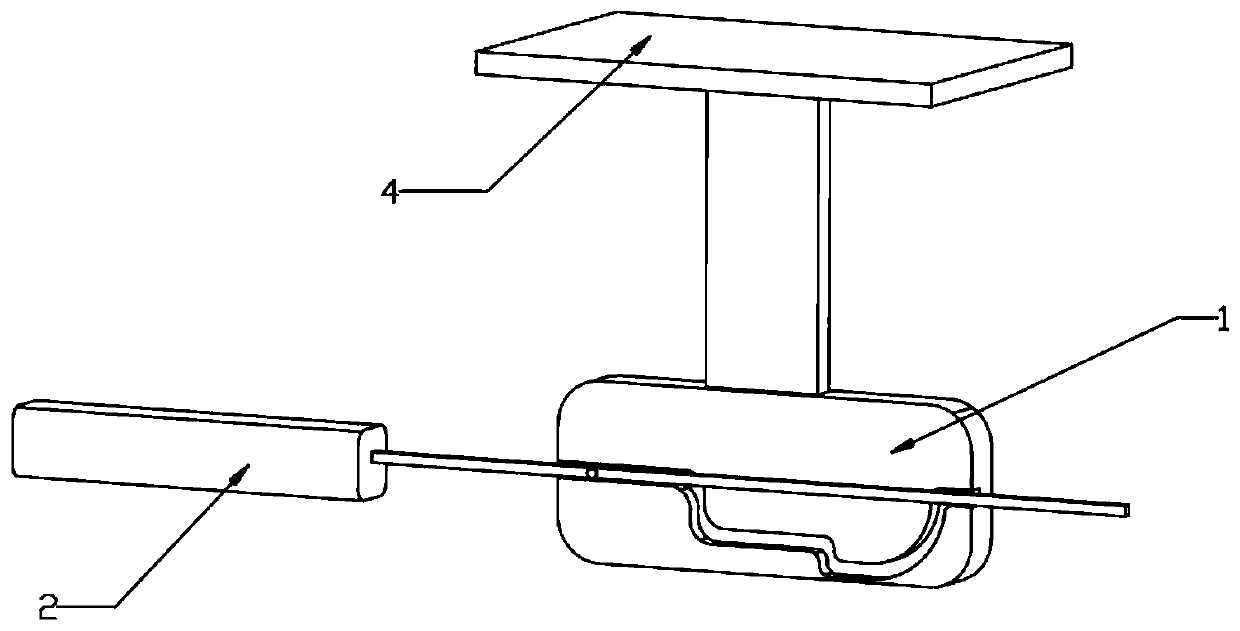

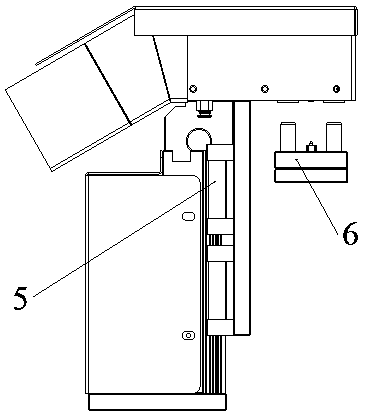

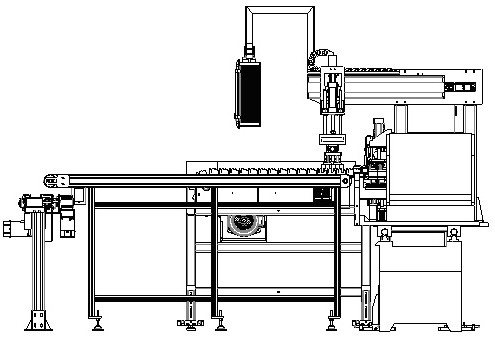

Automatic assembling machine for gas spring

ActiveCN111872674ANo manual operationImprove assembly efficiencyAssembly machinesMetal working apparatusGas springEngineering

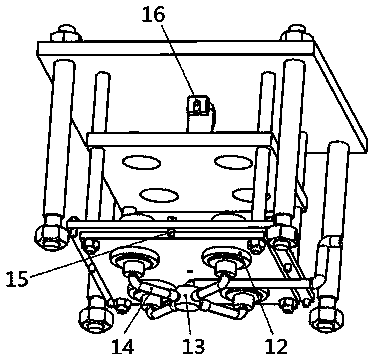

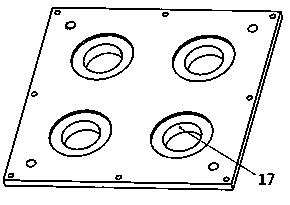

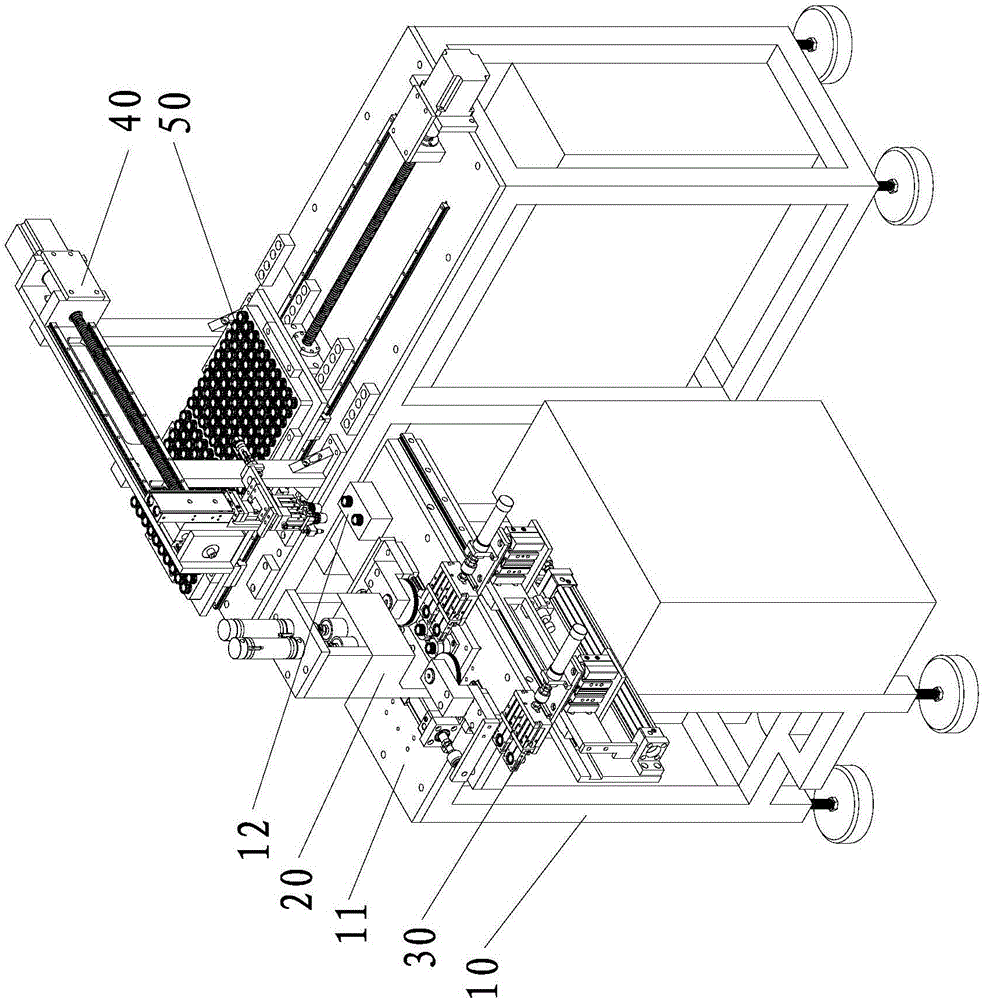

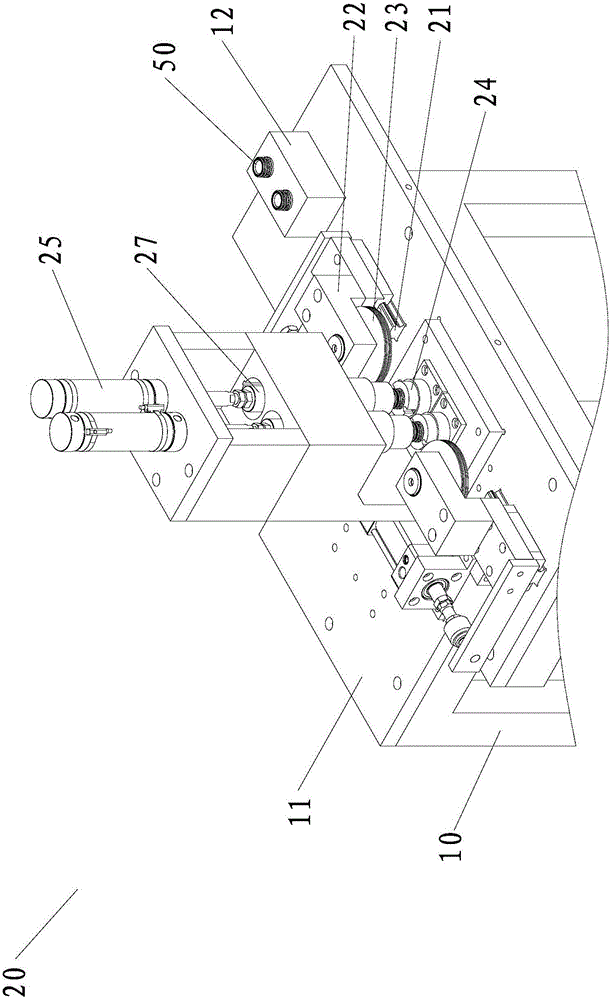

The invention provides an automatic assembling machine for a gas spring, and belongs to the technical field of gas spring automatic assembly. The automatic assembling machine comprises a support platform, a rotating disc, a piston rod press fitting mechanism, a piston rod feeding mechanism and a sealing ring feeding mechanism; the piston rod press fitting mechanism comprises an assembly rack, a multi-degree-of-freedom manipulator, a piston rod grabbing manipulator assembly and a guide sleeve vibration feeding assembly; the piston rod grabbing manipulator assembly grabs a piston rod to the assembly rack, the guide sleeve vibration feeding assembly feeds a guide sleeve to a feeding position, the multi-degree-of-freedom manipulator places the guide sleeve to the assembly rack, and a press-fitting air cylinder presses the guide sleeve into the piston rod; the piston rod feeding mechanism is used for vertically placing the piston rod obtained after the guide sleeve is assembled onto the rotating disc; and the sealing ring feeding mechanism grabs a sealing ring and presses the sealing ring on the piston rod obtained after the guide sleeve is assembled. According to the automatic assembling machine for the gas spring, manual operation is not needed in the installation process, the assembly efficiency can be improved, and the stability of the assembly quality is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

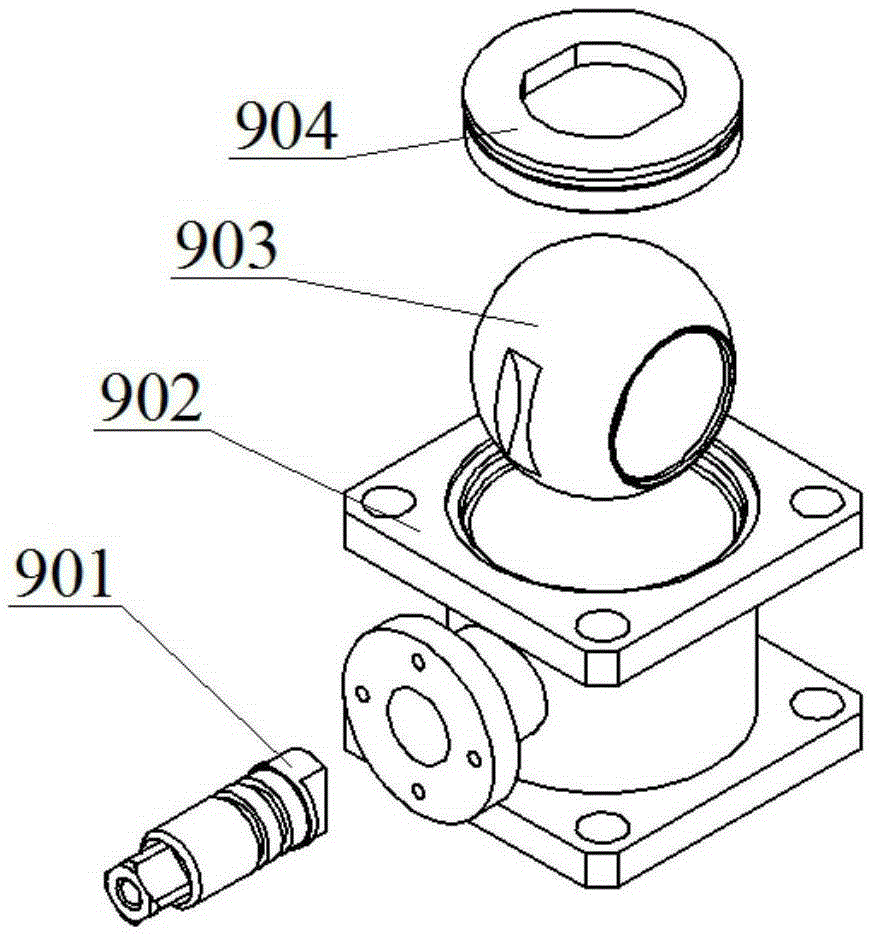

Mechanical device and assembling method for automatic square ball valve assembling system

InactiveCN105312898AImplement automatic assemblySimple processDetection of fluid at leakage pointAssembly machinesElectric machineCoupling

The invention discloses a mechanical device and an assembling method for an automatic square ball valve assembling system. The mechanical device comprises a four-jaw chuck. The four-jaw chuck is connected with a first pneumatic motor, a rubber pad is arranged above the four-jaw chuck, and an air cylinder pressing plate is arranged above the rubber pad; an electric machine is connected with a main transmission connector through a coupling, and the main transmission connector penetrates through the air cylinder pressing plate and is connected with the rubber pad; an air cylinder and a second pneumatic motor are arranged on the side of the four-jaw chuck, the air cylinder is connected with the air cylinder pressing plate, the second pneumatic motor is connected with a transmission sleeve end, and a pneumatic one-way valve is arranged below the four-jaw chuck. The assembling method for the automatic square ball valve assembling system comprises the four steps of valve body clamping, valve cover tightening, valve element inflation and disassembling after assembling is finished. According to the mechanical device and the assembling method for the automatic square ball valve assembling system, integration of the procedures of automatic square ball valve assembling and automatic inflation is achieved, so that the assembling efficiency of a square ball valve and the production quality of a product are improved, and the labor intensity of a worker is reduced.

Owner:CHINA UNIV OF MINING & TECH

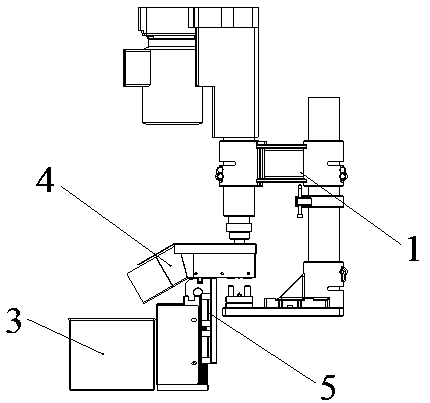

Automatic spare part stringing system of optical fiber connector

The invention discloses an automatic spare part stringing system of an optical fiber connector, comprising a base, a bracket, two side boards, a first shaft, a second shaft, a transmission chain, a motor, a clamp, a pneumatic sliding table and pneumatic claws, wherein a press-fitting air cylinder for maintaining PC or SC parts and a spring placed on the clamp to be fixed is arranged above one side of the second shaft; a first pneumatic claw and a second pneumatic claw are firstly used for putting the parts and the spring of the optical fiber connector on the clamp, then the press-fitting air cylinder presses the parts and the spring, thus the parts and the spring are fixed on the clamp, and the purpose of stringing the parts and the spring together by optical fibers is realized easily and reliably.

Owner:SHENZHEN KEXIN COMM TECH

Air pressure type rapid switching valve

ActiveCN106594294AImprove reliabilityExtended service lifeOperating means/releasing devices for valvesAerodynamic testingFour-way valveEngineering

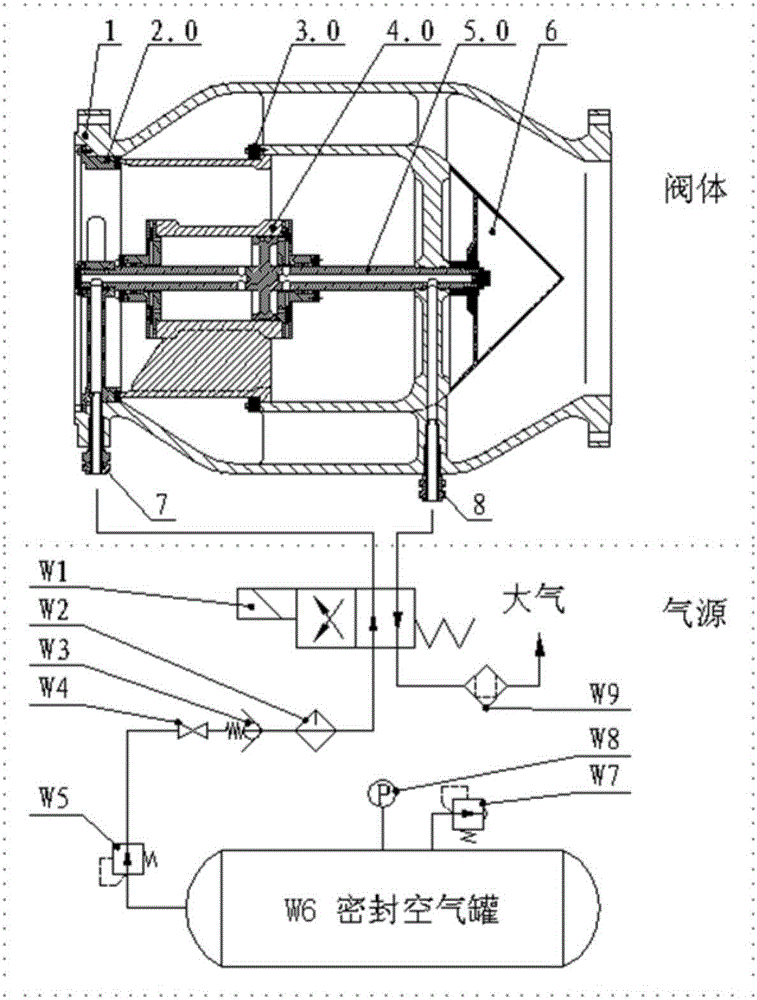

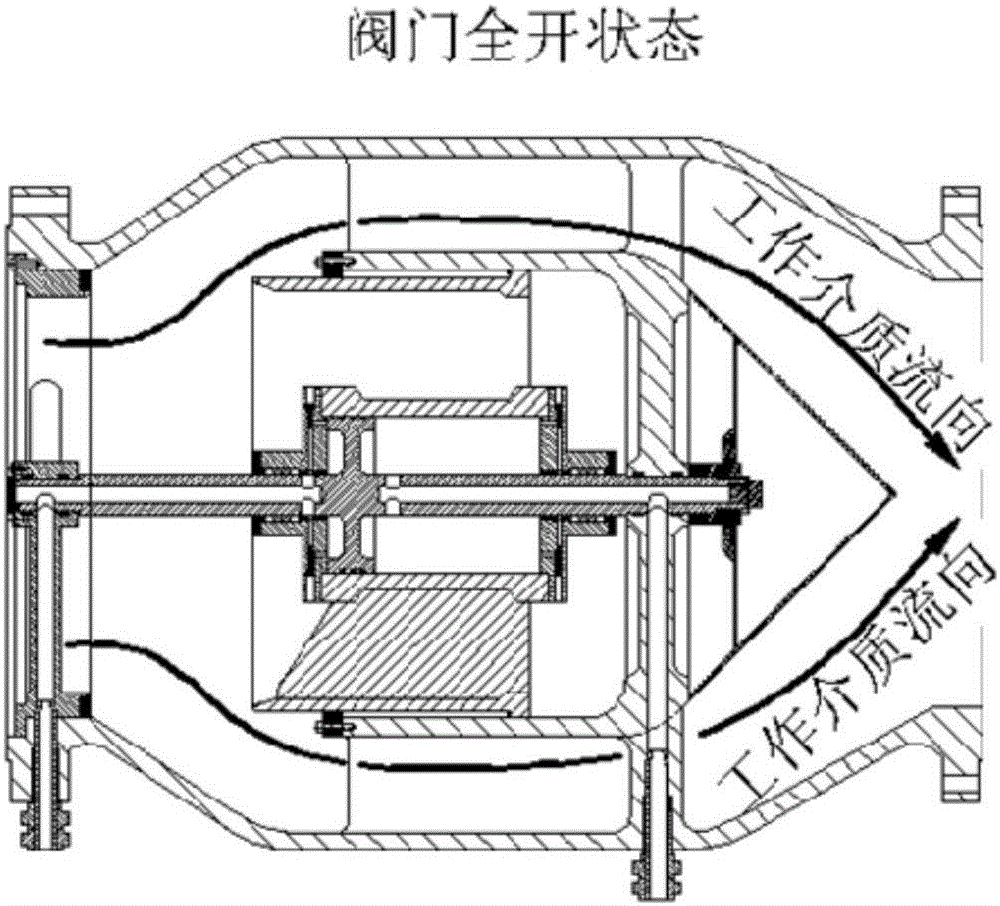

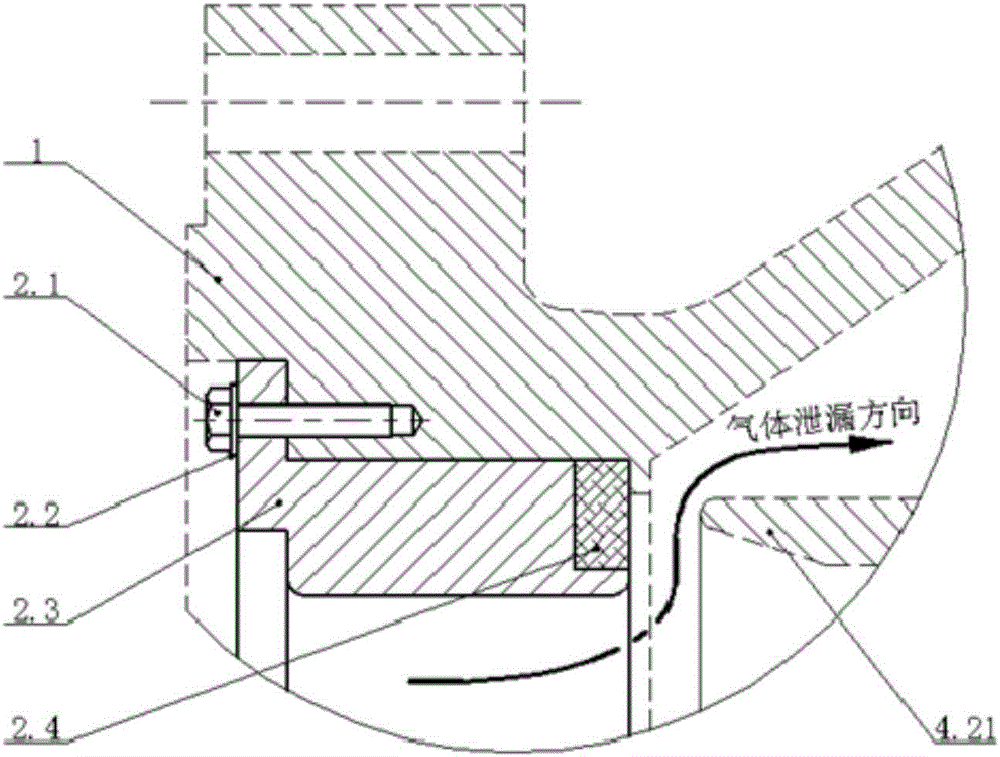

The invention relates to an air pressure type rapid switching valve which comprises two large parts, namely a valve body and an air source. The valve body is composed of a shell, a center shaft, an air cylinder, front and rear sealing assemblies, a pipe nozzle and the like. The air source is composed of a sealed air tank and an affiliated valve, pipeline and the like. When a two-position four-way valve for controlling the flowing direction of the air source is in a powered-off state, the front side of the air cylinder is inflated, the rear side of the air cylinder is deflated, the air cylinder presses the front and rear sealing assemblies, and the valve is in a closed state. Otherwise, when the two-position four-way valve for controlling the flowing direction of the air source is in a powered-on state, the rear side of the air cylinder is inflated, the front side of the air cylinder is deflated, and the valve is opened. The air pressure type rapid switching valve is mainly applied to a sub-tran-supersonic wind tunnel and used as a rapid valve, the opening or closing time is not longer than 1s, the opening and closing frequency every year is 15000, the repair cycle is 1 year, and the service life is 10 years.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Printing device and method for achieving bright-colored printing

InactiveCN106903982ABright printStir wellRotary pressesPrinting press partsMotor driveAir cylinder Press

The invention discloses a printing device with clear printing, which comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a stirring box through two support plates, a feeding port is opened on the top of the stirring box, one of the stirring boxes is The side is fixedly connected with a servo motor through a carrier plate, the output end of the servo motor is fixedly connected with one end of the U-shaped rod, the other end of the U-shaped rod is fixedly connected with one end of the rotating rod, and the other end of the rotating rod penetrates The mixing box extends to the inside and is movably connected to the inner wall, and a stirring rod is fixedly connected to the rotating rod and located in the mixing box. The present invention improves the mixing box, when the servo motor drives the toggle rod to move up and down through the U-shaped rod and the transmission rod, the filter screen can be vibrated up and down, so that the residue inside the dye can be filtered out, and when the telescopic cylinder is pressed down When lifting the plate, it can drive the brush roller arranged in the U-shaped splint to move up and down, thereby changing the printing height of the brush roller.

Owner:魏建华

Plasma automatic unloading machine and using method thereof

ActiveCN102029465APrevent jumpingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesPhysical hard workAir cylinder Press

The invention discloses a plasma automatic unloading machine and a using method thereof. The unloading machine comprises an unloading machine base, wherein a rotator box component and a rail component are fixedly arranged on the base; a stainless steel tube material rotating main shaft is arranged in the rotary box component, and a three-claw chuck is arranged on one end of the main shaft; two sets of trolley components are arranged on the rail component, a material receiving box component is arranged on the tail trolley component, an upright post component is arranged on the material receiving box component, a cutting component is arranged on the upright post component, and a plasma cutting gun is arranged on the cutting component; and a supporting roller component is arranged on the middle trolley component, a supporting roller is arranged on the supporting roller component, an air cylinder pressing component is arranged on the supporting roller component, and a pressing wheel is arranged on the air cylinder pressing component. The device can continuously and automatically cut the stainless steel tube material into the required tube materials according to the length of a drawing, so that unloading time is greatly shortened, efficiency is improved, cost is reduced greatly, and the labor of operators is reduced.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

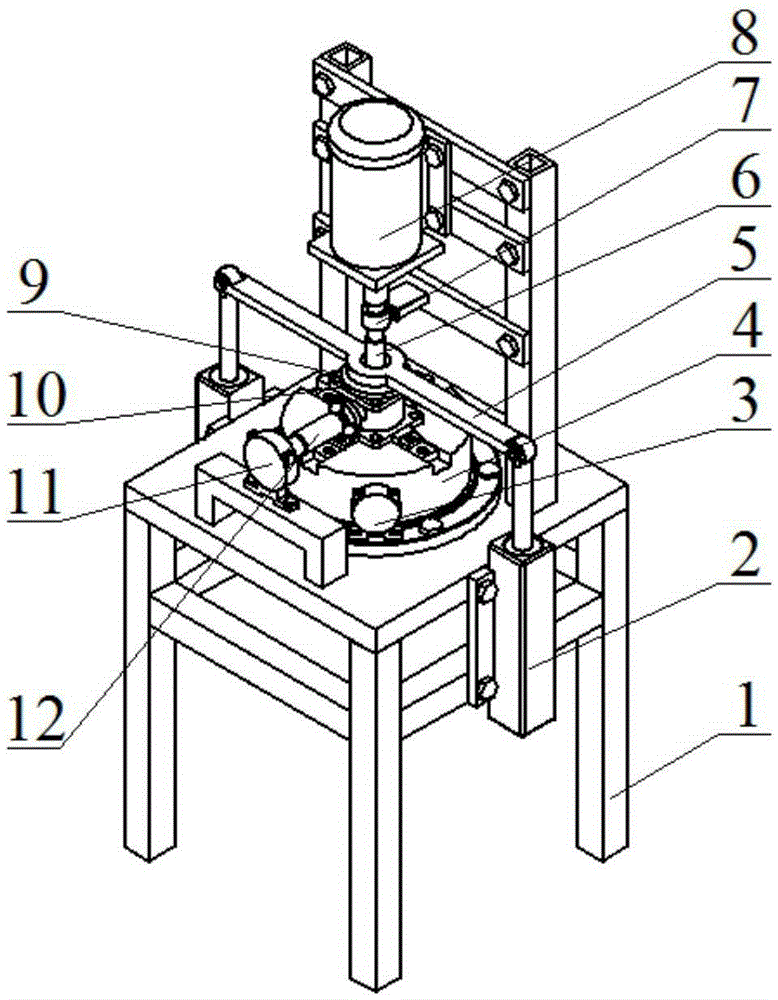

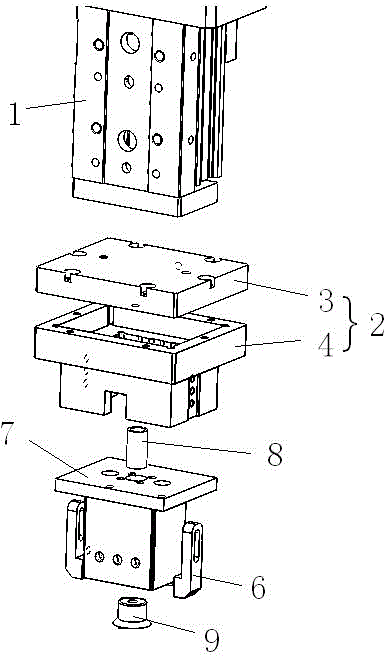

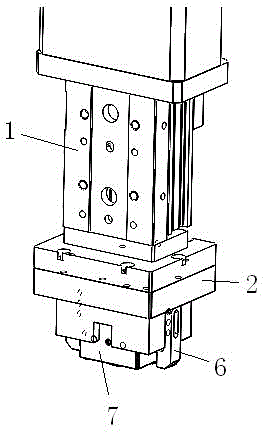

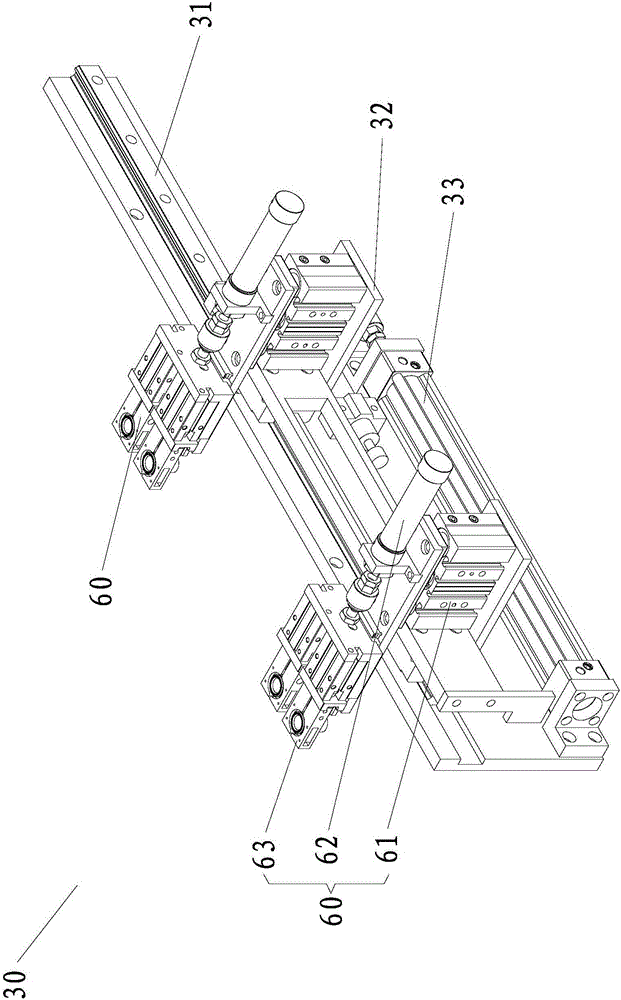

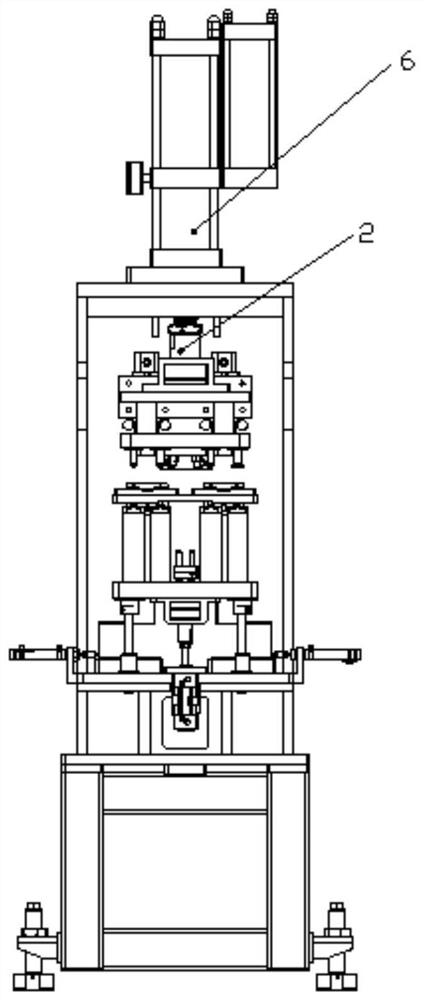

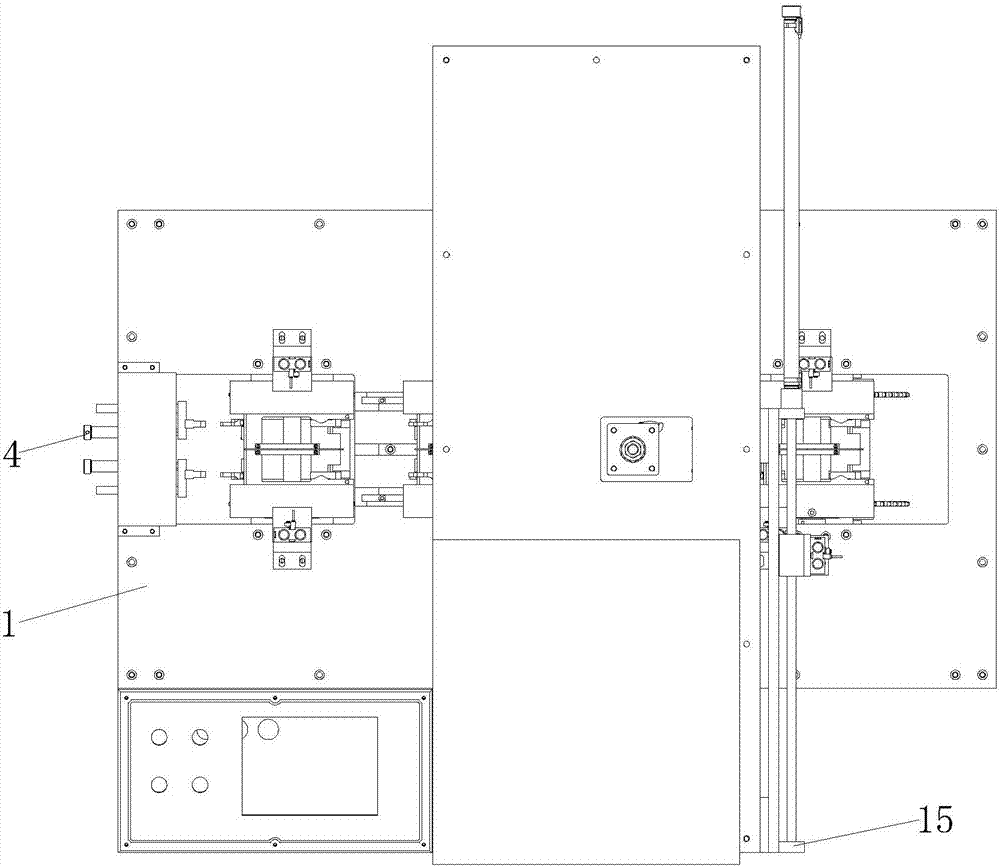

Automatic pressing device for steel shaft

InactiveCN106041482AImprove efficiencyPress in accuratelyMetal working apparatusMotor driveEngineering

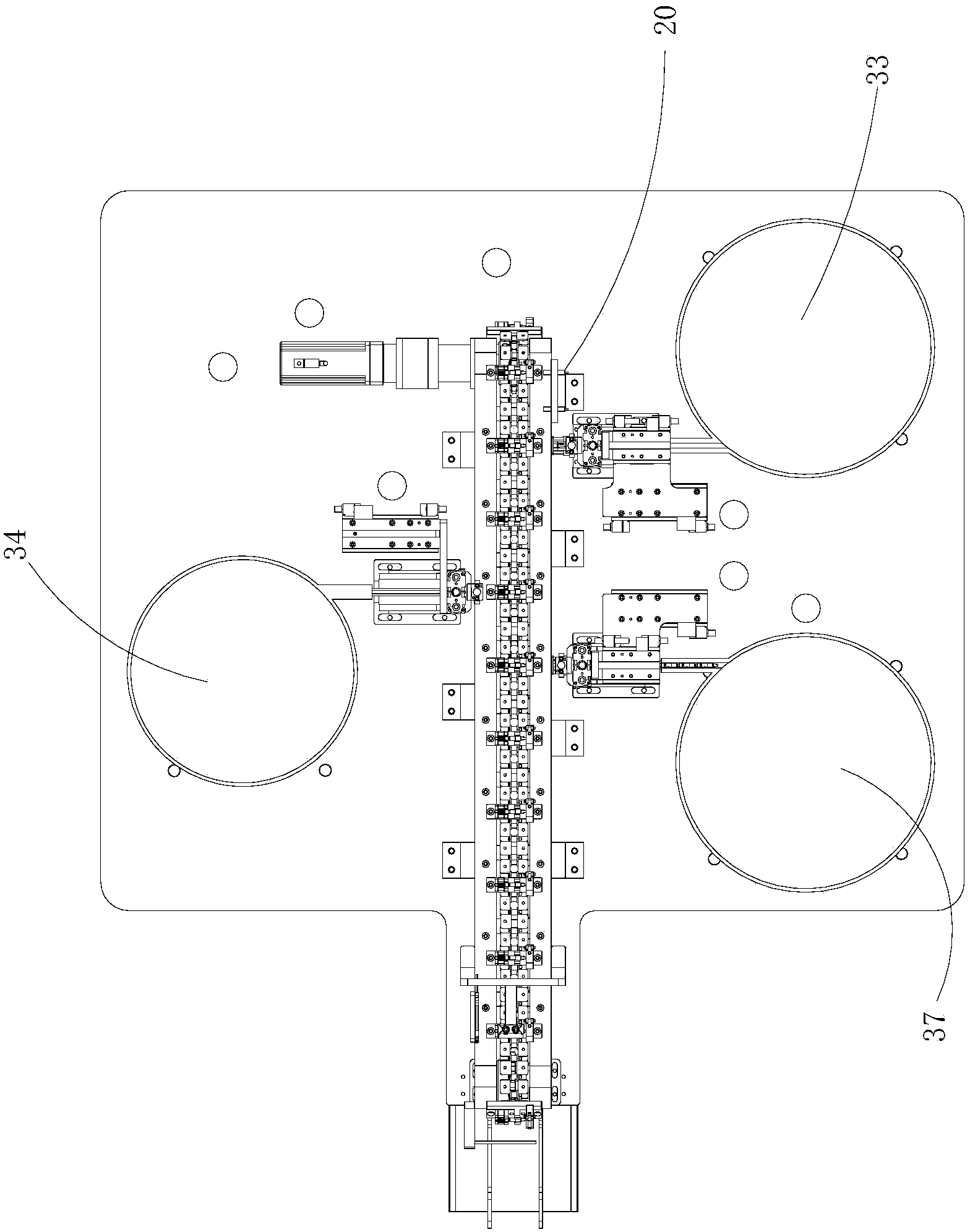

The invention relates to an automatic pressing device for a steel shaft. A rotating disc system, dual-control button boxes, prepressing systems, pressing systems, a jacking frame, a motor and air cylinder installation frames are installed on a base plate. The motor drives a divider through a synchronous belt. The rotating disc system is provided with feeding and discharging stations and thick and thin steel shaft prepressing stations. A rotating disc is connected with the divider. The thick steel shaft prepressing system is provided with a thick clamping jaw, thick rotating, feeding and prepressing air cylinders and a vibrating disc. The thin steel shaft prepressing system is provided with a thin clamping jaw, thin rotating, feeding and prepressing air cylinders and a vibrating disc. Each steel shaft pressing system is provided with a pressing air cylinder. By using the automatic pressing device, manual feeding is adopted, the rotating disc rotates a station, a gear box enters a prepressing station, the thick clamping jaw clamps a thick steel shaft at a discharge outlet, and the prepressing air cylinder prepresses the thick steel shaft in place; the thin clamping jaw clamps a thin steel shaft at the discharge outlet, and the prepressing air cylinder prepresses the thin steel shaft in place; and the steel shafts enter a steel shaft pressing station, and pressing blocks of the pressing air cylinders press the steel shafts in place. The automatic pressing device is high in efficiency, easy and convenient to operate and high in practicability.

Owner:XIAOGAN HUAGONG GAOLI ELECTRONICS

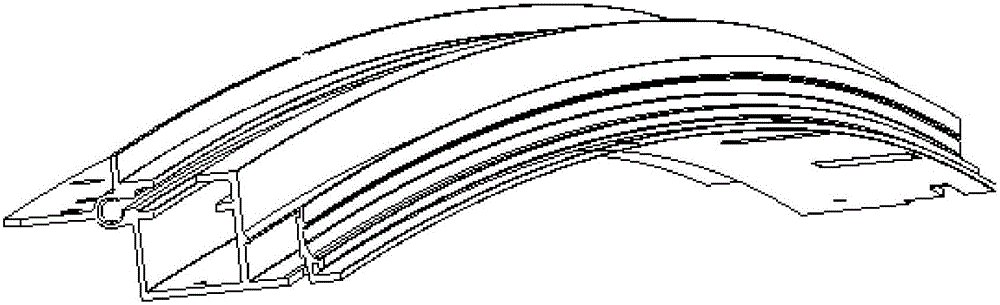

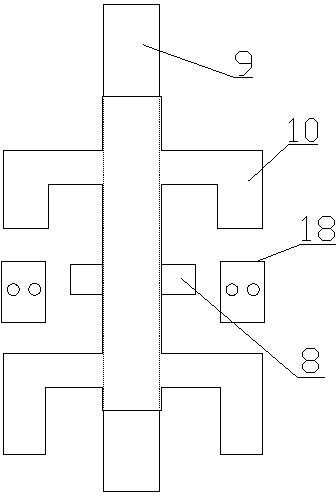

Combination mechanism for arc-shaped leg rubber band

The invention discloses a combination mechanism for an arc-shaped leg rubber band. The combination mechanism comprises a rack and further comprises an arc-shaped rubber band forming device and an rubber band combination and traction device which are respectively fixed on the rack, the rubber band combination and traction device is used for continuously performing combination and traction on materials and consists of two groups of parallelly-placed rubber-forming components in opposite direction, each rubber-forming component is provided with a servo motor in a matching way, and the servo motors drive the respective rubber-forming components to move forwardly and reversely, the rubber band combination and traction device consists of a traction wheel component and an air cylinder pressing wheel component for squeezing the traction wheel component. By controlling in a mutually independent way, the accurate and flexible adding of the arc-shaped leg rubber band is facilitated, the more accurate and evener distribution of the arc-shaped leg rubber band on a product is also facilitated.

Owner:ANQING HENG CHANG MACHINERY

Plate shearing machine with automatic feeding function

InactiveCN105414641AEnsure stabilityFor precise cuttingMetal-working feeding devicesShearing machinesAir cylinder PressDriving mode

The invention discloses a plate shearing machine with an automatic feeding function. The plate shearing machine comprises a machine frame, a sliding block and a workbench. A driving device is fixedly arranged at the front end of the machine frame and comprises a motor, a first belt pulley, a second belt pulley and a belt. The motor is connected with the first belt pulley in a driving mode, the first belt pulley drives the second belt pulley through the belt, and the second belt pulley is connected with a screw rod in a driving mode. The screw rod is located on the left side of the machine frame and is in sliding connection with the sliding block. An upper clamping block, a lower clamping block and a first air cylinder are arranged on the sliding block. The first air cylinder is connected with the upper clamping block, and the lower clamping block is fixedly arranged on the sliding block. According to the plate shearing machine, the screw rod is driven to rotate through the motor, so that the feeding function is achieved; a steel plate is clamped and released through the first air cylinder; the steel plate is clamped firstly and then conveyed, so that operation is stable, and efficiency is high. According to the plate shearing machine, the plate is pressed through an air cylinder pressing plate at first, and then a cutter is operated for cutting the plate, so that cutting is more accurate; besides, the plate shearing machine is simple in structure and convenient to use.

Owner:TIANJIN FUDACHANG TECH

Clamping device for overturning and milling arc-shaped work-pieces

InactiveCN106112619AAvoid poor consistencyGuaranteed Flip Milling DimensionsPositioning apparatusMetal-working holdersMotor driveEngineering

The invention discloses a clamping device for flipping and milling arc-shaped workpieces which is easy to use and has high processing efficiency. It comprises a base on which a pair of mounting brackets are arranged. There is an installation base plate, on which there is a servo motor that drives the rotating seat, and a profiling support block that matches the shape of the workpiece is provided on the base plate; the profiling support block is provided with a limit block that limits the surface of the workpiece along the length direction , the two ends of the installation base plate are respectively provided with a horizontal clamping cylinder that cooperates with the limit block to clamp the workpiece, and the end of the piston rod of the horizontal clamping cylinder is provided with a horizontal clamping block; A down-pressing cylinder that presses the upper surface of the workpiece is provided with a briquetting block at the end of the piston rod of the down-pressing cylinder.

Owner:ZHANGJIAGANG XUJUN MACHINERY PARTS CO LTD

Wheel sprue drilling device

The invention discloses a wheel sprue drilling device. The wheel sprue drilling device is composed of a machine frame, a fixture, an oil fog generator, a hydraulic cylinder, air cylinders and the like. When the wheel sprue drilling device is used, a wheel is positioned through a sensor, clamping blocks clamp the lower rim of the wheel through a gear rack and the second air cylinder, the first air cylinder presses the fixture to the upper rim of the wheel through a first guide column, the hydraulic cylinder lifts a motor and an inner-cooling drill bit through a second guide column, the motor drives the inner-cooling drill bit to rotate through a synchronous belt, and when the inner-cooling drill bit makes contact with a diversion taper hole, the inner-cooling drill bit drills a wheel sprue based on the guiding function of the inner-cooling drill bit. When the wheel sprue drilling device is used, on-line drilling removing can be carried out in the wheel sprue on the lower portion, the technology is advanced, and the wheel sprue drilling device has the advantages of being simple in structure, safe and stable in performance, high in automation degree and the like.

Owner:CITIC DICASTAL

Cover opening and closing device

ActiveCN103600875AAvoid stickingRealize fully mechanized operationPackagingAir cylinder PressIntegrated circuit

The invention relates to the technical field of integrated circuit chip processing and discloses a cover opening and closing device used for closing and opening a cover of a chip box. The chip box comprises a base, a chip accommodating cavity formed in the base and buckles arranged at upper ends of two sides of the base, a buckle head is arranged on the inner side of each buckle, and an arc concave surface is arranged on the outer side of each buckle. The cover comprises clamping grooves which are formed on two sides and used for matching with the buckle heads. The cover opening and closing device further comprises an air cylinder and a press block groove fixedly formed at the lower end of the air cylinder, two J-shaped claws are arranged on two sides of the press block groove respectively, the two claws are matched with the arc concave surfaces of the two buckles on the chip box respectively to achieve opening and closing of the buckles, a press block is arranged in the press block groove, a sucker which is controlled by a vacuum air channel is arranged at the lower end of the press block, and when the air cylinder presses downwards till the sucker is on the upper surface of the cover, the claws are located at opening positions of the buckles. By the cover opening and closing device, fully-mechanized operation is realized through the mechanical claws and the air cylinder.

Owner:JIAXING JINGYAN INTELLIGENT EQUIP TECH

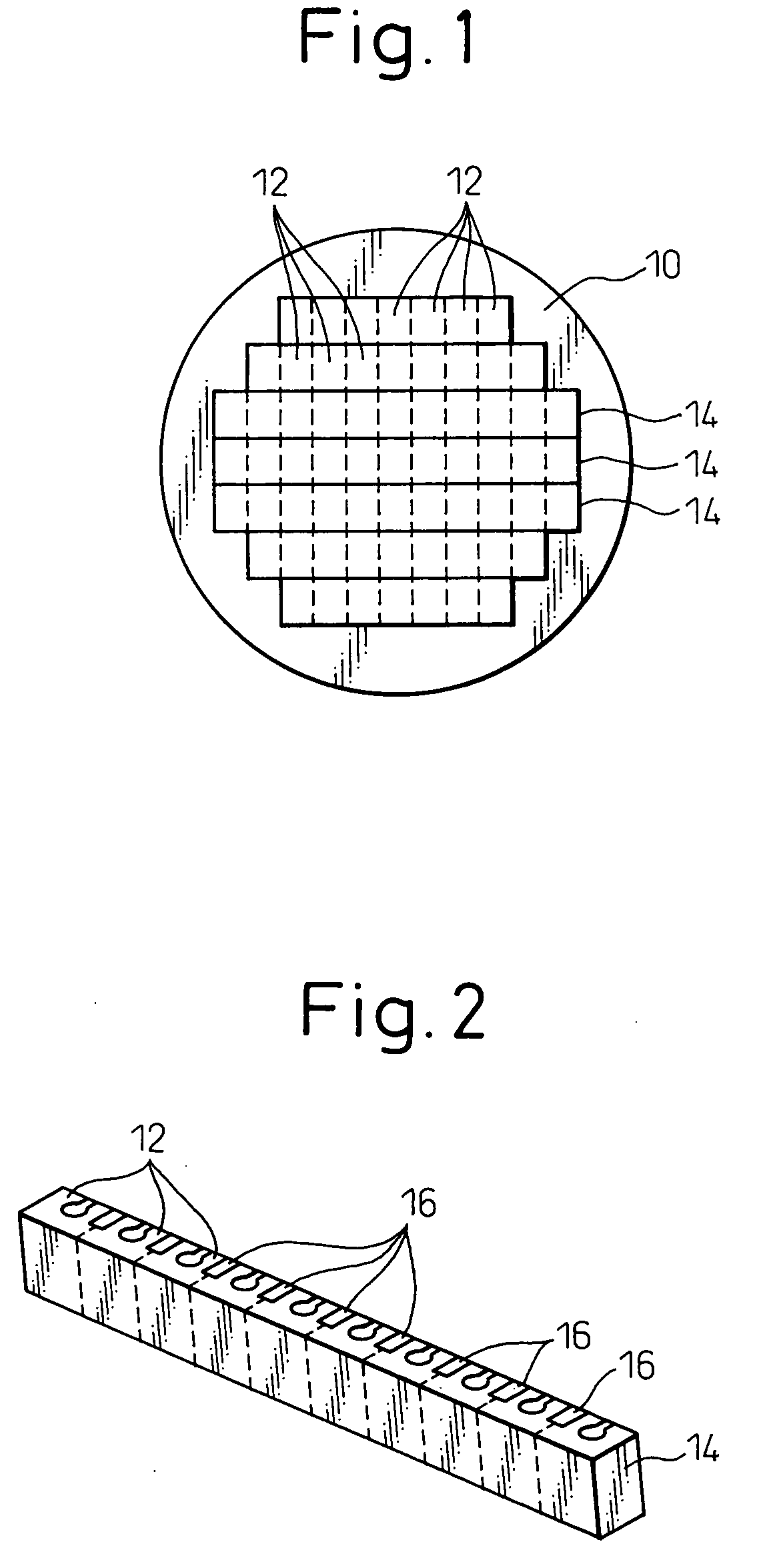

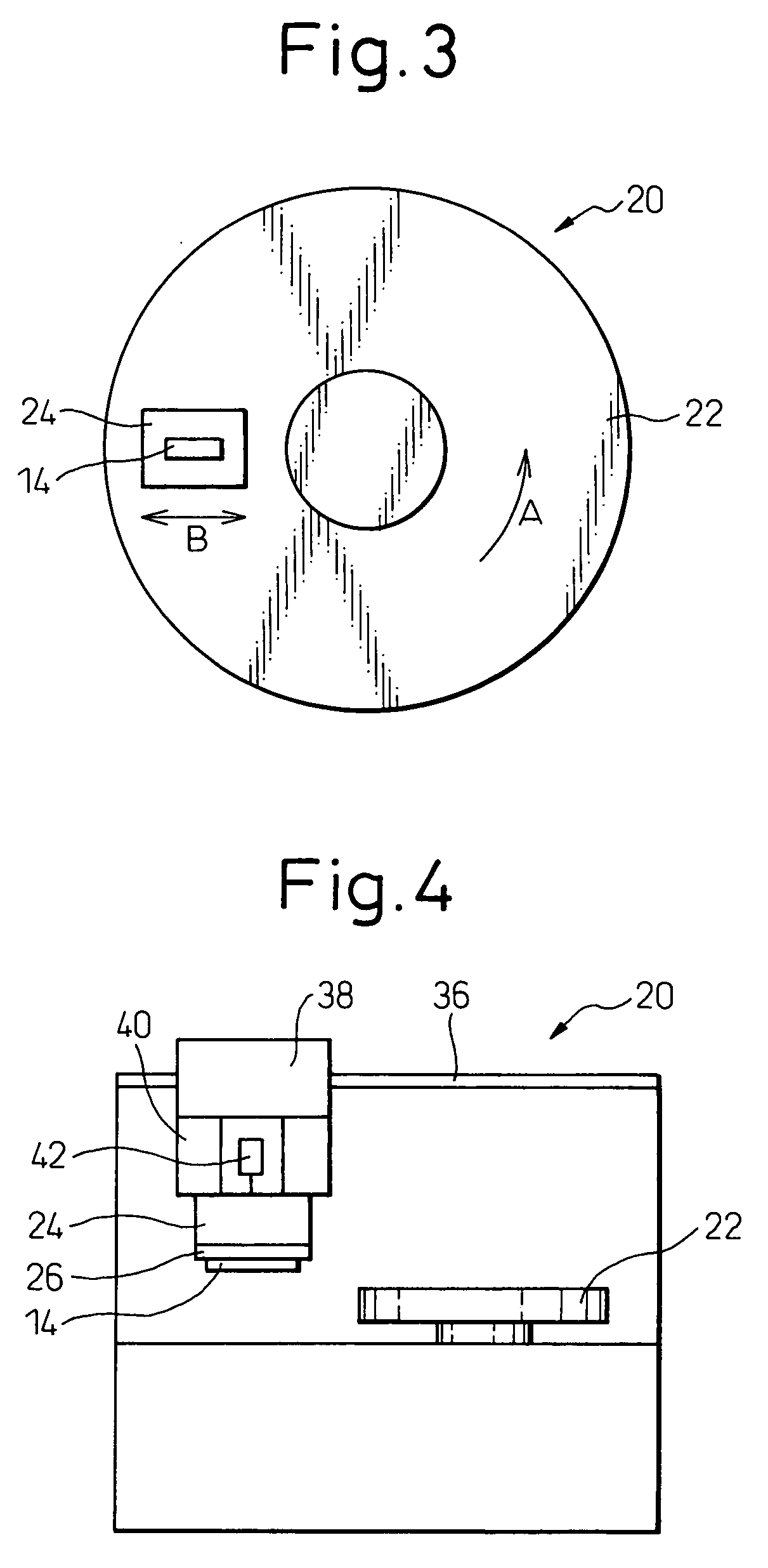

Apparatus and method for polishing row bars

InactiveUS6905394B2Accurate polishingEasily and reliably securedLapping machinesGrinding feed controlAir cylinder PressSurface plate

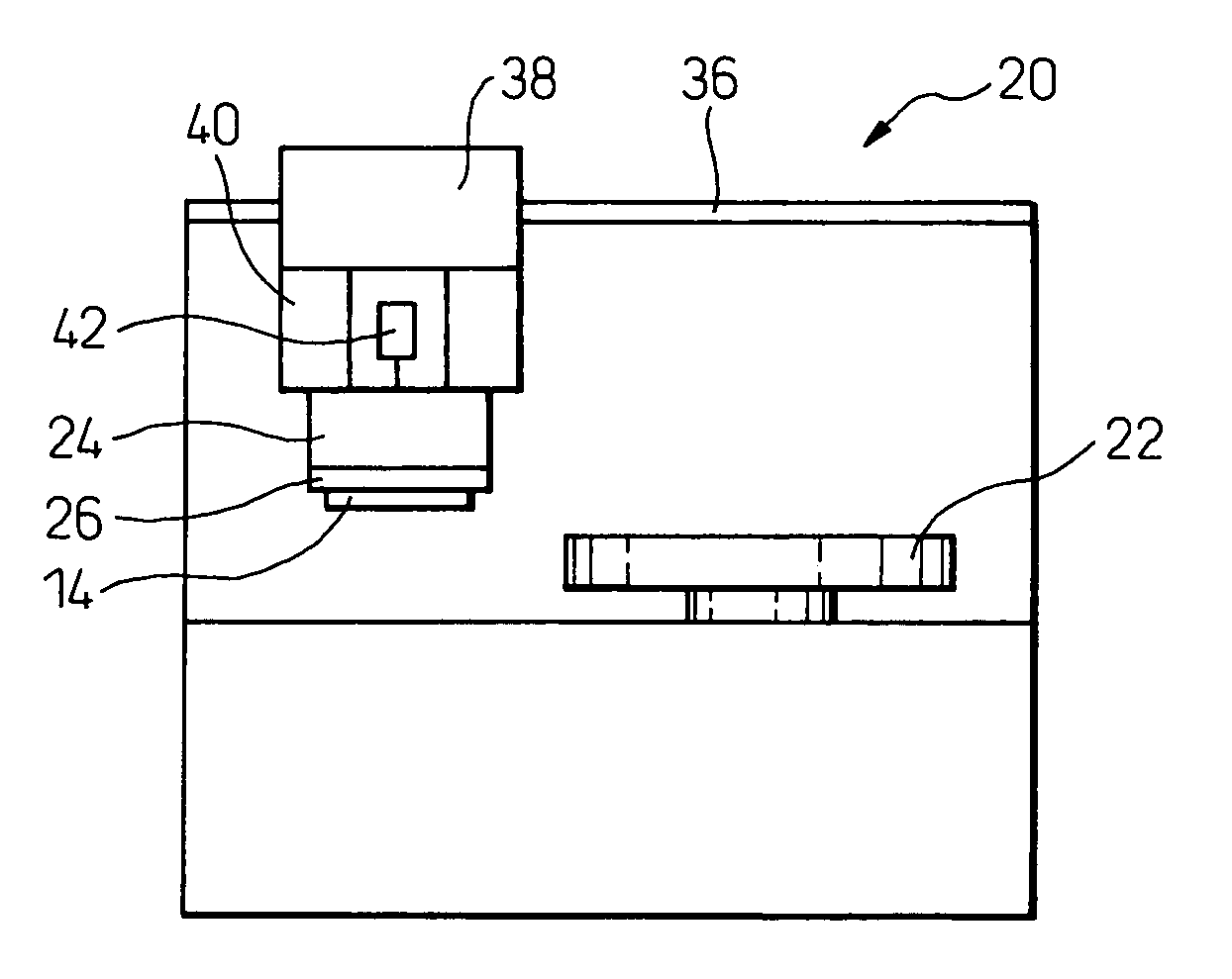

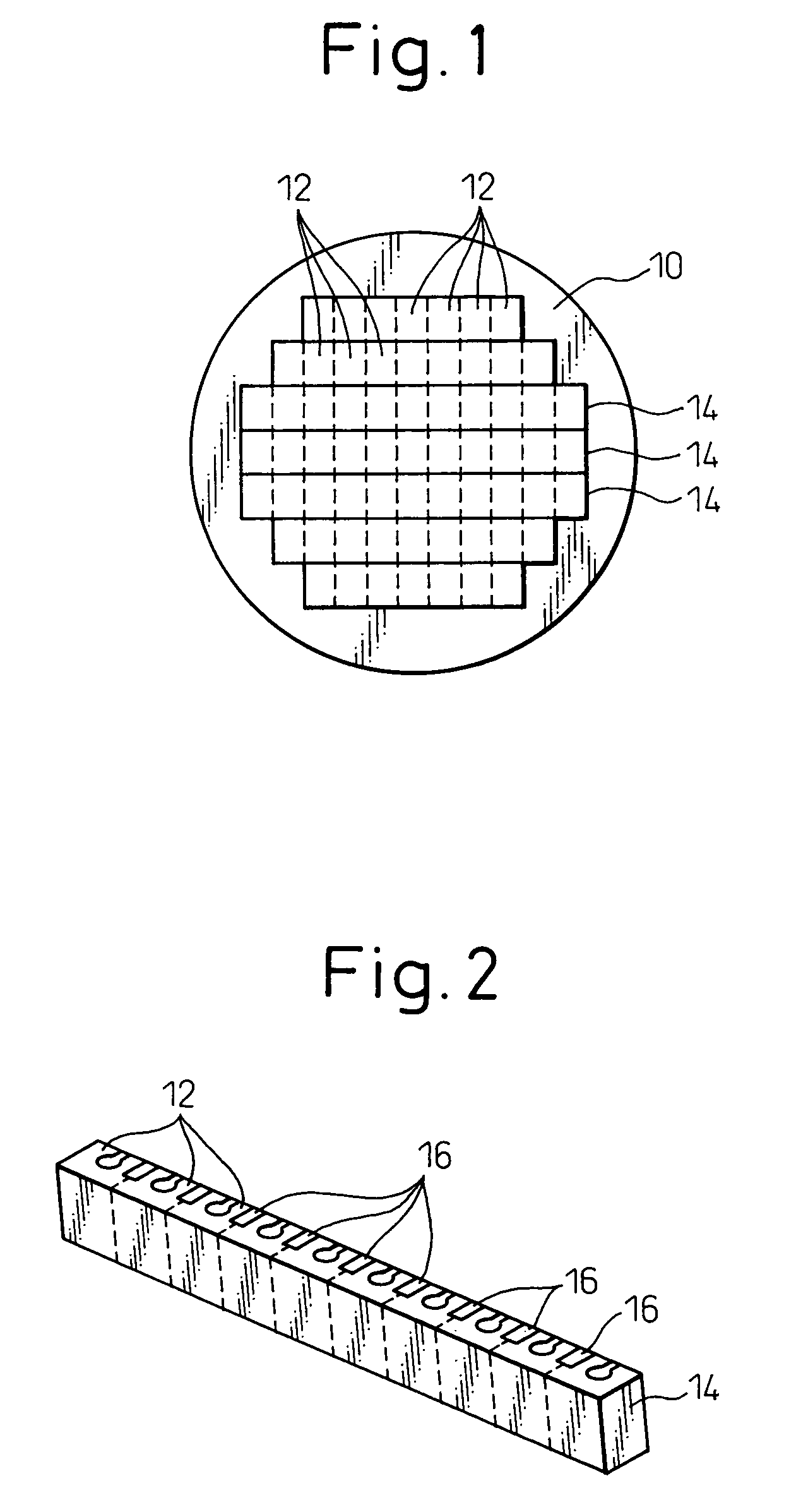

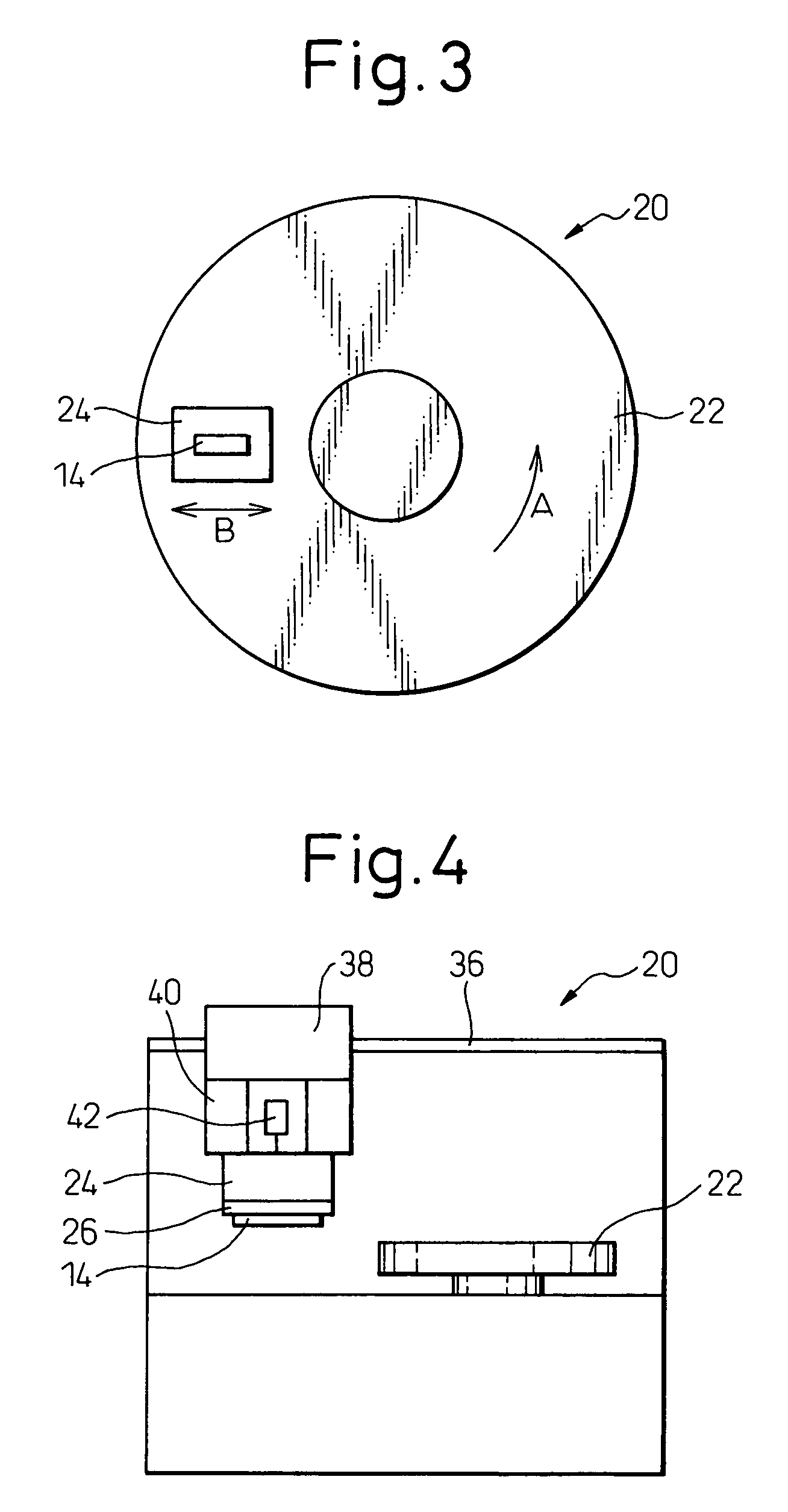

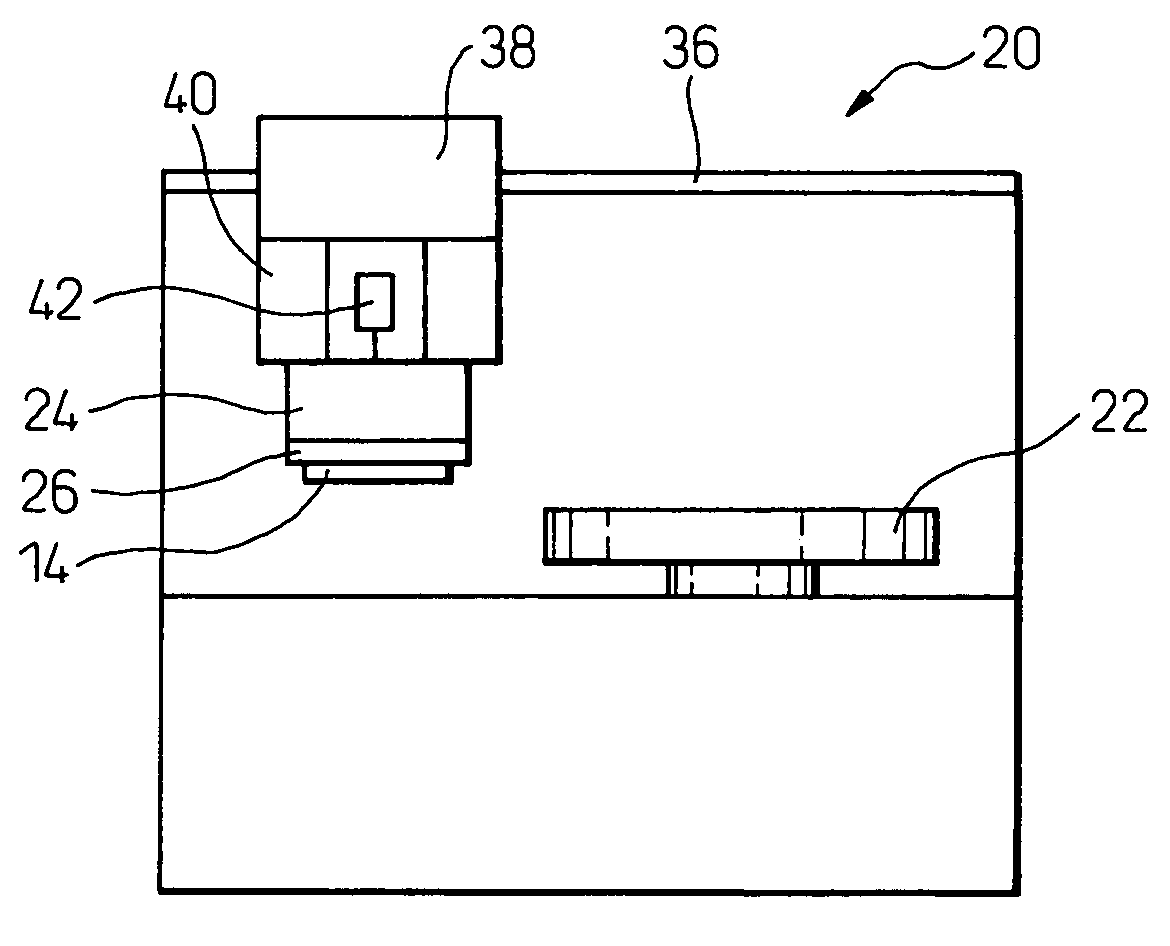

An apparatus and a method for polishing a row bar including magnetic head sliders. A lapping surface plate is rotatable, and a housing is movable above the lapping surface plate. A jig is secured to the housing for holding the row bar. The jig is formed by an elongated rigid member having a plurality of holes and an elongated elastic member fixed to the rigid member. An air cylinder presses the whole row bar, and a pressing devices individually presses portions of the elastic member corresponding to magnetic head sliders of the row bar through the holes of the rigid member. A portion of the elastic member is deformed to press a portion of the row bar in response to a change in the measured resistance of ELG resistance elements in the row bar.

Owner:FUJITSU LTD

Apparatus and method for polishing row bars

InactiveUS20050064793A1Accurate polishingEasily and reliably securedLapping machinesGrinding feed controlAir cylinder PressResistive element

An apparatus and a method for polishing a row bar including magnetic head sliders. A lapping surface plate is rotatable, and a housing is movable above the lapping surface plate. A jig is secured to the housing for holding the row bar. The jig is formed by an elongated rigid member having a plurality of holes and an elongated elastic member fixed to the rigid member. An air cylinder presses the whole row bar, and a pressing devices individually presses portions of the elastic member corresponding to magnetic head sliders of the row bar through the holes of the rigid member. A portion of the elastic member is deformed to press a portion of the row bar in response to a change in the measured resistance of ELG resistance elements in the row bar.

Owner:FUJITSU LTD

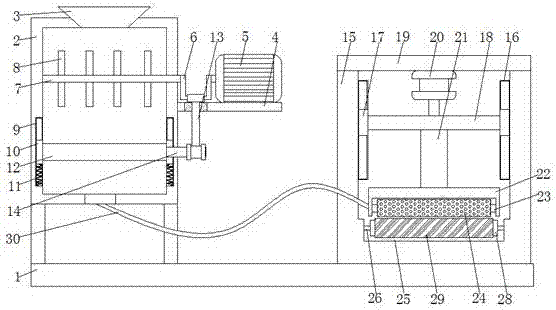

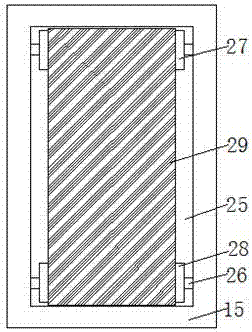

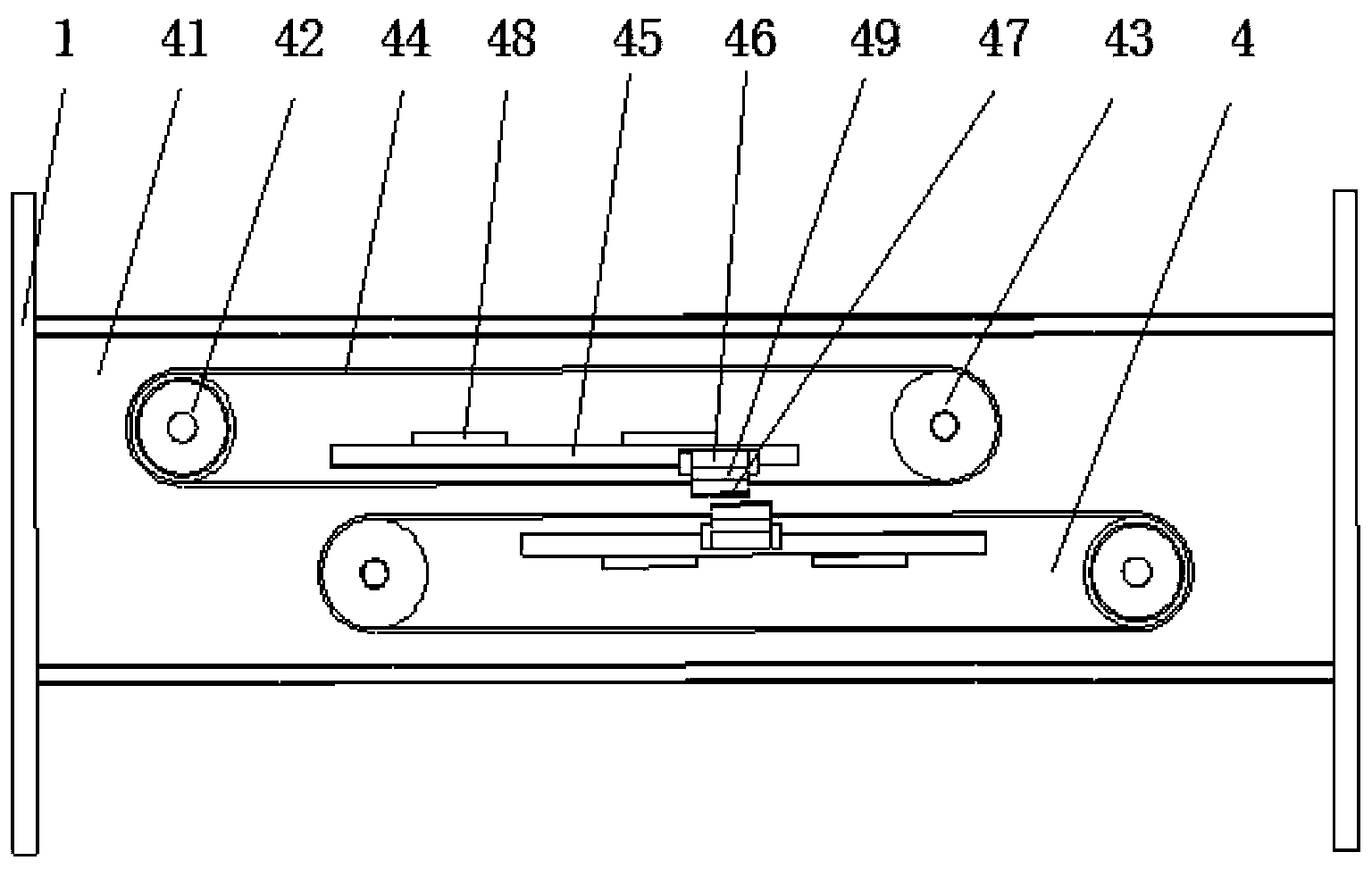

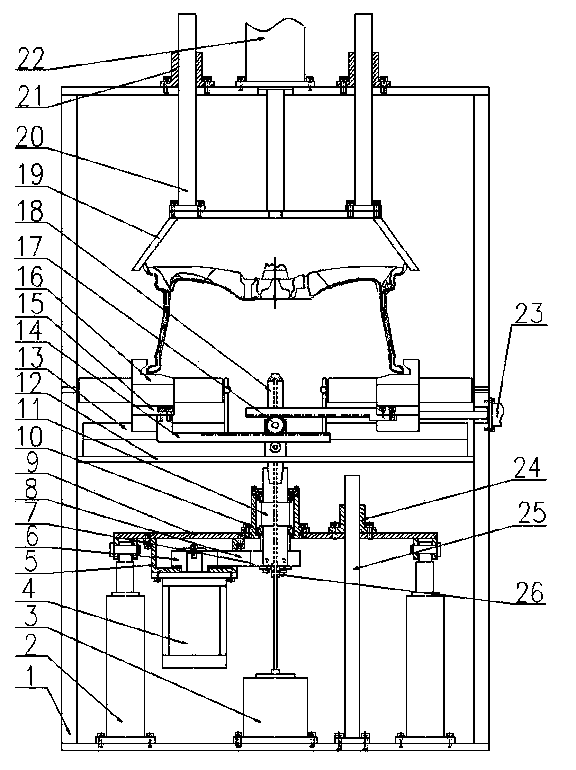

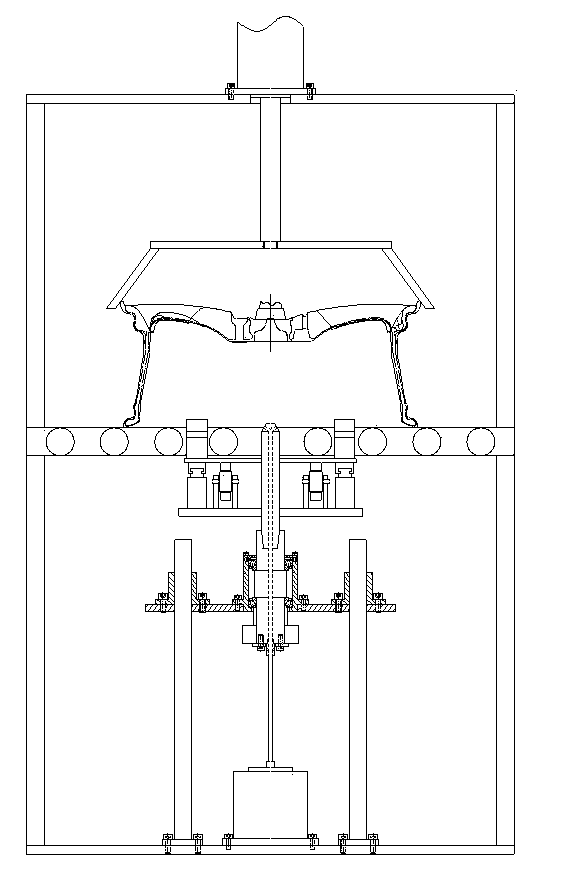

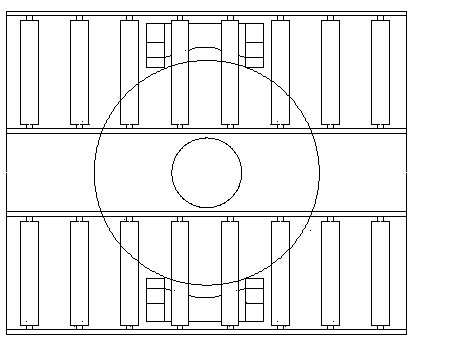

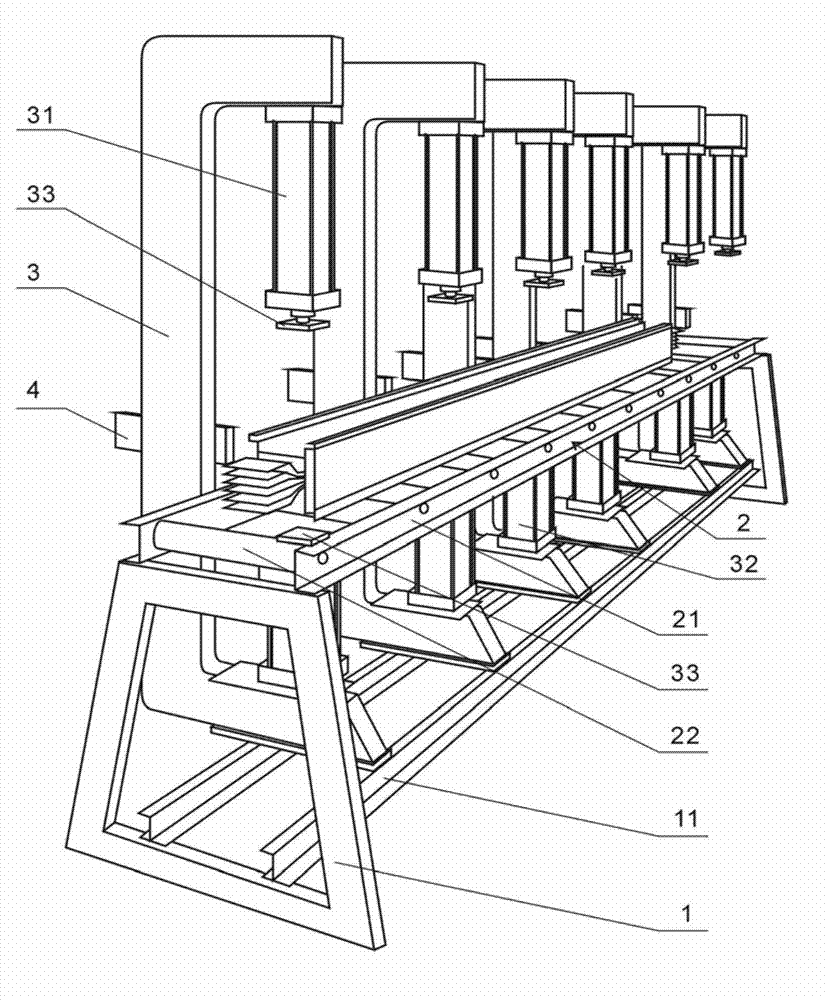

Assembly line for dense-type bus duct

ActiveCN103036172AEasy to operateSimple structureCable installation apparatusAssembly linePulp and paper industry

The invention relates to an assembly device for producing a bus duct, in particular to an assembly line for a dense-type bus duct. The assembly line for the dense-type bus duct comprises a hold-down mechanism and a tightening mechanism. An output end of an upper air cylinder and an output end of a lower air cylinder are respectively provided with a hold-down gasket in a fixed mode, a hold-down frame is arranged on a support frame in a movable mode, and two ends of the hold-down frame are respectively arranged on two sides of an idler wheel supporting platform. The upper air cylinder and the lower air cylinder are respectively fixedly arranged at two ends of the hold-down frame, and the hold-down gasket of the upper air cylinder and the hold-down gasket of the lower air cylinder correspond to the idler wheel supporting platform. The structure takes advantage of a matched structure of the movable hold-down frame and the idler wheel supporting platform, when the bus duct is assembled, the bus duct is placed on the idler wheel supporting platform, the hold-down frame is moved to enable the upper air cylinder and the lower air cylinder of the hold-down frame to correspond to side plates of the bus duct. Then the lower air cylinder is lifted, when the lower air cylinder is jacked up, the upper air cylinder presses down. Due to the fact that the hold-down gaskets are just adaptive to the side plates of the bus duct, the hold-down gaskets correspond to the side plates of the bus duct, hold-down force is even and strong, the hold-down gaskets and the side plates of the bus duct are compressed tightly and accurately, and operation is quite convenient.

Owner:ZHEJIANG MAILANG ELECTRIC

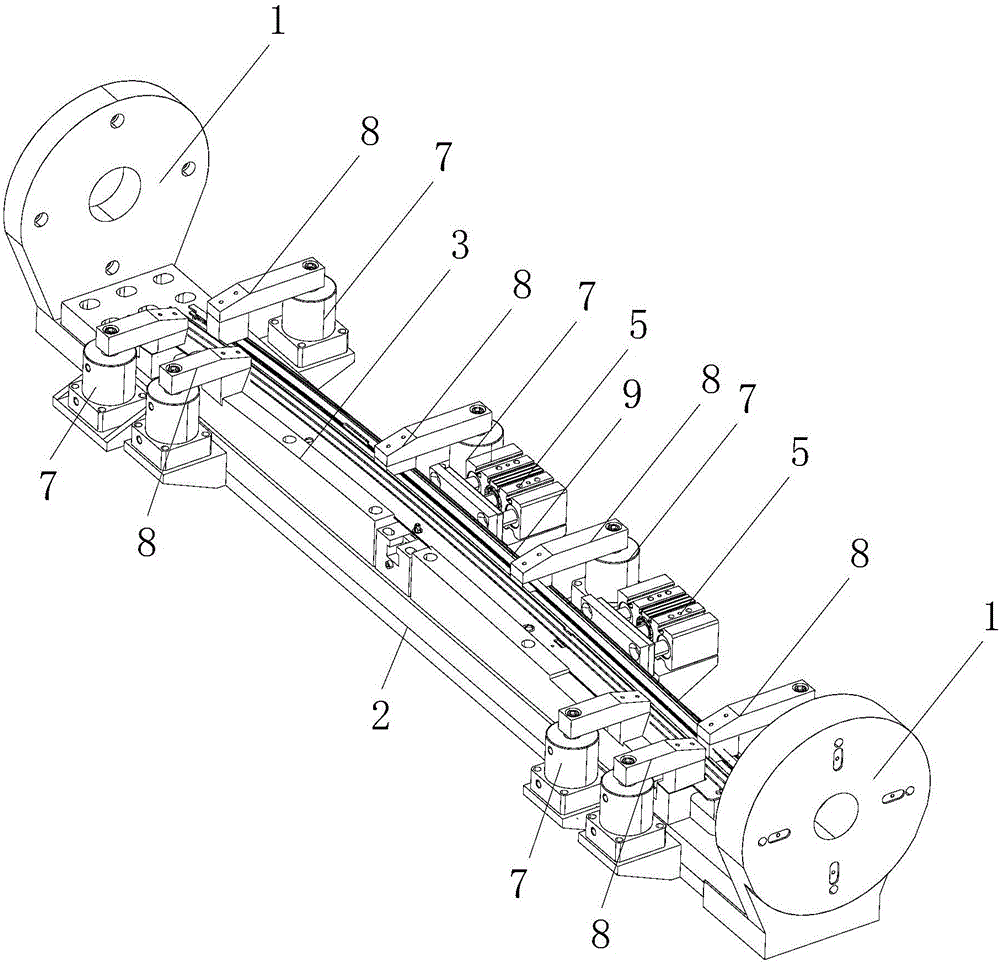

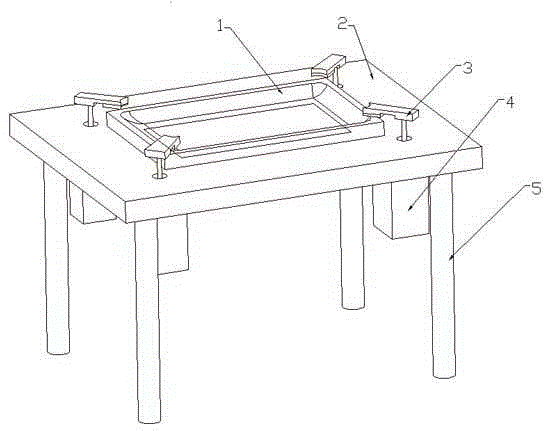

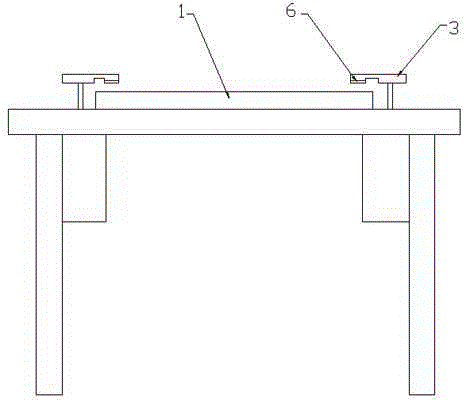

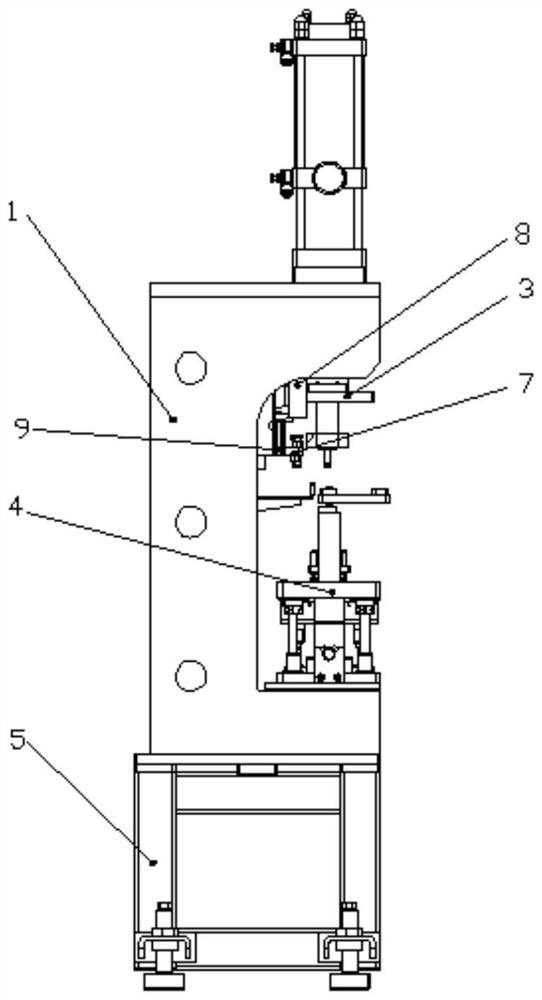

Pressing rivet device for skylight support and guide way

The invention provides a pressing rivet device for a skylight support and a guide way. Two bilateral symmetry C-shaped bodies are arranged for pressing riveting, bottom plates which sliding columns penetrate are arranged at bottoms of the bodies, top plates with pressing blocks at bottoms vertically slide on the sliding columns, and air cylinders press transition plates to press the top plates. By means of the method for pressing and riveting parts to be pressed and riveted, bilateral symmetry positioning placing plates are placed on a track in the middle of the two bodies so as to place the parts, areas to be pressed and riveted of the parts are placed above pressing rivet blocks in the space of the positioning placing plates, thereby, the parts are merely required to be placed manually and then slide by the track to be pressed and riveted, human safety can be guaranteed, meanwhile, the producing efficiency is greatly increased, the bodies are arranged on slide ways and slideable left and right, and the positions of the bodies can be adjusted according to actual conditions so as to achieve optimal pressing rivet effect.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Machining jig for thin-wall products with arc surfaces

InactiveCN105436916AEase of mass productionSimple structurePositioning apparatusMetal-working holdersAssembly lineEngineering

The invention discloses a machining jig for thin-wall products with arc surfaces. The machining jig is characterized by comprising a profiling jig panel and a vacuum air cylinder pressing claw. The machining jig has the advantages of being simple in structure, easy to manufacture and operate, suitable for an assembly line, capable of rapidly clamping and positioning the products, not prone to damage the products, high in positioning accuracy and high in production efficiency.

Owner:苏里

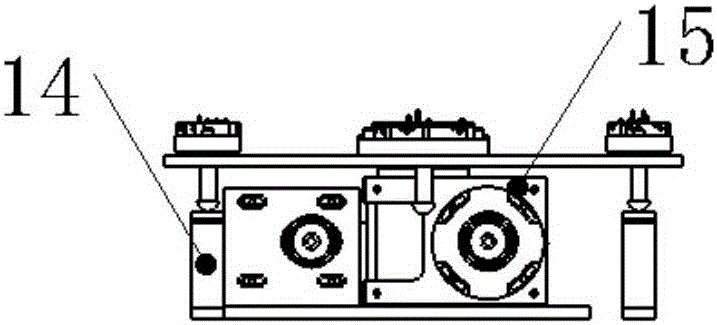

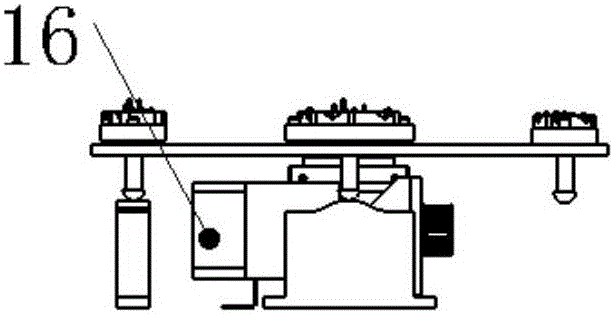

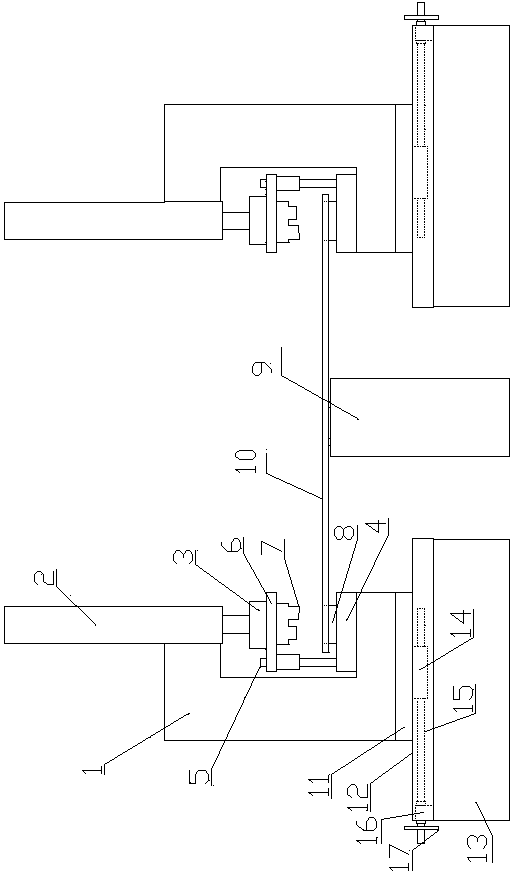

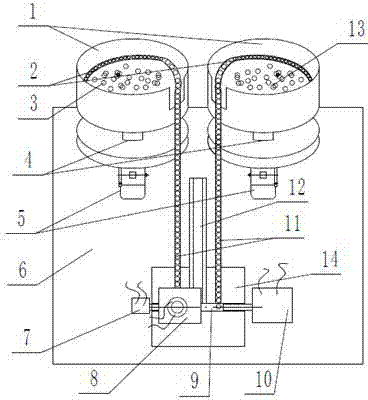

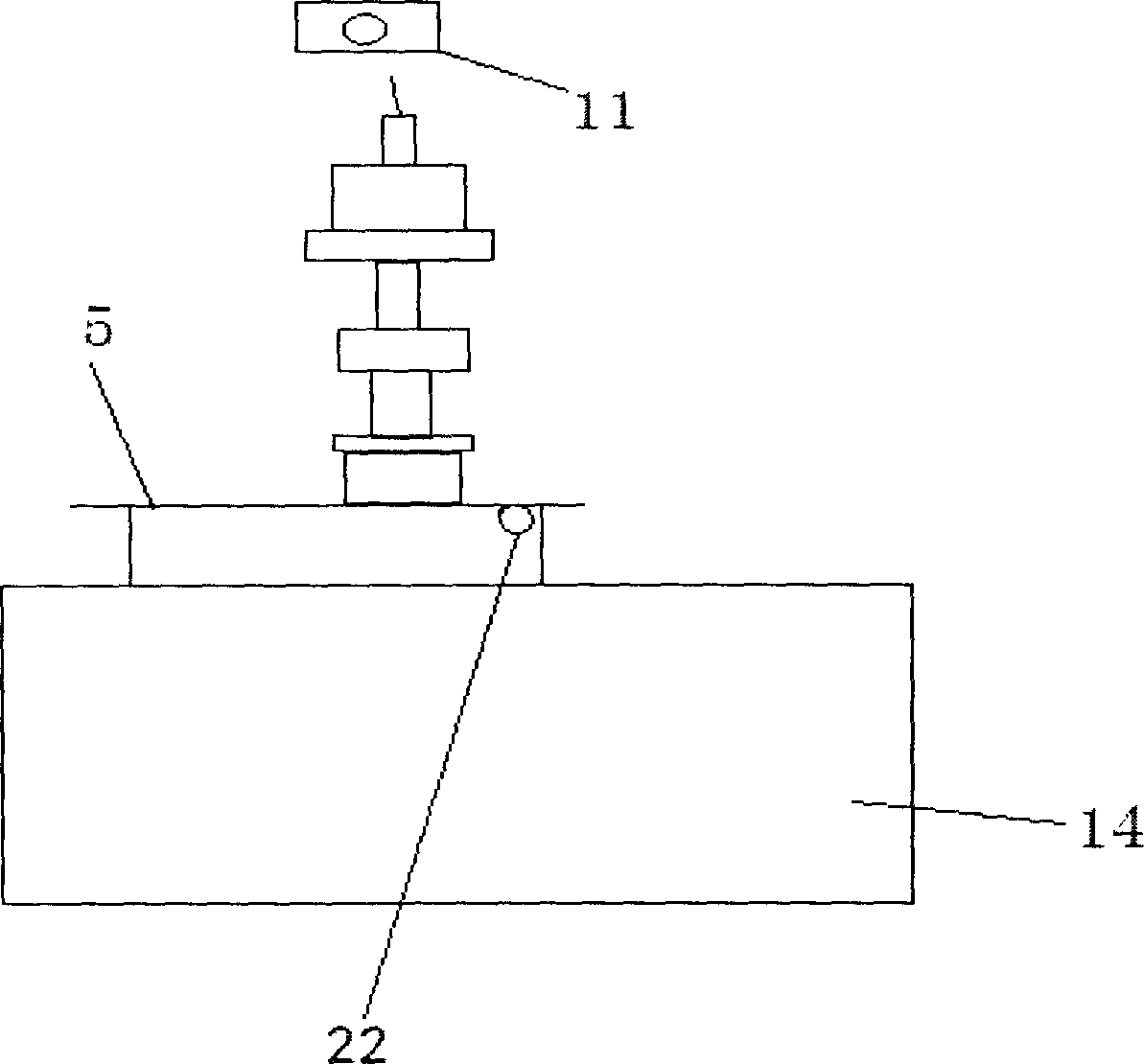

Double-layer coaxial cable connector assembly line

InactiveCN103618196AAchieve the purpose of the transferRealize feedingContact member assembly/disassemblyCoaxial cableAssembly line

A double-layer coaxial cable connector assembly line comprises spiral feeding machines, a base (6), a sliding rail (11), three air cylinders and an assembly board (14). Each spiral feeding machine comprises an electric motor (5), a center shaft (4) and two parallel hoppers (1). The assembly line is characterized in that the hoppers (1) are driven by the electric motors (5) to rotate, core columns (3) and shells (13) move to the sliding rail (11) along spiral rails (2) on the corresponding hoppers and are orderly arranged along a spiral groove, under the action of gravity, the shells (13) fall in a guide groove (9) of the assembly board (14), and the air cylinders press the core columns (3) into the shells (13). By means of mutual action of the two spiral feeding machines and the three air cylinders, feeding, pressing and transferring of finished products can be achieved once, and operation efficiency is improved by more than 10 times.

Owner:江苏烨鑫电子有限公司

Compression resistance detection test device of cellphone shell

InactiveCN107702994AImprove detection accuracyMaterial strength using tensile/compressive forcesCompressive resistanceEngineering

The invention provides a compression resistance detection test device of a cellphone shell. The device comprises a base, wherein a placing frame is arranged on the base; a fixed clamp is arranged at each of the two ends of the placing frame; a pressing-down air cylinder is arranged above the placing frame; a pressing-down block is arranged at the lower end of the pressing-down air cylinder; a pressing-down block is driven by the pressing-down air cylinder to press down the cellphone shell on the placing frame; a contact sensor is arranged on the base; a lifting motor is arranged at the lower end of the contact sensor; the contact sensor is driven by the lifting motor to move upwards to be in contact with the bottom of the cellphone shell, so that whether the cellphone shell is deformed isdetected. The cellphone shell is placed on the placing frame, the pressing-down block driven by the pressing-down air cylinder presses down the cellphone shell, and the deformation condition of the cellphone shell is detected by the contact sensor, so that a compression resistance test of the cellphone shell can be automatically completed; in addition, the maximum compressive resistance is detected and recorded by a force sensor, so that the detection accuracy is improved; an adjustable track is arranged, so that the device can be suitable for cellphone shells in different specifications.

Owner:芜湖辉灿电子科技有限公司

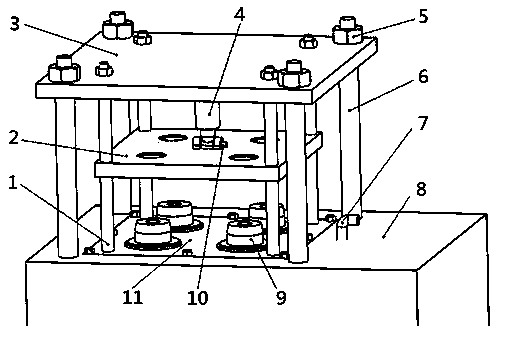

Auxiliary pressing device for rigid-flex board

PendingCN110913610AHeating fastIncrease the pressing speedMultilayer circuit manufactureEngineeringPrinted circuit board

The invention discloses an auxiliary pressing device for a rigid-flex board. The auxiliary pressing device comprises an upper pressing plate and a lower pressing plate. The upper surface of the upperpressing plate is connected with the main frame through a plurality of springs; the lower surface of the lower pressing plate is connected with a sliding block through a connecting column, the slidingblock can move up and down along a vertical sliding rail, a horizontal air cylinder is arranged on the side face of the sliding rail, a guide rail groove set is formed in the surface of the sliding block, and the guide rail groove set comprises a first guide rail groove, a second guide rail groove and a third guide rail groove which are connected in sequence. A pulley is arranged at the front endof a push rod of the horizontal air cylinder and embedded into the guide rail groove set. Compared with a traditional air cylinder press fit mode, the mode that the sliding block, the guide rail, thespring, the upper pressing plate and the lower pressing plate are matched is adopted in the device, so that the whole heating and press fit process of the rigid-flex printed circuit board is rapidlycompleted, the machining efficiency is high, and the press fit speed is high.

Owner:江苏弘信华印电路科技有限公司

Gas cylinder body airtightness detection device

InactiveCN104316273AGuaranteed sealing performanceAvoid wastingDetection of fluid at leakage pointGas cylinderSpray nozzle

The invention relates to a gas cylinder body airtightness detection device, and belongs to the field of measuring devices. The gas cylinder body airtightness detection device is provided with at least one gas way pipeline pipe or water way pipeline pipe, a bottom plate, a pressing plate, spraying nozzles and a top plate. The gas cylinder body airtightness detection device is characterized in that the bottom plate is provided with at least one spraying nozzle mounting hole, the pressing plate is arranged above the bottom plate, the pressing plate is provided with air cylinder pressing holes corresponding to the spraying nozzles, and the pressing plate is connected with the top plate through an oil cylinder; a gas cylinder body is buckled to the spraying nozzles in an inverted mode, the pressing plate is driven by the oil cylinder to press the bottom of the cylinder body so that the cylinder body can be clamped between the spraying nozzles and the pressing plate, it is guaranteed that a cylinder body opening is sealed, water or air is pumped into the cylinder body through spraying nozzle inner holes, a certain pressure is kept for a period of time, and whether the bottom of the cylinder body leaks the air or water is observed. By means of the gas cylinder body airtightness detection device, the airtightness of the gas cylinder body can be measured directly, the cylinder body which leaks the air can be detected in advance, waste caused by subsequent machining of waste pieces is avoided, the cost is reduced, and production efficiency is improved; the parts which can be detected by the gas cylinder body airtightness detection device are not restricted to the gas cylinder body, and all the products of the structure similar to that of the gas cylinder body can be detected.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

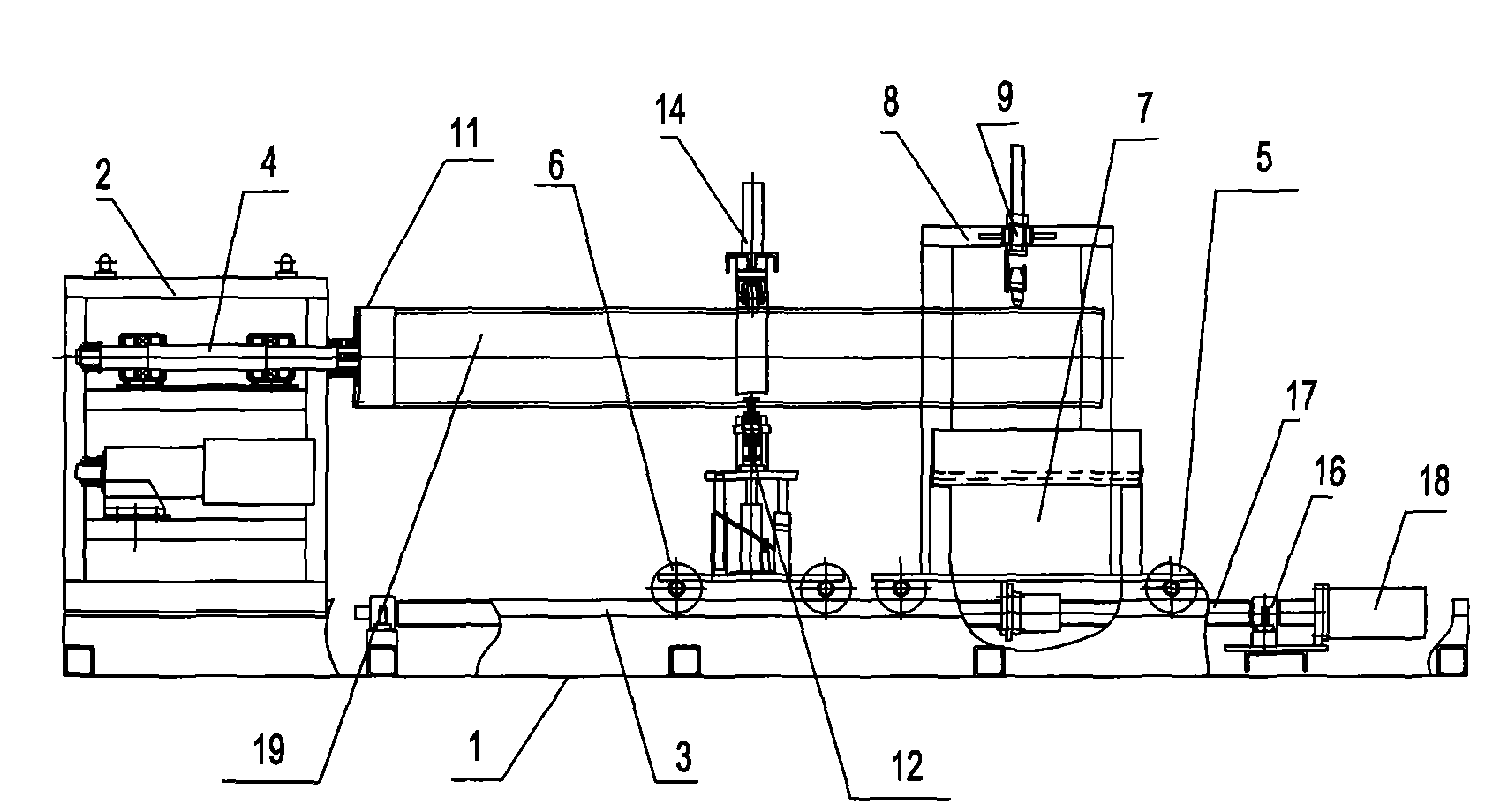

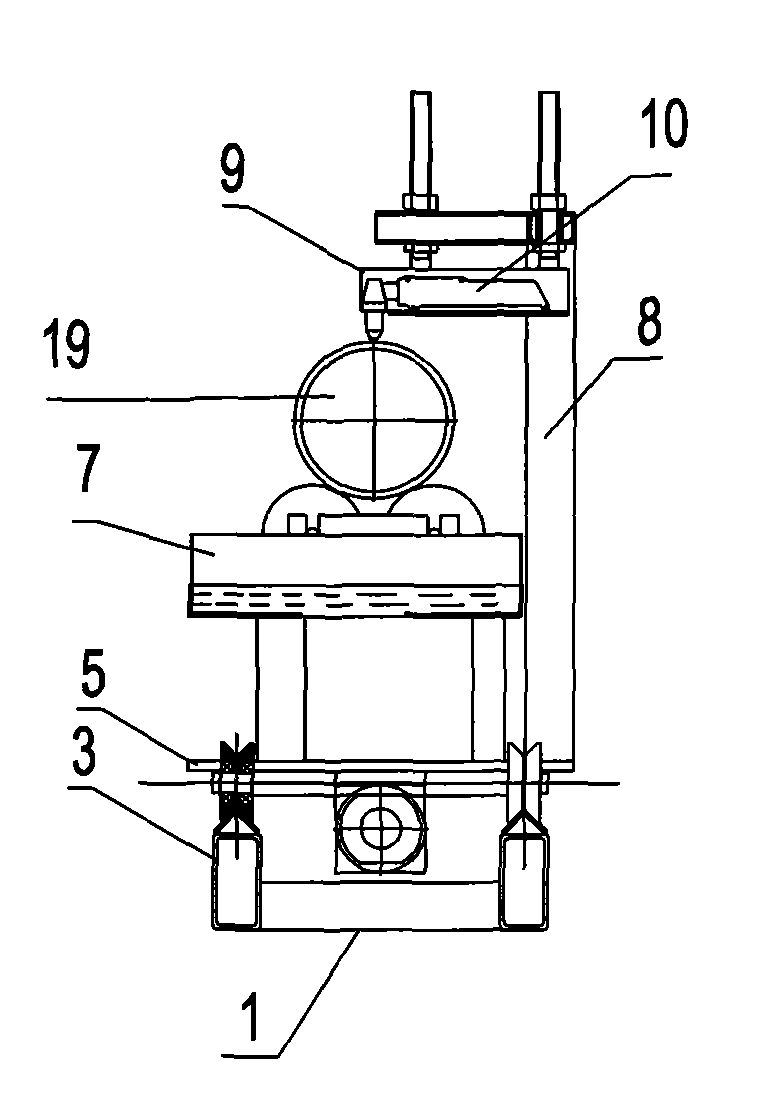

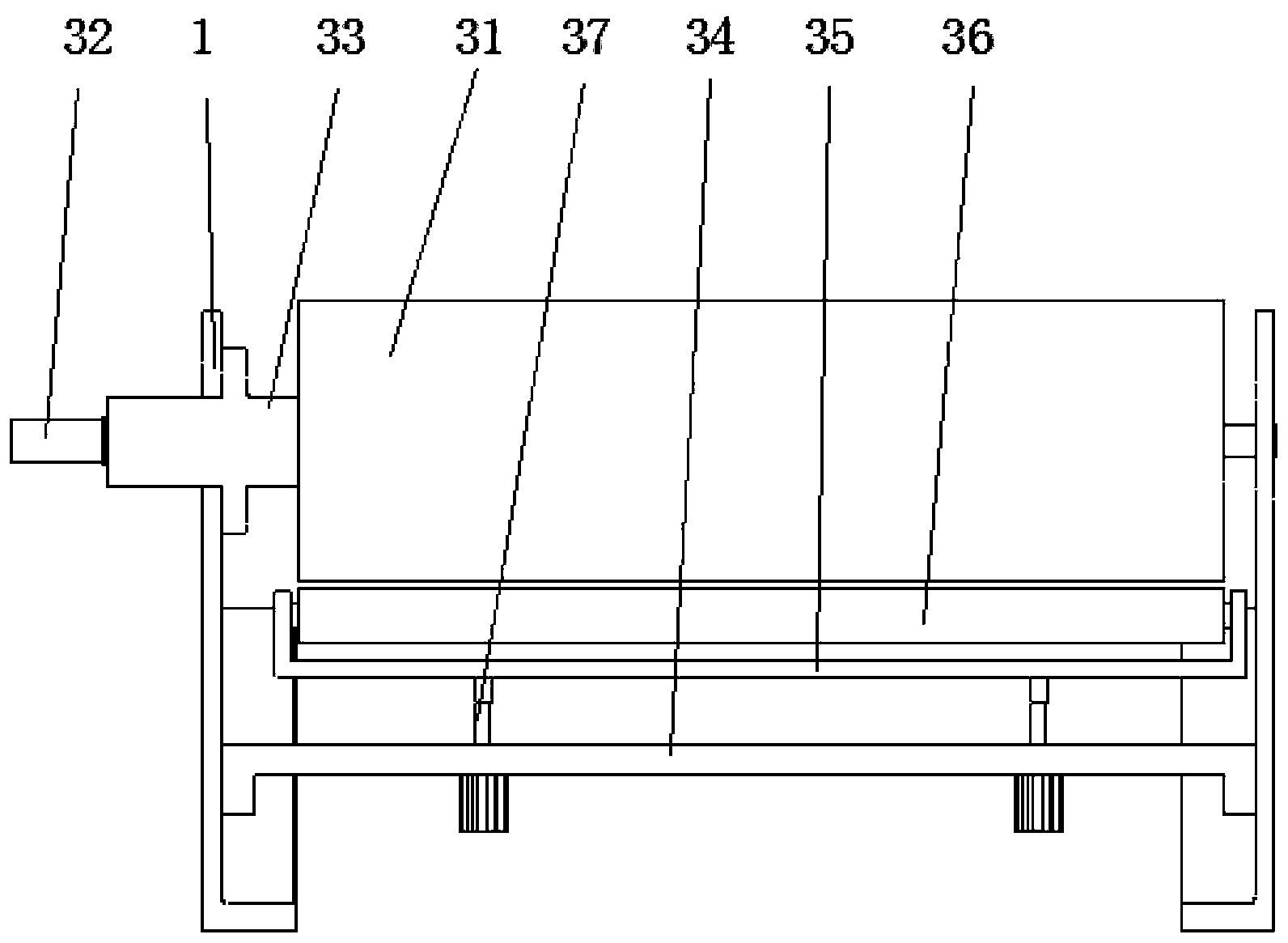

Automatic rolling equipment for lead sheathes

ActiveCN105921568AIncrease productivityPrevent leakageMetal-working feeding devicesStripping-off devicesInjection mouldingMechanical engineering

The invention provides automatic rolling equipment for lead sheathes, which comprises a frame, wherein a first workbench is arranged on the frame; a rolling device is arranged on the first workbench; a material taking device fitted with the rolling device is arranged on one side of the first workbench; a receiving device is arranged on the other side of the first workbench; the rolling device comprises rolling guide rails, rolling wheels, rolling air cylinders, positioning sheaths, positioning air cylinders and rotary motors; and the material taking device can be used for grabbing the lead sheaths to be processed and putting the lead sheaths to be processed on the positioning sheaths, then the positioning air cylinders press the lead sheathes on the positioning sheaths tightly, meanwhile, the lead sheaths and the positioning sheaths rotate under the driving of the rotary motors, and finally, the rolling wheels press the lead sheaths under the driving of the rolling air cylinders, so that sealing grooves are formed. The automatic rolling equipment has the advantages that the production efficiency is relatively high; and a lead material, which is at the positions of the sealing grooves originally, can reel, convex rings are formed on side walls near the openings of the sealing grooves, and parts obtained after secondary injection moulding can form inverted buckle structures at the positions of the sealing grooves, so that after the obtain lead sheathes are assembled, acid liquors are prevented from leaking or exuding.

Owner:QUANZHOU YUCRY TRAFFIC APPLIANCES

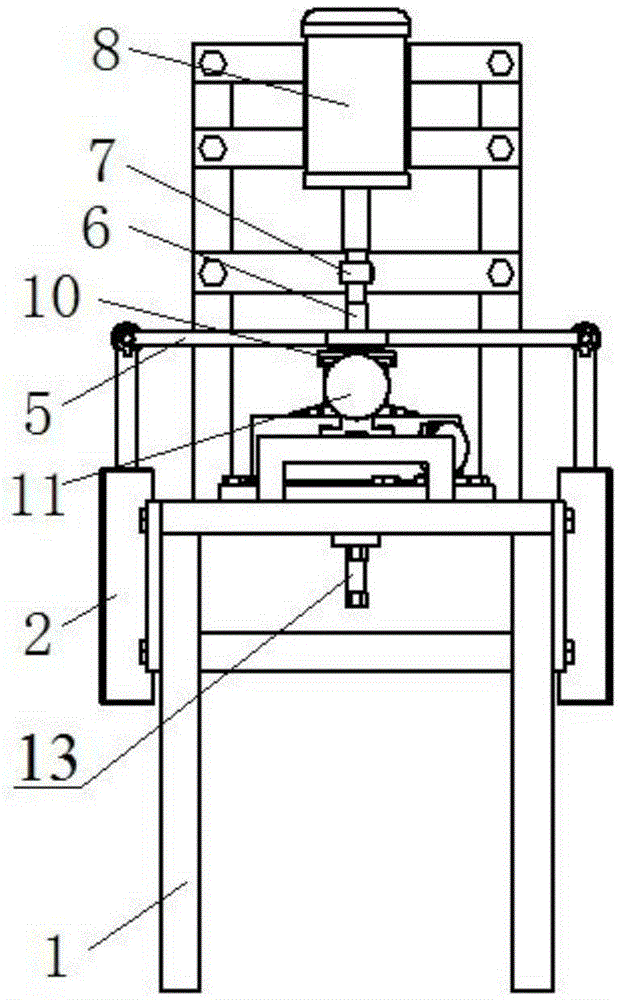

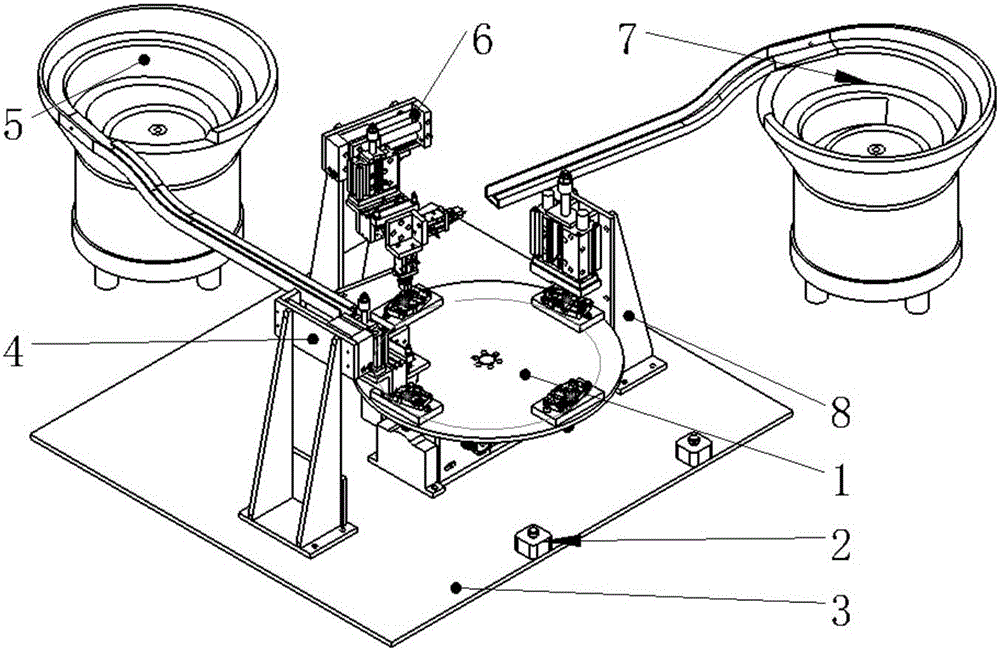

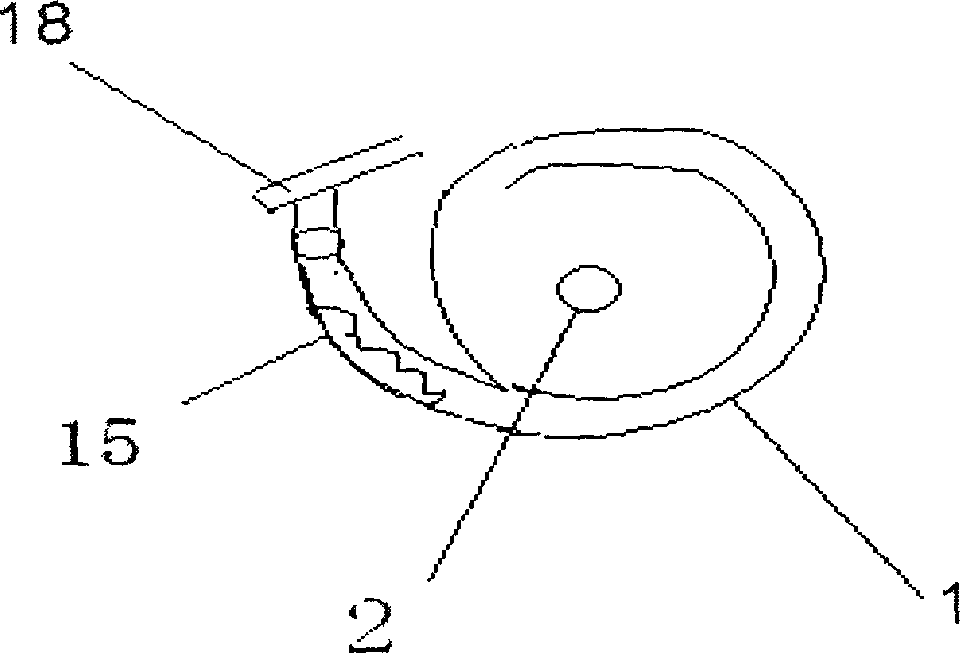

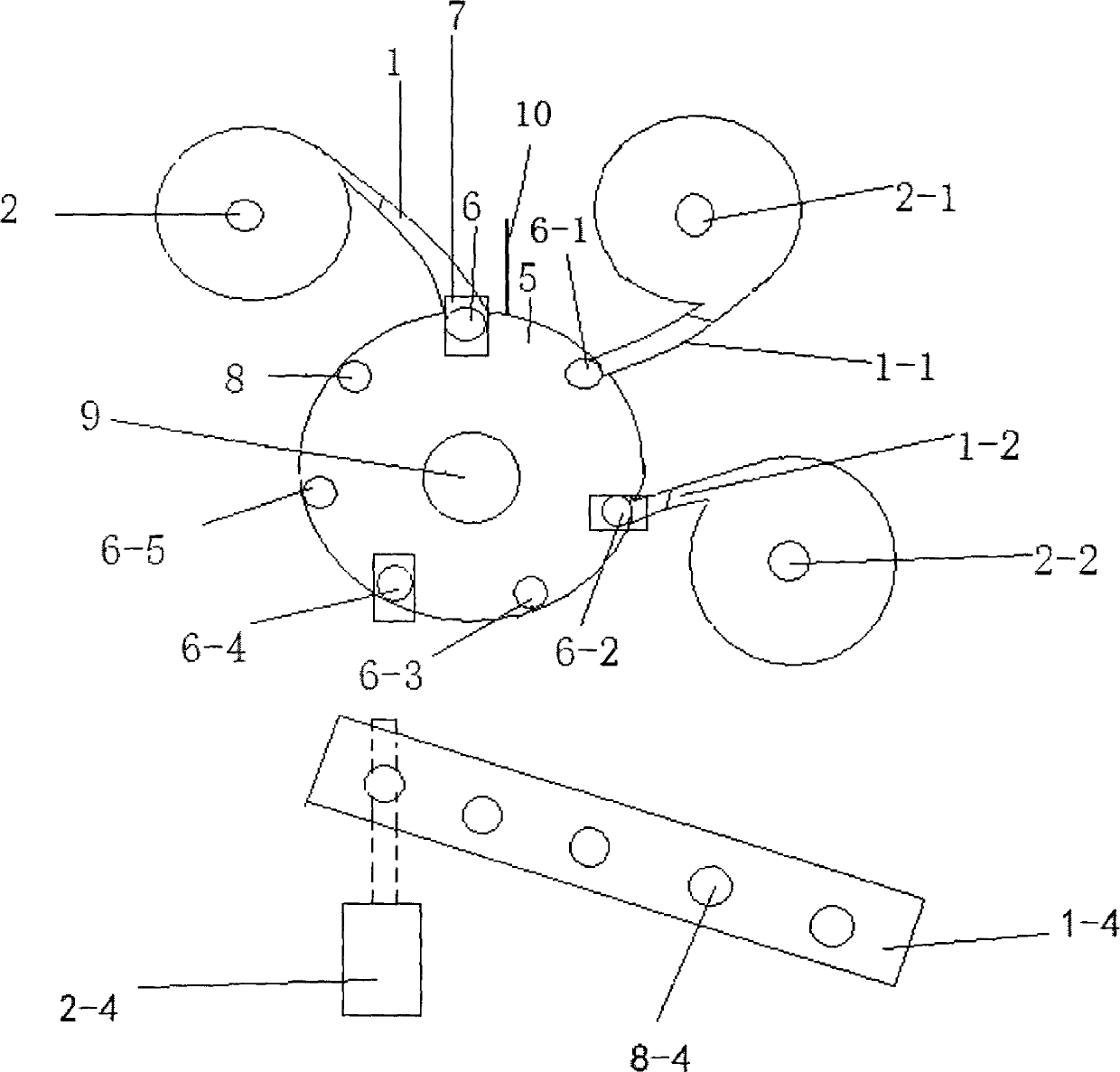

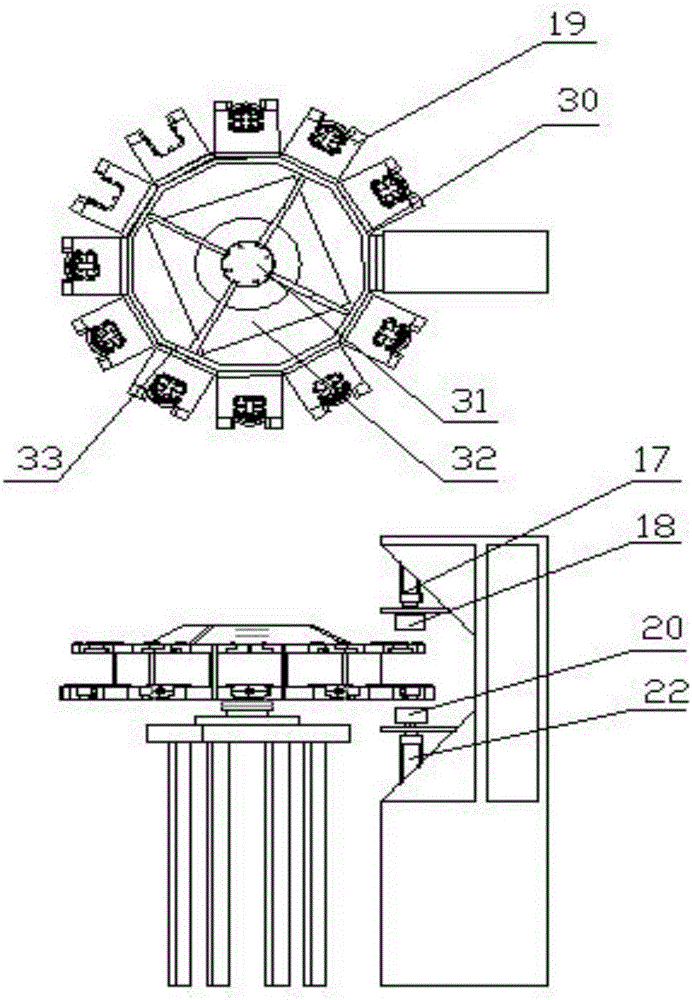

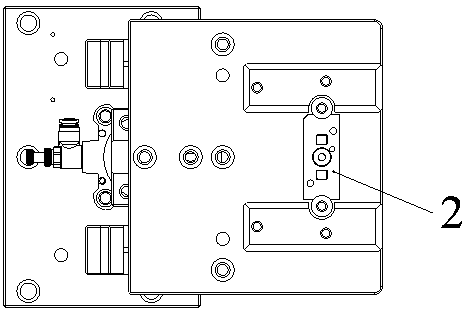

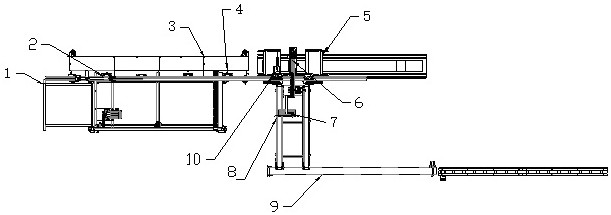

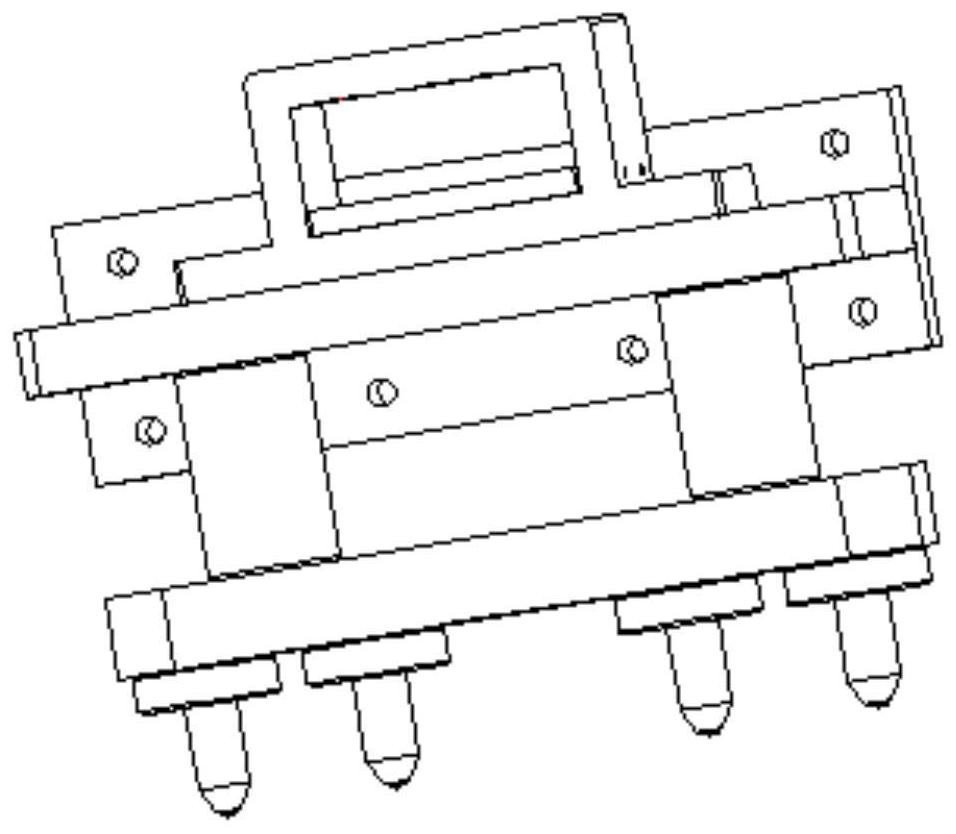

Seal assembling machine

The invention discloses a seal assembling machine. The seal assembling machine is characterized by comprising an air cylinder gland device (6), a handle feeding device head (6-1), an air cylinder pressing device (6-2), a glue dispensing device (6-3), an air cylinder pressing pad device (6-4), an air cylinder pressing pad reinforcing device (6-5) and a rotating disk (5) shared by the air cylinder gland device (6), the handle feeding device head (6-1), the air cylinder pressing device (6-2), the glue dispensing device (6-3), the air cylinder pressing pad device (6-4) and the air cylinder pressing pad reinforcing device (6-5). The air cylinder gland device (6) and the rotating disk (5) form a gland system, the handle feeding device head (6-1) and the rotating disk (5) form a handle system, the air cylinder pressing device (6-2) and the rotating disk (5) form a pressing system, the glue dispensing device (6-3) and the rotating disk (5) form a glue dispensing system, the air cylinder pressing pad device (6-4) and the rotating disk (5) form a pressing pad system, and the air cylinder pressing pad reinforcing device (6-5) and the rotating disk (5) form a pressing pad reinforcing system. A baffle (10) is installed on the side edge between the air cylinder gland device (6) and the handle feeding device head (6-1) above the rotating disk (5). A downward sliding track is installed below the baffle (10). All the vibration device, the power device and the air cylinder punching device (6) are connected with a computer control case (14) processed by computer programming programs and installed below the air cylinder pressing pad reinforcing device (6-5), and are controlled by the computer programming programs in the computer control case (14). The seal assembling machine can achieve full-automatic assembly, and is stable in product quality, high in yield and low in production cost.

Owner:LANXI SHENDIAO STATIONARY CO LTD

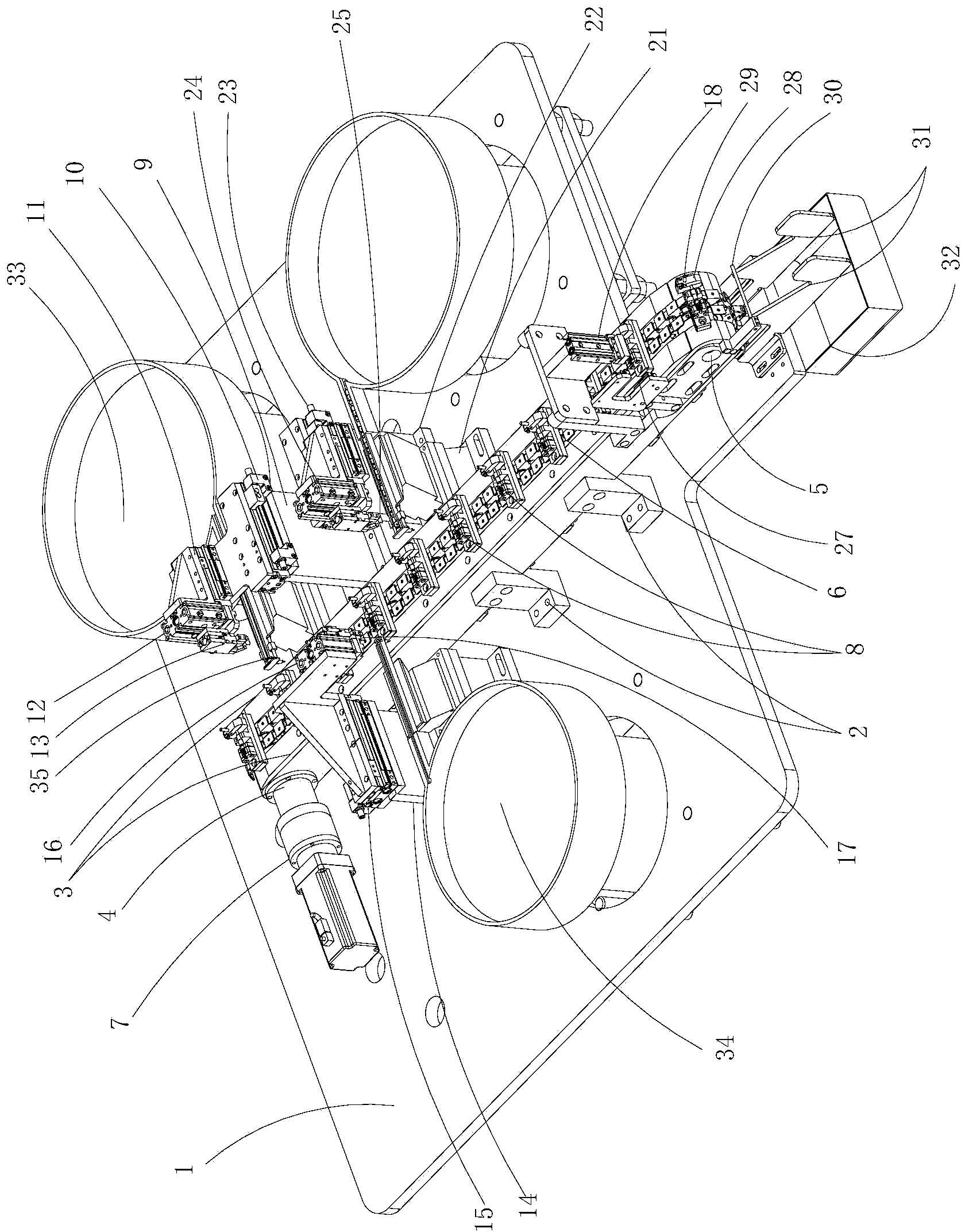

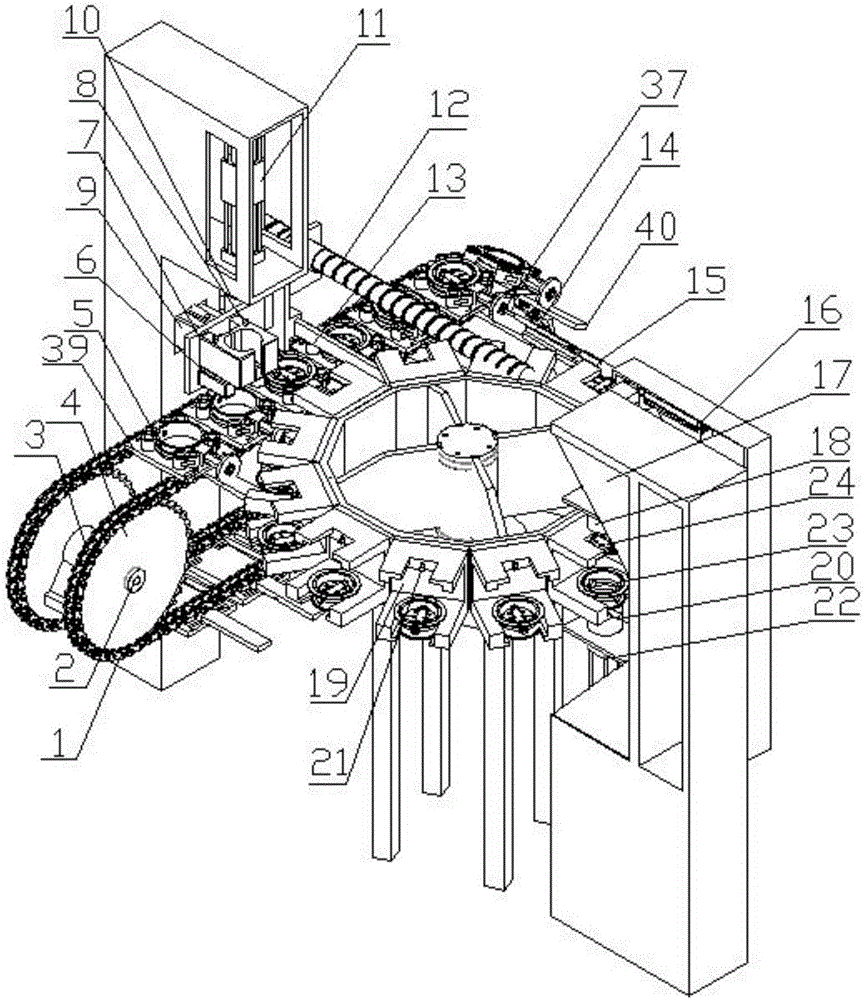

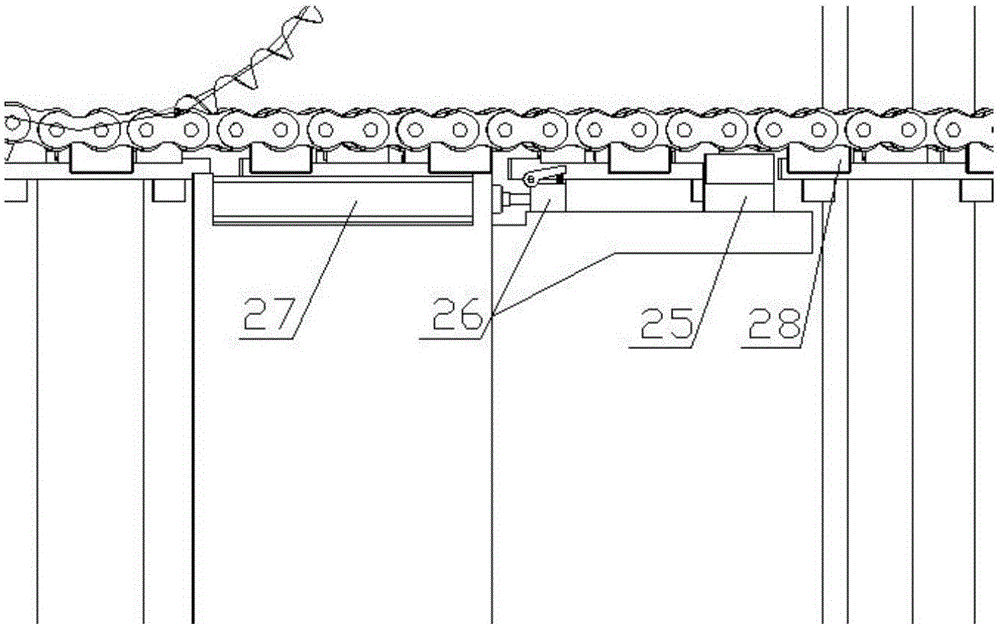

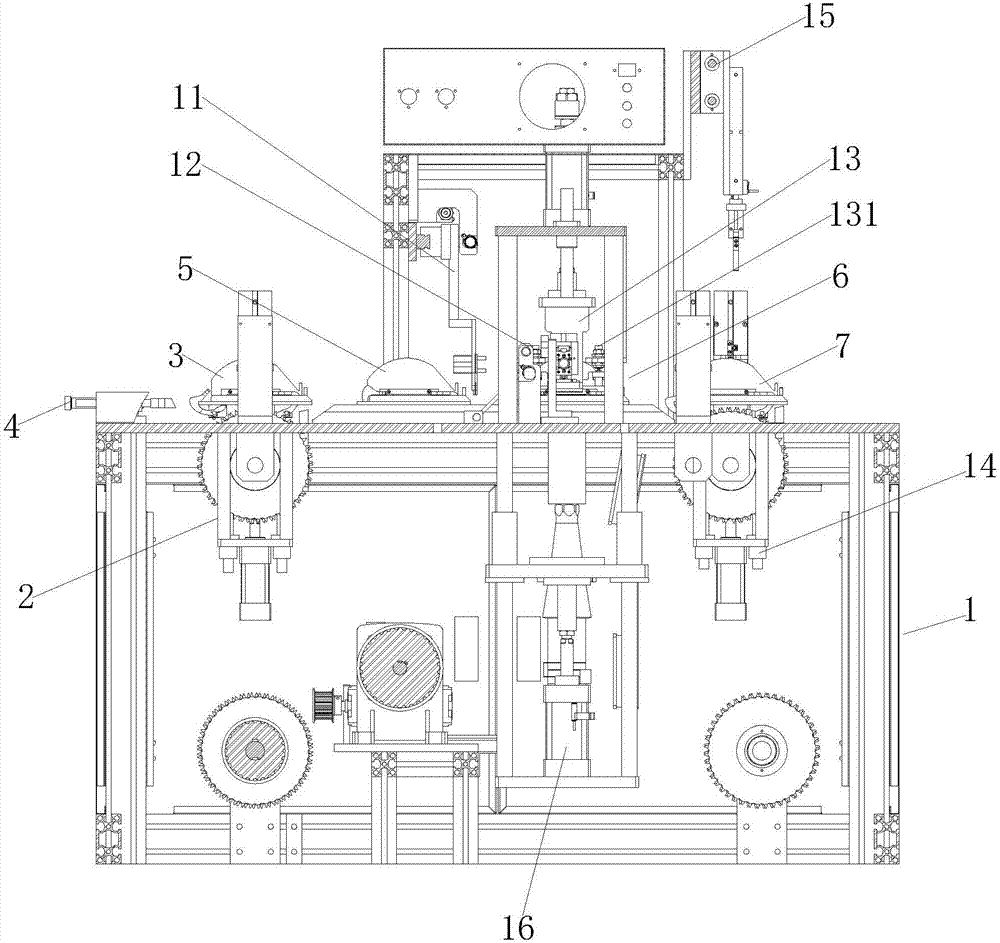

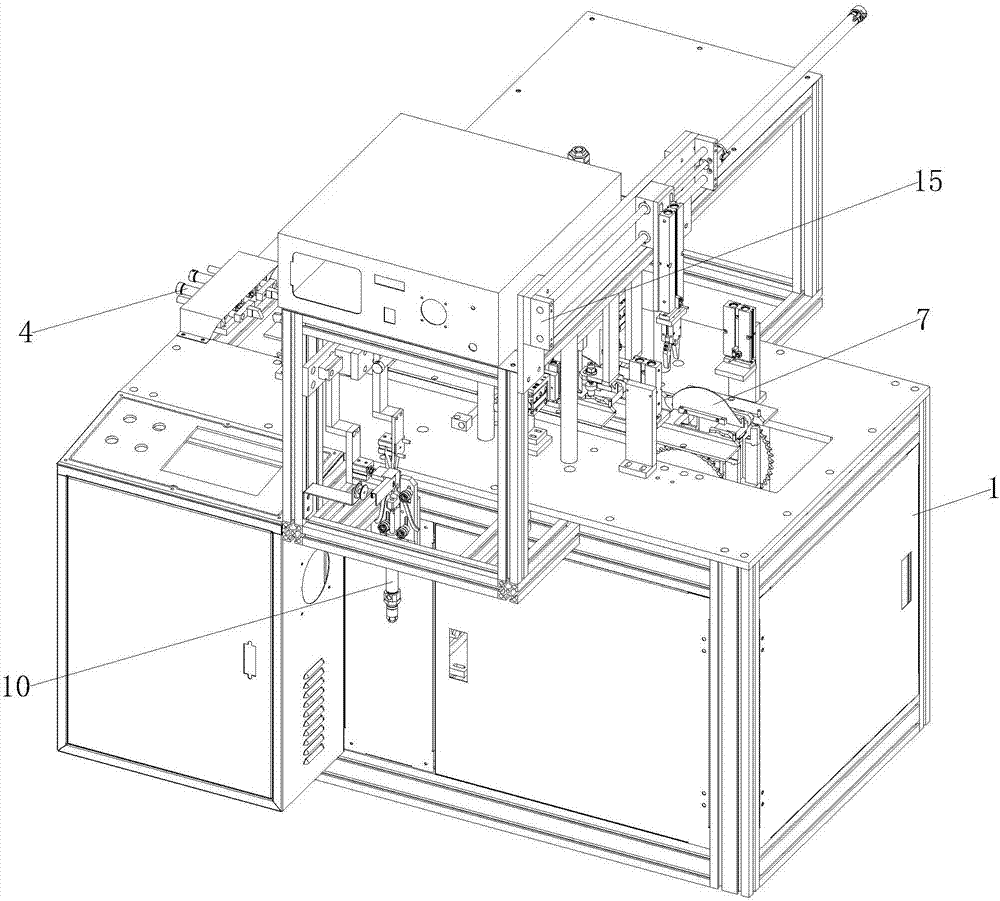

Automatic assembling machine for butterfly valve

InactiveCN106392628AGuarantee personal safetyImplement automatic assemblyAssembly machinesEngineeringButterfly valve

The invention discloses an automatic assembling machine for a butterfly valve, and relates to the valve manufacturing industry. The automatic assembling machine is used for automatic butterfly valve assembling. The automatic assembling machine comprises a chain conveying assembly, an air cylinder pushing positioning assembly, a dish plate and rubber sleeve combined clamp assembly, a rotation mechanism and air cylinder pressing-in assembly, a rubber sleeve mechanical arm assembly, a rubber sleeve air cylinder pressing-in assembly and a valve rod pushing-in assembly. The automatic assembling machine is characterized in that butterfly valve assembling is achieved jointly through the whole system, only a small number of workers are needed for supplementing materials and conducting assembling of simple procedures, automatic mechanical assembling is achieved, the manufacturing cost is saved, the labor intensity is relieved, and the personal safety of the workers is guaranteed.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Drilling automatic clamping device of double-lug supporting plate nut

InactiveCN109530762AImprove drilling accuracyImprove consistencyDrilling/boring measurement devicesPositioning apparatusEngineeringAir cylinder Press

The invention relates to a drilling automatic clamping device of a double-lug supporting plate nut. A part positioning mechanism used for positioning the double-lug supporting plate nut is arranged below a double-servo power head, a waterproof metal plate used for guiding drilling cuttings into a drilling cuttings collecting box is arranged on the periphery of the upper part of an air cylinder pressing mechanism, the clamping and positioning mechanism is arranged on the upper part of the air cylinder pressing mechanism, and the cuttings collecting box is arranged on one side of the air cylinder pressing mechanism. According to the device, the double-servo drilling power head is adopted for realizing automatic drilling machining of parts, the positioning and clamping modes of the parts areimproved so that the product hole diameter size precision can be improved, the product machining consistency can be effectively improved, and the pneumatic clamping can effectively solve the problem of twining chips around a cutter during cutting; the drilling cuttings collecting box is arranged so as to prevent cutting fluid from splashing, so that the drilling machining environment is improved,meanwhile, the compatibility requirement of multi-model part drilling is met, and large-batch automatic production and machining of the double-lug supporting plate nut can be realized.

Owner:JIANGXI HONGDU AVIATION IND GRP

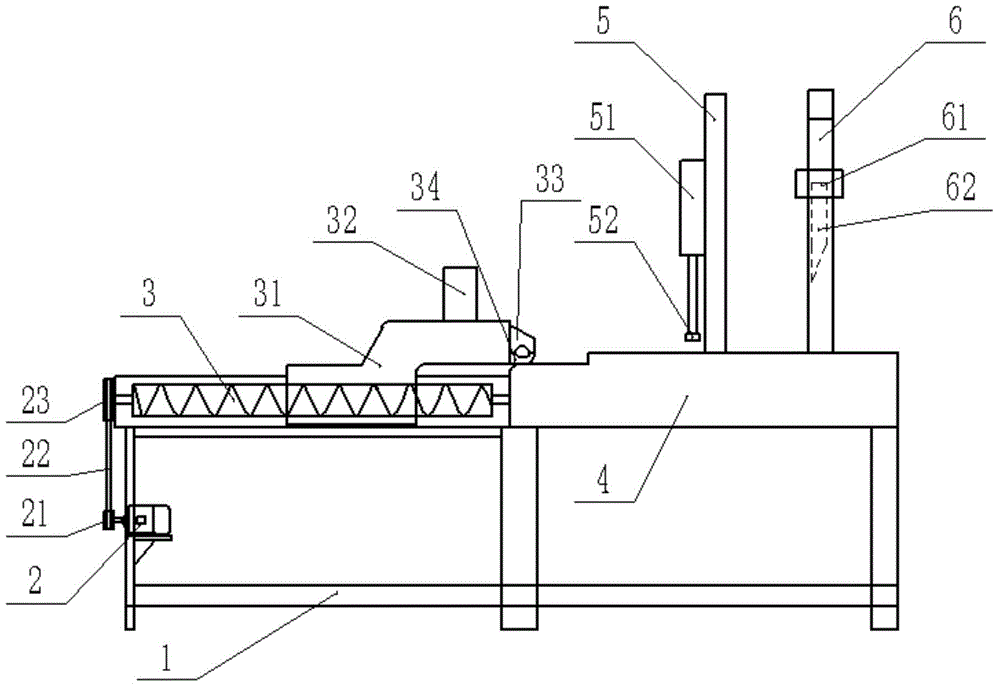

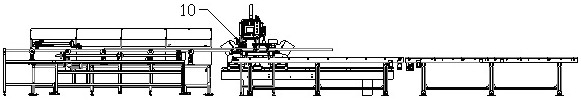

Photovoltaic frame double-material cutting system

PendingCN111644693AImprove cutting accuracyIncrease productivityMetal sawing devicesMetal sawing accessoriesManufactured materialEngineering

The invention relates to a photovoltaic frame double-material cutting system. The photovoltaic frame double-material cutting system comprises a raw material loading frame, a progressive feeding claw,a raw material feeding module, jacking assemblies, a double-head cutting saw, an unloading manipulator, a cantilever operation electric control cabinet, an unloading assembly line, a material-splitting assembly line and a cutting and positioning mechanism. The cutting and positioning mechanism comprises a material pressing air cylinder, side inserting pieces, a jacking air cylinder and side inserting tongues, after raw materials are fed in place, the material pressing air cylinder presses downwards, the side inserting pieces extends out and are pressed on a pressing plate of the material-pressing air cylinder to prevent upward motion, the jacking air cylinder rises, and the side inserting tongues extend and jack the lower surface of a copying block of the jacking air cylinder to prevent downward motion. According to the photovoltaic frame double-material cutting system, automatic double-material cutting is realized, one machine supplies one processing line body, the processing efficiency is improved, the labor strength is alleviated, and operating personnel is away from a saw blade outlet to eliminate potential safety hazards.

Owner:JIANGYIN AKCOME SCI & TECH

Equipment for riveting battery cover plate

ActiveCN112743030AQuality assuranceFlexible adjustment of riveting heightCell lids/coversStructural engineeringAir cylinder Press

The invention discloses equipment for riveting a battery cover plate. The equipment comprises a riveting support, a riveting rack table, a riveting pressing part and a riveting jacking part; the riveting support is fixed on the riveting rack table; the riveting pressing part is connected with the head of the riveting support; the riveting jacking part is connected with the table top of the riveting support; wherein the riveting pressing part comprises a gas-liquid pressure cylinder, a cylinder pressure head, a riveting pressure head assembly, a sliding block and a linear guide rail; The riveting jacking component comprises a jacking assembly; and the jacking assembly comprises a jacking bottom plate, a front air cylinder pressing head, a rear air cylinder pressing head, a jacking positioning plate, a front air cylinder floating connector base, a rear air cylinder floating connector base, four riveting jacking rods, a front jacking air cylinder, a rear jacking air cylinder and four bases. While the riveting quality is guaranteed, the application range is widened; and the riveting efficiency is improved.

Owner:马鞍山南实科技有限公司

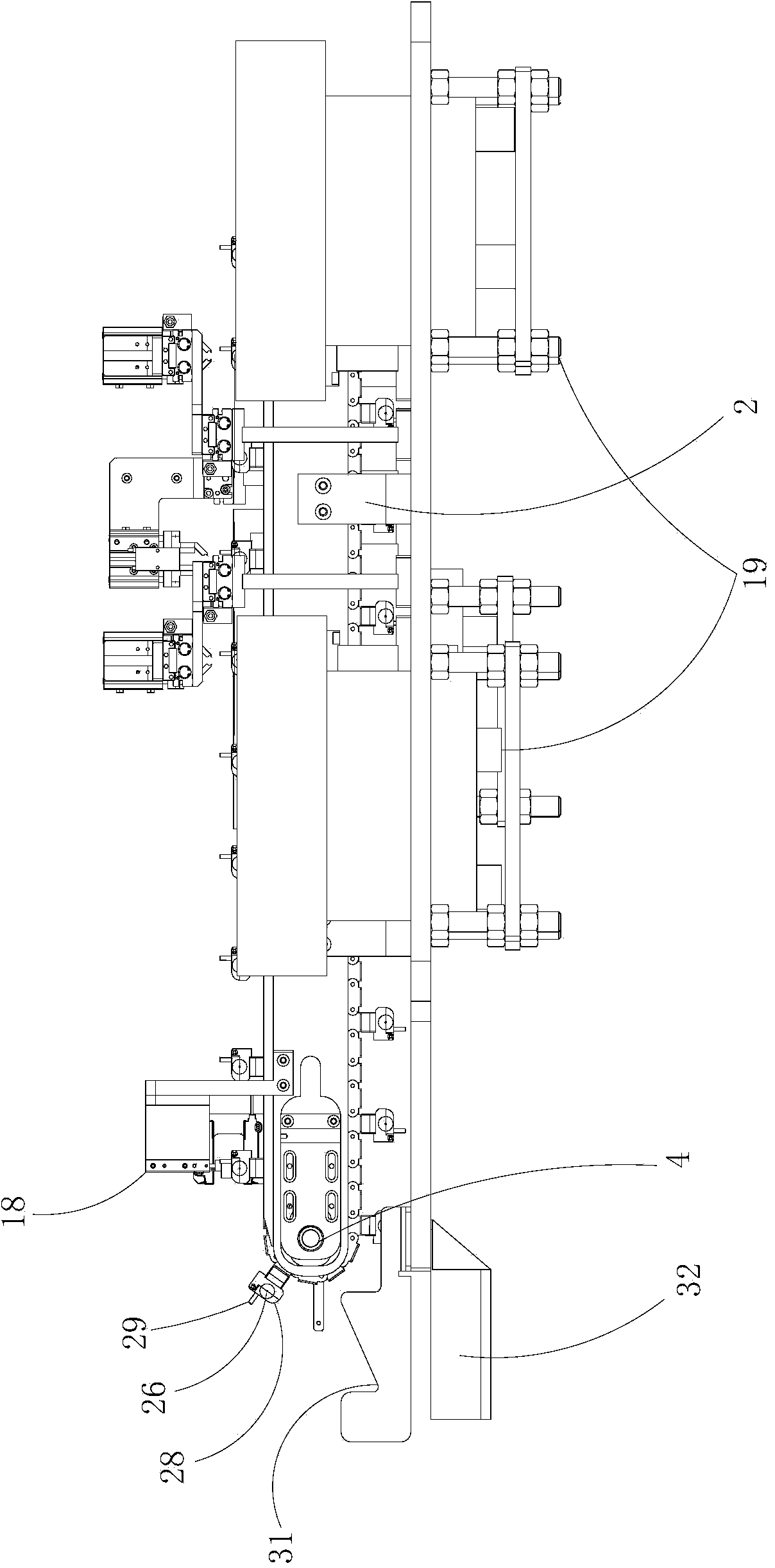

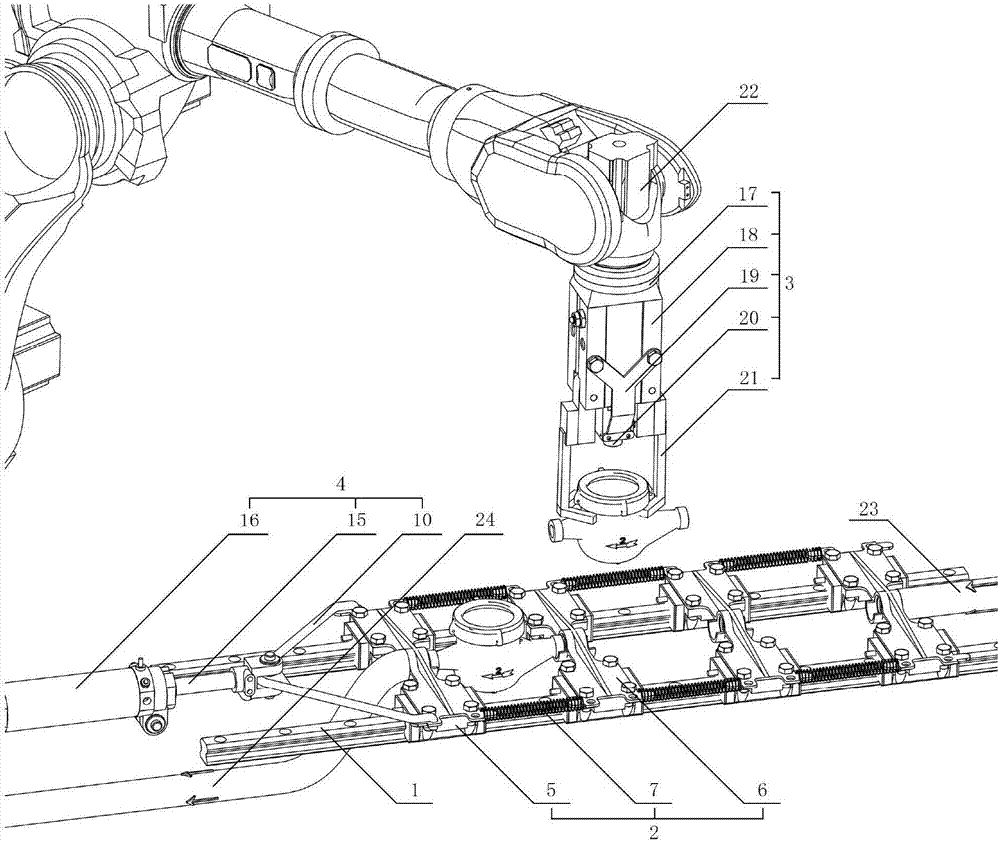

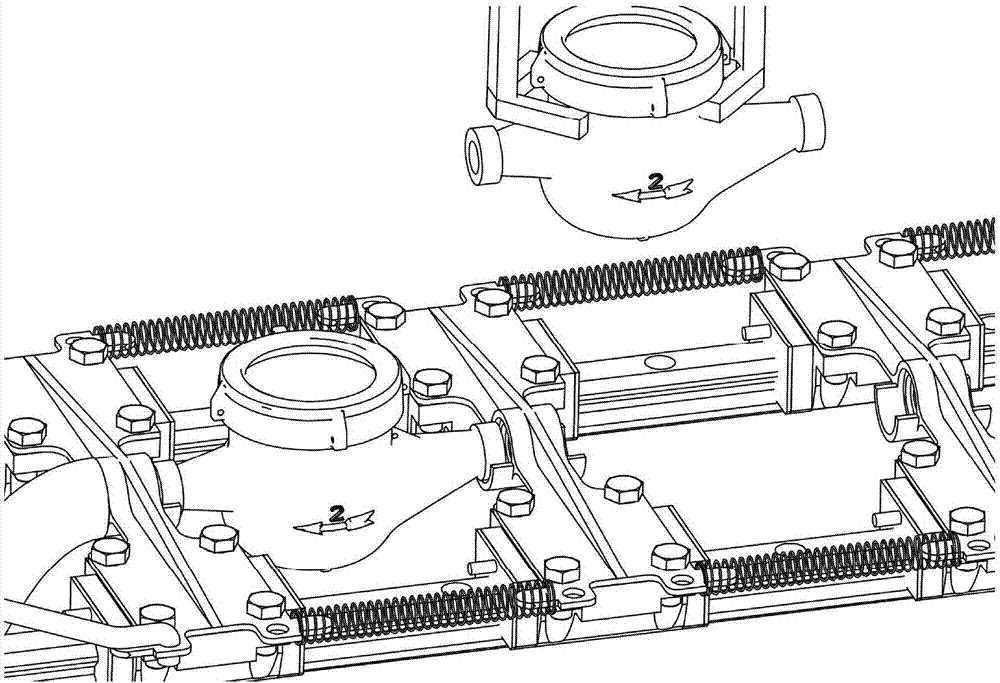

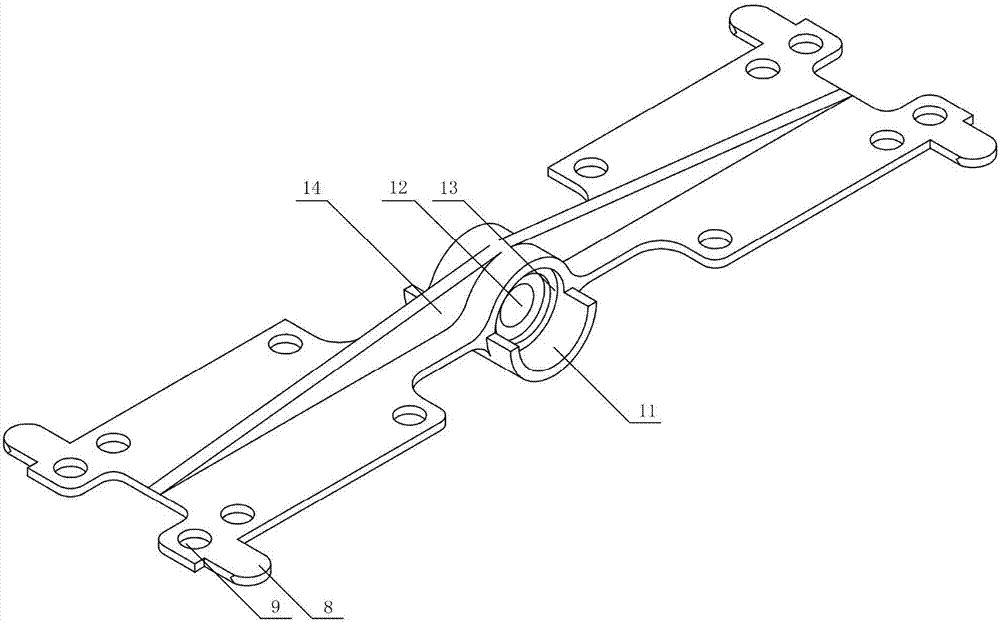

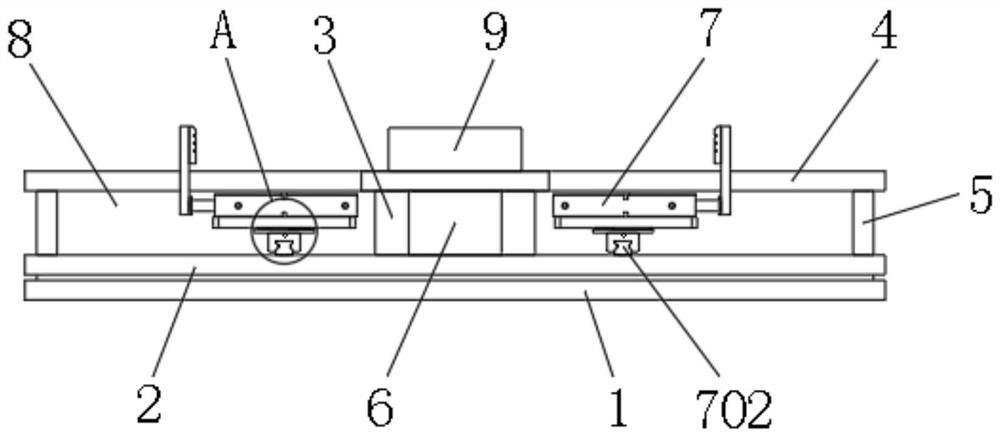

Calibration device and method for automatic fixing and visual pose adjustment of water meters

InactiveCN107478304AAccurate and quick testGuaranteed accuracyTesting/calibration apparatusEngineeringMechanical engineering

The invention discloses a calibration device and method for automatic fixing and visual pose adjustment of water meters. The device comprises parallel guide rails, a sliding mechanism, a water meter clamping mechanism and an air cylinder pressing mechanism, wherein the sliding mechanism, the water meter clamping mechanism and the air cylinder pressing mechanism are arranged on the parallel guide rails; the water meters are clamped by the water meter clamping mechanism and placed on the sliding mechanism, and then the air cylinder pressing mechanism drives the sliding mechanism to move along the parallel guide rails; a standard image is shot, a mechanical arm moves above the to-be-detected water meters, the to-be-detected water meters are grabbed, rotation is conducted again according to visions so that the posture of each to-be-detected water meter can be matched with a standard posture, the to-be-detected water meters are vertically placed between two connecting frames through the mechanical arm and placed in a half-moon-shaped lifting structure, an air cylinder barrel works so that an inlet and an outlet of each water meter and horizontal through holes of the connecting frames can be tightly pressed and communicated, and a fluid passage is formed to calibrate the water meter. Full automation of calibration of the water meters is achieved, manual water meter feeding is replaced, manual operation is not needed in the whole process of pipeline connection, feeding and calibration, manpower is saved, and the water meter calibration efficiency is improved.

Owner:CHINA JILIANG UNIV

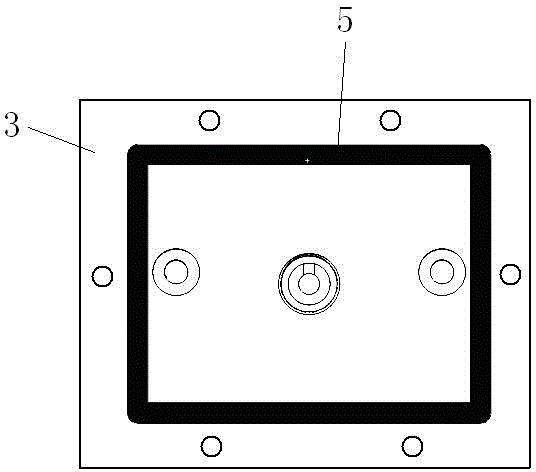

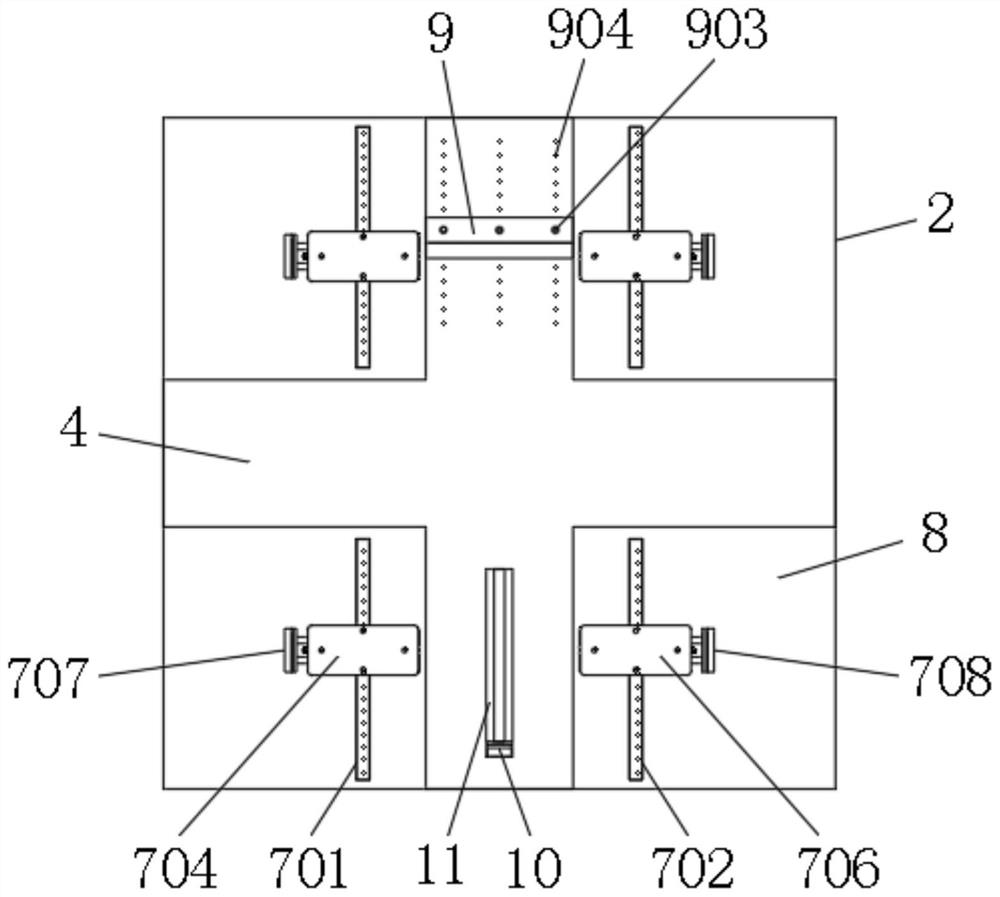

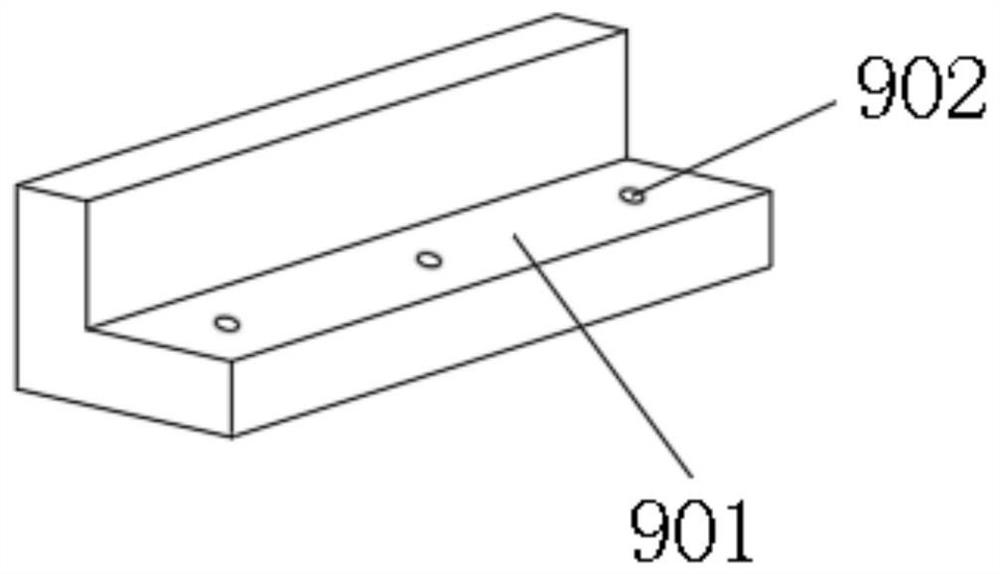

Air cylinder pressing clamp for numerical control machine tool

PendingCN112692617ARapid positioningQuick clampingPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention provides an air cylinder pressing clamp for a numerical control machine tool, and relates to the technical field of numerical control machining. The air cylinder pressing clamp for the numerical control machine tool comprises a base, a rotating platform is rotationally connected to the top of the base, a center base is fixedly connected to the center of the top of the rotating platform, a supporting plate is fixedly connected to the top of the center base, and clamping mechanisms are fixedly installed at the front ends and the rear ends of the two sides of the top of the rotating platform; and openings corresponding to the clamping mechanisms are formed in the corners of the supporting plate, a limiting mechanism is installed at the rear end of the top of the supporting plate, and a pushing mechanism is installed between fixing blocks. By designing the clamping mechanisms, the limiting mechanism and the pushing mechanism, various to-be-machined workpieces of different shapes and sizes can be rapidly clamped and fixed, and after the workpieces are placed on the supporting plate, the pushing mechanism can automatically push the workpieces to move to the designated position, so that the overall working efficiency is greatly improved, and the clamp is worthy of vigorous popularization.

Owner:江苏艾克赛勒金属科技有限公司

Automatic strip-installing and flanging welding machine for mask

The invention discloses an automatic strip-installing and flanging welding machine for a mask. The automatic strip-installing and flanging welding machine comprises a machine body. A first closing clamp is arranged on the inner side of the machine body; a first station is arranged above the first closing clamp, and a second station is arranged on the other side of the first station; and a strip clamping and pulling mechanism is arranged on one side of the second station and comprises a fixed strip-clamping air cylinder, a first transverse-moving air cylinder, a second transverse-moving air cylinder, a first transverse-moving strip-clamping air cylinder and a second transverse-moving strip-clamping air cylinder. According to the automatic strip-installing and flanging welding machine for the mask, a mask product needing to be machined is put on a material disc of the first station manually; the first closing clamp and the second closing clamp make action simultaneously to clamp the mask; when the material disc moves to a third station from the second station, strips are clamped by strip clamping pins on the two edges of the material disc and taken by the strip clamping pins to the third station; and a lower mould rises, a strip pressing air cylinder presses the strips, a flanging set conducts flanging, and an upper mould falls for welding and completes resetting. The automationdegree is high, the production efficiency is high, and the production cost is reduced effectively.

Owner:东莞市汇通自动化设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com