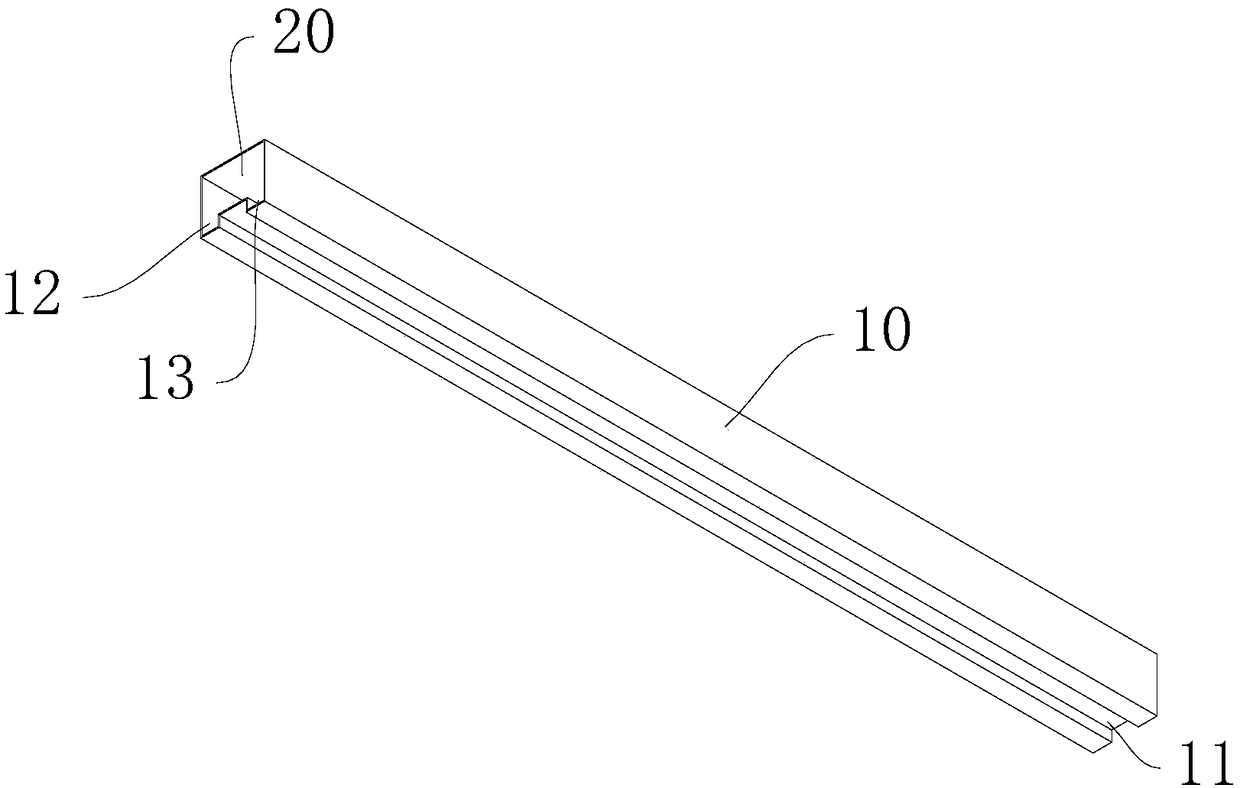

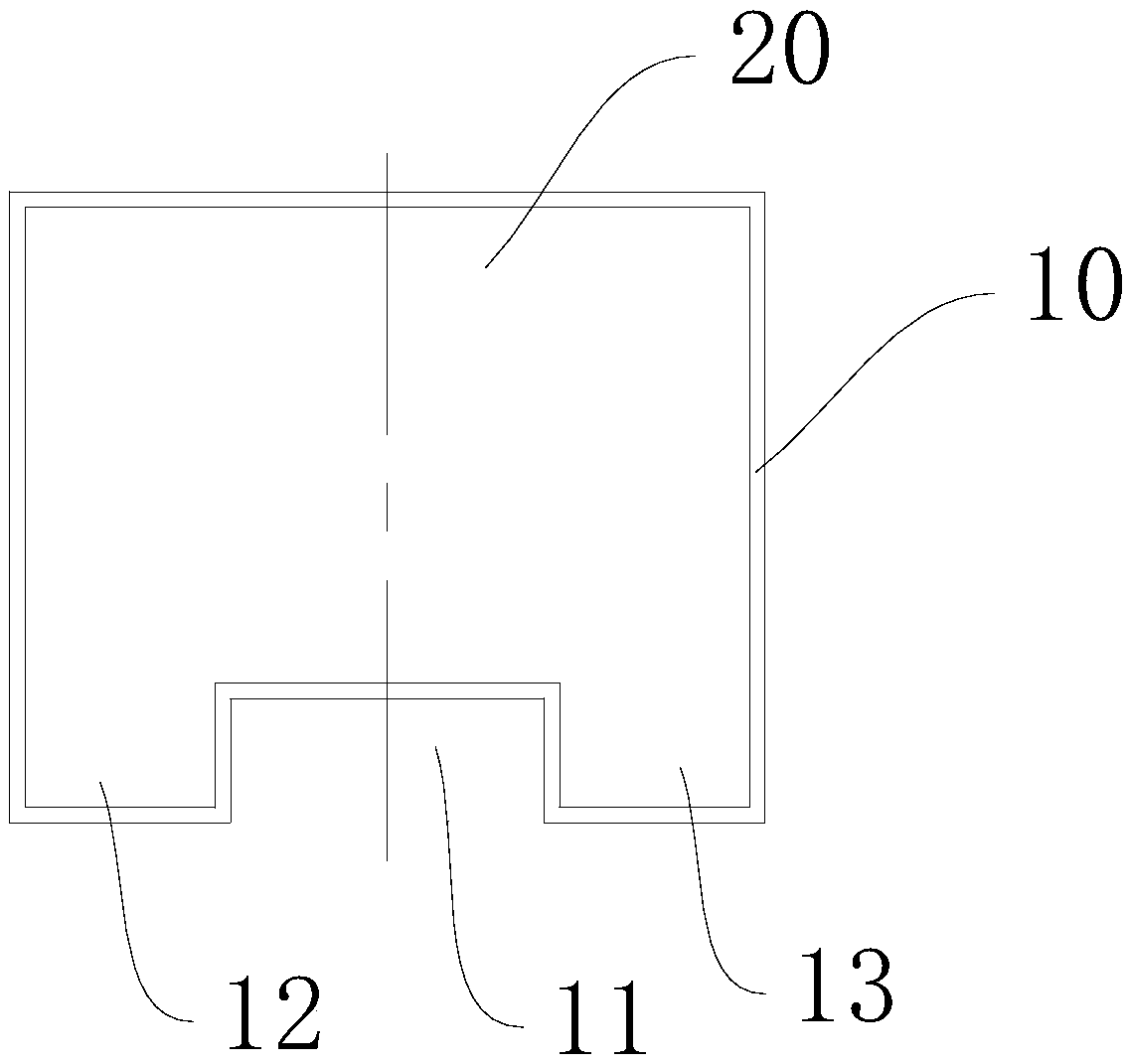

Piping outfitting supplied material and automatic plugging equipment having same

A tube-packing and automatic technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of low production efficiency of manual insertion, poor consistency of device insertion, uncontrollable product quality, etc., so as to solve the problem of low production efficiency and avoid poor consistency. , the effect of increasing the assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

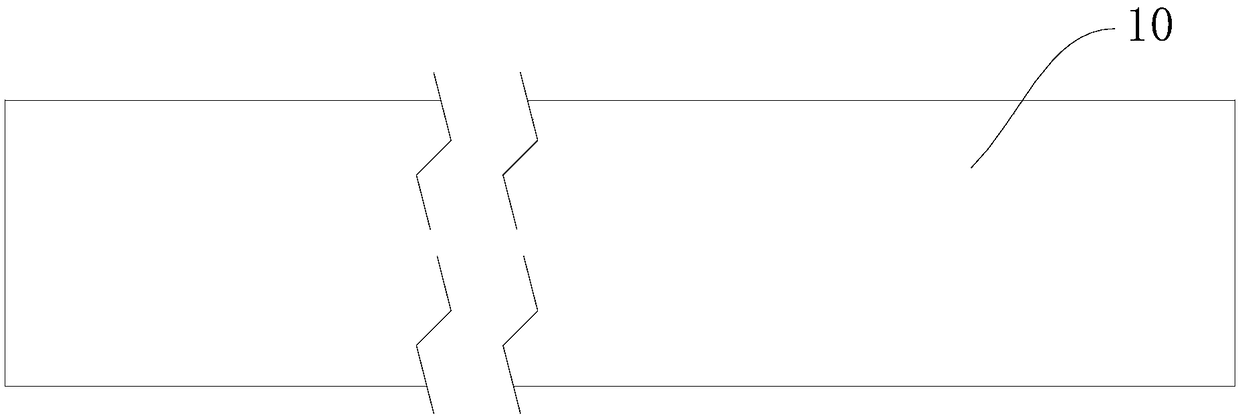

Method used

Image

Examples

Embodiment 2

[0037] The automatic plugging device of the second embodiment, wherein the difference between the second embodiment and the first embodiment is:

[0038] In the technical solution of the second embodiment, the incoming pipe material is detachably connected to the automatic plug-in device, and the incoming pipe material is connected with a pusher assembly to push the electronic components out of the installation cavity 20 . The pusher assembly extends into the mounting cavity 20 to push the electronic components in the mounting cavity 20 . Specifically, the push assembly includes a push mechanism and a push rod. One end of the push rod is connected to the push mechanism, and the other end can extend into or out of the installation cavity 20 . The pushing mechanism is set to a combined structure of a gear, a gear and a motor, or a combined structure of a lead screw, a nut and a motor, or is directly driven by a hydraulic cylinder, an air cylinder, or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com