Seal assembling machine

A technology for assembly machines and seals, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, and achieve the effects of low production costs, stable product quality, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

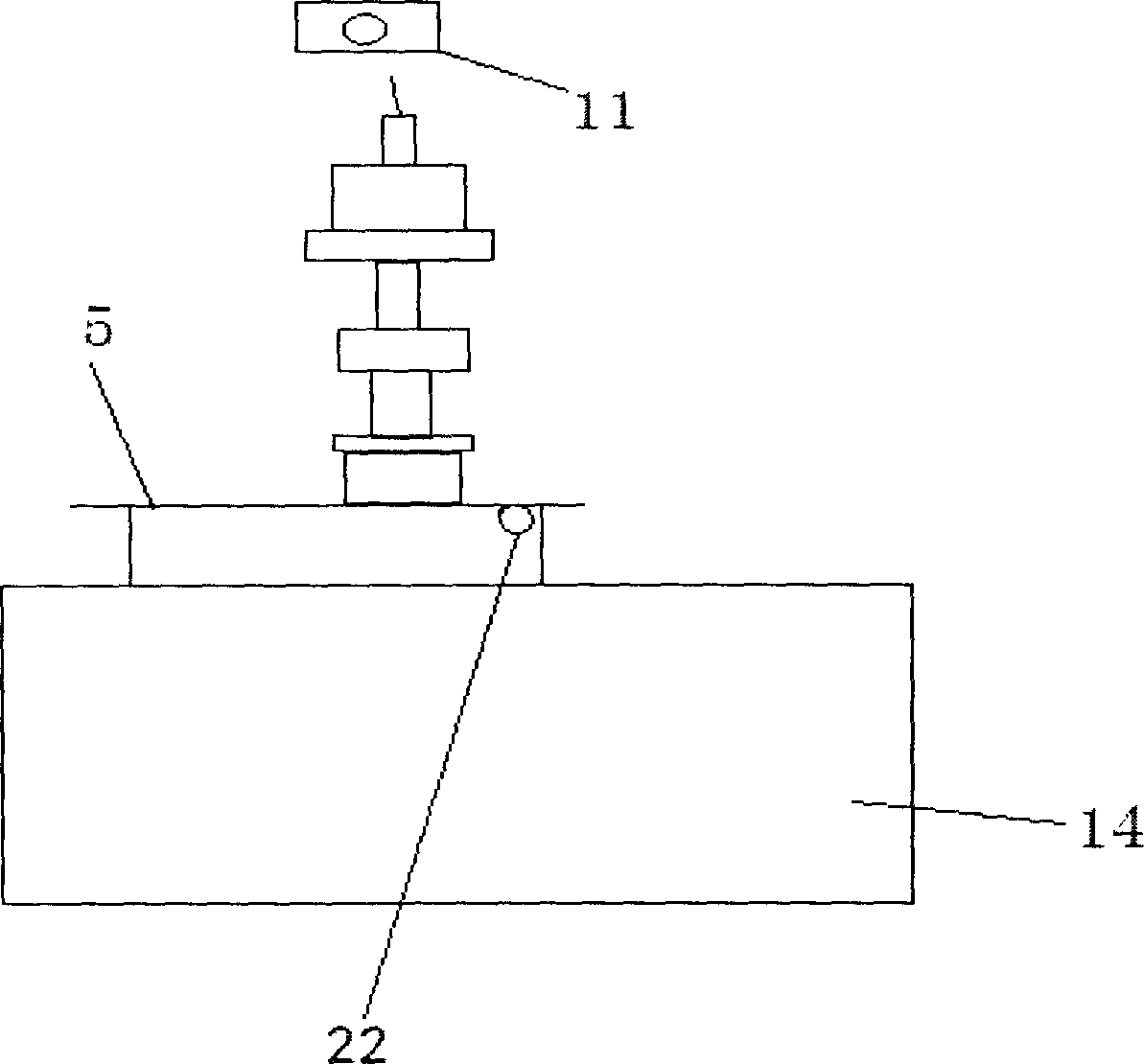

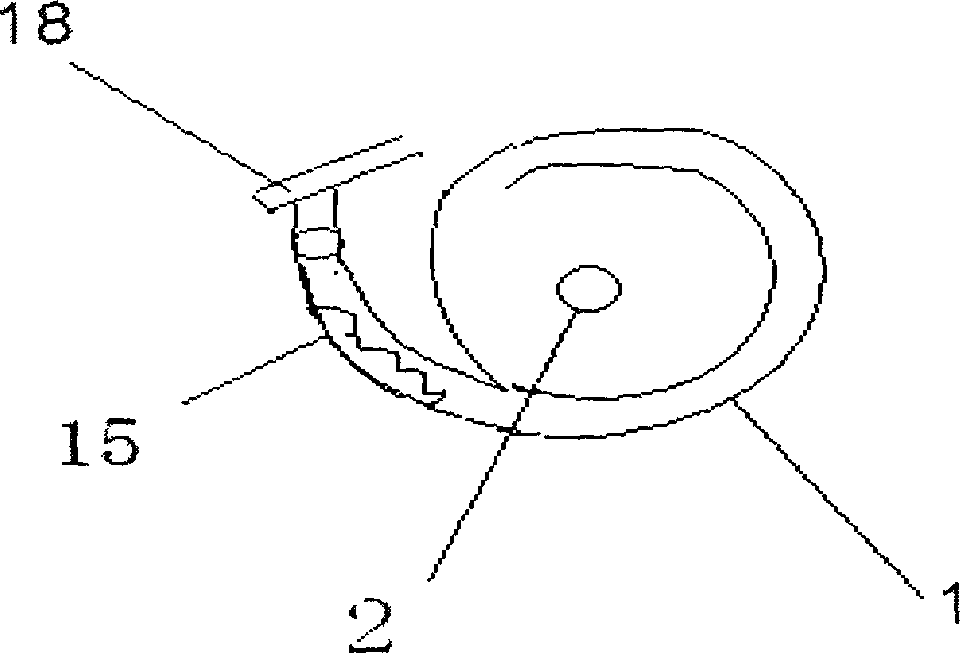

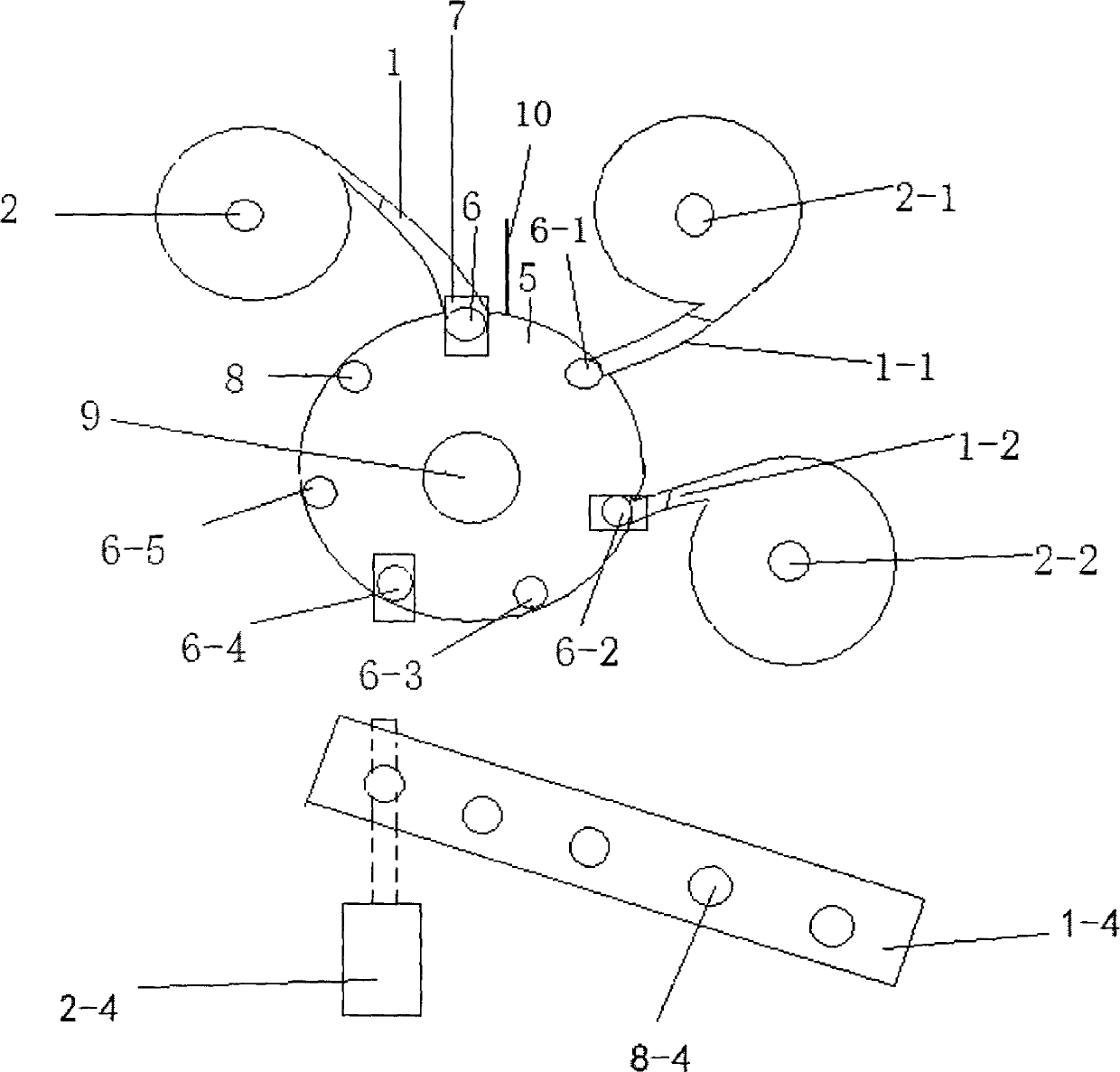

[0019]A seal assembly machine, characterized in that it includes a cylinder capping device (6), a handle feeding device head (6-1), a cylinder pressing device (6-2), a glue dispensing device (6-3), a cylinder The pressure pad device (6-4), the cylinder pressure pad reinforcement device (6-5) and a turntable (5) shared by the above-mentioned devices, the above-mentioned devices and the same turntable (5) constitute the gland system, the handle system, and the pressure joint system respectively , dispensing system, pressure pad system, pressure pad reinforcement system; capping system includes cap feeding track (1), bottom shaft of cap feeding device (2), turntable (5), cylinder capping device (6), stamping clamping die (7), product hole (8), turntable bottom shaft (9), baffle plate (10), proximity switch (11), computer control box (14); the cover delivery track (1) is a spiral driven by a vibrating device The rising disc track and its extended track, the center of the disc trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com