Automatic pressing device for steel shaft

An automatic device and technology for pressing steel shafts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, different steel shaft specifications, and inconvenient picking, so as to achieve strong practicability and improve product quality. Quality, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

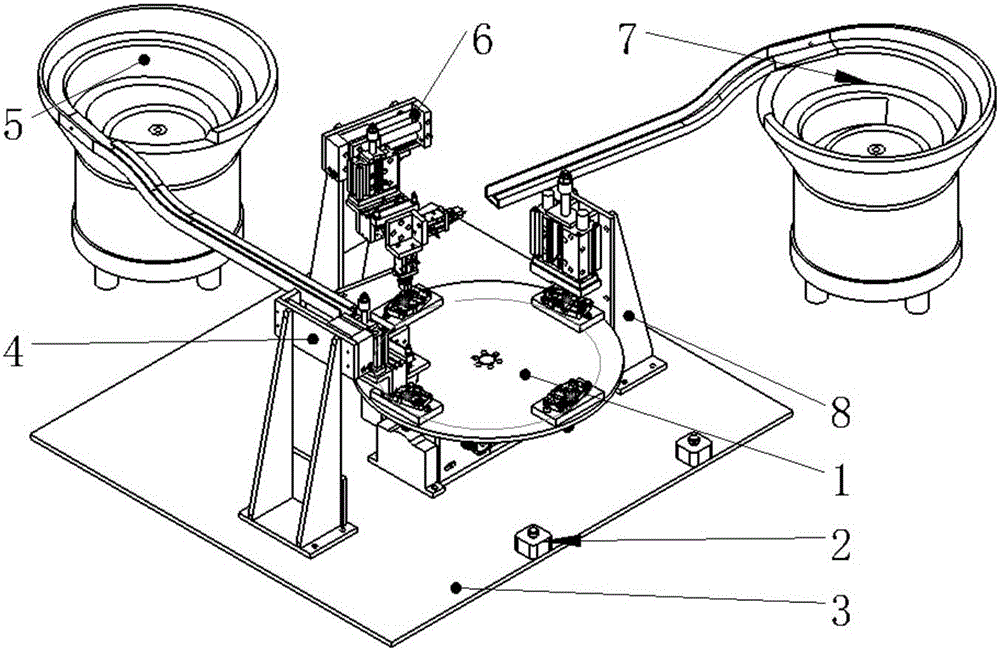

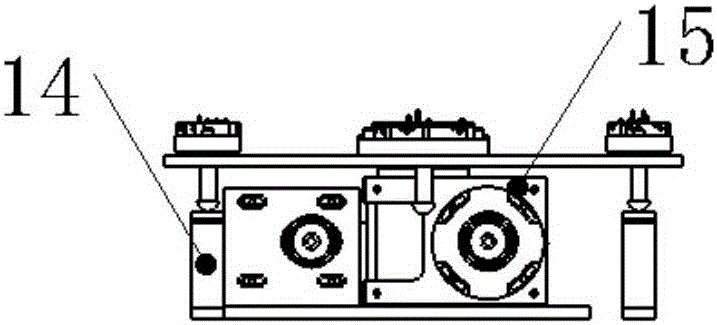

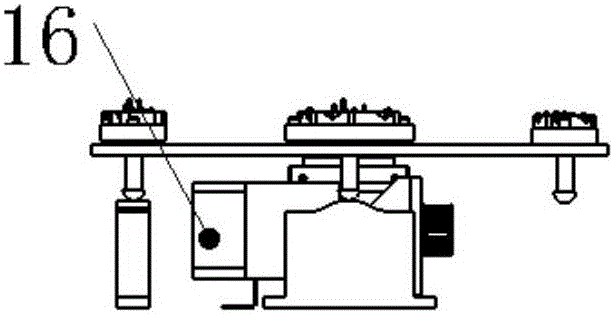

[0020] refer to figure 1 , Figure 2A , Figure 2B , Figure 4 , Figure 5 , turntable system 1, double control button box 2, thick steel shaft preloading system 4, thin steel shaft preloading system 6, steel shaft crimping system 8, jacking frame 14, motor 16, thick cylinder mounting frame 17, thin cylinder The mounting frame 22 and the crimping cylinder mounting frame 27 are mounted on the base plate 3 by screws. The motor 16 drives the splitter 15 through a synchronous belt.

[0021] refer to Figure 2A , B, C, the loading and unloading station 9 of the turntable system 1, the thick steel shaft pre-pressing station 10, the thin steel shaft pre-pressing station 11, and the pressing steel shaft station 12 are fixed on the rotating disc 13 with screws On, the rotating disk 13 is connected with the divider 15 by screws. The loading and unloading station 9 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com