Plasma automatic unloading machine and using method thereof

An automatic blanking and plasma technology, applied in the direction of plasma welding equipment, auxiliary equipment, auxiliary welding equipment, etc., to achieve the effect of ensuring stability and accuracy, preventing jumping, and reducing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

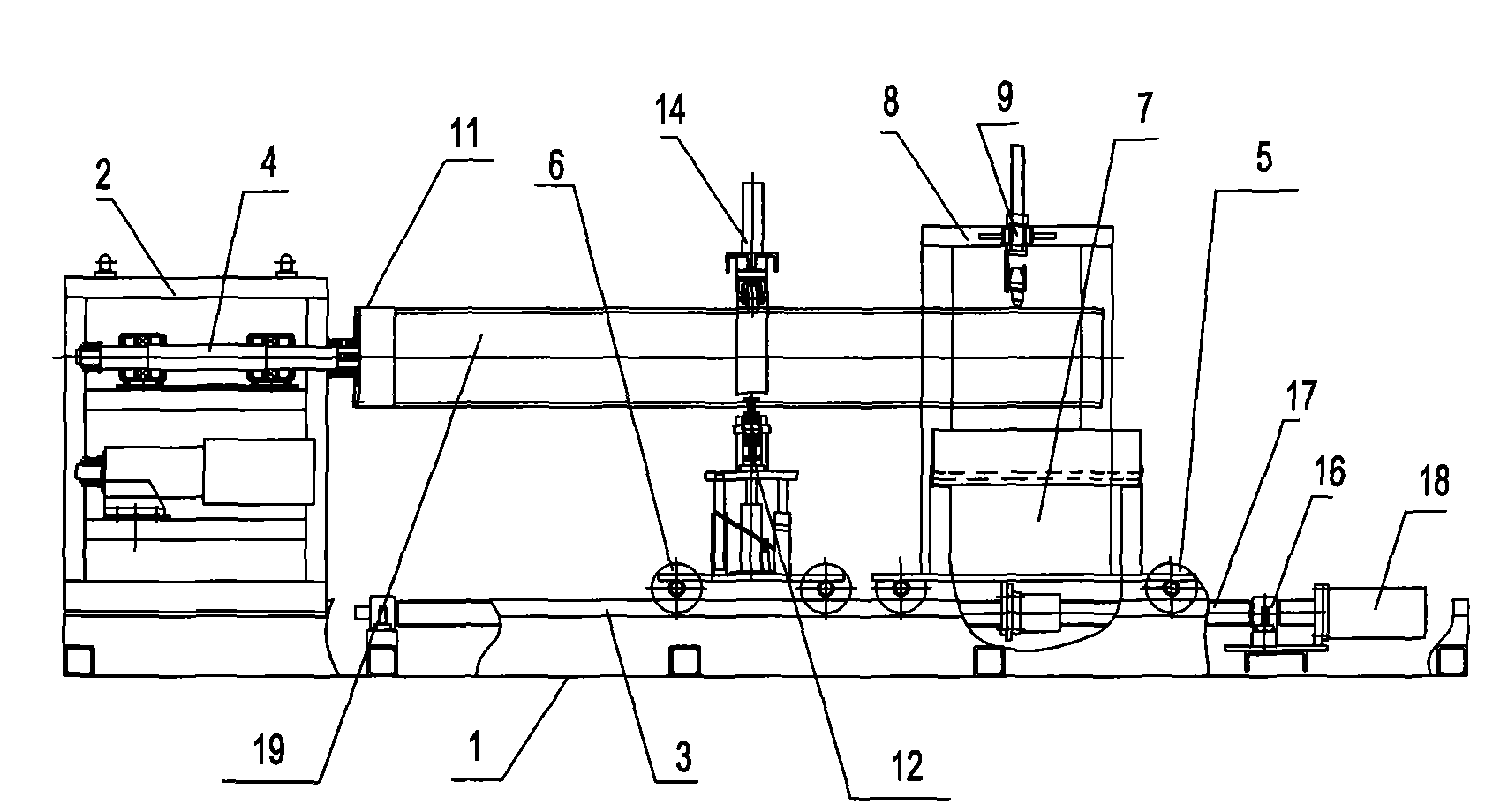

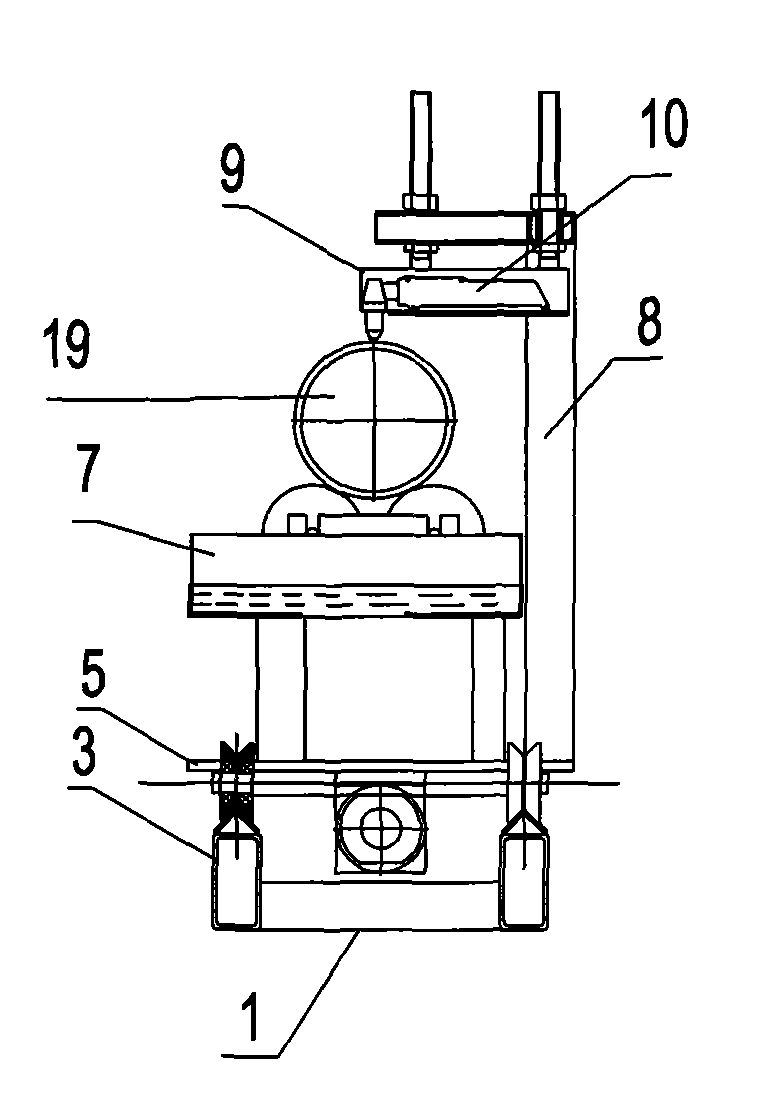

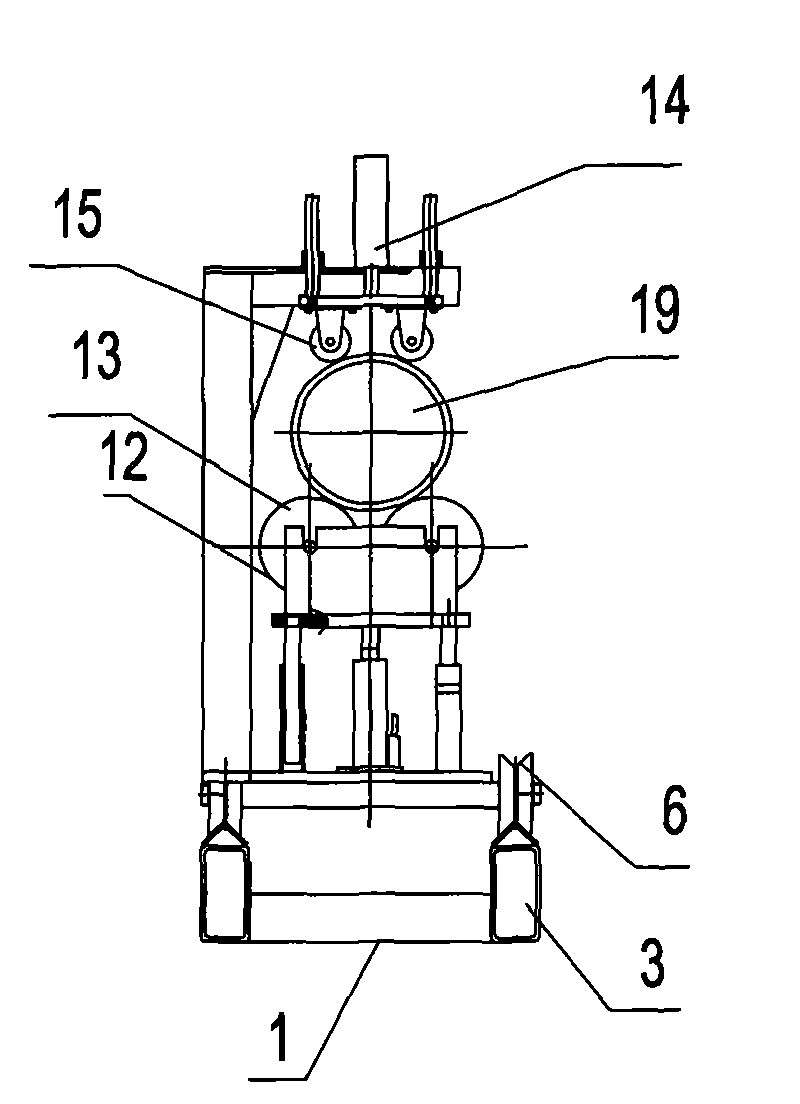

[0025] like figure 1 As shown, a plasma automatic blanking machine of the present invention includes a blanking machine base 1, a rotary box assembly 2 and a track assembly 3 are fixedly installed on the blanking machine base, and the rotary box assembly is installed on the track assembly The top of the rotating box assembly is provided with a stainless steel pipe material rotating main shaft 4, and a three-jaw chuck 11 is installed at one end of the main shaft; two groups of trolley assemblies are installed on the track assembly, which are respectively the tail end trolley assembly 5 and the middle trolley assembly 6. A material receiving box assembly 7 is installed on the rear end trolley assembly, a column assembly 8 is installed on the material receiving box assembly, and a cutting assembly 9 is installed on the column assembly, such as figure 2 As shown, the plasma cutting gun 10 is installed on the cutting assembly; the middle trolley assembly is arranged on the track b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com