Gas cylinder body airtightness detection device

A technology of air tightness detection and gas cylinders, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of reducing enterprise production efficiency, process and material waste, and increasing production cost and other issues to achieve the effect of increasing productivity, avoiding waste and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

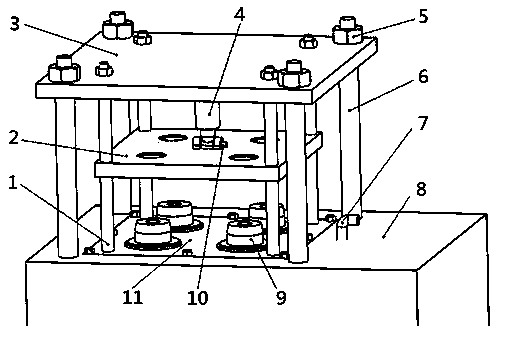

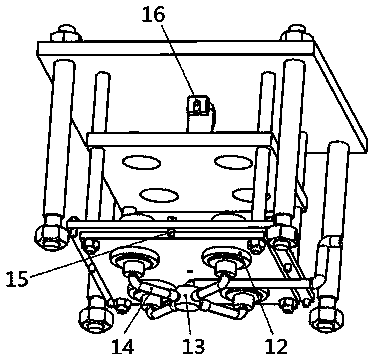

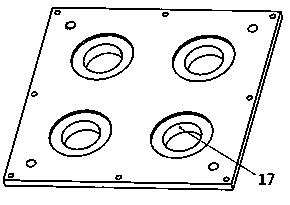

[0024] See Figure 1-6 , the present invention is made up of water pipeline pipe, bottom plate 11, nozzle 9, pressure plate 2, top plate 3, four nozzle installation holes 17 are opened on the bottom plate 11, nozzle 9 is housed on the nozzle installation hole 17, and pressure plate 2 is arranged above the bottom plate 11, The pressure plate 2 is provided with a cylinder pressure hole 18 corresponding to the nozzle 9 and a slide bar penetration hole 19 corresponding to the slide bar 1. A top plate 3 is arranged above the pressure plate 2, and the top plate 3 is fixed by four columns 6 with nuts 5. Connected to the water tank 8 or the bottom plate 11, the middle part of the top plate 3 is fixedly equipped with an oil cylinder 4, the oil cylinder 4 is connected to the pressure plate 2, a slide bar 1 is provided between the bottom plate 11 and the top plate 3, and the pressure plate 2 can move along the slide bar 1 under the drive of the oil cylinder 4. Moving up and down, the wa...

Embodiment 2

[0031] In this embodiment, air is used to replace the water in Embodiment 1 to fill the cylinder body 21 of the gas cylinder to detect its airtightness. The structure and working process of the detection device are the same as those described in Embodiment 1.

[0032] The invention has the advantages that the airtightness of the gas cylinder can be detected when the gas cylinder has only the body structure, and the leaking gas cylinder body can be detected in advance, so as to avoid the waste caused by subsequent processing of waste parts, reduce the cost and improve the productivity. Moreover, it can detect gas cylinder barrels of different calibers and airtight products similar to the structure of the gas cylinder barrel, and only need to replace the corresponding pressure plate and nozzle module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com