Mechanical device and assembling method for automatic square ball valve assembling system

A technology of automatic assembly and mechanical device, applied in assembly machines, by detecting the appearance of fluid at the leak point, metal processing equipment, etc., it can solve the problem of difficulty in ensuring product quality stability and uniformity, square valve assembly and inflation process dispersion, Assembly quality skills, experience influence and other issues, to achieve the effect of saving assembly labor, achieving uniformity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

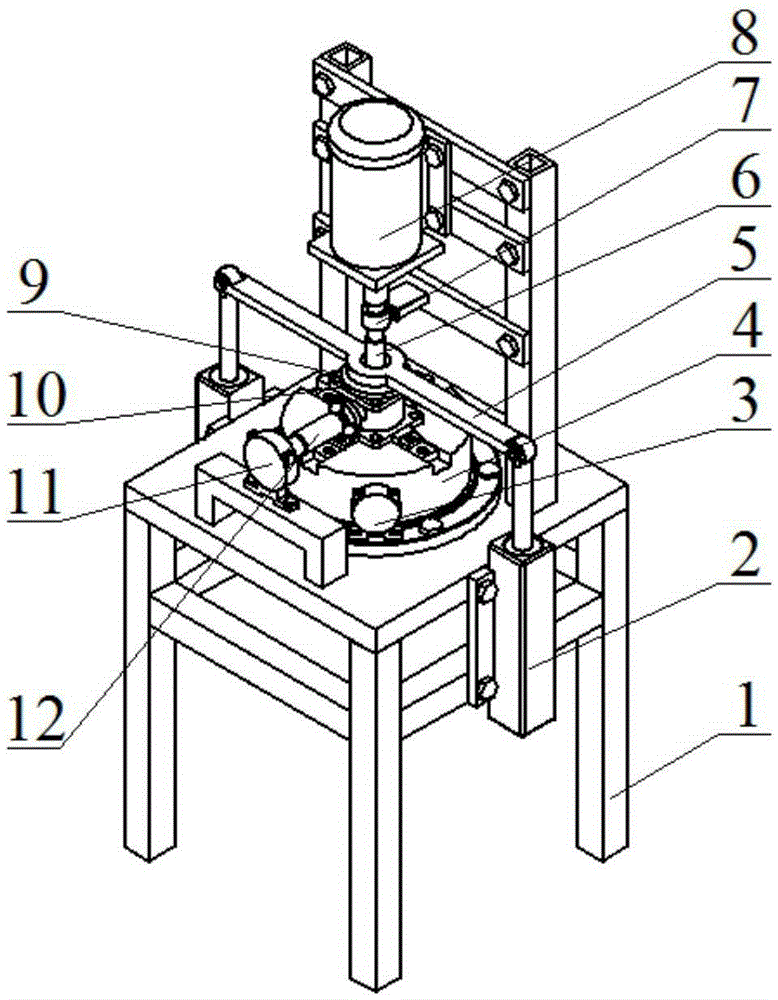

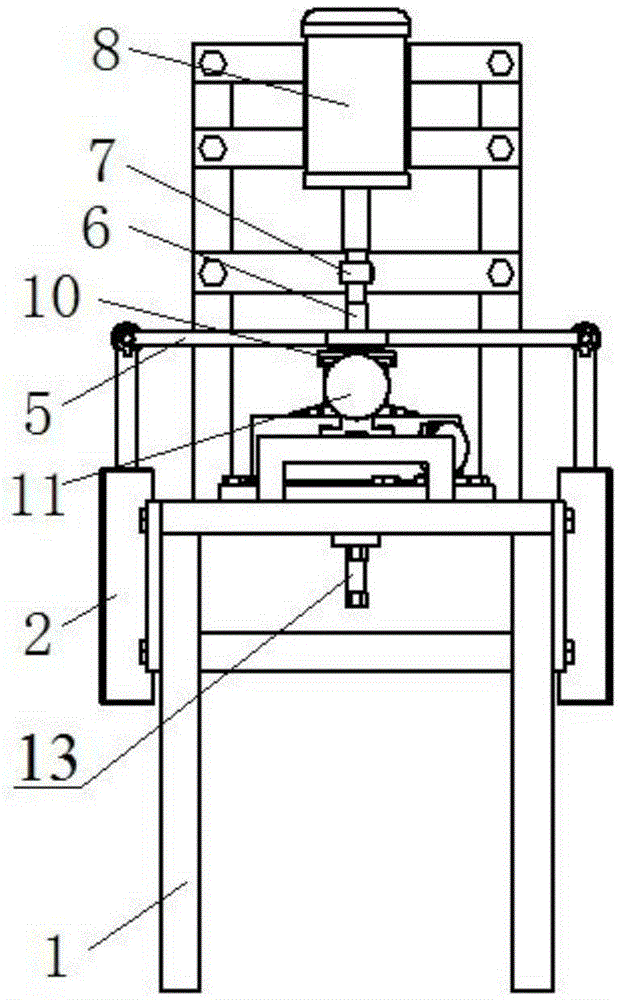

[0025] Such as Figures 1 to 7 As shown, a mechanical device of a square ball valve automatic assembly system includes a cylinder 2, an air motor one 3, a four-jaw chuck 4, a cylinder pressure plate 5, a motor 8, a rubber pad 10, an air motor two 11, a transmission sleeve 12 and a pneumatic Check valve 13.

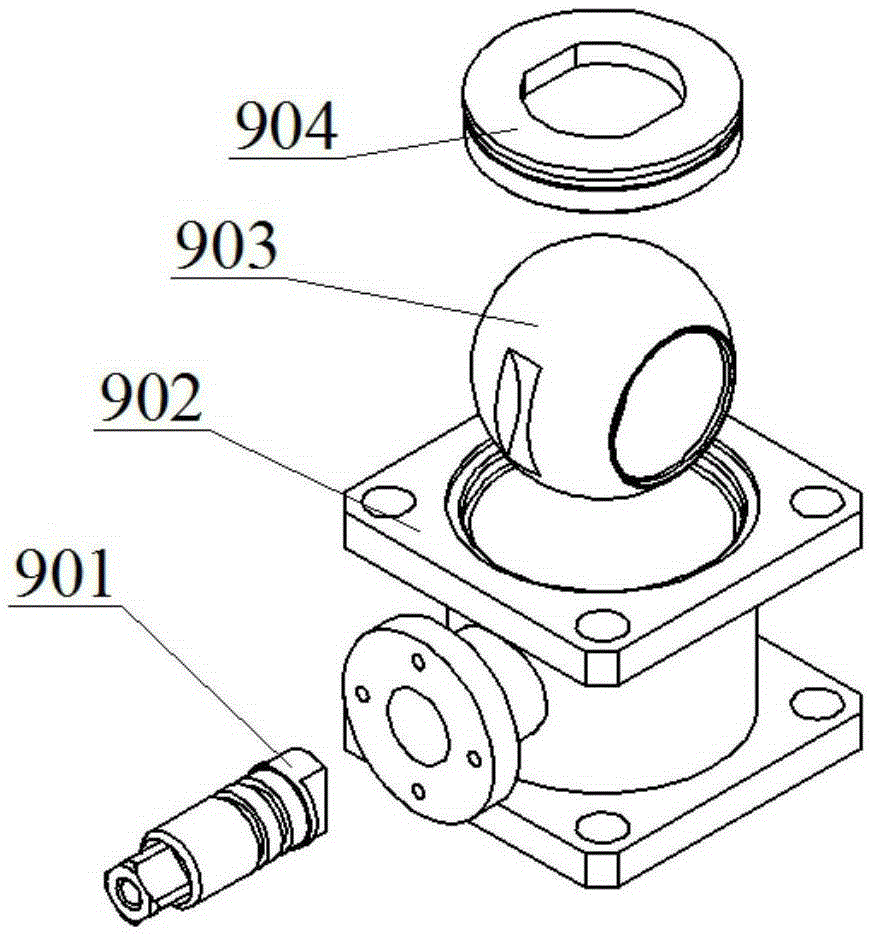

[0026] The four-jaw chuck 4 is connected with the air motor one 3. During the clamping and dismounting process, the four-jaw chuck 4 is driven by the air motor one 3. A rubber pad 10 is arranged above the four-jaw chuck 4. The lower surface of the rubber pad 10 There is a profile protrusion matching the profile hole of the valve cover 904, the cylinder pressure plate 5 is set above the rubber pad 10, the motor 8 is connected with the top of the main drive connector 6 through the coupling 7, and the coupling 7 is provided with Torque sensor, the bottom of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com