Automatic assembling machine for butterfly valve

A technology for assembly machines and valves, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of many operators, low work efficiency, and poor assembly quality, so as to ensure personal safety, reduce labor intensity, save The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

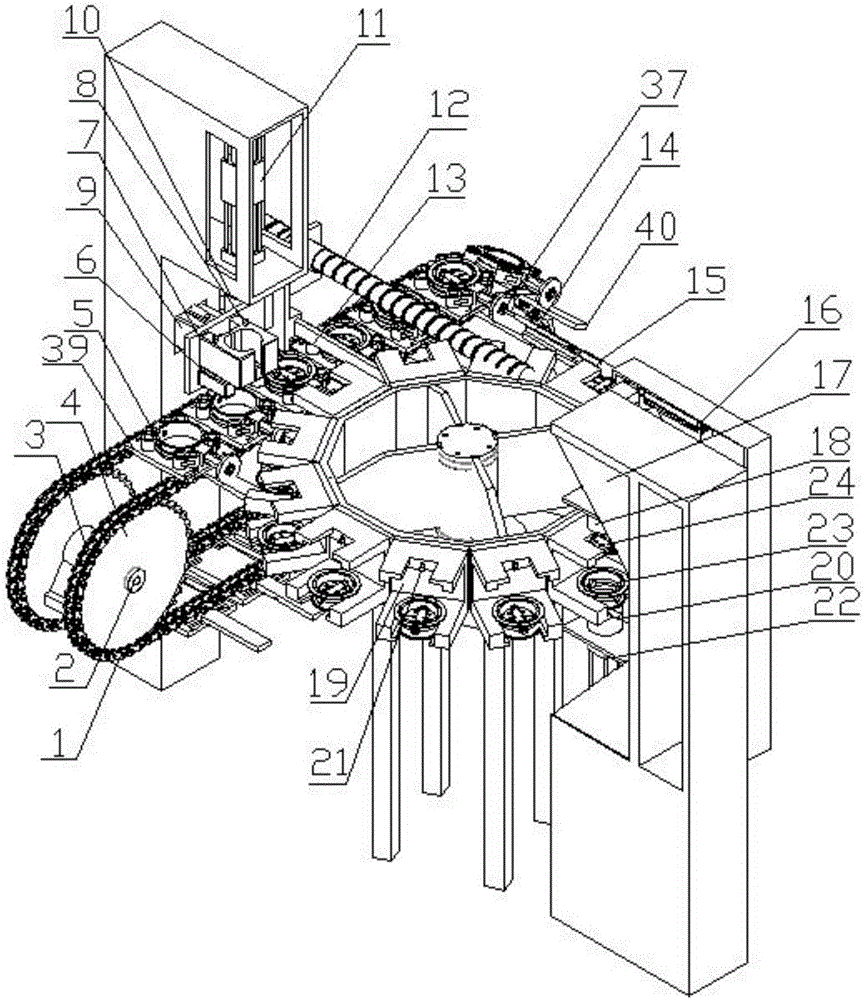

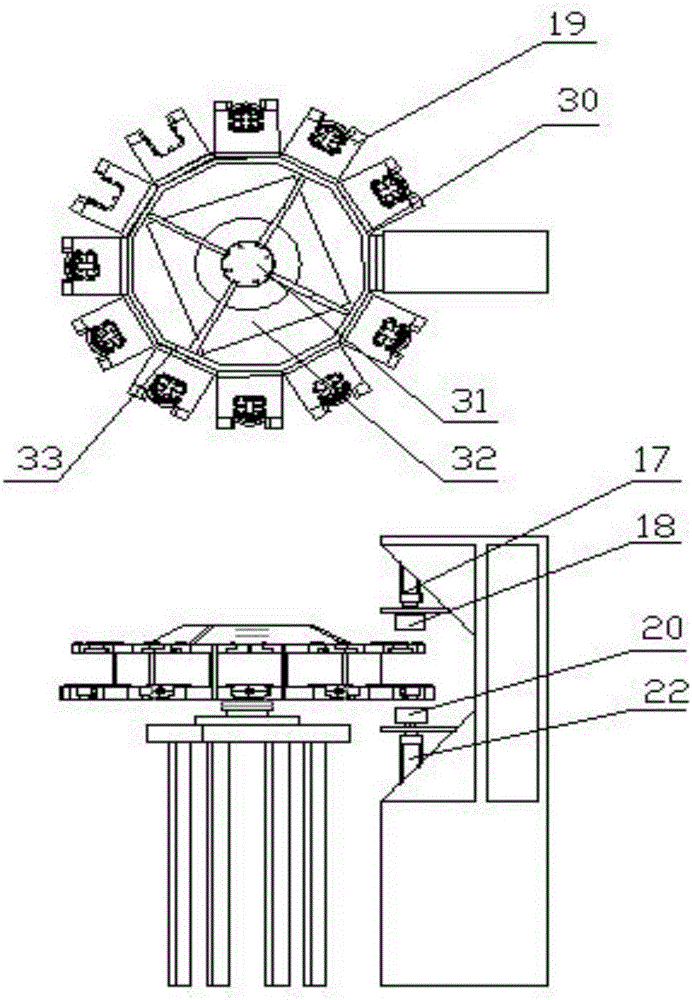

[0025] The present invention consists of a chain conveying assembly, a cylinder pushing and positioning assembly, a rotating mechanism assembly, a disc rubber sleeve advancing and positioning assembly, a large rubber sleeve manipulator assembly, a large rubber sleeve cylinder pressing assembly, and a valve stem pushing assembly and so on.

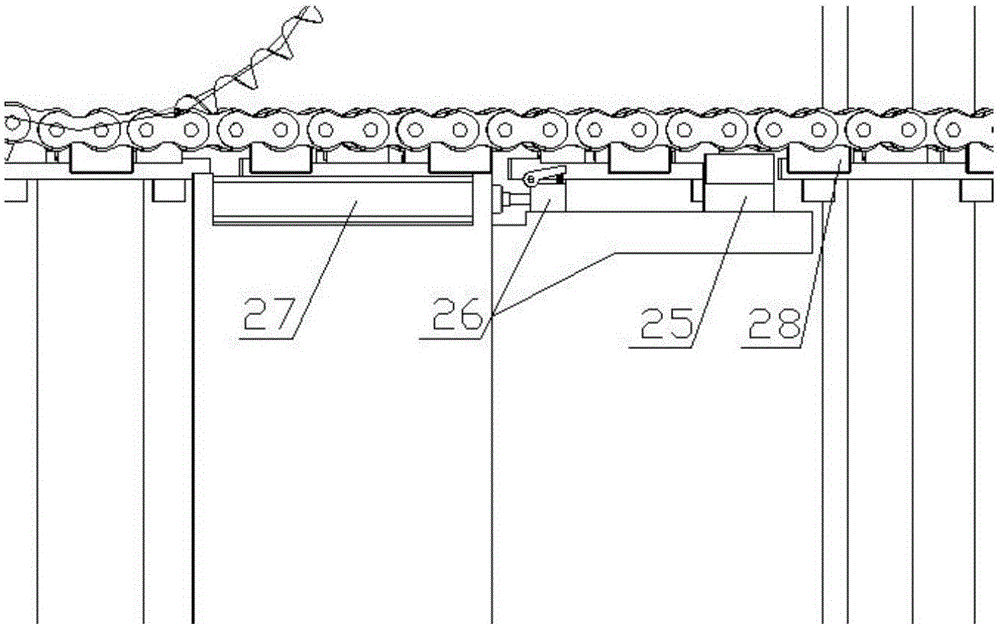

[0026] See attached figure 1 , the chain conveying assembly is composed of chain shaft 2, sprocket 4, chain 1, valve body seat plate 39, tensioner 3, etc., the chain 1 drives the upper valve body 5 to realize the feeding action, and the tensioner 3 is used to prevent Chain 1 comes off and loose. By controlling the stop position of the seat plate 39 of the valve body, the positioning between the valve body assemblies is completed, and the synchronous accuracy of assembly during the intermittent movement of each assembly is ensured. The chain adopts a double-pitch chain with a double pitch of 38.1 mm, and a double-pitch sprocket with 20 tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com