Clamping device for overturning and milling arc-shaped work-pieces

A clamping device and workpiece technology are applied in the field of clamping devices for reverse milling and cutting of arc workpieces, which can solve the problems of cumbersome procedures, poor product milling consistency, low production efficiency, and large-scale production of enterprises. High production efficiency, avoiding the effect of poor workpiece consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

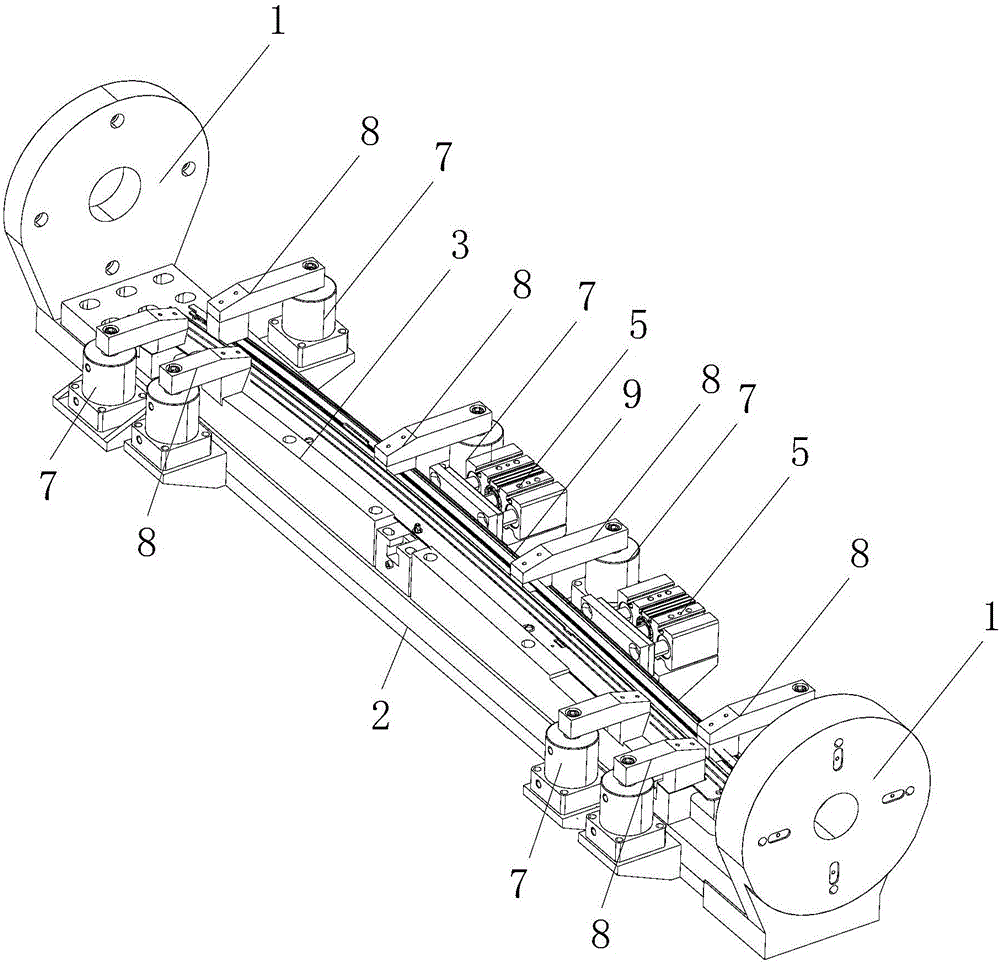

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 2 As shown, a clamping device for flipping and milling an arc-shaped workpiece includes a base (not shown in the figure), on which a pair of mounting brackets (not shown in the figure) are arranged, and a rotating seat 1 is hinged on the mounting bracket.

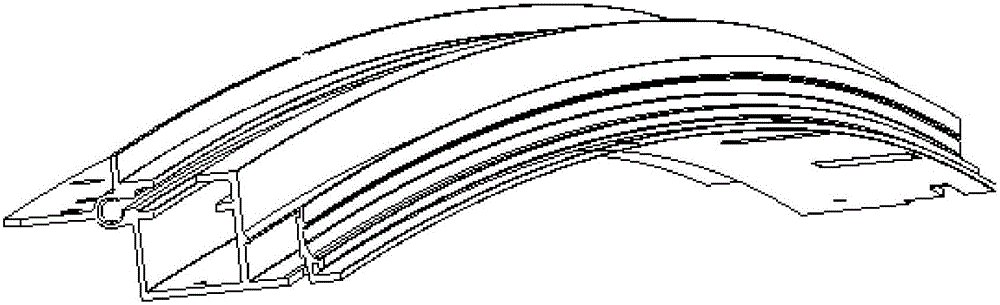

[0014] An installation base plate 2 is erected between the two revolving bases 1, and a servo motor for driving the revolving base 1 is arranged on the base. There is a limit block 4 that limits the surface of the workpiece along the length direction, and a number of positioning pins (not shown) for positioning the workpiece are also provided on the profiling support block 3 . A horizontal clamping cylinder 5 which cooperates with the limit block 4 to clamp the workpiece is respectively provided at both ends of the installation base plate 2, and a horizontal clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com