Air pressure type rapid switching valve

A fast-switching, pneumatic technology, applied in lift valve, valve details, valve device, etc., can solve the problems of hydraulic pipes and pipe joints vibrating and oil leakage, gaskets must be lined with reinforcing ribs, and the temperature of hydraulic stations rises too quickly. , to achieve the effect of long service life, economical and convenient source of sealing gas, and rapid action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

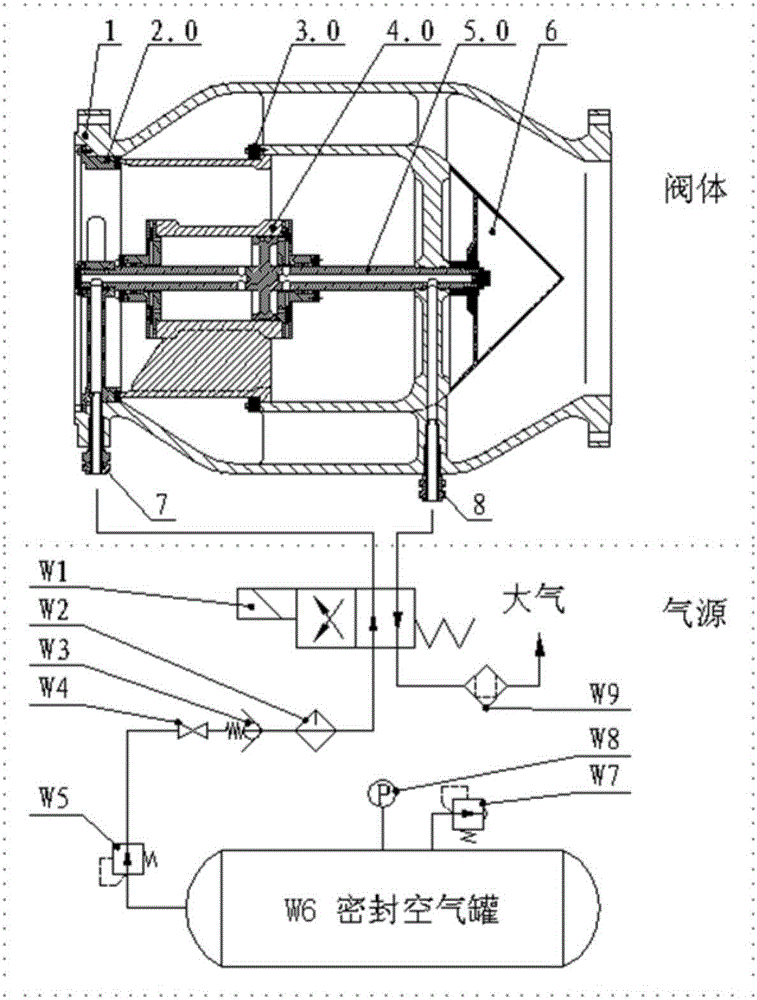

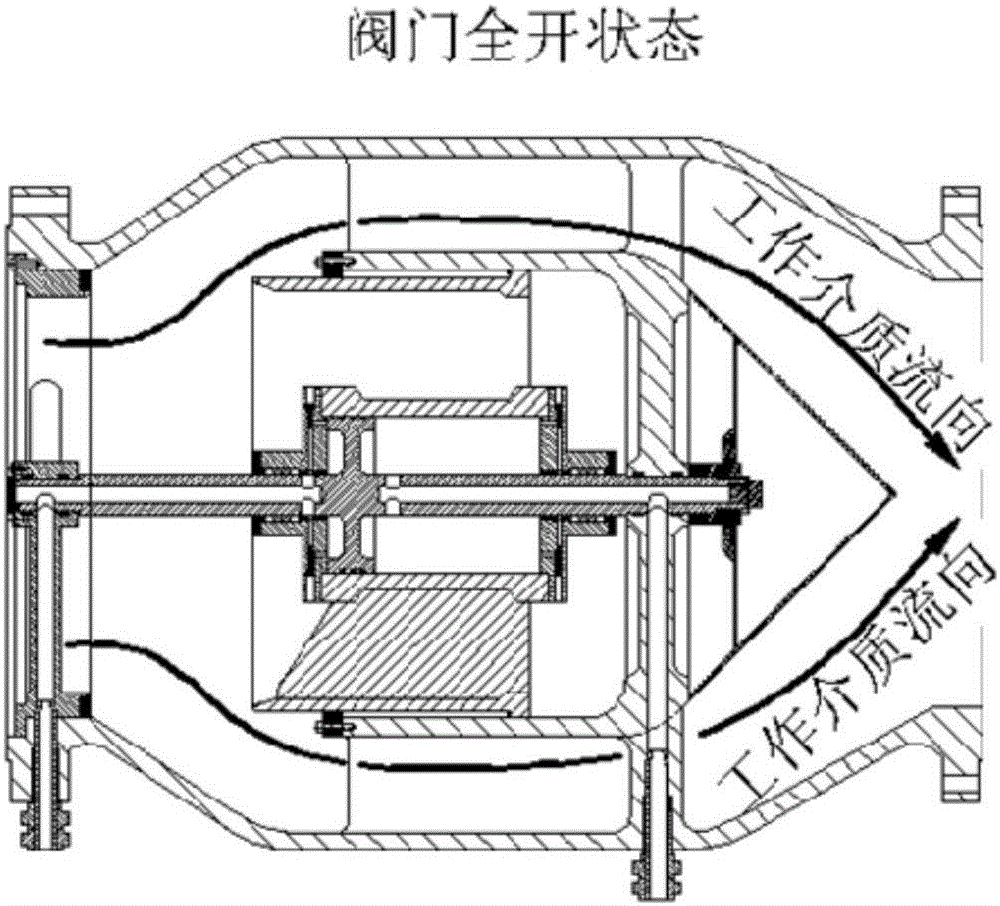

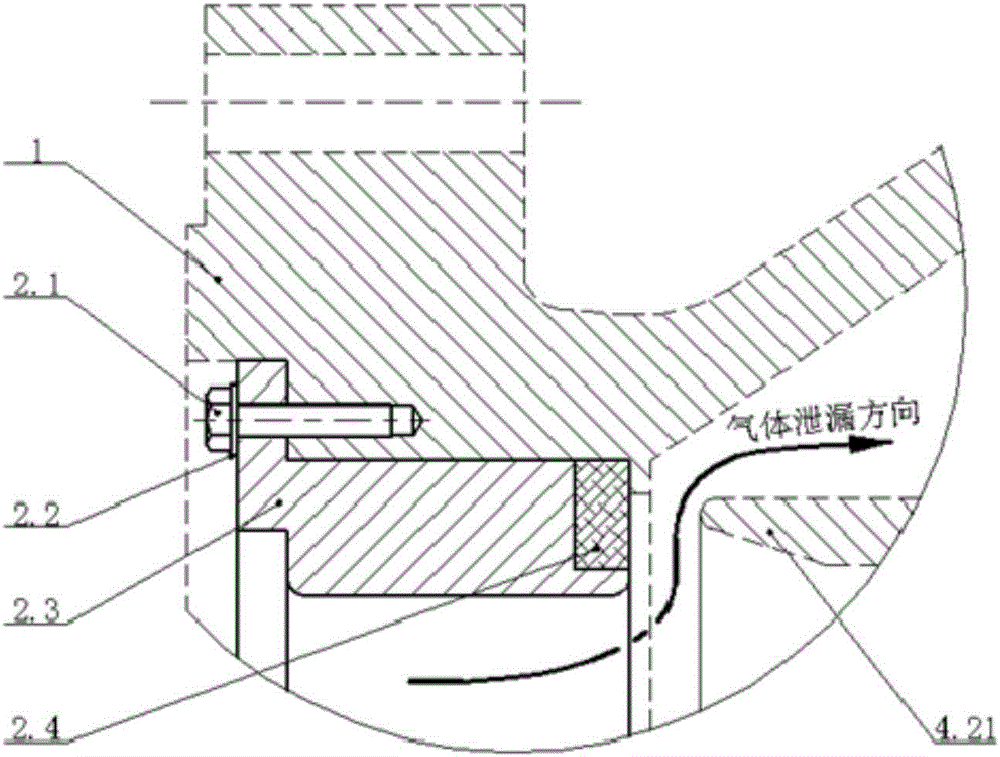

[0043] The invention provides a pneumatic quick switch valve, as attached figure 1 Schematic, including two parts: the valve body and the gas source. The structure in the dotted line frame in the upper part represents the valve body, and the structure in the dotted line frame in the lower part represents the gas source. figure 1 Indicates the closed state of the valve, attached figure 2 Indicates the open state of the valve. The features of the valve body include the shell (1), the front sealing assembly (2.0), the rear sealing assembly (3.0), the cylinder (4.0), the central shaft (5.0), the rectifying tail cone (6), the nozzle (7, 8) etc.; the characteristics of the air source include two-position four-way valve (W1), lubricator (W2), one-way valve (W3), stop valve (W4), pressure reducing valve (W5), sealed air tank (W6), Safety valve (W7), pressure gauge (W8), oil-gas separator (W9), etc. When the two-position four-way valve (W1) is in the de-energized state, the upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com